How to Curve Molding: Expert Tips for Perfect Results

Curving molding can seem challenging. But with the right steps, it’s manageable.

Curved moldings add elegance and style to any space. They can transform plain walls and furniture into stunning features. The process of curving molding involves precise measurements and careful bending techniques. It’s a skill that combines creativity with craftsmanship. Whether you are a DIY enthusiast or a professional, learning how to curve molding can enhance your projects.

This guide will walk you through the essential steps, materials, and tips for success. By the end, you’ll have the confidence to tackle curved moldings with ease. Let’s get started on creating beautiful, curved moldings for your home or project!

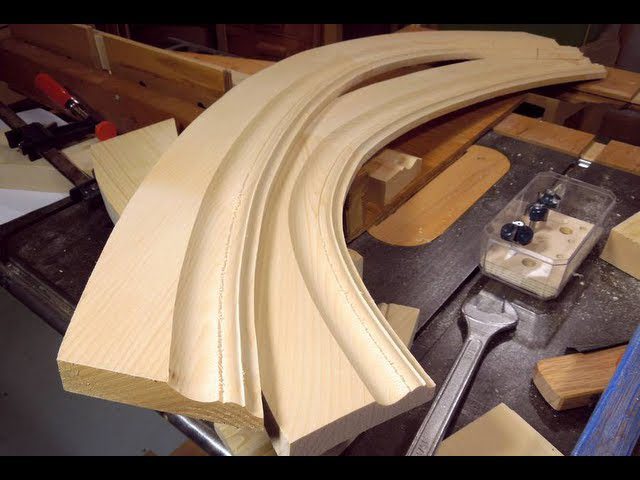

Credit: www.youtube.com

Introduction To Curving Molding

Curving molding adds a beautiful touch to your home. It requires skill and patience. Using the proper technique is very important. This ensures a smooth and even curve. Using the right tools is also crucial. You will need a coping saw and a miter saw. Sandpaper is also necessary for smooth edges. Practice makes perfect, so do not rush.

Importance Of Proper Technique

A proper technique prevents mistakes. It saves time and materials. Poor technique can lead to uneven curves. This will look bad and might not fit well. Proper technique also makes the job safer. You will avoid injuries and damage to tools. Always measure twice and cut once. This old saying is very true. Take your time and be precise.

Common Applications

Curved molding is used in many places. It is common around windows and doors. You will also see it on curved walls. It can add elegance to arches and ceilings. Some people use it for custom furniture. It can also be found in picture frames. The applications are endless. It brings a touch of class to any project.

Essential Tools And Materials

To curve molding, you need some important tools. A miter saw is crucial for cutting angles. Use a coping saw for curved cuts. A jigsaw helps with detailed cuts. Sandpaper is essential for smoothing edges. Wood glue ensures strong joints. Clamps hold pieces together while glue dries. A measuring tape ensures precise cuts. Safety glasses protect your eyes.

Choose flexible molding for easy curves. Wood types like pine or poplar work well. MDF is also a good choice. Avoid hardwoods as they are hard to bend. Prime the molding before painting. This helps the paint stick better. Measure the area carefully to avoid waste. Buy extra material in case of mistakes.

Preparing The Molding

First, measure the area where you want to curve the molding. Use a tape measure for accurate results. Mark the measurements on the molding with a pencil. Cut the molding carefully along the marked lines. Use a saw for straight cuts and a miter box for angled cuts. Always wear safety glasses while cutting.

After cutting, sanding the edges is very important. Use sandpaper to smooth rough edges. Start with coarse sandpaper and then switch to fine sandpaper. This will make the molding smooth and ready for installation. Sanding also helps the paint to stick better.

Credit: sawdustgirl.com

Heating Techniques

A heat gun is great for curving molding. Hold the heat gun a few inches away. Move it back and forth over the molding. Do this until the molding gets warm. Be careful not to burn it. Once warm, bend the molding slowly. Hold it in place until it cools down. The molding will keep its new shape.

Using steam is another option. Boil water to create steam. Hold the molding above the steam. Let the steam heat the molding. Be patient, this can take a few minutes. Once soft, bend the molding. Hold it until it cools. The molding will then stay curved.

Bending The Molding

Start by soaking the molding in water. This makes it flexible. Use clamps to hold it in place. Bend the molding slowly. Take your time. Speed can cause breaks.

Heat can help. Use a heat gun or hairdryer. Keep the heat moving. Do not focus on one spot. This prevents overheating. Overheating causes cracks. Patience is key. Let the molding cool naturally.

Credit: www.finewoodworking.com

Securing The Molding

Curving molding involves heating it gently to make it flexible. Then, carefully bend the molding around the desired shape. Finally, secure it in place until it cools and hardens.

Using Clamps

Clamps help keep the molding in place. They hold it steady while the adhesive dries. Make sure the clamps are tight. But not too tight. Too much pressure can damage the molding. Always check the positioning. Adjust if needed before the glue sets.

Adhesive Options

Using the right adhesive is key. Wood glue is a common choice. It is strong and reliable. Some prefer construction adhesive. This works well for heavier moldings. Always read the instructions. Follow them carefully for best results.

Finishing Touches

Choose a good quality paint or stain. Paint offers many colors. Stain shows the natural wood. Use a brush for small areas. Use a roller for large areas. Apply a thin coat first. Let it dry well. Apply a second coat if needed. This ensures even coverage.

Seal your molding to protect it. Use a clear sealer or varnish. This makes the wood last longer. Apply it after painting or staining. Use a clean brush. Apply thin, even coats. Let each coat dry fully. Sand lightly between coats. This gives a smooth finish.

Troubleshooting Common Issues

Warped molding can be a big problem. Use a heat gun to make it straight. Be careful not to burn the wood. Clamp the molding after heating. Let it cool while clamped. This should fix the warp. Repeat if needed for stubborn warps. Ensure the molding is dry before starting.

Broken molding can be repaired with glue. Use wood glue for a strong bond. Apply glue to both broken ends. Press them together firmly. Wipe off extra glue. Clamp the pieces until dry. Sand the area to make it smooth. Paint or stain to match the rest.

Frequently Asked Questions

What Tools Do I Need To Curve Molding?

To curve molding, you need a miter saw, heat gun, and clamps. Additionally, a flexible molding material like PVC is essential.

Can I Curve Wooden Molding?

Yes, you can curve wooden molding, but it requires steam bending. This process softens the wood, making it pliable.

How Do I Heat Flexible Molding?

Use a heat gun to gradually heat the flexible molding. Ensure even heating to avoid damaging the material.

Is Curving Molding A Diy Project?

Curving molding can be a DIY project with the right tools and patience. Beginners should start with flexible materials.

Conclusion

Curving molding may seem tricky, but with practice, it gets easier. Start with basic tools and materials. Follow the steps closely and take your time. Patience is key. Measure twice, cut once. Soon, you’ll create beautiful curved moldings for your space.

Practice makes perfect. Enjoy the process and the results. Happy molding!