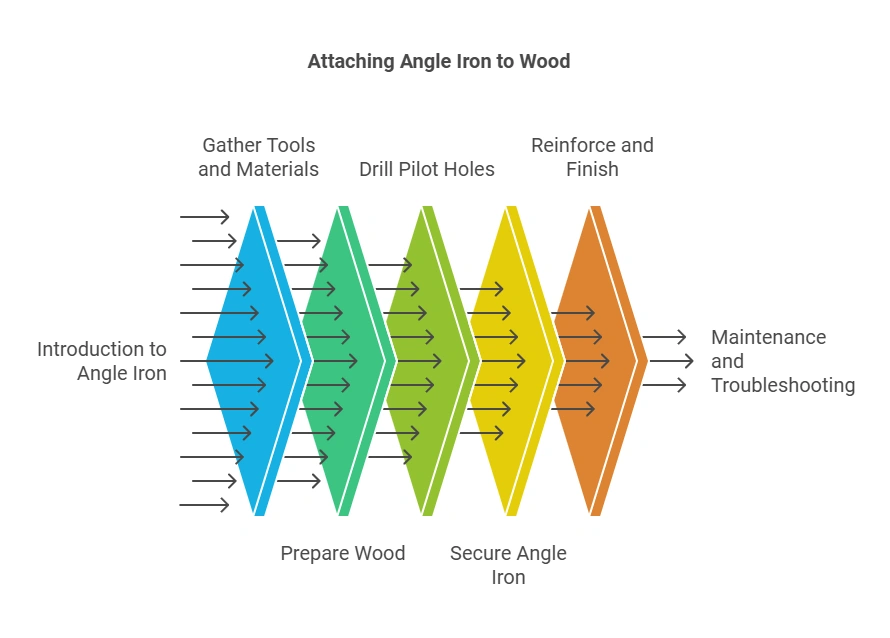

How to Attach Angle Iron to Wood: A Step-by-Step Guide

To attach angle iron to wood, use bolts or screws for a strong connection. Pre-drill holes to prevent wood splitting and ensure a tight fit.

Attaching angle iron to wood can enhance the strength and durability of various projects. This method is often used in furniture making, construction, and home improvement. Angle iron provides structural support while maintaining a sleek look. Using the right fasteners and techniques ensures a secure bond between the metal and wood.

Proper preparation is essential for a successful attachment. Pre-drilling holes in the wood and using suitable screws or bolts can prevent damage. Understanding the right tools and materials will make the process efficient and effective. This guide will provide you with clear steps to achieve a strong, reliable connection.

Introduction To Angle Iron Usage

Angle iron is a strong material used in many projects. It combines well with wood for added strength. Common projects include furniture, shelves, and support frames. This combination provides durability and stability.

Using angle iron with wood offers several benefits. It enhances the overall strength of structures. This combination also resists warping and bending over time. Angle iron can help reduce the need for heavy materials.

Another benefit is the ease of attachment. Screws or bolts can easily connect angle iron to wood. This makes construction quick and efficient. Overall, angle iron is a great choice for many woodworking projects.

Essential Tools And Materials

To attach angle iron to wood, gather essential tools and materials first.

- Angle iron (choose the right size)

- Wood (select appropriate type)

- Drill with metal bits

- Screws or bolts

- Wrench for tightening

- Measuring tape

- Square for accurate angles

- Safety goggles for protection

Choosing the right angle iron and wood is crucial. Angle iron must match your project’s needs. Wood should be sturdy and suitable for your purpose. Ensure all materials are of high quality for best results.

Preparation Steps

Start by measuring the length of the angle iron. Use a tape measure for accuracy. Mark the spot on the wood where the angle iron will attach. Use a pencil for clear markings. Double-check all measurements before proceeding.

Safety is very important. Always wear safety goggles to protect your eyes. Use gloves to prevent cuts from sharp metal edges. Make sure the area is well-lit and free of clutter. Keeping tools organized helps avoid accidents.

Drilling Pilot Holes

Choosing the correct drill bit is key for attaching angle iron to wood. Use a bit that matches the size of your screws. A twist drill bit works well for most projects. Cobalt bits are best for harder wood types.

For accurate drilling, mark your spots clearly. Use a pencil to make small dots where you want holes. Hold the drill steady to avoid slipping. A drill guide can help keep the bit straight.

| Bit Type | Best For |

|---|---|

| Twist Bit | General Use |

| Cobalt Bit | Hardwood |

| Spade Bit | Large Holes |

Securing Angle Iron To Wood

Securing angle iron to wood requires the right fasteners. Use lag screws for a strong hold. Wood screws are also effective for lighter applications. Choose stainless steel or galvanized fasteners to prevent rust. Select screws that are at least 2 inches long for better grip.

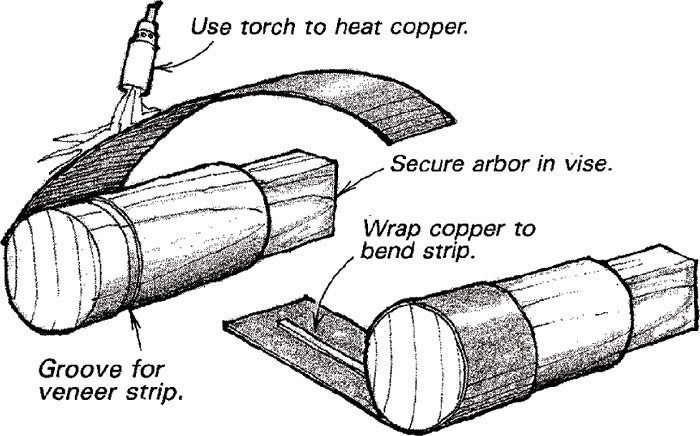

Start by marking the angle iron’s position on the wood. Drill holes through the angle iron into the wood. Ensure the holes are slightly larger than the fasteners. Insert the fasteners and tighten them with a wrench or screwdriver. This method provides a secure attachment.

