How to Calculate Load Capacity of Wood: Essential Guide

To calculate the load capacity of wood, determine the wood species and its grade, then use the formula: Load Capacity = Modulus of Rupture (MOR) x Section Modulus (S). Always consider safety factors based on the application.

Understanding the load capacity of wood is essential for structural integrity. Wood is a versatile material widely used in construction, furniture, and various applications. Knowing how much weight it can support ensures safety and longevity. Factors such as wood species, grade, and dimensions play a crucial role in determining load capacity.

Engineers and builders must evaluate these aspects to avoid structural failures. This guide simplifies the calculation process, helping you make informed decisions. Whether you are a DIY enthusiast or a professional, mastering load capacity calculations is vital for successful projects.

Introduction To Load Capacity In Woodworking

Calculating the load capacity of wood is vital for safe woodworking. Accurate calculations prevent accidents and structural failures. Knowing how much weight wood can hold helps in choosing the right materials.

Several factors affect wood strength. Wood species can greatly influence capacity. Hardwoods like oak are usually stronger than softwoods like pine.

Moisture content also plays a key role. Wet wood loses strength, while dry wood performs better. The dimensions of the wood piece are crucial too. Thicker and wider pieces can carry more weight.

Lastly, the grain direction matters. Wood is stronger along the grain than across it. Understanding these factors ensures proper load capacity calculations.

Types Of Wood And Their Properties

Hardwoods</strong come from deciduous trees. They are dense and strong. This makes them great for furniture and flooring. Common hardwoods include oak, maple, and cherry.

Softwoods come from coniferous trees. They grow faster and are lighter than hardwoods. Common softwoods include pine, cedar, and spruce. Softwoods are often used in construction.

| Property | Hardwood | Softwood |

|---|---|---|

| Density | High | Low |

| Strength | Very strong | Less strong |

| Common Uses | Furniture, flooring | Construction, paper |

The direction of the grain affects load-bearing. Wood is stronger along the grain. Cross-grain loading can cause weakness. Always consider grain direction for best results.

Understanding Wood Load Capacity

Wood can bear different types of loads. These include static loads and dynamical loads. Static loads are constant and do not change over time. Dynamical loads vary and can cause stress on wood.

Moisture content plays a key role in wood’s load capacity. Higher moisture levels weaken the wood. Dry wood has better strength and durability. Testing wood moisture can help determine its load capacity.

Measuring moisture content is done using a moisture meter. This tool provides quick and accurate readings. Keeping moisture levels low is essential for maintaining wood strength.

Fundamentals Of Wood Mechanics

Stress in wood refers to the internal forces acting on it. It shows how much force the wood can handle. Strain measures how much wood deforms under stress. Both concepts help understand wood mechanics.

The Modulus of Elasticity is a key factor in wood strength. It indicates how much a piece of wood will bend. A higher modulus means less bending. Different wood types have different moduli. Knowing this helps in choosing the right wood for projects.

| Wood Type | Modulus of Elasticity (GPa) |

|---|---|

| Oak | 12-15 |

| Pine | 8-11 |

| Maple | 10-13 |

| Birch | 11-14 |

Calculating Static Load Capacity

Calculating the static load capacity of wood is important for safety. Follow these simple steps:

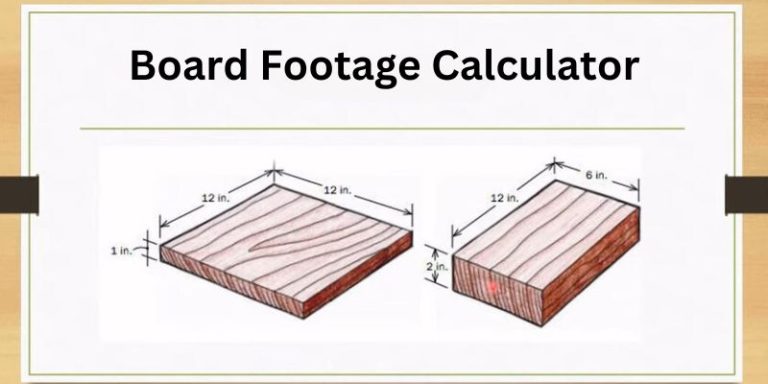

- First, measure the dimensions of the wood piece.

