How Long to Wait Before Staining: Quick Deck Prep Guide

You should wait several weeks for pressure-treated wood to dry out before staining it. Kiln-dried wood can be stained immediately, but if the wood is not kiln-dried, you may need to wait a little longer.

Staining or sealing the wood too soon can prevent proper absorption and adherence of the finish, and it can also interfere with the effectiveness of the pressure treatment. To determine if the wood is ready for staining, you can sprinkle water on the surface of the deck.

If the water absorbs into the wood, it is dry enough to stain. However, if the water beads up and sits on the surface, there is still too much moisture and you should let it dry out for longer.

The Basics Of Pressure Treated Wood

After building a pressure-treated wood deck, allow several weeks for the lumber to dry out before staining. Kiln-dried wood can be stained right away, but for air-dried wood, you may need to wait a bit longer. Ensure the wood is dry enough for the stain to adhere properly.

Pressure treated wood is treated with preservatives to enhance durability and resistance to decay and insects. It is commonly used for outdoor structures like decks and fences.

Types Of Pressure Treated Wood

There are two main types: wet pressure treated wood and kiln-dried pressure treated lumber.

Kiln Dried Vs. Air Dried Lumber

Kiln-dried lumber is ready for staining immediately, while air-dried wood may require additional drying time before staining.

When staining pressure treated wood, ensure the wood is dry enough to absorb the stain properly. Sprinkle water on the surface – if it absorbs, it’s ready; if it beads up, it needs more drying time.

Staining too soon can affect the finish and the wood’s protective treatment. Optimal staining results come from properly dried wood.

Determining The Right Time To Stain

To determine the right time to stain a pressure-treated wood deck, it’s crucial to allow the wood to dry thoroughly after installation. The drying process can take several weeks for the wood to be ready for staining. If the wood is kiln-dried, staining can be done immediately; otherwise, waiting a bit longer is necessary.

Moisture Content And Readiness

When it comes to staining pressure-treated wood, determining the right time to do so is crucial to achieving a beautiful and long-lasting finish. One of the key factors to consider is the moisture content of the wood. If the wood is too wet, the stain won’t absorb properly, resulting in a patchy and uneven finish.

To determine the moisture content of the wood, there are a couple of methods you can use. One way is to sprinkle water onto the surface of the wood. If the water is quickly absorbed, then the wood is ready to be stained. If the water beads up and sits on the surface, then there is still too much moisture in the wood, and you should wait a little longer before staining.

Another way to test the moisture content is to use a moisture meter. This tool measures the moisture content of the wood and can give you an accurate reading of when the wood is ready to be stained.

The Role Of Weather In Drying Wood

Aside from the moisture content of the wood, the weather also plays a significant role in how long it takes for pressure-treated wood to dry. If you live in a hot and dry climate, the wood may dry out faster than if you live in a cooler and more humid climate.

It’s essential to keep an eye on the weather forecast and plan to stain your deck during a dry spell. Rain or high humidity can slow down the drying process and affect the quality of the finish.

Readiness

In general, it’s best to wait at least six months before staining pressure-treated wood. This gives the wood enough time to dry out and allows any chemicals from the pressure-treating process to dissipate.

However, if you’re unsure whether the wood is ready to be stained, you can perform a simple test. Apply a small amount of stain to a hidden area of the wood and wait for it to dry. If the stain adheres well and the color is even, then the wood is ready to be stained. If the stain doesn’t absorb or the color is patchy, then the wood needs more time to dry.

In conclusion, waiting for pressure-treated wood to dry and being mindful of the weather conditions are crucial factors when determining the right time to stain. By following these tips and taking the time to prepare properly, you can achieve a beautiful and long-lasting finish for your deck.