Reinforcement Tips

To add structural stability, use angle iron effectively. This metal piece helps strengthen wooden structures. It is essential for supporting heavy loads.

Using adhesives can enhance the bond between angle iron and wood. Choose a strong epoxy or construction adhesive for best results. Ensure the surfaces are clean and dry before applying adhesive. This helps create a durable connection. Allow enough curing time for the adhesive to set properly.

Always consider the weight and stress on the joint. This ensures the angle iron provides maximum support. Proper attachment methods help prevent future issues.

Finishing Touches

After attaching the angle iron, sanding is essential. Use fine-grit sandpaper to smooth rough edges. This helps prevent splinters and gives a nice finish.

Next, consider painting the angle iron. Choose a color that matches your wood. A good paint protects the metal from rust.

Inspecting the attachment is crucial. Check for any loose screws or bolts. Tighten them if needed to ensure stability.

Look for any gaps between the metal and wood. Fill these gaps with wood filler for a clean look. This prevents moisture from entering.

Maintenance And Upkeep

Regular maintenance ensures the strength of your angle iron attachment. Check for rust or corrosion at least once a month. Clean any dirt or debris from the joints. Look for loose screws or bolts. Tighten them immediately to prevent further damage.

Inspect the wood for signs of wear. Cracks or splits can weaken the connection. Replace any damaged wood promptly. Use a protective sealant to guard against moisture and pests. This simple step extends the life of your attachment.

Keep an eye on the environment around your installation. High humidity can cause wood to expand. This can strain the angle iron. Regular checks can prevent major issues down the line.

Troubleshooting Common Issues

Alignment problems can happen during the installation of angle iron. Check the level of your wood before attaching. Use a square to ensure the angle iron sits correctly. Make adjustments as needed for a better fit.

Replacing damaged components is crucial for a strong bond. Inspect all parts for cracks or bends. Remove any damaged angle iron or wood. Replace them with new, high-quality materials. This ensures a secure and safe attachment.

Advanced Techniques And Considerations

Joining multiple angle irons can enhance the strength of your projects. Use bolts or screws to connect the angles securely. Ensure the holes are drilled accurately for a tight fit. Washers can help distribute the load evenly.

For custom modifications, consider the specific needs of your project. Cut the angle iron to the desired length before attachment. Welding is another option for a more permanent solution. Always wear safety gear when working with metal.

| Technique | Description |

|---|---|

| Bolting | Simple and removable connection method. |

| Screwing | Fast and effective for lighter loads. |

| Welding | Creates a strong, permanent bond. |

Real-life Examples

Many people use angle iron for home DIY projects. One common use is for shelves. Angle iron provides strong support. It can hold heavy items without bending.

Another example is using angle iron for furniture. It adds a modern touch to tables and chairs. This makes them both stylish and sturdy.

In construction, angle iron plays a vital role. Builders use it for frame support in buildings. This helps structures remain safe and secure.

Angle iron is also used in bridges and fences. Its durability withstands harsh weather. Overall, it is a popular choice for various projects.

Conclusion And Best Practices

Attaching angle iron to wood is a straightforward task. Start by measuring and marking the desired spots on the wood. Drill pilot holes to prevent the wood from splitting. Use screws or bolts to secure the angle iron firmly. Make sure the angle iron is level before tightening.

For best results, choose the right type of wood and angle iron. Consider using rust-resistant screws if the project is outdoors. Always wear safety gear while working to protect yourself.

For DIY enthusiasts, practice makes perfect. Take your time with each step. Don’t rush through the process. Seek help if needed and enjoy your project!

Frequently Asked Questions

How Do You Attach Angle Iron To Wood?

To attach angle iron to wood, use screws or bolts designed for metal-to-wood connections. First, drill pilot holes in the wood and angle iron. Align the pieces, and secure them tightly. For additional strength, consider using washers and nuts if bolting.

Ensure the connection is stable and secure.

What Tools Are Needed For This Project?

Essential tools include a drill, screwdriver, measuring tape, and a level. A saw may be needed to cut the angle iron to size. Additionally, having clamps can help secure the pieces while you work. Safety gear like gloves and goggles is also recommended for protection.

Can I Use Adhesive To Attach Angle Iron?

While adhesive can provide some bond, it’s not recommended for heavy-duty applications. Mechanical fasteners like screws or bolts offer a more reliable connection. If using adhesive, ensure it’s suitable for metal and wood. Always follow the manufacturer’s instructions for best results and longevity.

Is Angle Iron Suitable For Outdoor Use?

Yes, angle iron can be used outdoors if properly treated. It’s important to choose galvanized or coated steel to resist rust and corrosion. Regular maintenance, like inspections and repainting, will also help prolong its life. This ensures your project remains durable and visually appealing.

Conclusion

Attaching angle iron to wood can enhance your projects’ strength and durability. With the right tools and techniques, it becomes a straightforward task. Always ensure proper measurements and secure fittings for the best results. Embrace this method to elevate your woodworking skills and achieve professional-looking outcomes.

Happy building!