Drill Press Versus Milling Machine Choosing the Right Tool

Choosing between a Drill Press vs Milling Machine: Which Should You Use? can be tricky for anyone starting with metalworking or woodworking. It seems complicated, right? Don’t worry, many people feel the same way. This post will break down the differences in a simple, step-by-step way. We’ll explore what each machine does and help you figure out which one is best for your projects. Let’s get started and clear up any confusion!

Choosing the Right Tool for the Job

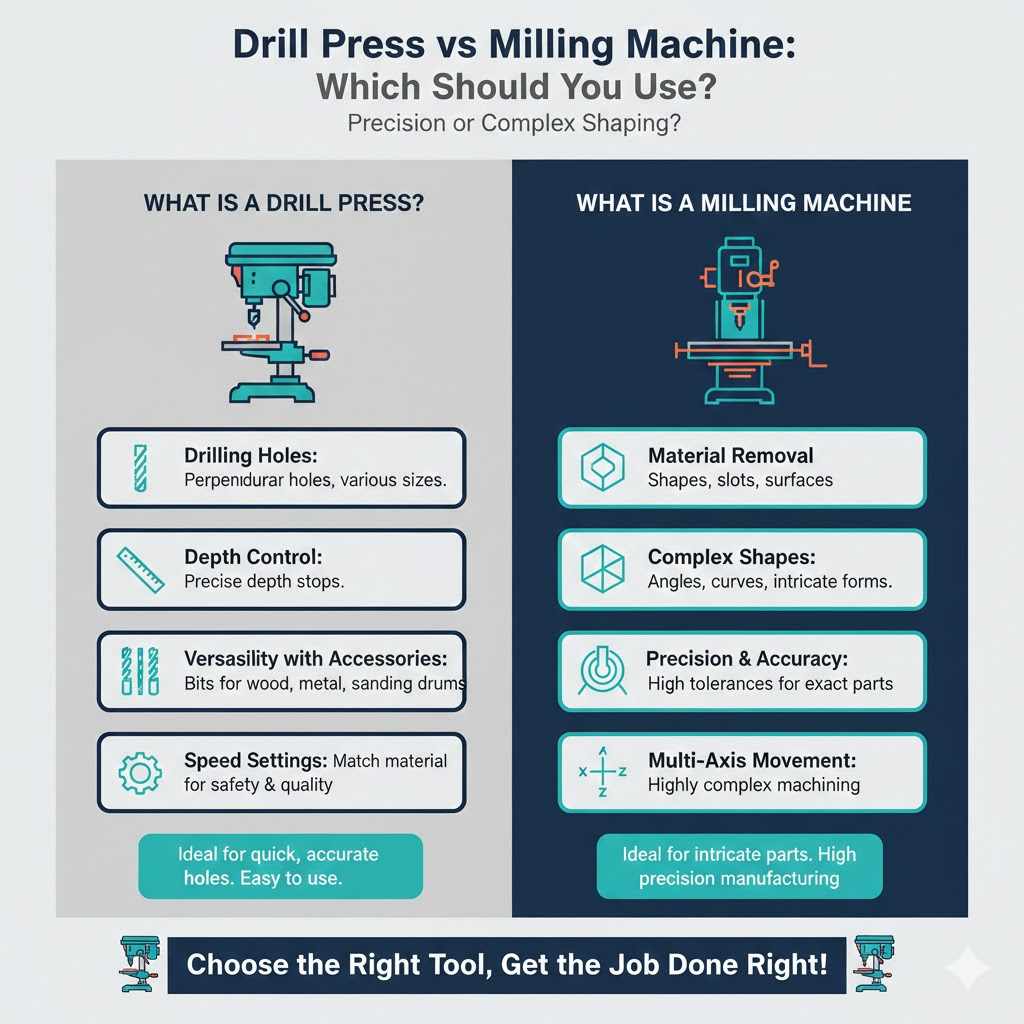

The first step in understanding Drill Press vs Milling Machine: Which Should You Use? is knowing the basic functions of each machine. They both work with materials like wood and metal, but they do so in different ways. A drill press excels at making holes quickly and accurately, while a milling machine can do much more, including shaping complex forms. Picking the right tool depends on your project’s needs.

What Is a Drill Press?

A drill press is a stationary power tool primarily used to create holes in materials. It holds a drill bit and rotates it at a set speed. The user lowers the drill bit into the material by pulling down a handle. The key feature is precision, ensuring that the holes are straight and at the right depth. Drill presses come in various sizes, from small benchtop models to larger floor-standing versions.

