How Long for ABS Glue to Dry? Proper Cure Time

You’ve just finished a great DIY project, or maybe a quick repair, using ABS glue. The pieces look fantastic together, but now comes the waiting game. How long does this stuff actually take to dry and become strong?

You don’t want your hard work falling apart after just a few days, especially if the item is going to be used regularly. Getting this right ensures your project lasts. This post will clearly explain the drying and curing times for ABS glue so you can move forward with confidence.

Understanding ABS Glue Drying and Cure Times

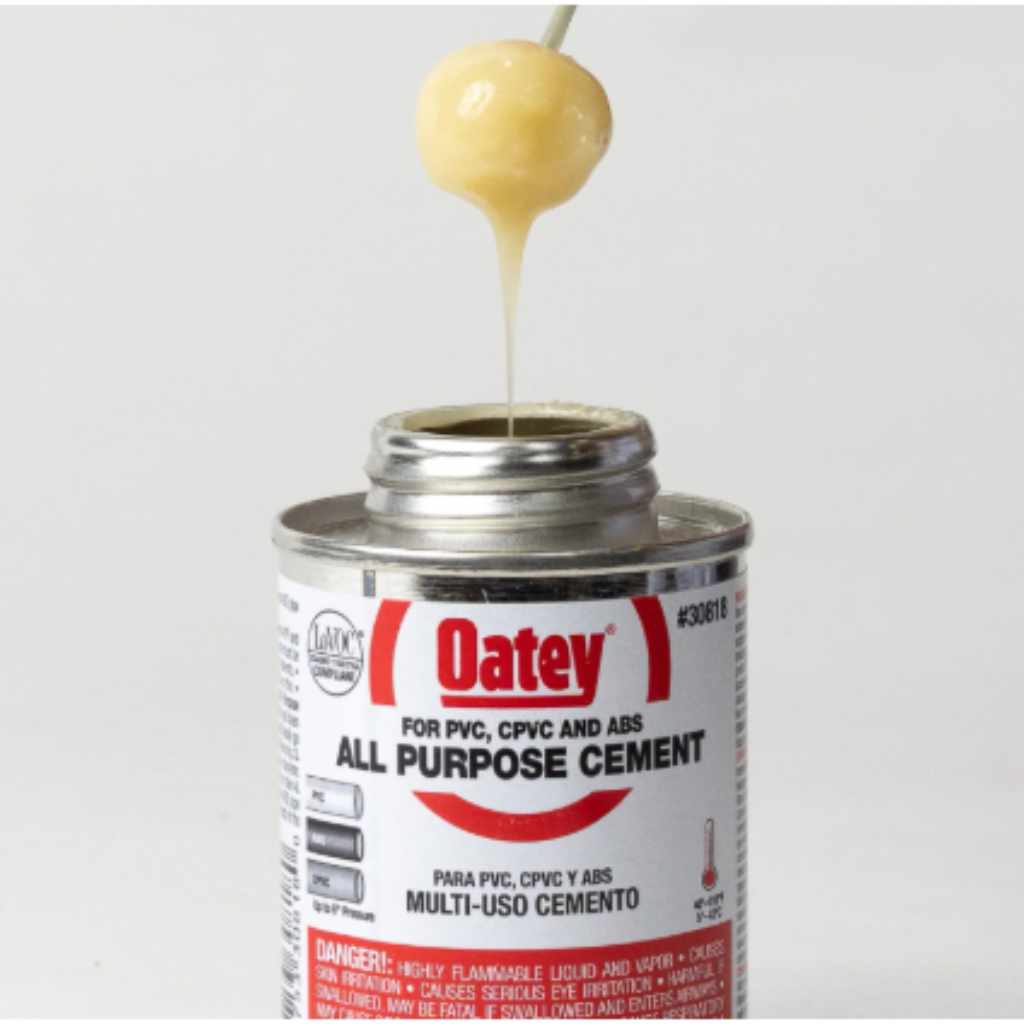

ABS glue, often called ABS cement, is a powerful adhesive specifically designed for bonding acrylonitrile butadiene styrene (ABS) plastic. It works a bit differently than standard glues. Instead of just sticking two pieces together, ABS glue actually melts the surface of the plastic slightly.