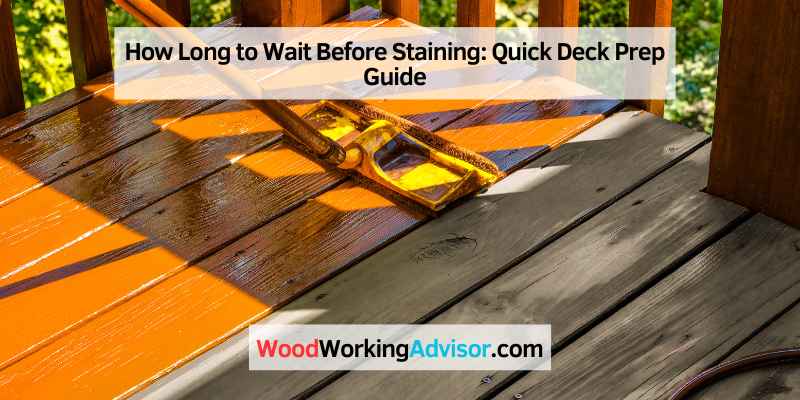

Prepping Your Deck For Staining

Before staining a pressure treated wood deck, it’s crucial to allow the wood to dry thoroughly. Depending on whether the wood is kiln-dried or not, this process can take several weeks. To check if the wood is ready, sprinkle water on the surface – if it absorbs, it’s dry enough to stain.

Staining your pressure-treated wood deck can enhance its natural beauty and protect it from harsh weather. However, before you start staining, it’s important to prepare your deck properly. Here are some essential steps to follow:

Cleaning the Wood Surface

Before staining your deck, it’s crucial to clean the wood surface to remove dirt, grime, and any other debris that may have accumulated over time. You can use a pressure washer or a good quality deck cleaner to do the job.

Sanding: Necessary or Not?

Sanding is not always necessary before staining a pressure-treated wood deck, but it can be helpful in removing any rough spots or splinters. If you choose to sand your deck, use a fine-grit sandpaper and sand in the direction of the wood grain.

Once you’ve cleaned and sanded (if needed) your deck, the next step is to ensure that it’s dry enough to stain. The drying time can vary depending on factors such as humidity, temperature, and the type of wood.

To determine whether your deck is dry enough to stain, you can perform a simple water test. Sprinkle a few drops of water on the surface of the deck. If the water beads up, the wood is not ready for staining yet. But if the water is absorbed into the wood, then your deck is dry enough to stain.

In conclusion, prepping your deck for staining is a crucial step in the staining process. By following the steps mentioned above, you can ensure that your deck is clean, dry, and ready for staining. Remember, a well-prepared deck will result in a beautiful and long-lasting stain.

Moisture Testing Methods

Before staining a pressure-treated wood deck, it’s crucial to conduct moisture testing to determine the optimal timing. Testing methods include using a moisture meter or sprinkling water on the wood to check absorption. Waiting for the wood to dry out completely is essential to ensure proper adhesion of the stain.

Before staining a pressure-treated wood deck, it is crucial to determine the moisture content of the wood. Moisture testing methods can help you determine whether the wood is ready for staining or if it needs more time to dry out. Here are two common moisture testing methods:

Water Sprinkle Test

The water sprinkle test is a simple yet effective way to check the moisture content of the wood. To perform this test, sprinkle a few drops of water onto the surface of the deck. If the water is quickly absorbed into the wood, it indicates that the moisture content is low and the wood is ready for staining. On the other hand, if the water beads up and sits on the surface, it means that there is still too much moisture in the wood, and you should wait for it to dry out further before applying any stain.

Using A Moisture Meter

Another reliable method for testing the moisture content of pressure-treated wood is by using a moisture meter. A moisture meter is a handheld device that measures the moisture levels within the wood. To use a moisture meter, simply insert the probes into the wood and wait for the reading. If the moisture content is below the recommended level for staining, you can proceed with the staining process. However, if the moisture content is still too high, it is advisable to wait for the wood to dry out more before applying any stain.

By utilizing these moisture testing methods, you can ensure that your pressure-treated wood deck is properly dried and ready for staining. Remember, staining wood that is still too moist can lead to poor adhesion and subpar results. So, it’s important to be patient and wait until the wood is adequately dry before applying any stain.

Consequences Of Premature Staining

Staining pressure-treated wood too soon can lead to several issues, including poor absorption, which affects the appearance and durability of the deck. Additionally, premature staining can compromise the protective qualities of the wood treatment, leaving the deck vulnerable to moisture, rot, and decay.

Issues With Absorption

Staining the wood before it’s adequately dried can result in improper absorption of the stain and sealer. This leads to an uneven finish and reduces the effectiveness of the treatment. As a result, the deck may appear blotchy, and the stain may not penetrate the wood as intended.

