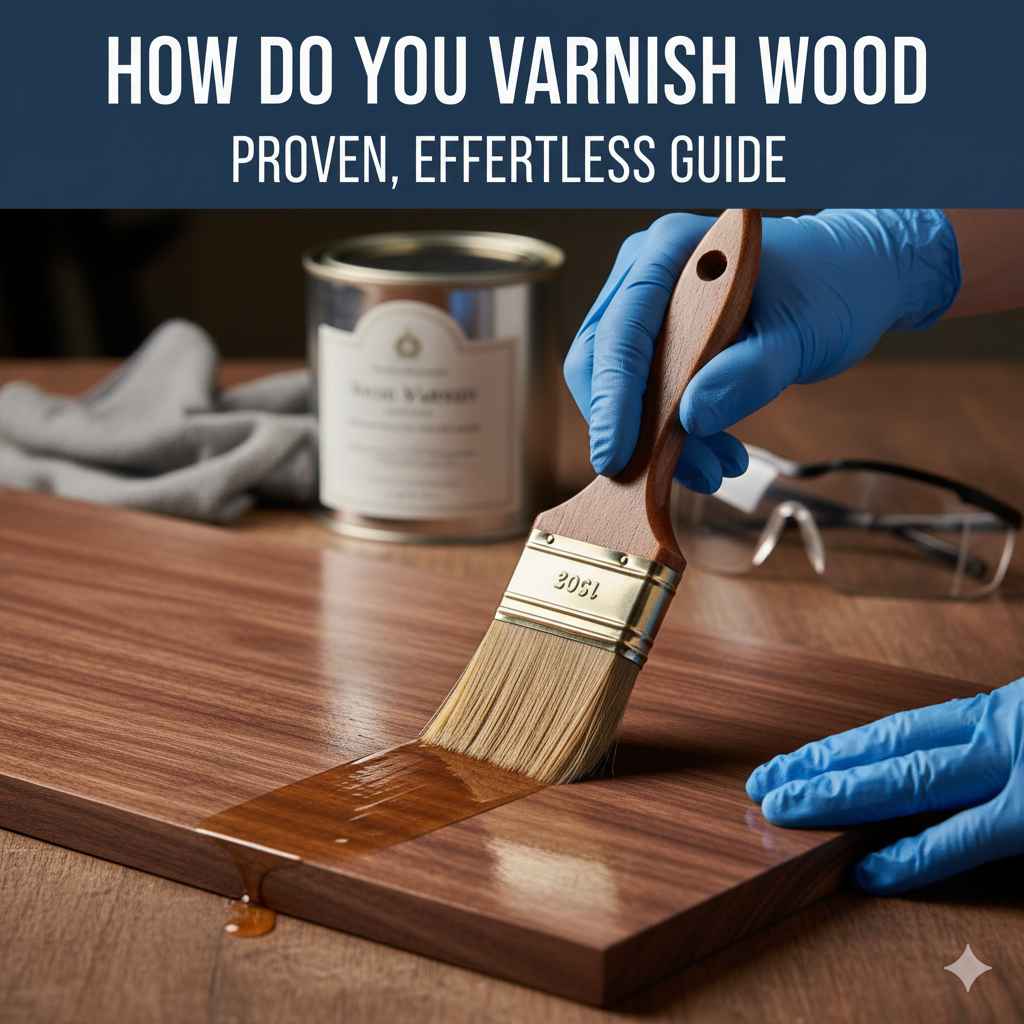

How Do You Varnish Wood: Proven, Effortless Guide

Varnishing wood involves preparing the surface by cleaning and sanding, applying thin, even coats of varnish with a brush or sprayer, and sanding lightly between coats for a smooth, durable, and beautiful finish. Follow these simple steps for a professional-looking result on your woodworking projects.

Ever looked at a beautiful piece of furniture and wondered how it got that protective, glossy sheen? That’s often the magic of varnish! But when it comes to doing it yourself, it can feel a little daunting. You might worry about drips, streaks, or a finish that just doesn’t look quite right. Don’t you worry! My goal is to make this process feel as easy as making a cup of tea.

Varnishing is a fantastic way to protect your wood from daily wear, moisture, and UV rays, while also enhancing its natural beauty. It’s a skill that truly elevates your DIY projects from good to gallery-worthy. We’ll walk through it step-by-step, covering everything from picking the right varnish to that final, satisfying buff.