This process, called solvent welding, fuses the two pieces of ABS into a single, strong bond. Because of this unique mechanism, the drying and curing times are important to consider for achieving the best results. Knowing exactly how long for ABS glue to dry?

Proper cure time will help you avoid premature stress on your bonded items.

When you apply ABS glue, you’ll notice it’s quite liquid. This liquid contains solvents that dissolve a thin layer of the ABS plastic. Once you press the pieces together, these dissolved surfaces combine.

The solvents then begin to evaporate, leaving behind a solid, fused bond. This evaporation process is what leads to drying. However, drying is just the first stage.

True strength, or a full cure, takes longer as the plastic molecules fully re-establish their bonds.

Factors Affecting ABS Glue Drying Time

Several factors can influence how quickly your ABS glue dries and cures. These aren’t fixed times, but rather ranges that depend on your specific situation.

Temperature

Higher temperatures generally speed up the evaporation of solvents. If you’re working in a warm environment, your ABS glue might dry faster than in a cool one. However, extremely high heat can sometimes cause issues with the plastic itself, so moderate warmth is best.

Humidity

Humidity plays a significant role. High humidity means there’s more moisture in the air, which can slow down the evaporation of the solvents in the glue. Low humidity, on the other hand, can help solvents evaporate more quickly.

Airflow

Good ventilation is key. If the area is stuffy, the evaporated solvents will linger, slowing down the drying process. Moving air, like from a fan on a low setting, can help carry away the solvents and speed things up.

Be careful not to use a fan that blows dust or debris onto the wet glue.

Amount of Glue Used

Using too much ABS glue can also extend drying time. A thin, even coat is usually sufficient. A thick blob of glue will take much longer for the solvents to evaporate from, meaning it will remain soft for a longer period.

Type of ABS Glue

Different brands and formulations of ABS glue can have slightly different drying times. Some are formulated to dry faster, while others might be designed for a longer working time. Always check the product label for specific instructions.

Typical Drying and Curing Times

So, how long for ABS glue to dry? Proper cure time is what we’re aiming for. It’s helpful to break this down into stages: handling dry and full cure.

Handling Dry (Set Time)

This is the point where the glue is no longer wet to the touch and you can carefully handle the bonded piece without smudging or disturbing the joint. For most standard ABS cements, this typically occurs within 10 to 30 minutes. Some fast-drying formulas might achieve this in as little as 5 minutes.

At this stage, the bond is not yet at its strongest.

Structural Strength (Drying Time)

This is when the bond has solidified enough to withstand some light stress or movement. It’s usually safe to move the item or perform minor adjustments. This stage typically takes between 1 to 2 hours.

You can usually test a small, inconspicuous area by gently trying to wiggle the pieces.

Full Cure (Maximum Strength)

This is the most critical part for ensuring a lasting bond. Full cure means that the solvents have completely evaporated, and the plastic has fully re-bonded, achieving its maximum possible strength. This is when you can put the item to its intended use, even if it involves pressure or stress.

Full cure for ABS glue typically takes 24 to 72 hours. For critical applications or items that will be subjected to significant forces, waiting the full 72 hours is highly recommended.

Steps to Ensure Proper Drying and Curing

To make sure your ABS glue dries and cures correctly, follow these simple steps:

- Prepare Surfaces: Ensure the ABS surfaces you’re bonding are clean, dry, and free of any grease, dirt, or old adhesive. A quick wipe with a suitable cleaner or even sandpaper can help create a better surface for bonding.

- Apply Glue Sparingly: Use a thin, even layer of ABS glue. A little goes a long way, and too much can prolong drying.

- Join Parts Quickly: ABS cement works fast. Once applied, join the pieces immediately and hold them firmly in place for the recommended time (often 30 seconds to a minute) to allow initial bonding.

- Allow Ample Drying Time: Resist the urge to stress the joint too early. Follow the general guidelines for handling dry, structural strength, and full cure times.

- Ensure Good Ventilation: Work in a well-ventilated area. This helps the solvents evaporate efficiently.

- Maintain Stable Temperature: Avoid extreme temperatures. A moderate room temperature is ideal for consistent drying.

