Drilling Hammer Vs Engineer Hammer: The Proven Best Pick

For the proven best pick, choose a drilling hammer for precision work like hand-drilling small holes in masonry with a star drill. For heavy-duty striking, metalworking, and general-purpose demolition, an engineer’s hammer is your best choice. Each tool is designed for a specific job, so the “best” depends entirely on your project.

Hello, fellow makers! I’m Md Meraj, and today we’re tackling a common point of confusion in the workshop: the drilling hammer versus the engineer’s hammer. At a glance, they might look similar—both are heavy, tough-looking tools. But using the wrong one can lead to frustration, damaged materials, or even injury. It’s a classic case of having the right tool for the right job.

Don’t worry, though! Sorting this out is much easier than you think. In this guide, I’ll walk you through the key differences, show you exactly when to use each one, and help you choose with total confidence. Let’s clear up the confusion and get you back to building.

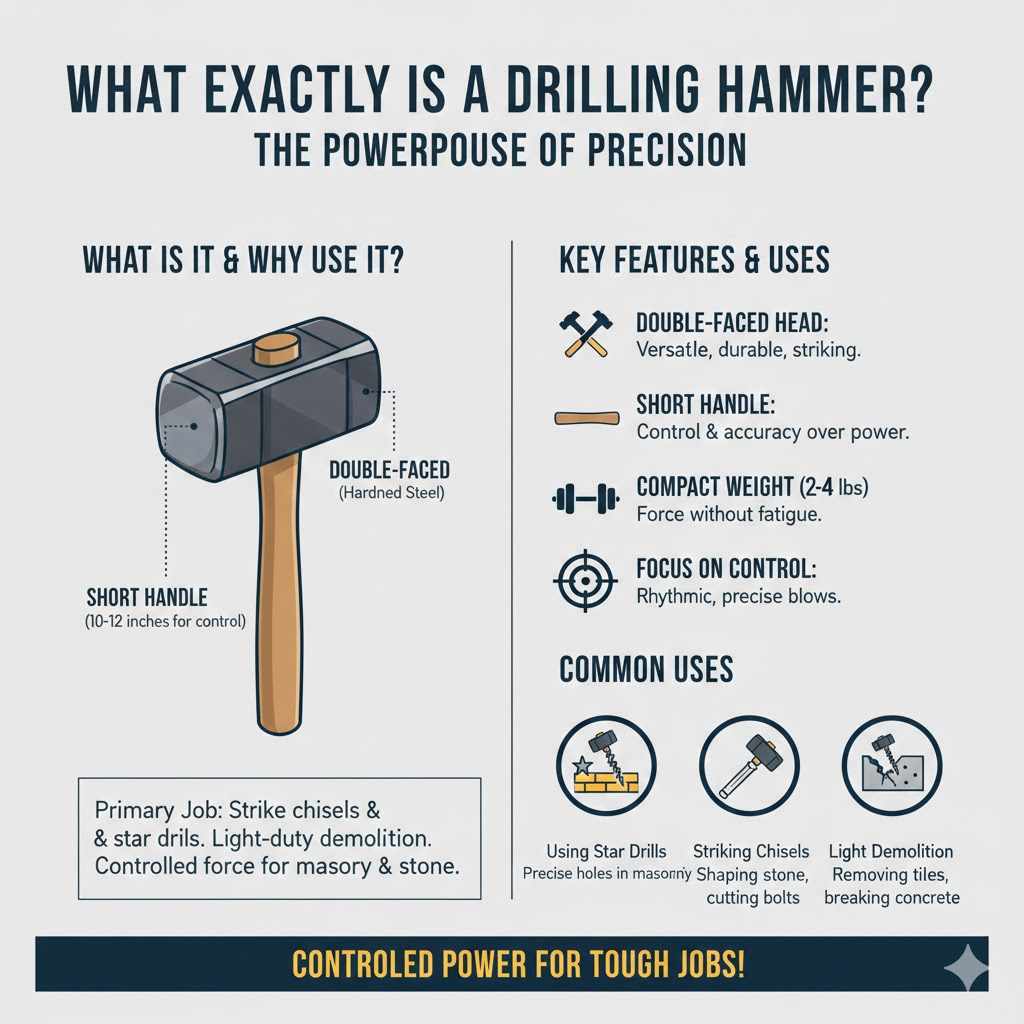

What Exactly Is a Drilling Hammer?

