How to Measure Band Saw Blade: Accurate Sizing Guide

To measure a band saw blade, first, determine its length by measuring the distance between the two wheel centers. Then, measure the width and thickness using calipers for accuracy.

Measuring a band saw blade is essential for optimal performance and safety. An incorrect blade size can lead to poor cuts and potential equipment damage. Understanding how to measure your blade ensures you select the right replacement, enhancing your cutting efficiency.

Whether you are a professional woodworker or a hobbyist, knowing the correct blade dimensions will improve your project outcomes. Regularly checking your band saw blade size can also help you maintain your equipment effectively. This guide will walk you through the steps to measure your band saw blade accurately and confidently.

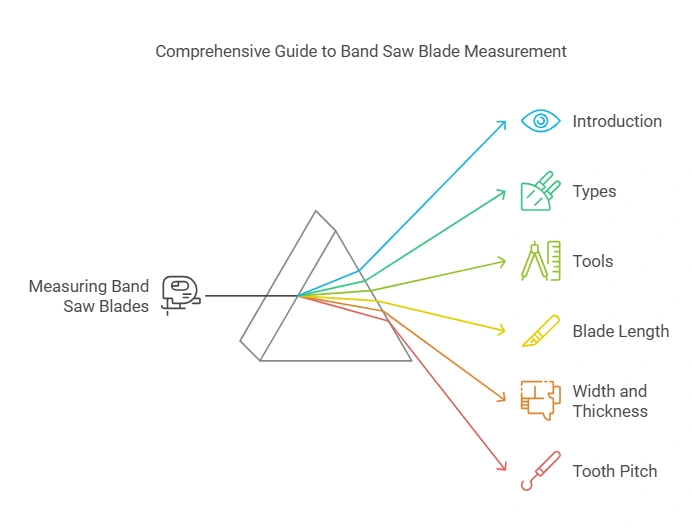

Introduction To Band Saw Blade Measurement

Measuring a band saw blade is very important for effective cutting. Accurate blade sizing leads to better performance and longer blade life. A properly sized blade reduces wear and tear on both the blade and the saw.

Common pitfalls include measuring incorrectly or using the wrong tools. Using a tape measure may lead to errors. Always use a caliper or a specialized blade measuring tool. Another mistake is not accounting for blade tension. Tension affects the blade’s performance and accuracy.

| Common Pitfalls | Impact |

|---|---|

| Incorrect measurement | Leads to poor cuts |

| Wrong tools | Causes inaccurate sizing |

| Ignoring blade tension | Affects performance |

Types Of Band Saw Blades

Band saw blades come in various types, each suited for specific tasks. Common types include bi-metal, carbon steel, and carbide-tipped blades. Each blade has unique features for cutting different materials.

Bi-metal blades are strong and flexible. They are great for cutting metal and wood. Carbon steel blades are ideal for wood and softer materials. They are easy to sharpen.

Carbide-tipped blades last longer than others. They work well on tough materials like metal and composites. Choose the right blade based on the material you will cut.

| Blade Type | Best For | Durability |

|---|---|---|

| Bi-metal | Metal, Wood | High |

| Carbon Steel | Wood, Soft Materials | Medium |

| Carbide-tipped | Tough Materials | Very High |

Tools For Measuring Band Saw Blades

Measuring band saw blades requires specific tools. Essential measuring instruments include:

- Calipers: These help measure the width and thickness of the blade.

- Micrometer: Useful for precise thickness measurements.

- Ruler: A simple tool for quick width checks.

- Protractor: Measures angles for blade alignment.

Setting up for measurement is crucial. Ensure the blade is clean and free of debris. Place the measuring tool on a flat surface. Take measurements at several points for accuracy. Record all measurements for future reference.

Determining Blade Length

Measuring a band saw blade length is easy. Follow these simple steps:

- First, turn off the saw. Safety is important.

- Next, remove the blade from the saw. Be careful!

- Now, lay the blade flat. Make sure it is straight.

- Use a measuring tape to find the total length. Start at one end.

- Record the length in inches or millimeters.