- Next, determine the species of wood for accurate strength values.

- Use a load capacity chart to find the allowable load for that species.

- Multiply the allowable load by the wood’s cross-sectional area.

- Finally, check for any safety factors needed for your project.

Utilizing load capacity charts helps you make safe choices. These charts list different wood types and their strengths. Always consult these charts before starting any project. They ensure the wood can hold the weight required.

Dynamic Load Considerations

The impact of repeated loading on wood is significant. Each load can cause fatigue over time. This weakens the wood and reduces its strength. Understanding this helps in designing safer structures.

Safety factors are crucial for dynamic loading. They account for the uncertainties in load and material performance. A common practice is to use a safety factor of 1.5 to 2. This ensures that the wood can handle unexpected forces.

| Safety Factor | Description |

|---|---|

| 1.5 | Used for light dynamic loads. |

| 2.0 | Recommended for heavy dynamic loads. |

Software And Tools For Load Calculations

Using Computer-Aided Design (CAD) software helps in accurately calculating load capacity. This software provides 3D modeling and visualization tools. Users can analyze various load conditions easily.

Several popular CAD programs exist, such as AutoCAD, SketchUp, and SolidWorks. These tools allow for precise designs while ensuring safety and compliance with building codes.

Load calculation apps simplify the process further. They offer quick calculations based on user inputs. Apps like Beam Calculator and WoodBeam can be very useful.

| Tool/App | Features |

|---|---|

| AutoCAD | 2D/3D design, extensive libraries |

| SketchUp | User-friendly interface, great for beginners |

| SolidWorks | Advanced modeling, engineering simulations |

| Beam Calculator | Quick load analysis, user-friendly |

| WoodBeam | Specific for wood structures, easy inputs |

Practical Tips For Ensuring Safety

Regular inspection and maintenance are key to ensuring safety. Check wood for cracks, rot, or insects. Look for signs of wear in beams and supports. Repair any issues immediately to avoid accidents.

Always adhere to building codes. These codes provide guidelines for load capacity. Follow local regulations to ensure your structure is safe. Use proper materials that meet the required standards.

Keep records of all inspections and repairs. This helps track the condition of the wood. Regular updates can save time and money in the long run.

Case Studies

Real-life examples show how load failure can happen. One case involved a deck that collapsed under weight. This deck had not been planned for heavy furniture and many people. The result was injuries and costly repairs.

Another example involved a wooden beam in a warehouse. The beam could not support the weight of stored items. This failure led to a loss of products and significant downtime.

Success stories highlight the importance of proper load capacity planning. One company used calculations to safely store heavy materials. They avoided accidents and saved money on repairs.

Another project involved a home renovation. The builders calculated the load for a new roof. This careful planning ensured safety and improved the home’s value.

Frequently Asked Questions

How Is Load Capacity Of Wood Calculated?

The load capacity of wood is calculated using its species, dimensions, and moisture content. Structural engineers often refer to standardized tables for specific values. Factors like span length and load type also influence calculations. Always ensure you use accurate measurements for safe results.

What Factors Affect Wood’s Load Capacity?

Several factors affect wood’s load capacity, including species, age, moisture content, and defects. Different wood species have varying strengths. Additionally, the wood’s condition and environmental factors can impact its overall performance. Understanding these factors is crucial for accurate load capacity assessment.

How Do You Determine Wood Species?

To determine wood species, examine the grain pattern, color, and texture. You can also use online resources or consult experts for identification. Wood species charts and samples are helpful tools. Accurate identification is essential, as different species have unique load capacities and characteristics.

What Tools Do I Need For Calculations?

For calculating wood load capacity, essential tools include a calculator, measuring tape, and wood species reference guide. A load calculator app can also be useful for quick assessments. Ensure you have a reliable moisture meter to check wood moisture content.

Accuracy in measurements is critical for safe calculations.

Conclusion

Calculating the load capacity of wood is essential for safety and durability. Understanding the factors that influence strength helps in making informed decisions. By following the guidelines outlined in this post, you can ensure your projects are both efficient and secure.

Always prioritize accuracy to achieve the best results in your woodworking endeavors.