How to Get Polyethelene Terephthalate to Stick to Wood: Expert Tips

Have you ever faced the challenge of trying to get polyethylene terephthalate (PET) to stick to wood? You’re not alone.

Many DIY enthusiasts and professionals struggle with this task. But you’re in the right place to learn how to solve this problem effectively. Imagine the satisfaction of finally achieving a seamless bond between these two materials. This article will guide you through simple and practical steps to make PET adhere to wood reliably.

You’ll discover tips that can save you time and frustration, making your projects more successful. Stay tuned to unlock these secrets and transform your crafting skills!

Materials And Tools Needed

To make polyethylene terephthalate stick to wood, gather these items. You will need sandpaperto roughen the wood surface. This helps the material stick better. Use a clean clothto wipe dust away after sanding. You will also need polyethylene terephthalate sheets. These are your main material for sticking. Get a strong adhesivesuitable for both materials. It must work on wood and plastic. A glue gunor brush can help spread the adhesive evenly. Finally, have clampsready. They hold the materials together while the glue dries. Make sure you have all these items before starting.

Surface Preparation Techniques

Applying polyethylene terephthalate to wood involves specific surface preparation techniques. Sand the wood to create a smooth surface. Use a suitable adhesive to enhance bonding and ensure long-lasting adhesion.

Cleaning The Wood Surface

Start by removing dust and dirt from the wood. Use a damp cloth for wiping. Make sure the cloth is clean. Dirt can stop the glue from sticking. Let the wood dry completely after cleaning. Moisture can cause problems later. Check for any oily spots. Oil can prevent sticking. Use soap and water for stubborn stains. Ensure all soap is washed off before drying. Clean surfaces help glue work better.

Sanding For Better Adhesion

Sanding makes wood surfaces rougher. Rough surfaces help glue stick. Use sandpaper to rub the wood gently. Choose sandpaper with medium grit. Move sandpaper in a circular motion. This helps create an even texture. Be careful not to over-sand. Too much can damage the wood. After sanding, clean the wood again. Remove all dust particles. Dust can weaken glue bonds.

Choosing The Right Adhesive

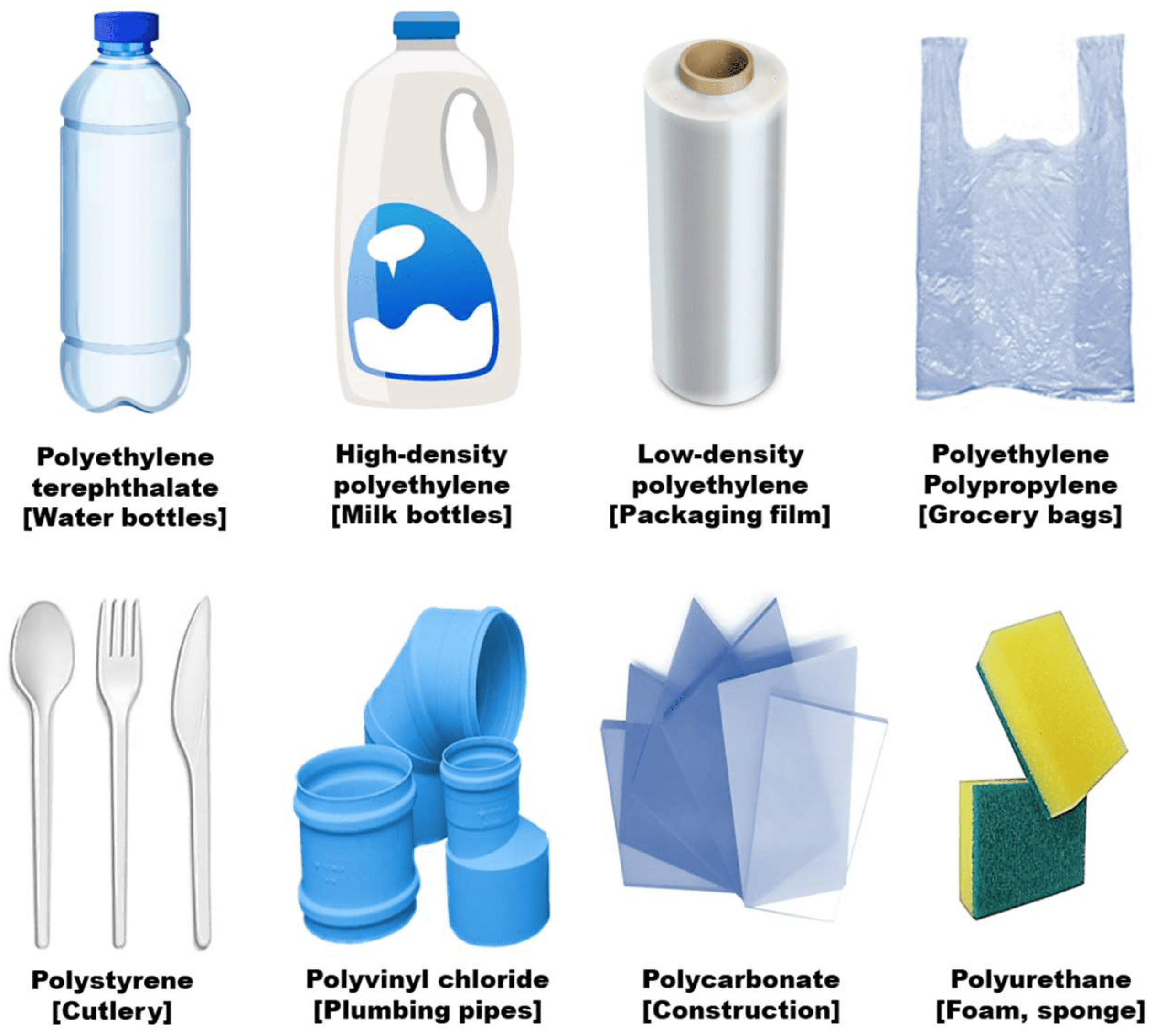

Polyethylene Terephthalate(PET) is a tough plastic. Sticking it to wood needs the right adhesive. Some types work better than others. Epoxyis strong and holds well. It dries clear. Another choice is polyurethane adhesive. It expands and fills gaps.

