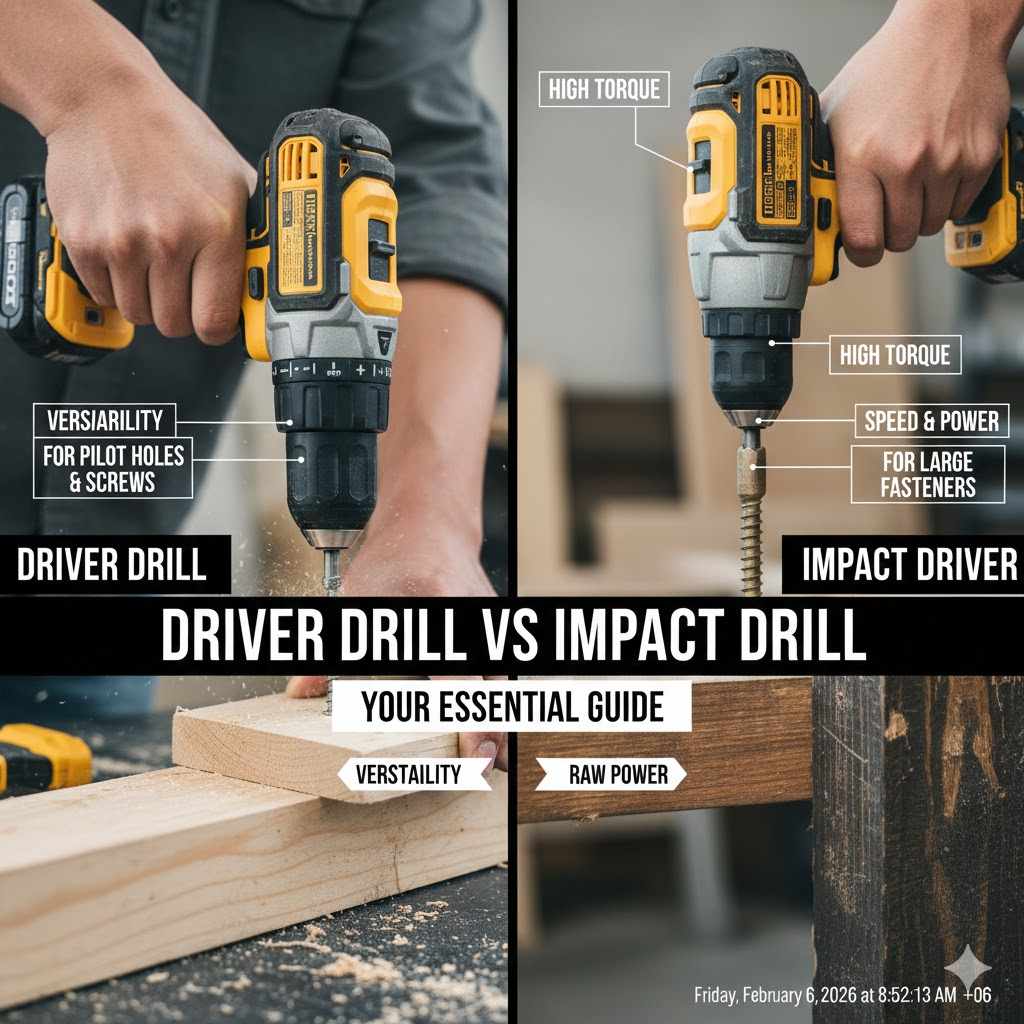

Driver Drill Vs Impact Drill: Your Essential Guide

A driver drill is your all-in-one tool for drilling holes and driving screws with precise control, thanks to its adjustable clutch. An impact drill (also called an impact driver) is a specialist, using powerful rotational bursts to effortlessly drive long screws and large fasteners into tough materials, saving your wrist and preventing stripped screw heads.

Welcome to the workshop! If you’ve ever stood in the tool aisle, staring at two drills that look almost the same but have very different price tags, you’re not alone. The driver drill vs. impact drill debate can feel confusing, but I promise it’s much simpler than it looks. It’s one of the most common questions I get from fellow DIYers and aspiring woodworkers.

Feeling overwhelmed by the choice is perfectly normal. You want to buy the right tool for the job without wasting money. You need a tool that makes your projects easier, not more frustrating. Good news! You’ve come to the right place. In this guide, I’ll break down everything you need to know in simple, clear terms. We’ll look at what each tool does best, when to use it, and how to choose the right one for you. Let’s get you building with confidence.