A drilling hammer, sometimes called a lump hammer or a club hammer, is a type of small sledgehammer designed for light-duty demolition and striking tools like chisels or star drills. It’s the tool you grab when you need controlled force without the overwhelming power of a full-sized sledgehammer.

Think of it as the powerhouse of precision. Its main job, historically, was to be used with a star drill—a hardened steel chisel with a star-shaped tip. You strike the star drill, rotate it slightly, and strike again to slowly chip away at brick, stone, or concrete to create a hole. It’s a slow and steady process that requires a hammer with good balance and control.

Key Features of a Drilling Hammer

Understanding a drilling hammer is all about its design. It’s built for specific tasks that demand both strength and accuracy.

- Double-Faced Head: The head is usually a solid block of hardened steel with two identical flat striking faces. This symmetry allows you to use either side, making it versatile and durable.

- Short Handle: The handle is typically short, often around 10 to 12 inches. This short length gives you excellent control and accuracy, which is crucial when you’re striking a small target like the end of a chisel or a star drill. You’re trading leverage for precision.

- Compact Weight: Drilling hammers are heavy for their size, usually weighing between 2 to 4 pounds. This weight provides enough force to chip masonry or drive a chisel without being too tiring to swing repeatedly.

- Focus on Control: Everything about this hammer is built for controlled, repeated blows. It’s not for wild, powerful swings but for focused, rhythmic work.

Common Uses for a Drilling Hammer

So, when would you actually reach for a drilling hammer? Here are the most common scenarios:

- Using Star Drills: This is its classic purpose. If you need to make a single, precise hole in a brick wall or a concrete slab without a power drill, this is the tool.

- Striking Chisels: It’s perfect for driving stone or cold chisels. Whether you’re shaping a stone paver or cutting through a rusted bolt with a cold chisel, the drilling hammer delivers the right amount of force.

- Light Demolition: Need to gently persuade a stubborn tile off a wall or break up a small piece of concrete? The drilling hammer has enough power for the job without the risk of causing major damage to the surrounding area.

- Setting Stakes: Driving masonry nails, small wooden stakes, or survey markers into hard ground is another excellent use for this tool.

What Is an Engineer’s Hammer?

An engineer’s hammer, also known as a cross peen hammer or double face engineer’s hammer, is a staple in metalworking, fabrication, and machine shops. While it can be used for general heavy striking, its design is specifically tailored for shaping metal and working with other industrial tools.

This hammer is built for serious force. Its head is designed to deliver powerful, concentrated blows for tasks like riveting, forming metal, and driving punches. If a drilling hammer is about precision, the engineer’s hammer is about purposeful power.

Key Features of an Engineer’s Hammer

The engineer’s hammer has a distinct design that sets it apart. Let’s break it down:

- Two Different Faces: This is the most telling feature. One face is flat and hardened, used for general striking. The other face is a wedge-like shape called a cross peen (or sometimes a rounded peen). This peen is used for shaping metal, starting rivets, or striking in tight spaces where the flat face won’t fit.

- Longer Handle: Compared to a drilling hammer, the engineer’s hammer has a longer handle, typically 12 to 16 inches. This extra length provides more leverage, allowing you to generate greater swinging speed and more powerful impacts.

- Substantial Weight: These hammers usually weigh between 2 and 4 pounds, similar to a drilling hammer, but their design makes the force feel much more significant due to the longer handle and swing arc.

- Focus on Power and Shaping: This hammer is engineered to move and shape tough materials, primarily metal. The combination of a heavy head and a long handle makes it a powerful striking tool.

Common Uses for an Engineer’s Hammer

You’ll find the engineer’s hammer in any setting where heavy materials need to be shaped or moved by force:

- Metal Fabrication: Its primary role is shaping hot or cold metal. The flat face is used for flattening and smoothing, while the peen is used for bending, stretching, or forming metal.