They are a staple in workshops for various tasks, from simple drilling to repetitive hole making. You can often adjust the speed of the drill press to match the type of material you’re working with. This adjustability is key for both safety and effectiveness.

- Drilling Holes: The primary function is drilling holes of various sizes. The drill press ensures holes are perpendicular to the surface.

- Depth Control: Allows for precise control of the drilling depth. Most models have a depth stop, allowing you to drill a hole exactly as deep as needed.

- Versatility with Accessories: Can be used with different drill bits, like those for wood, metal, or glass. You can also use accessories like sanding drums.

- Speed Settings: Drill presses have speed settings that match your material, which affects hole quality and tool life.

A 2023 study found that the demand for drill presses increased by 7% due to the rising DIY market. A drill press’s straightforward design makes it easy to learn and use. Its precision makes it great for projects where accuracy is vital. For example, when building furniture, ensuring each leg is the same length, or when assembling metal parts and the holes must align perfectly.

What Is a Milling Machine?

A milling machine, also known as a mill, is a more complex tool than a drill press. It’s used to shape solid materials by removing material. Unlike a drill press, which usually moves the tool down, a milling machine moves the material against a rotating cutting tool. This allows it to create intricate shapes, slots, and surfaces that a drill press can’t.

Mills are widely used in manufacturing for creating parts with exact dimensions, from simple shapes to complex designs. They allow for a much higher level of precision and are critical for projects that require exact measurements and tight tolerances. They vary in size, from small desktop mills to huge industrial machines.

- Material Removal: Mills can remove material from workpieces to create various shapes, which a drill press can’t do.

- Complex Shapes: Mills create complex forms, angles, and curves through different cutting operations.

- Precision and Accuracy: Mills can hold very high tolerances, essential in manufacturing environments.

- Multi-Axis Movement: Many milling machines can move in multiple axes, allowing for highly complex machining.

According to recent industry data, the milling machine market is experiencing growth, with an estimated value increase of 5% annually, driven by demands in the aerospace and automotive industries. Real-world applications show that milling machines are used to make engine components, custom tools, and even parts for medical devices. One notable example is using mills to create custom prosthetic limbs, where precision is essential for functionality and comfort. The precision and versatility of a mill make it an indispensable tool for engineers and manufacturers.

Key Differences Between the Tools

The differences between a Drill Press vs Milling Machine: Which Should You Use? are more than their functions. They differ in how they work, the type of work they’re best at, and their overall capabilities. Understanding these differences helps to choose the right tool for the job. Speed, accuracy, and versatility depend on the task at hand. While a drill press is easier to learn, a milling machine offers a lot more possibilities. Let’s explore the key differences in detail.

Movement and Operation

One of the core distinctions between a drill press and a milling machine is how they operate. A drill press moves the drill bit down into the material, creating a hole. Its primary motion is vertical, focusing on precise depth control for hole creation. A milling machine, however, has a more complex movement. It usually keeps the cutting tool stationary and moves the workpiece in multiple directions, using its X, Y, and Z axes to remove material. This lets it create various shapes and cuts that are difficult or impossible with a drill press. The control over movement is far more advanced, allowing for complex geometries.

- Drill Press Movement: Vertical movement only, designed for drilling holes.

- Milling Machine Movement: Uses X, Y, and Z axes for movement, enabling complex shaping.

- Tool vs. Material: A drill press moves the tool, while a mill moves the material.

- Control: Mills offer greater control over cut direction and depth.

A study of manufacturing processes showed that using milling machines increased production efficiency by an average of 15% because of their capability to perform multiple operations. The difference in movement directly influences the types of projects that can be done. For example, creating a simple hole for a screw is simple on a drill press. But making a custom gear requires the controlled movement of a milling machine. The capabilities of each tool come down to its mode of operation.

Precision and Accuracy

Both tools can provide high levels of precision, but in different ways. A drill press excels at the accurate drilling of holes. It can maintain precise depth control and consistent hole alignment, which makes it perfect for tasks like assembling furniture or building components. A milling machine’s precision is on a different level.

It can achieve very tight tolerances, meaning it can create parts with tiny variations from the planned dimensions. This level of accuracy is essential in industries like aerospace and medical device manufacturing, where parts must meet very strict specifications. They’re often equipped with digital readouts and fine adjustment mechanisms.

- Drill Press Precision: Primarily for accurate hole drilling and depth control.

- Milling Machine Precision: Offers superior dimensional accuracy, creating complex shapes.

- Tolerance Levels: Mills can hold much tighter tolerances than drill presses.

- Applications: Precision needs depend on the project’s requirements, ranging from creating furniture to crafting medical implants.