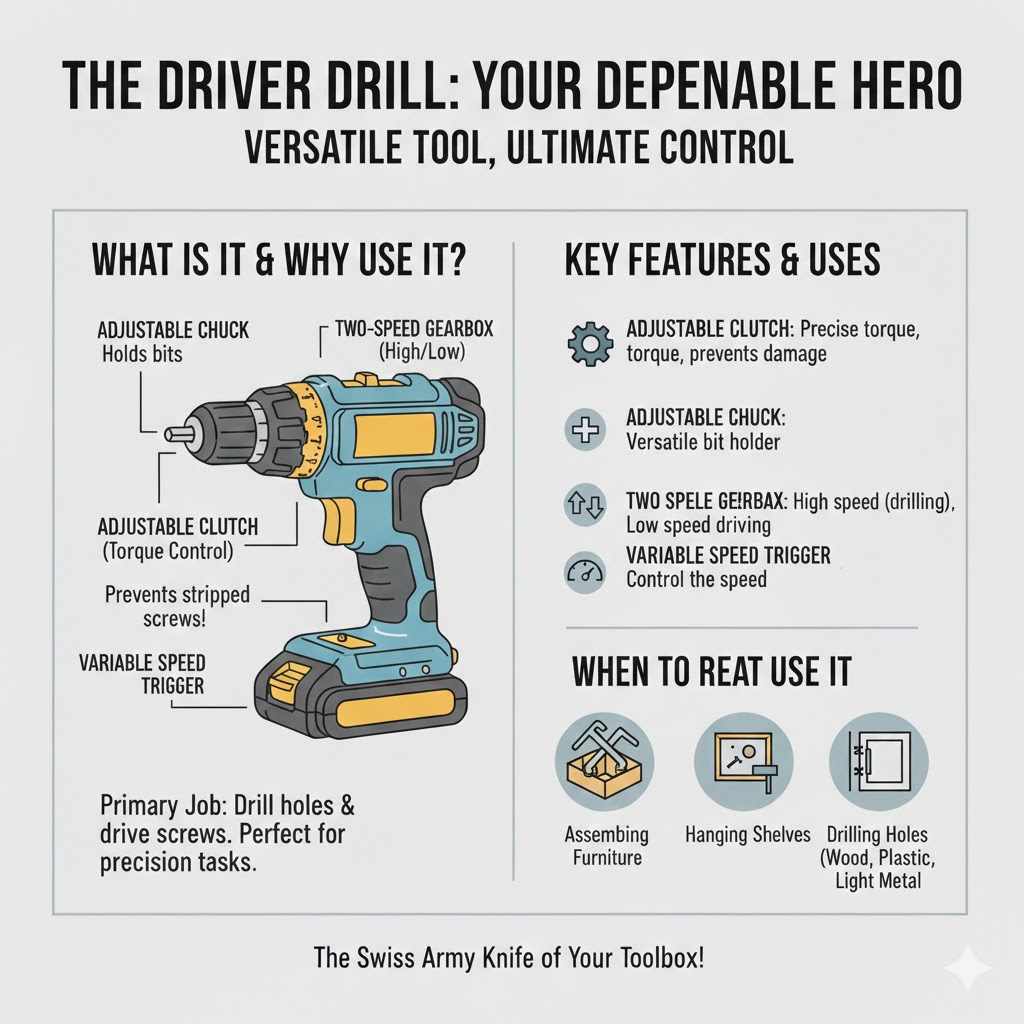

What is a Driver Drill? The Dependable All-Rounder

Think of a driver drill as the Swiss Army knife of your power tool collection. It’s incredibly versatile and likely the first power tool most people buy. Its main job is twofold: drilling holes and driving screws. If you’re just starting out, this is probably the tool you’ll reach for most often.

The magic of a driver drill lies in its control. It’s designed for precision and finesse, which is crucial for so many household tasks and woodworking projects. Let’s look at the key features that make it so special.

Key Features of a Driver Drill

- Adjustable Chuck: This is the part at the front that you twist to open and close. It’s a versatile clamp that can hold a huge variety of bits, including round-shank drill bits, hex-shank driver bits, and even wire brushes or hole saws. This is its biggest advantage—it can hold almost any type of bit you need.