ABS Glue vs. Other Adhesives

It’s worth noting how ABS glue differs from common glues like super glue (cyanoacrylate) or epoxy.

| Adhesive Type | How It Works | Typical Set Time | Typical Full Cure Time | Best For |

|---|---|---|---|---|

| ABS Glue (Solvent Cement) | Solvent welding, melts and fuses plastic | 10-30 minutes (handling dry) | 24-72 hours | Bonding ABS to ABS |

| Super Glue (Cyanoacrylate) | Fast chemical reaction triggered by moisture | Seconds to minutes | Several hours to a day | Quick fixes, non-porous materials |

| Epoxy | Two-part chemical reaction, creates a hard resin | 5 minutes to several hours (depending on type) | 24-72 hours | Strong, rigid bonds, various materials |

As you can see, ABS glue has a unique process. While super glue offers instant grabbing power, it doesn’t fuse the plastic. Epoxy creates a strong bond but isn’t a solvent weld, meaning it adheres to the surface rather than becoming part of it.

This makes ABS glue the superior choice for permanently joining ABS components.

Common Mistakes to Avoid

Even with clear guidelines, people sometimes make errors that compromise their ABS glue bonds.

- Not Reading Instructions: Every product can be a little different. Always take a moment to read the manufacturer’s specific directions.

- Rushing the Cure Time: This is perhaps the most common mistake. You might think it’s strong enough, but waiting the full cure time is essential for long-term durability.

- Poor Surface Preparation: If the surfaces are dirty or greasy, the glue won’t be able to do its job properly, leading to a weak bond.

- Using Too Much Glue: As mentioned, excess glue can hinder drying. It also often creates an unsightly mess.

- Exposing to Stress Too Soon: Trying to use or stress the bonded item before it’s fully cured can break the new bond before it’s had a chance to form completely.

Frequently Asked Questions

Question: Can I speed up the drying of ABS glue with a hairdryer?

Answer: While some gentle warmth can help, using a hairdryer on high heat is generally not recommended. Excessive heat can warp or damage the ABS plastic itself, and it might cause the solvents to evaporate too quickly from the surface, leaving the inner bond weaker.

Question: What happens if I don’t wait for the full cure time of ABS glue?

Answer: If you don’t wait for the full cure time, the bond will not reach its maximum strength. This can lead to the joint failing under stress, breaking apart, or showing cracks over time, especially if the item is used frequently or put under pressure.

Question: Is ABS glue waterproof once cured?

Answer: Most standard ABS glues are generally considered water-resistant once fully cured. However, prolonged submersion in water or exposure to harsh chemicals can eventually degrade the bond. Always check the specific product details for its resistance properties.

Question: Can I use ABS glue on other types of plastic?

Answer: ABS glue is specifically formulated for ABS plastic. While it might temporarily soften some other plastics, it won’t create a reliable, fused bond. For other plastics, you should use an adhesive designed for that specific material type.

Question: How do I clean up uncured ABS glue?

Answer: Uncured ABS glue can usually be wiped away with a clean cloth dampened with denatured alcohol or the same solvent used in the ABS cement itself. For cured glue, it’s much harder to remove and might require scraping or sanding.

Final Thoughts

When tackling a project that involves ABS plastic, knowing precisely how long for ABS glue to dry? Proper cure time is fundamental for ensuring your repairs and creations are durable and reliable. Remember that ABS cement doesn’t just stick surfaces together; it fuses them by dissolving a small layer of the plastic itself.

This solvent welding process requires patience. A quick glance at the drying time reveals that while a bond might feel dry to the touch within minutes, it’s still developing its full strength. The critical window for full cure, when the plastic molecules have re-established their strongest connections, typically spans 24 to 72 hours.

Factors like temperature, humidity, and airflow all play a part in this timeline, so be mindful of your working environment. Always prepare your surfaces properly, apply glue thinly, and resist the urge to subject the bonded item to stress too soon. Giving the ABS glue the full time it needs to cure means you’re investing in a bond that will last, preventing future headaches and ensuring your hard work holds up under normal use.

Trust the process and the recommended curing times for the best outcome.