- Driving Punches and Chisels: It’s ideal for striking hardened tools like punches, drifts, and cold chisels when working on machinery or metal parts.

- Riveting: The peen is used to form the head of a rivet, making it a critical tool in traditional metal assembly.

- Heavy-Duty General Use: Beyond metal, it’s a great hammer for small-scale demolition, driving large spikes, or seating heavy components into place.

Drilling Hammer vs. Engineer Hammer: The Head-to-Head Comparison

Now that we understand each tool individually, let’s put them side-by-side. Seeing the differences clearly will make your choice simple. The best hammer for you truly depends on the material you’re working with and the outcome you need.

This table gives you a quick snapshot of the core differences. Below it, we’ll dive a little deeper into why these differences matter for your projects.

| Feature | Drilling Hammer (Club Hammer) | Engineer’s Hammer |

|---|---|---|

| Primary Job | Striking star drills and masonry chisels for precision work. | Shaping metal and heavy-duty striking (punches, rivets). |

| Head Shape | Symmetrical, with two identical flat striking faces. | Asymmetrical, with one flat face and one cross or rounded peen. |

| Handle Length | Short (approx. 10-12 inches) for control and accuracy. | Longer (approx. 12-16 inches) for leverage and power. |

| Typical Weight | 2 to 4 pounds, concentrated in a compact head. | 2 to 4 pounds, designed for a powerful swing. |

| Main Material Focus | Stone, brick, concrete (indirectly via a chisel). | Metal (shaping, riveting, striking). |

| Type of Force | Controlled, repetitive, and accurate strikes. | Powerful, high-impact, forceful blows. |

Why the Head Shape Matters

The head is the heart of the hammer. The drilling hammer’s two flat faces give you a reliable, broad striking surface. This is perfect for hitting the top of a chisel squarely, ensuring all the force transfers directly down the shaft. There’s no “wrong” side to use.

The engineer’s hammer’s dual-head is all about versatility in metalwork. The flat face works like any normal hammer for general striking. The peen, however, concentrates all the force of your blow into a small line or point. This allows you to dent, bend, or stretch metal in a very controlled way. It’s a shaper, not just a striker.

Handle Length: Control vs. Power

This is perhaps the most significant functional difference. The short handle of a drilling hammer keeps your hand close to the head. This makes it much easier to aim precisely and deliver rapid, light taps—exactly what you need when you’re slowly chipping a hole with a star drill. It’s a one-handed tool designed for finesse.

The longer handle of an engineer’s hammer is a classic lever. It multiplies the force of your swing, resulting in a much more powerful impact. You’ll often use two hands for a full-power swing. This leverage is essential for deforming steel or driving a large pin into a tight hole.

The Final Verdict: Which One Is the Proven Best Pick for You?

The “proven best pick” isn’t about one hammer being better than the other. It’s about picking the one that’s proven to be best for your specific task. It’s like asking whether a screwdriver or a wrench is better—it depends on if you have a screw or a bolt!

Choose the Drilling Hammer If…

- You are drilling a few holes in brick or concrete by hand with a star drill.

- You are shaping stone with a masonry chisel.

- You need to perform light demolition, like removing a single tile or brick, without damaging the surroundings.

- You need to drive hardened masonry nails.

- Your project requires accurate, controlled strikes in a tight space.

Choose the Engineer’s Hammer If…

- You are working with metal: shaping it, riveting it, or bending it.

- You need to strike hard steel tools like punches, drifts, or cold chisels with significant force.

- You are performing heavier demolition tasks, like breaking apart small rocks or a machine assembly.

- You need to drive large stakes, pins, or rebar into the ground or other materials.

- Your project calls for raw power and leverage over pinpoint accuracy.

Safety First: A Word on Using These Hammers Correctly

No matter which hammer you choose, safety should always be your top priority. These are heavy tools capable of causing serious injury if used improperly. I always tell folks in my workshop: your most important tool is a safe mindset.