Your Varnish Vibe: Choosing the Right Type

Before we even think about brushes, let’s chat about varnish itself. Not all varnishes are created equal, and picking the right one is key to your project’s success and longevity. Think of it like choosing the right paint for your walls – different needs, different solutions!

Here’s a breakdown of the most common types you’ll encounter, along with what they’re best for:

Oil-Based Varnishes

These are the classic workhorses. They offer excellent durability and a rich, warm tone to the wood. Because they are oil-based, they tend to level out beautifully, minimizing brush strokes.

- Pros: Very durable, excellent protection, beautiful warm amber tone, good for high-traffic areas.

- Cons: Longer drying times, strong odor (requires good ventilation), can yellow over time, requires mineral spirits for cleanup.

- Best For: Floors, tabletops, outdoor furniture, anything needing maximum protection.

Water-Based (Acrylic or Polyurethane) Varnishes

These have grown incredibly popular, and for good reason! They dry much faster, have a low odor, and clean up with just soap and water, making them super beginner-friendly. They tend to dry clear, preserving the natural color of the wood.

- Pros: Fast drying, low odor, easy cleanup with water, dries clear, less prone to yellowing.

- Cons: Can be less durable than oil-based options (though modern formulas are excellent), may show brush strokes more if applied incorrectly.

- Best For: Indoor furniture, cabinets, decorative items, projects where quick drying and low odor are priorities.

Spar Varnish

Originally designed for the masts of sailing ships (hence “spar”), this varnish is formulated with UV inhibitors and extra flexibility. It’s built to withstand the harsh elements.

- Pros: Excellent UV protection, flexible (resists cracking), good for outdoor use.

- Cons: Can be softer than other varnishes, may take longer to cure fully, often has a yellow tint.

- Best For: Outdoor furniture, boat brightwork, doors exposed to direct sunlight.

Pre-Catalyzed and Conversion Varnishes

These are more professional-grade finishes, often used in commercial furniture making. They offer exceptional hardness, chemical resistance, and durability. While they can offer a fantastic, long-lasting finish, they often require specialized application and ventilation due to their potency and curing agents.

- Pros: Extremely hard and durable, excellent chemical resistance, fast curing.

- Cons: Potentially toxic fumes, requires specialized application (e.g., spray equipment), not typically recommended for beginners in a home setting.

- Best For: High-wear surfaces in commercial settings, custom cabinetry where extreme durability is paramount.

Gather Your Gear: Essential Tools and Materials

Alright, you’ve picked your varnish. Now, let’s get our toolkit ready. Having the right supplies makes the whole process smoother and the results so much better. Don’t worry, you probably have some of these already!

Here’s a checklist of what you’ll need:

- Selected Varnish: (As discussed above!)

- Sandpaper: A range of grits – usually starting around 120-150 for initial prep, then 180-220 for smoothing between coats.

- Sanding Block or Orbital Sander: For even sanding.

- Tack Cloth or Microfiber Cloth: For wiping away dust.

- Good Quality Brushes: Natural bristles for oil-based varnish, synthetic for water-based. Consider foam brushes for a very smooth finish without much effort.

- Paint Rollers (Optional): Small foam rollers can be great for large, flat surfaces.

- Paint Tray or Container: To pour your varnish into.

- Gloves: To protect your hands.

- Safety Glasses: Always protect your eyes!

- Respirator Mask: Especially important for oil-based varnishes or when sanding.

- Drop Cloth or Plastic Sheeting: To protect your work area.

- Clean Rags: For wiping up drips.

- Mineral Spirits (for oil-based) or Water (for water-based): For cleaning up tools.

Prep School: Getting Your Wood Ready for Varnish

This might be the most important step! Think of it like preparing a canvas before painting. A perfectly prepped surface ensures your varnish adheres well and looks flawless. Skipping this can lead to a less durable finish and visible imperfections.

Step 1: Clean the Surface

Your wood needs to be perfectly clean. Dust, dirt, grease, and old finishes will all interfere with the new varnish. Use a damp (not wet!) cloth to wipe down the wood. For any stubborn grease, you might need a mild detergent or degreaser, followed by a clean water wipe.

Step 2: Sand, Sand, Sand!