Hot glueis fast and easy. It is not as strong. Use it for small projects. Silicone adhesiveis flexible. It works for projects that need bending. Each adhesive has pros and cons.

Think about the project size. Big projects need strong glue. Also, look at drying time. Some glues dry quickly. Others take longer. Consider the environment. Is it hot or cold? Some glues work better in heat. Choose wisely for best results.

Credit: www.walmart.com

Application Methods

Begin by choosing the right adhesive. Make sure it is suitable for both materials. Clean the wood surface. Remove any dust or dirt. Use a brush or a cloth to apply the glue. Cover the wood evenly. Avoid leaving any dry spots.

Spread the glue with a small spatula. This helps in getting an even layer. Press down gently on the wood. Make sure the glue spreads out. Check for any areas that need more glue. Add more if needed. Let the glue dry completely before touching.

Drying And Curing Process

Temperature and humidity are key factors in curing. Polyethylene terephthalate needs a warm environment. A temperature of 70°F to 75°F works well. The room should not be too dry. Humidity around 50% is best. A fan can help keep the air moving. This helps the material dry evenly.

The curing process takes time. Plan for at least 24 hours. Some projects may need 48 hours. Check the surface after 24 hours. It should feel firm and not sticky. If it is still soft, give it more time. Patience is important for the best results.

Credit: thehoneypot.co

Troubleshooting Common Issues

Polyethelene Terephthalate, or PET, may not stick well to wood. This can happen due to several reasons. Clean surfaces are important. Dirt and dust can stop adhesion. Rough surfaces can help glue stick better. Sanding the wood might be needed for a smooth finish. Use a strong adhesive made for PET and wood. Check the glue’s instructions. Temperature and humidity can also affect adhesion. Work in a dry and warm place.

Imperfections on wood can cause problems. Cracks or holes make it hard for PET to stick. Fill these gaps with wood filler. Uneven surfaces should be sanded flat. Sanding helps glue hold better. Oil or wax on wood can stop adhesion. Clean wood with alcohol to remove oils. Make sure the wood is dry before applying glue. A smooth surface ensures better sticking. Always double-check for any imperfections.

Expert Tips For Success

Many struggle with getting Polyethylene Terephthalateto adhere to wood. First, clean the wood surface well. Dust and grease can cause issues. Use a soft cloth for cleaning. Next, sand the wood with fine sandpaper. This makes the surface rough. Rough surfaces help things stick better. Always choose the right glue. Not all glues work with these materials. Test a small area first. This ensures the glue works well.

Strong bonds last longer. After applying glue, press the materials together. Hold them for a few minutes. This helps the bond set. Wait for the glue to dry completely. Patience is key. Avoid moving the objects during drying. Temperature and humidity can affect drying time. Follow the glue instructions carefully. This ensures the best results.

Credit: www.amazon.com

Frequently Asked Questions

How To Bond Polyethylene Terephthalate To Wood?

To bond polyethylene terephthalate (PET) to wood, use a strong adhesive like epoxy or polyurethane. Clean both surfaces thoroughly before applying the adhesive. Press them together firmly and allow sufficient time for curing. Sanding the wood and PET surface can also improve adhesion.

What Adhesive Works Best For Pet And Wood?

Epoxy adhesives are highly recommended for bonding PET to wood. They provide strong and durable bonds. Polyurethane adhesives are also effective, offering flexibility and resistance to environmental factors. Always follow the manufacturer’s instructions for optimal results. Proper surface preparation is crucial for a successful bond.

Can I Use Super Glue For Pet To Wood?

Super glue, or cyanoacrylate, can be used for small, non-load-bearing bonds between PET and wood. However, it is not ideal for larger or structural applications. For stronger and more reliable bonds, opt for epoxy or polyurethane adhesives. Proper surface preparation enhances the bond strength.

Is Surface Preparation Necessary For Bonding?

Yes, surface preparation is crucial for effective bonding. Clean both PET and wood surfaces to remove any dust, grease, or contaminants. Sanding the surfaces creates texture, enhancing adhesive grip. Proper preparation ensures a strong and durable bond. It is a vital step in achieving successful adhesion.

Conclusion

Polyethylene Terephthalate (PET) can bond with wood using simple steps. Start by cleaning the wood surface thoroughly. Apply a suitable adhesive for PET. Ensure even application for strong adhesion. Press firmly to secure the bond. Let the adhesive dry completely.

This method ensures a lasting connection between PET and wood. Explore different adhesives for varied results. Test small areas before full application. Achieving successful adhesion requires patience. Follow these steps for effective bonding. Experiment with techniques for improved results. Enjoy crafting projects with PET and wood.

Make them durable and reliable.