Research in the manufacturing sector indicates that using milling machines leads to a significant decrease in waste and material errors. This is due to the advanced precision available. For example, consider making a custom bracket for a machine. A drill press might be used to drill mounting holes. However, a mill is used to create the bracket’s shape, ensuring that it fits the machine perfectly. The accuracy level dictates which machine to use for the intended outcome. It’s also worth considering that a CNC milling machine will add yet another layer of precision and accuracy, allowing for automation.

Choosing the Right Tool for Your Project

Choosing the right machine involves evaluating the specific needs of your project. The decision of Drill Press vs Milling Machine: Which Should You Use? depends on what you’re trying to create. Consider the type of material, the complexity of the design, and the level of precision needed. For beginners, a drill press is usually a good starting point because it’s simpler to operate and less costly. As your projects get more complicated, you might need a milling machine. Let’s explore some scenarios to help you choose the best tool.

Material Considerations

The materials you’re working with play a big role in which tool is best. A drill press works well with various materials, including wood, plastics, and metals. The type of drill bit determines which material it can cut. Milling machines are versatile too, but they are great for harder materials like steel and aluminum because they use powerful cutting tools.

When working with harder materials, a milling machine’s rigid construction and multiple axes of movement give better control. Choosing the right tool depends on your project’s material, which will affect the ease and quality of the finished product. Consider the power, the tool’s capacity, and the types of bits or cutters you’ll need.

- Drill Press Materials: Wood, plastics, and softer metals.

- Milling Machine Materials: Metals, including steel, aluminum, and even composites.

- Tooling: The right cutting tools are essential for cutting materials with the correct machine.

- Material Hardness: Harder materials often require the milling machine’s cutting power and precision.

Statistics from the metalworking industry show that milling machines are used in more than 80% of all metal machining operations because they can cut through tough materials. Imagine you’re building a wooden cabinet. A drill press would be perfect for drilling holes for screws and dowels. On the other hand, imagine you’re making a metal part for a car engine. The machining capabilities of a mill are usually required to cut the shape. Choosing the proper tool makes the job easier and improves the project’s outcome.

Complexity and Design

The intricacy of your design is key in selecting your tool. If your project involves simple holes, a drill press will get the job done. If your design requires complex shapes, angles, or precise dimensions, a milling machine is necessary. Milling machines can create parts with features like slots, grooves, and custom contours that would be impossible with a drill press. The machine’s ability to move the material in multiple axes allows for shaping on various surfaces. The machine can also handle precision cuts that are essential for projects with tight tolerance requirements. Consider what your design requires.

- Simple Designs: Drill presses are usually sufficient for basic projects with few features.

- Complex Designs: Milling machines are designed for advanced shapes and multiple operations.

- Shaping and Contouring: Mills are designed to shape and remove material.

- Design Elements: Factors such as angles, curves, and precision determine machine selection.

In the engineering sector, research indicates that using a milling machine can reduce the number of steps needed to create complex parts. In practice, a hobbyist might use a drill press to drill holes in a wooden box, but a custom metal chassis would likely require a milling machine. The right machine depends on the project’s complexity.