This is where we create a smooth canvas. Start with a medium-grit sandpaper (around 120-150 grit) to remove any rough spots, old finishes, or mill marks. Always sand in the direction of the wood grain. If you’re using an orbital sander, move it slowly and evenly across the surface.

Once you’ve gone over it with the coarser grit, move to a finer grit (180-220). This smooths out the scratches left by the previous sandpaper, creating a silky surface. It’s the difference between a “meh” finish and a “wow” finish!

Step 3: Dust Off the Evidence

After sanding, your wood is covered in fine dust. This is where the tack cloth or a clean, dry microfiber cloth comes in. Wipe the surface thoroughly, going with the grain. A tack cloth is slightly sticky and is excellent at picking up microscopic dust particles that regular cloths might miss. Repeat this until you’re absolutely sure there’s no dust left.

Pro Tip: For water-based varnishes, vacuuming up dust first can sometimes be helpful, but always follow up with a tack cloth or microfiber. For oil-based, avoid any solvents that might leave a residue.

The Nitty-Gritty: Applying the Varnish

Now for the exciting part – applying the varnish! Remember, the key here is thin, even coats. It’s much better to apply three thin coats than one thick, gloopy one.

Step 1: Stir, Don’t Shake

This is crucial! If you shake the varnish can, you’ll introduce tiny air bubbles. These bubbles can pop as the varnish dries, leaving little craters in your finish. Gently stir the varnish with your stirring stick to mix the ingredients without creating froth. If you see any skin on top, carefully lift it out.

Step 2: The First Coat

Pour a small amount of varnish into your paint tray or a clean container. Dip your brush (or foam brush) about a third of the way into the varnish. Don’t overload it!

Start applying the varnish in long, even strokes, following the direction of the wood grain. If you’re varnishing a flat surface, start at one edge and work your way across. Overlap each stroke slightly to avoid missed spots.

Work quickly but deliberately. If you’re using an oil-based varnish, you’ll have more time to work with it. For water-based, it dries faster, so aim for smooth, continuous strokes.

As you finish a stroke, lightly drag the brush over the area again to catch any drips or thick spots. The goal is a thin, consistent film of varnish.

Step 3: Drying Time

This is where patience comes in! Varnish needs time to dry. The can will specify drying times, but these are often for “touch dry.” For successful recoating, you’ll need to let it dry long enough for the surface to harden sufficiently. Always follow the manufacturer’s recommendations, as they can vary significantly.

Typical Drying Times (Approximate):

| Varnish Type | Touch Dry | Recoat Time | Full Cure |

|---|---|---|---|

| Oil-Based | 4-12 hours | 12-24 hours | 7-30 days |

| Water-Based | 30-60 minutes | 2-4 hours | 7-14 days |

| Spar Varnish | 4-12 hours | 12-24 hours | 7-30 days |

Note: Drying and curing times can be affected by temperature, humidity, and ventilation. Always check your product’s label for precise information.

Step 4: The Second Coat (and Beyond)

Once the first coat is dry to the touch and feels no longer tacky, it’s time for the magic of sanding between coats. This step is crucial for achieving a super smooth, professional finish. Use a very fine-grit sandpaper (220-320 grit) or a synthetic scouring pad.

Lightly sand the entire surface. You’re not trying to remove the varnish, just to knock down any minor imperfections, dust nibs (those tiny bits of dust that landed during drying), or slight brush marks. The surface might look dull and cloudy after sanding – this is normal!

After sanding, use your tack cloth or microfiber cloth again to remove all the dust. Then, apply your second coat of varnish, just like you did the first.

Most projects will benefit from 2-3 coats. For high-wear surfaces like tabletops or floors, you might want to go for 4-5 coats. Always allow adequate drying time between each coat, and lightly sand and clean before applying the next.

The Grand Finale: Curing and Care

You’ve applied your final coat! Congratulations! But wait, there’s just one more thing: curing. While the varnish might feel dry to the touch very quickly, it takes much longer to reach its full hardness and durability. This is called curing. Giving the varnish adequate time to cure is essential for its long-term performance.

Let It Cure

Respect the cure time! For about 7 to 30 days (depending on the varnish type and conditions), try to treat your varnished item gently. Avoid placing heavy objects on it, sliding things across the surface, or exposing it to excessive moisture.

