How to Oil Your Chainsaw Chain: Proven Effortless Guide

Learn how to oil your chainsaw chain the easy way! Proper chain lubrication prevents wear, improves cutting, and ensures your chainsaw runs smoothly for years. This guide breaks down the simple steps for beginners.

Hey there, fellow DIYers and woodworking friends! Md Meraj here. Do you ever look at your chainsaw and feel a little intimidated by its power and parts? You’re not alone! Many of us love the idea of tackling projects, but the tools can seem like a whole different language. One crucial bits of chainsaw care is keeping its chain well-oiled. It’s not just about making it shiny; it’s super important for how well your saw works and how long it lasts. A dry chain can lead to serious damage, making your saw less effective and potentially dangerous. The good news?

Oiling your chainsaw chain is actually one of the simplest and most rewarding maintenance tasks you can do. Stick around, and I’ll walk you through this step-by-step, making it as easy as pie. We’ll cover everything you need to know to keep your chainsaw purring like a kitten.

Why Oiling Your Chainsaw Chain Matters More Than You Think

Think of your chainsaw chain like the chain on your bicycle. If you never give it a little lubrication, it gets rusty, stiff, and hard to pedal, right? Your chainsaw chain is no different, except it’s working much, much harder. That constant, high-speed movement across a metal guide bar creates a lot of friction. Without proper oil, this friction turns into heat. A lot of heat. This heat can warp your chain, damage its links, and even melt the guide bar itself.

Beyond just preventing damage, a well-oiled chain cuts more efficiently. The oil acts as a lubricant, allowing the cutters to slice through wood smoothly. This means less strain on your saw’s engine, making the job easier for you and extending the life of your tool. It’s a small bit of maintenance that pays off big time in performance and durability.

Common Chainsaw Chain Oiling Mistakes to Avoid

Before we dive into the “how-to,” let’s quickly touch on what not to do. These are common slip-ups that can cause more problems than they solve:

Using the wrong oil: This is a big one! Regular motor oil isn’t designed for the unique demands of a chainsaw chain and bar system. We’ll talk about the right stuff soon.

Over-oiling: While less common than under-oiling, too much oil can create a messy situation and attract dirt.

Under-oiling: This is the most frequent culprit for premature wear and tear. A little oil is good, no oil is disastrous.

Forgetting to check: Oiling isn’t a “set it and forget it” task. You need to check regularly, especially during longer cutting sessions.

Oiling a running saw: For your safety, never try to oil the chain while the engine is running.

Essential Supplies: What You’ll Need to Get Started

You don’t need a whole workshop full of fancy gadgets for this. Here are the simple things that will make the job a breeze:

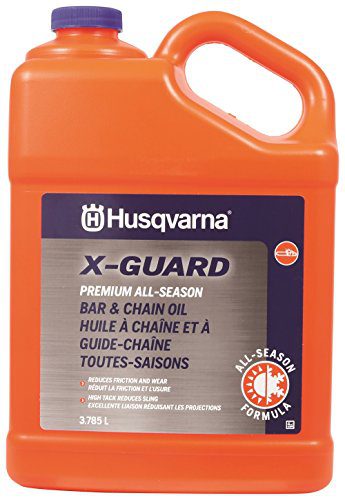

Chainsaw Bar and Chain Oil: This is specially formulated to cling to the chain and resist being flung off at high speeds. You’ll find it at hardware stores and places that sell outdoor power equipment. Green or blue colored oils are common.

A Clean Rag or Paper Towels: For wiping away any drips and spills.

Gloves (Optional but Recommended): To keep your hands clean and provide a better grip.

A Stable Surface: To safely place your chainsaw while you work.

Quick Tip: Always consult your chainsaw’s owner’s manual for specific recommendations on oil type and capacities.

Understanding Chainsaw Oil: What to Use and Why

This is where many beginners get confused. Chainsaws need a special kind of oil called “bar and chain oil.” Why can’t I just use motor oil? Great question!

Motor oil is designed to lubricate moving parts within an engine. It’s not sticky enough to stay on a fast-moving chainsaw chain. When the chain spins at thousands of revolutions per minute, regular motor oil would simply be flung off immediately. This would leave the chain and bar unprotected, leading to rapid wear and overheating.

Bar and chain oil, on the other hand, is formulated with tackifiers. These are sticky agents that help the oil cling to the chain, even at high speeds. This ensures continuous lubrication of the chain, the drive links, and the guide bar groove. Many bar and chain oils also contain additives to help them work well in various temperatures and to resist breakdown. For a fantastic resource on chainsaw maintenance, the U.S. Forest Service offers great safety and maintenance tips.