- Adjustable Clutch (Torque Control): See that ring of numbers behind the chuck? That’s the clutch. It allows you to set the amount of rotational force (torque). When the drill reaches your set torque, the clutch slips with a clicking sound, stopping the bit from turning further. This is your best friend for preventing over-tightening screws, which can strip the screw head or damage the surface of your project.

- Two-Speed Gearbox: Most driver drills have a switch on top to select between a low-speed, high-torque setting (great for driving screws) and a high-speed, low-torque setting (perfect for drilling holes).

When to Use a Driver Drill

A driver drill shines when you need control over power. It’s your go-to for delicate tasks and general-purpose work around the house.

- Assembling Flat-Pack Furniture: The adjustable clutch is perfect for driving those small screws into particleboard without stripping them out.

- Hanging Pictures and Shelves: You can drill precise pilot holes in drywall and then gently drive the screws to the perfect depth.

- Drilling Holes: This is its primary function! Whether it’s wood, plastic, or even thin metal, a driver drill gives you the smooth, consistent speed needed for clean holes.

- Working on Softwoods: For projects with pine, cedar, or other softwoods, the controlled torque prevents you from driving screws too deep and splitting the wood.

- Minor Home Repairs: From tightening a loose cabinet hinge to fixing a fence picket, a driver drill has the versatility to handle it all.

What is an Impact Drill? The Powerhouse Specialist

Now, let’s talk about the impact drill, more commonly known as an impact driver. This tool might look like a compact, stubby version of a driver drill, but it works in a completely different and far more powerful way. It is a specialist designed to do one thing exceptionally well: drive long screws and large fasteners with incredible speed and force.

An impact driver uses both rotation and concussive blows. Inside the tool, a spring-loaded hammer and anvil mechanism slams together thousands of times per minute. These rapid, powerful rotational impacts transfer a massive amount of torque directly to the fastener, making it feel almost effortless to drive a 3-inch screw into dense wood.

Key Features of an Impact Drill

- Quick-Change Hex Collet: Instead of an adjustable chuck, an impact driver has a 1/4-inch hex collet. You simply pull the collet forward, insert a hex-shank bit, and let go. It locks the bit in place securely. This design is built for high-torque applications and only accepts 1/4-inch hex-shank bits.

- Rotational Impact Mechanism: This is the heart of the tool. It delivers massive amounts of torque in short bursts, which not only drives fasteners faster but also reduces the chance of “cam-out” (when the driver bit slips out of and strips the screw head). It also means there’s very little twisting force transferred back to your wrist.

- High Torque Output: Impact drivers typically have three to four times the torque of a standard driver drill. This raw power is what lets them handle jobs that would stall a regular drill.

- Compact and Lightweight: Because they don’t need a heavy gearbox and clutch system, impact drivers are usually smaller and lighter than driver drills, making them great for working in tight spaces or overhead.

When to Use an Impact Drill

Reach for your impact driver when you need to drive lots of long screws or work with tough materials. It turns big, strenuous jobs into quick work.

- Building a Deck: Driving hundreds of 3-inch deck screws is the perfect job for an impact driver. It will save you tons of time and arm fatigue.

- Installing a Subfloor: Securing subflooring with long screws is fast and easy with an impact driver.

- Driving Lag Bolts: Building a playset, pergola, or framing a wall often requires lag bolts. An impact driver can drive them without needing a socket wrench.

- Working with Dense Hardwoods: Driving fasteners into oak, maple, or other hardwoods is much easier with the power of an impact driver.

- Removing Stubborn Screws: The same rotational impacts that drive screws in can also help break loose rusted or over-tightened fasteners.