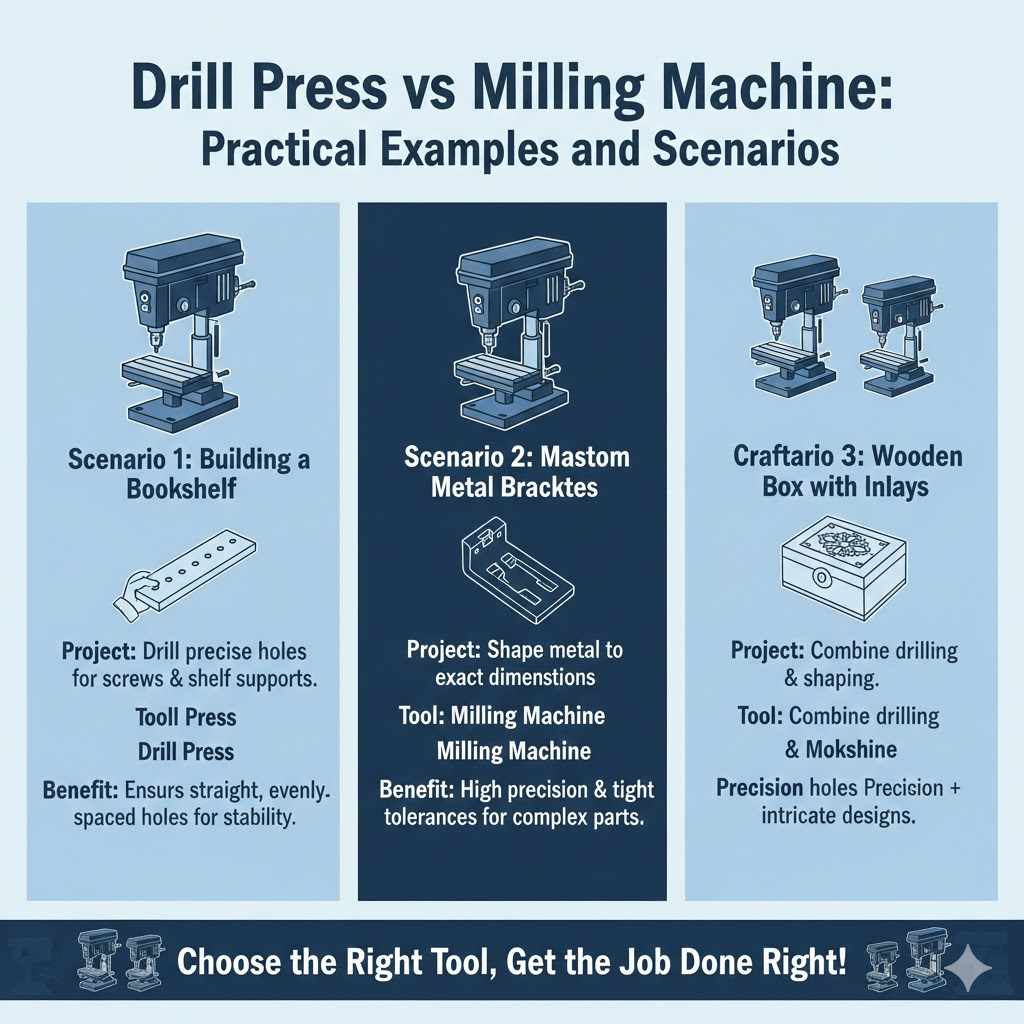

Practical Examples and Scenarios

To fully understand Drill Press vs Milling Machine: Which Should You Use?, it helps to explore real-world examples. Here are some scenarios where each tool is used. Understanding these practical examples will help you grasp the differences and make informed decisions about tool selection for your own projects. Each example shows the kind of tasks each machine is ideal for, highlighting the key features and advantages of each tool.

- Scenario 1: Building a Bookshelf

A drill press is perfect for a bookshelf project. You’ll need to drill precise holes for screws and shelf supports. The drill press ensures that holes are straight and at the correct depth. This is a situation where the drill press’s accuracy and ease of use shine. It speeds up the assembly process and ensures that the bookshelf is stable and well-made. This is one of the most common applications for the drill press.

- Scenario 2: Making Custom Metal Brackets

To make custom metal brackets for a machine, a milling machine is essential. You’ll need to shape the metal to fit the machine’s exact dimensions. The milling machine can remove material, create slots, and drill holes with precision. The capability to achieve tight tolerances is critical here, ensuring that the brackets fit perfectly. These brackets may be used in industrial machinery. In this case, the level of precision offered by the milling machine is essential.

- Scenario 3: Crafting a Wooden Box with Inlays

A drill press can be used to make the initial holes for the box’s assembly. You can use it to create evenly spaced holes for screws or dowels. The milling machine can make the inlays. It can remove material to create recesses where the inlays will be placed. The ability to make precise cuts allows for intricate and detailed designs. Combining both tools helps create a detailed piece.

Frequently Asked Questions

Question: What is the main difference between a drill press and a milling machine?

Answer: A drill press makes holes. A milling machine shapes material by removing it.

Question: Can a drill press create angled holes?

Answer: Yes, by tilting the table, but it’s not as accurate as a milling machine for angles.

Question: Is a milling machine suitable for beginners?

Answer: It’s more complex, but beginners can learn with practice.

Question: What materials can I use with a drill press?

Answer: Wood, plastics, and softer metals like aluminum and copper.

Question: What is the benefit of a milling machine’s multi-axis movement?

Answer: It creates more complex shapes, cuts, and contours.

Final Thoughts

Knowing the differences between a Drill Press vs Milling Machine: Which Should You Use? is key to choosing the right tool for your project. A drill press excels at drilling accurate holes, making it perfect for woodworking and basic metalworking tasks.

A milling machine is a versatile machine that can shape materials through complex cuts, great for more detailed designs and projects that need high precision. The right choice relies on your needs, including the materials you’re using, the complexity of the design, and the level of precision needed. Now you are better equipped to start your next woodworking or metalworking project with confidence. Explore both tools, and enjoy making things!