Impact On Wood Protection

When pressure-treated wood is stained too early, the protective chemicals within the wood may not have fully set, causing the stain and sealer to interfere with the treatment. This can compromise the wood’s ability to resist moisture, insects, and decay, ultimately shortening its lifespan and requiring premature maintenance.

Choosing The Right Stain Or Sealant

When it comes to choosing the right stain or sealant for your pressure-treated wood deck, it’s essential to consider the type of stain and sealant that will best protect your investment. Let’s explore the options and properties of different stains and sealants so you can make an informed decision.

Stain Types And Their Properties

There are various types of stains available for pressure-treated wood, each with its unique properties. Semi-transparent stains offer a natural look and allow the wood’s grain to show through. Solid stains provide more color options and better protection against UV rays. Penetrating oil-based stains deeply penetrate the wood, offering excellent protection and enhancing the wood’s natural beauty. Water-based stains are environmentally friendly and offer quick drying times.

Sealants And Their Longevity

Choosing the right sealant is crucial for protecting your pressure-treated wood deck from the elements. Clear sealants offer minimal color change and are ideal for preserving the natural look of the wood. Semitransparent sealants add a hint of color while still allowing the wood grain to show through. Solid sealants provide maximum UV protection and are available in a wide range of colors to suit your preferences. When selecting a sealant, consider the longevity of the product and its ability to withstand harsh weather conditions.

Application Tips For Best Results

When it’s time to stain your pressure-treated wood deck, following the right application tips is crucial for achieving the best results.

Techniques For Even Application

- Use a brush or roller for smooth, even coverage.

- Apply stain in the direction of the wood grain.

- Avoid overlapping strokes to prevent uneven color distribution.

Dealing With Common Staining Challenges

- If wood is too wet, wait for it to dry before staining.

- Test moisture levels by sprinkling water on the deck.

- If water absorbs, wood is ready for staining.

Maintenance After Staining

After staining pressure treated wood, it is important to wait for the wood to dry out completely. The drying time can vary, taking several weeks for the wood to dry if it was not kiln-dried. It is recommended to test the wood’s moisture content before staining to ensure optimal results.

Routine Cleaning

After staining your pressure-treated wood deck, regular cleaning is essential to maintain its appearance and prolong the life of the stain.

When To Reapply Stain Or Sealant

Keep an eye on the condition of your stained deck. If you notice fading or wear, it’s time to reapply stain or sealant to protect the wood.

Frequently Asked Questions

How Long Should You Wait To Stain A New Pressure Treated Deck?

Due to the pressure-treating process, it can take several weeks for the lumber to dry out before staining a new pressure treated deck. If the wood is kiln-dried, it can be stained immediately. However, if it’s not, you may have to wait a little longer.

It’s best to check the moisture level by sprinkling water on the surface. If it absorbs, it’s ready for staining. Avoid staining too soon, as it can interfere with the pressure treatment protection.

What Happens If I Stain Pressure Treated Wood Too Soon?

If you stain pressure treated wood too soon, the finish won’t adhere properly to the surface, and it can interfere with the pressure treatment protection. Due to the nature of the pressure-treating process, it can take up to several weeks for the lumber to dry out.

Kiln-dried lumber can be painted or stained immediately, while others may require a little longer. It’s essential to wait until the wood is dry enough before staining to avoid any issues.

How To Tell If Pressure Treated Wood Is Ready To Stain?

To determine if pressure treated wood is ready to stain, sprinkle water on its surface. If the water absorbs, it’s dry enough. If it beads up, it’s still too wet.

How Do I Know If My Deck Is Dry Enough To Stain?

To check if your deck is dry enough to stain, sprinkle water on the surface. If it absorbs, it’s ready. If it beads up, it’s still too wet.

Conclusion

The timing for staining a pressure treated wood deck depends on the drying process. Kiln-dried lumber can be stained immediately, while air-dried lumber may require several weeks to dry out. Staining too soon can hinder the absorption of stain and interfere with the pressure treatment protection.

To determine if the deck is ready, sprinkle water on the surface – if it absorbs, it’s dry enough to stain. It’s important to follow these guidelines to ensure a successful staining process for your pressure treated wood deck.