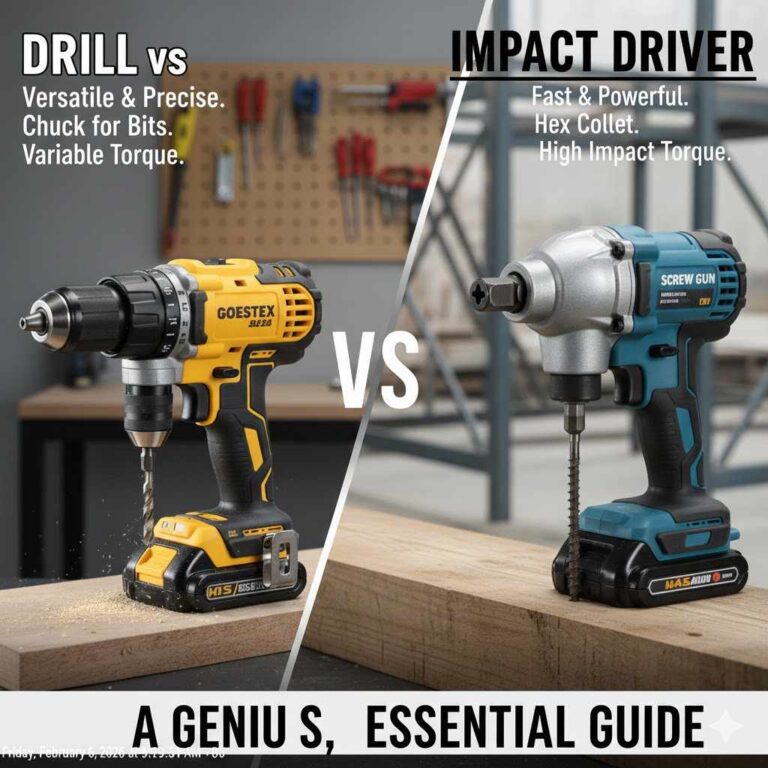

Driver Drill vs. Impact Drill: A Head-to-Head Comparison

To really understand the difference, let’s put these two tools side-by-side. Seeing how they stack up in key areas will help you decide which one you need for your next project.

| Feature | Driver Drill | Impact Drill (Impact Driver) |

|---|---|---|

| Primary Use | Drilling holes and driving screws with precision control. | Driving long screws and large fasteners with high torque. |

| Power & Torque | Lower torque, delivered consistently and smoothly. | Very high torque, delivered in powerful rotational bursts. |

| Control & Precision | Excellent, thanks to the adjustable clutch that prevents over-driving. | Less precise. Its power can easily damage delicate materials if not used carefully. |

| Bit Holder | Adjustable 3-jaw chuck holds a wide variety of bits (round and hex). | 1/4-inch quick-change hex collet for hex-shank bits only. |

| Versatility | Highly versatile. A true jack-of-all-trades for drilling and driving. | Specialized. Excellent for driving fasteners, but not ideal for drilling holes. |

| Noise Level | Relatively quiet. The clutch makes a clicking sound at its torque limit. | Extremely loud. The hammering mechanism creates a rapid, loud “rat-a-tat-tat” sound. Hearing protection is a must. |

| User Fatigue | Can cause more wrist strain on tough jobs due to rotational force (reactionary torque). | Minimal wrist strain, as the impacts transfer energy to the screw, not your arm. |

Power and Performance

When we talk about power, it’s important to be specific. A driver drill offers consistent, smooth power perfect for drilling clean holes. An impact driver delivers raw, hammering torque that’s all about driving force. You wouldn’t use a sledgehammer to tap in a finishing nail, and you wouldn’t use a tiny hammer to break up concrete. It’s the same principle here—it’s about applying the right kind of power for the task.

Control and Finesse

This is where the driver drill is the clear winner. The adjustable clutch is a game-changer for beginners and pros alike. Setting the clutch to a low number for small screws in softwood protects your workpiece from damage. Impact drivers lack this feature.

They deliver full power unless you have a high-end model with electronic speed settings, and even then, their raw power can be too much for delicate tasks. If you’re building a beautiful piece of furniture, the driver drill is your trusted friend for precision work.

Versatility: Can One Tool Do It All?

The driver drill is far more versatile out of the box. Its adjustable chuck can hold countless types of bits. You can drill, drive, sand, or even mix paint with the right attachment.

Can you drill holes with an impact driver? Yes, you can. Companies make special impact-rated drill bits with a hex shank. However, it’s not the ideal tool for the job. The impacting action can make it difficult to start a hole accurately, and the resulting hole may not be perfectly clean or round. It works in a pinch, but for any job where precision matters, a driver drill is the better choice.

Which Tool Should You Buy First?

This is the big question for anyone starting their tool collection. Here’s my simple recommendation:

For 9 out of 10 beginners, homeowners, and DIYers, the driver drill is the best first purchase.

Its versatility is unmatched. You can tackle almost any common household project with it, from assembling furniture and hanging curtains to drilling pilot holes for small woodworking projects. It’s the foundational tool upon which you can build your entire collection.