Here are a few non-negotiable safety rules to follow:

- Always Wear Safety Glasses: This is the most important rule. Metal shards, stone chips, or even parts of a striking tool can fly off at high speed. Protect your eyes at all times.

- Inspect Your Hammer Before Use: Check the handle for cracks or splits. Make sure the hammer head is securely attached. A loose head can fly off during a swing and become a dangerous projectile.

- Strike Squarely: Always aim to strike your target flat and square with the hammer’s face. Hitting at an angle can cause the hammer to glance off, potentially causing injury or damaging your workpiece.

- Keep a Firm Grip: Hold the hammer firmly, but don’t tense up. A relaxed but secure grip gives you the best control. Consider wearing work gloves to improve your grip and absorb some of the vibration.

- Clear Your Swing Path: Make sure there are no people, pets, or fragile objects behind you or in your swing path. This is especially important when using the longer-handled engineer’s hammer.

For more detailed guidelines on hand tool safety, I always recommend looking at official resources. The U.S. Occupational Safety and Health Administration (OSHA) offers excellent, straightforward advice for keeping yourself safe in the workshop.

Frequently Asked Questions (FAQ)

1. Can I use an engineer’s hammer on wood?

You can, but it’s not ideal. The heavy weight and hard face can easily dent or crush wood fibers. For woodworking, it’s always better to use a dedicated claw hammer or a wooden mallet, which are designed to work with wood without damaging it.

2. What’s the main difference between an engineer’s hammer and a ball-peen hammer?

They are very similar! A ball-peen hammer has one flat face and one rounded, ball-shaped peen. An engineer’s hammer typically has a cross-peen, which looks more like a rounded wedge. The ball-peen is specifically for rounding over rivets and shaping metal with a domed effect, while the cross-peen is better for stretching and moving metal in a linear direction.

3. Is a drilling hammer the same as a sledgehammer?

Think of a drilling hammer as a “mini” sledgehammer. Sledgehammers are much larger and heavier (typically 8 to 20 pounds) with very long handles designed for two-handed, maximum-force swings. A drilling hammer (2-4 pounds) is a one-handed tool designed for more controlled tasks.

4. What size engineer’s hammer should a beginner buy?

A 2.5-pound or 3-pound engineer’s hammer is a great starting point. It’s heavy enough to deliver a powerful blow for most tasks without being too heavy and fatiguing for someone new to using it. You can always get a heavier one later if your projects require it.

5. Why is one side of the hammer head shaped differently?

On an engineer’s hammer, the different shapes (flat face and cross-peen) provide different functions. The flat face is for general striking, spreading force over a wide area. The peen concentrates the force into a smaller area, allowing you to shape or stretch material like metal.

6. Can I use a drilling hammer for demolition?

Yes, for light-duty demolition. It’s perfect for breaking up a single brick, cracking old mortar, or chipping away at a small section of concrete. For anything larger, like breaking up a sidewalk or a foundation, you will need a proper sledgehammer.

7. Does the handle material matter?

Yes, it does. Traditional handles are made from hickory, which is strong and good at absorbing shock. Modern handles are often made of fiberglass or steel with a rubber grip. Fiberglass is very durable and weather-resistant. It often comes down to personal preference, but many professionals still swear by the feel of a good hickory handle.

Conclusion: Choosing with Confidence

And there you have it! The mystery of the drilling hammer vs. the engineer’s hammer is solved. It all comes down to a simple idea: one is for controlled striking on masonry tools, and the other is for powerful shaping of metal.

- Drilling Hammer: Your go-to for precision and control when striking chisels, star drills, or stakes. Think masonry and delicate demolition.

- Engineer’s Hammer: Your powerhouse for shaping metal, driving punches, and handling general-purpose heavy-duty tasks. Think metalwork and forceful persuasion.

By understanding their unique designs, you can walk into any hardware store or tackle any project with the confidence of knowing you have the perfect tool for the job. Choosing the right hammer not only makes your work easier and more efficient but also much safer.

Happy building, and remember to always work safely and enjoy the process!