For furniture, this means not putting it into service immediately. For outdoor items, ensure they are protected from heavy rain during this critical period. Understanding the full cure time, as noted in our table above, is vital for a finish that lasts.

Buffing for Brilliance (Optional)

If you want an extra-smooth, satiny finish rather than a high gloss, or if you want to achieve a specific sheen level, you can buff the final coat after it has fully cured (meaning after the 7-30 day period).

Use a very fine-grit polishing pad (like steel wool grade #0000) or a polishing compound specifically designed for wood finishes. Work in gentle, overlapping motions following the grain. This will flatten the surface slightly and give it a beautiful, soft sheen.

Ongoing Care

Once your varnish is fully cured, it’s ready for action! To keep it looking its best:

- Clean gently: Use a soft, damp cloth. Avoid abrasive cleaners or scouring pads, which can scratch the varnish.

- Wipe up spills: Don’t let liquids sit on the surface for extended periods, as even cured varnish can be damaged by prolonged exposure to certain substances.

- Use coasters and placemats: This is always a good idea for tabletops and furniture to prevent scratches and water rings.

- Avoid harsh chemicals: Stick to mild soap and water for cleaning.

Troubleshooting Common Varnish Woes

Even the best of us run into a little hiccup now and then. Here are some common issues and how to fix them:

- Drips and Runs: Usually caused by applying the varnish too thickly or not spreading it evenly. If caught while still wet, you can often smooth them out with your brush. If dry, you’ll need to sand them down smooth and reapply varnish to that area.

- Brush Marks: Can happen if you used too much pressure, applied the varnish too unevenly, or used the wrong type of brush. Sand lightly with fine-grit paper and apply a thinner, more even coat next time.

- Sticky Surface: This often means the varnish hasn’t dried or cured properly. This could be due to applying too thick a coat, poor ventilation, high humidity, or low temperatures. Wait longer, ensure good airflow, and if necessary, try to gently scrape off the sticky section and re-varnish.

- Cloudiness or Haze: In humid conditions, varnish (especially oil-based) can sometimes “blush” or turn cloudy. Ensuring good ventilation and not varnishing in damp environments helps prevent this. If it happens, sometimes a gentle buff with a polishing compound can help.

- Dust Nibbs: Tiny specks of dust embedded in the finish. The solution is always to lightly sand with fine-grit paper and wipe clean between coats.

Remember, most minor imperfections can be sanded out and corrected with another thin coat!

Frequently Asked Questions (FAQs)

Q1: Do I need to prime wood before varnishing?

Generally, no. Priming is for painting. Varnish is designed to work directly on the wood surface after proper preparation (cleaning and sanding). Some very specific situations or types of wood might benefit from a seal coat, but for standard varnishing, prep sanding is enough.

Q2: How many coats of varnish are usually needed?

For most indoor projects, 2 to 3 coats is sufficient. For surfaces that get a lot of use or are exposed to moisture and UV rays (like tabletops, doors, or outdoor furniture), 3 to 5 coats provide better protection.

Q3: Can I varnish over an existing paint or stain?

Yes, but only if the existing finish is sound and stable. You’ll need to clean it thoroughly and lightly sand it to create a surface the varnish can adhere to. If it’s chipped or peeling, you’ll need to remove the old finish first.

Q4: How do I varnish curved or irregularly shaped objects?

The technique is the same: thin, even coats. Use a high-quality brush that can get into nooks and crannies. Work from the top down, letting gravity help you spread the varnish. Be mindful of any areas where varnish might pool.

Q5: What’s the difference between varnish and polyurethane?

This is a common point of confusion! Polyurethane is a type of synthetic resin that is a key ingredient in many modern varnishes. Often, the terms are used interchangeably, especially for water-based finishes. “Varnish” is a broader term for a liquid coating that dries to a hard, protective film. So, polyurethane is a specific type of resin that makes a varnish perform well.

Q6: Can I use varnish outdoors?

Yes, but you need to choose the right type. Spar varnish is specifically designed for outdoor use due to its UV resistance and flexibility. Regular interior varnishes will not hold up well to sun and weather and may crack or peel.

Q7: My varnish has dried to a sticky texture. What did I do wrong?

This usually occurs when the varnish is applied too thickly, in poor drying conditions (too cold, too humid), or with inadequate ventilation. The surface has sealed over, trapping solvents underneath.