For custom blades, calculate the length as follows:

| Measurement | Formula |

|---|---|

| Blade Length | 2 x (Wheel Diameter + Blade Width) |

| Radius | Wheel Diameter / 2 |

Width And Thickness Considerations

Blade width affects how a band saw cuts. Wider blades cut straight lines better. They also handle thicker materials. Thinner blades are great for curves. They provide more flexibility but may break easily.

Thickness matters for strength and durability. Thicker blades resist bending under pressure. They last longer in tough jobs. Thinner blades can cut fine details but wear out quickly. Choosing the right thickness is key for project success.

Tooth Pitch And Type

To measure a band saw blade, start by checking the tooth pitch. This refers to the distance between the teeth. It is measured in teeth per inch (TPI). Count the number of teeth in one inch of the blade. A higher TPI means finer cuts. A lower TPI is better for thicker materials.

Matching the tooth design to the material is important. For wood, use a hook tooth design. This helps in faster cutting. For metal, a bimetal blade with a variable pitch is ideal. It reduces heat and improves blade life.

| Material | Tooth Design |

|---|---|

| Wood | Hook Tooth |

| Metal | Bimetal with Variable Pitch |

Recording And Interpreting Measurements

Measuring band saw blades accurately is crucial for effective cutting. Use a reliable measuring tool to ensure precision. Write down your measurements clearly to avoid confusion.

Maintain a consistent format for recording data. This practice helps in tracking changes over time. Always include the date and time for reference.

Understanding measurement tolerances is important. Tolerances indicate how much variation is acceptable. Too much deviation can affect cutting quality.

| Best Practices | Description |

|---|---|

| Use a Caliper | For precise measurements of blade thickness. |

| Record Regularly | Keep consistent logs for better analysis. |

| Check Tolerances | Ensure measurements are within acceptable limits. |

Maintenance And Replacement Tips

To ensure accurate and consistent performance, regularly check your band saw blade. Clean the blade after each use. Look for signs of wear like cracks or missing teeth. These signs indicate it’s time for a replacement.

Measure the blade’s length to confirm it fits your saw. A dull blade can cause poor cuts and increase risk of injury. Replacing the blade regularly helps maintain quality.

| Signs to Replace Blade | Actions |

|---|---|

| Visible cracks | Replace immediately |

| Dullness | Sharpen or replace |

| Missing teeth | Replace immediately |

| Frequent binding | Check and replace |

Troubleshooting Common Sizing Issues

To solve length discrepancies, check the blade’s actual length first. Measure from the top wheel to the bottom wheel. Ensure the blade is tight and properly aligned. A loose blade can cause incorrect measurements.

For width and thickness variations, use calipers for accurate readings. Measure the blade’s width and thickness at multiple points. This ensures you catch any irregularities. Adjust the tension on the blade if it seems too loose.

Keep your saw clean. Dirt can affect measurements and performance. Regular maintenance helps keep the blade in optimal shape. Check your saw’s manual for specific size recommendations.

Frequently Asked Questions

How Do I Find The Right Band Saw Blade Size?

To find the right band saw blade size, measure the distance between the upper and lower blade guides. This will give you the maximum blade length. Additionally, check the width of your saw’s throat for the blade width. Always refer to the manufacturer’s specifications for exact measurements.

What Tools Do I Need To Measure Band Saw Blades?

To measure band saw blades, you typically need a measuring tape or ruler. A caliper can help measure the blade width accurately. You may also need a notepad to record your measurements. Ensure your tools are calibrated for precise results to avoid discrepancies.

Can I Use Any Blade On My Band Saw?

No, you cannot use any blade on your band saw. Each band saw has specific blade size and type requirements. Using an incompatible blade can lead to poor performance or damage. Always consult your saw’s manual for recommended blade specifications.

What Is The Standard Length For Band Saw Blades?

The standard length for band saw blades varies widely based on the saw model. Common lengths range from 70 inches to 144 inches. Always measure your saw’s blade path to determine the exact length needed. Refer to the manufacturer’s guidelines for specific length recommendations.

Conclusion

Measuring a band saw blade accurately is essential for optimal performance. Understanding the right techniques can enhance your cutting efficiency. Regularly check blade dimensions to ensure precision in your projects. Proper measurement not only prolongs blade life but also improves safety.

Stay informed and make every cut count for better results.