However, if your very first project is building a large deck or framing a shed, an impact driver will make your life significantly easier. For most people, though, the impact driver is the second drill they should buy. Many tool brands offer combo kits that include both a driver drill and an impact driver with a shared battery system. These kits are often an incredible value and the perfect way to start a tool collection, giving you the best of both worlds.

Safety First: Tips for Using Your Drills

No matter which tool you choose, safety in the workshop is always priority number one. These powerful tools demand respect. For more detailed guidance, always check the tool’s manual and resources like the Occupational Safety and Health Administration (OSHA) guidelines for power tools.

- Always Wear Safety Glasses: Wood chips, metal shavings, or bits of drywall can fly anywhere. Protect your eyes every single time.

- Protect Your Hearing: Impact drivers are extremely loud and can cause hearing damage over time. Always wear earplugs or earmuffs when using one.

- Secure Your Workpiece: Use clamps to hold your material firmly in place. This prevents it from spinning and causing an injury, especially when drilling larger holes.

- Use the Right Bit for the Job: A dull or incorrect bit is dangerous and inefficient. Use sharp bits designed for the material you are working with (e.g., wood bits for wood, metal bits for metal).

- Keep Your Hands Clear: Maintain a safe distance from the rotating bit. Never wear loose clothing, jewelry, or gloves that could get caught.

- Start Slow: When drilling a hole, start at a slow speed to create a dimple that will guide the bit and prevent it from “walking” across the surface.

Frequently Asked Questions (FAQ)

1. Do I really need both a driver drill and an impact drill?

For most beginners and homeowners, a good driver drill is enough to get started. However, as you take on larger projects like building decks, fences, or framing, an impact driver becomes invaluable. Owning both allows you to use the perfect tool for every task, making your work faster, easier, and more professional.

2. Can I use regular drill bits in an impact drill?

No, you should not. Impact drivers require bits with a 1/4-inch hex shank to fit into their collet. More importantly, you should use “impact-rated” bits. These bits are made from more durable steel that can withstand the violent torque of the impacting mechanism. Using standard bits can cause them to shatter, which is a serious safety hazard.

3. How is a hammer drill different from an impact drill?

This is a great question and a common point of confusion. An impact drill (impact driver) delivers rotational (twisting) impacts. A hammer drill delivers linear, forward-and-back impacts, like a tiny jackhammer. This action is designed to pulverize masonry, so you use a hammer drill for drilling holes in brick, concrete, or stone.

4. Why did my screw head strip when I used my impact drill?

Stripping a screw head, or “cam-out,” usually happens for two reasons with an impact driver. First, you might be using the wrong size or type of driver bit (e.g., a #1 Phillips bit on a #2 screw). Always match the bit to the screw head perfectly. Second, you might not be applying enough firm, straight pressure behind the tool, allowing the bit to jump out of the screw head under torque.

5. What’s the most important feature to look for in a beginner’s drill?

For a beginner’s driver drill, the most important feature is a good adjustable clutch with plenty of settings. This gives you the control you need to learn how to drive screws properly without damaging your projects. For any cordless tool, look for a reputable brand with a good battery system (e.g., 18V or 20V MAX), as you can expand your collection of “bare tools” later that use the same battery.

6. Can I use an impact drill to remove stuck or rusty screws?

Absolutely! This is one of its hidden strengths. The rapid rotational impacts are excellent at breaking loose fasteners that are frozen by rust or are over-tightened. Just make sure you are in reverse, use the correct bit size, and apply steady pressure.

Conclusion: Choosing the Right Tool for Your Project

So, there you have it. The driver drill vs. impact drill mystery is solved! It’s not about which tool is “better,” but about which tool is right for the specific task in front of you.

Your versatile driver drill is the reliable friend you’ll call on for everyday tasks, precise hole drilling, and delicate assembly. Its adjustable clutch and chuck make it the perfect all-rounder for any home workshop. Your powerful impact driver is the specialist you bring in for the heavy lifting—driving long screws into dense wood, building large structures, and making demanding jobs feel easy.

As you begin your journey in woodworking and DIY, start with a quality driver drill. It will serve you well and help you build foundational skills. When your projects grow in scale and ambition, adding an impact driver to your toolbox will feel like unlocking a superpower.

Now you can walk down that tool aisle with confidence, knowing exactly what you’re looking for and why. Pick up your tool, get back to your workshop, and start building something amazing. You’ve got this!