Here’s a quick look at what makes specialized oil so important:

| Type of Oil | Purpose | Why It’s Suitable for Chainsaws |

|---|---|---|

| Chainsaw Bar & Chain Oil | Lubricates chain, sprockets, and guide bar groove. | Contains tackifiers to cling to the chain at high speeds; resists fling-off. Protects against heat and friction. |

| Standard Motor Oil (e.g., 10W-30) | Lubricates internal engine parts. | Not sticky enough; will be flung off quickly, leaving chain and bar unprotected and prone to damage. |

| Vegetable Oil or Cooking Oil | Edible lubricant. | Breaks down quickly, becomes gummy/sticky, attracts dirt, and doesn’t offer adequate high-speed lubrication. Can harm the saw. |

Step-by-Step: How to Oil Your Chainsaw Chain Effortlessly

Now for the main event! Follow these simple steps, and you’ll have your chainsaw chain perfectly oiled in no time. Safety first, always!

Step 1: Safety First! Power Down and Secure Your Chainsaw

Turn off the engine: Make sure the chainsaw is completely off and the ignition is disengaged.

Let it cool: If you’ve been using the saw, give it a few minutes to cool down. The chain and bar can get hot.

Place it on a stable surface: Find a flat, sturdy spot to put your chainsaw. This prevents it from tipping over while you’re working on it.

Engage the chain brake: This is a crucial safety step. Ensure the chain brake is engaged to prevent accidental chain movement.

Step 2: Locate the Oil Reservoir and Filler Cap

Your chainsaw has a dedicated oil tank for lubricating the chain. You’ll find a separate cap for this, usually distinct from the fuel cap. It’s often marked with an oil can symbol or the word “BAR OIL.”

Take a moment to identify the oil filler cap. It’s typically larger and might be a different color than the fuel cap.

Note its location. On most saws, it’s on the body of the saw, near the guide bar.

Step 3: Prepare to Fill – Clean the Area

Before you open the oil cap, it’s a good idea to give the area around it a quick wipe-down with your rag. This prevents any dirt or debris from falling into the oil tank, which could clog the oiler system later.

Step 4: Open the Oil Reservoir Cap

Carefully unscrew and remove the oil reservoir cap. Place it somewhere clean where it won’t get lost or dirty.

Step 5: Fill the Reservoir with Bar and Chain Oil

Take your bottle of bar and chain oil.

Slowly and carefully pour the oil into the reservoir.

Don’t overfill! Most saws have a “full” or “max” line. Fill it up to that line. Overfilling can cause oil to leak out and make a mess.

If you accidentally spill a little oil, wipe it up with your rag immediately.

Step 6: Replace and Secure the Oil Cap

Once the reservoir is filled to the correct level, screw the oil cap back on firmly. Make sure it’s snug to prevent any leaks while you’re operating the saw.

Step 7: Wipe Down and Inspect

Use your clean rag to wipe away any excess oil from the cap and the surrounding area. Give the guide bar and chain a quick glance to ensure everything looks normal.

Step 8: Test the Oil Flow

This is a critical step for ensuring your oiler is working.

Disengage the chain brake.

Start the chainsaw. Let it run at a moderate idle for about 10-15 seconds.

Aim the guide bar towards a safe, light-colored surface (like an old piece of cardboard or a stump you’re not actively cutting). Do NOT aim it at yourself, others, or anything valuable.

Look for a thin line of oil. You should see a faint, steady line of oil being thrown off the chain onto the surface. This indicates that the oil pump is working and lubricating the chain properly.

If you don’t see oil:

Check that the oil reservoir is filled.

Ensure the oil cap is on correctly.

The oiler port (where oil goes from the tank to the bar) might be clogged. This may require cleaning or professional attention.

The bar’s oil holes might be blocked with sawdust and debris. Gently clean them with a toothpick or thin wire.

Step 9: Get Back to Cutting!

Once you’ve confirmed the oiler is working, you can safely disengage the chain brake and get back to your cutting tasks.

How Often Should You Oil Your Chainsaw Chain?

This is a question many new chainsaw users ask, and the answer is: more often than you think! Your chainsaw’s oiler works automatically, delivering oil whenever the chain is moving.

Here’s a good rule of thumb:

Refill the oil reservoir every time you refill the fuel tank. This is the easiest habit to form. By the time you’re out of gas, you’ll also need to top up your oil.

Check oil flow periodically during long cutting sessions. If you’re felling a large tree or doing extensive limbing, stop every 15-20 minutes of actual cutting time (not just running time) to check the oil flow again.

Listen to your saw. If you start hearing a high-pitched squeal or the chain seems to be dragging, it’s a sign it’s running dry and needs oil immediately.

Factors Affecting Oil Consumption

A few things can influence how quickly your chainsaw uses bar and chain oil:

Cutting Conditions: Cutting through very dry or dense wood can sometimes cause the saw to use a bit more oil than usual.

Ambient Temperature: Very cold temperatures can make oil thicker and flow slower, while direct hot sun can make it thinner and evaporate faster.

Saw’s Age and Condition: Older saws or those with worn parts might have slightly different oil flow characteristics.

Chain and Bar Type: Different chains and bar designs can affect oil distribution slightly.

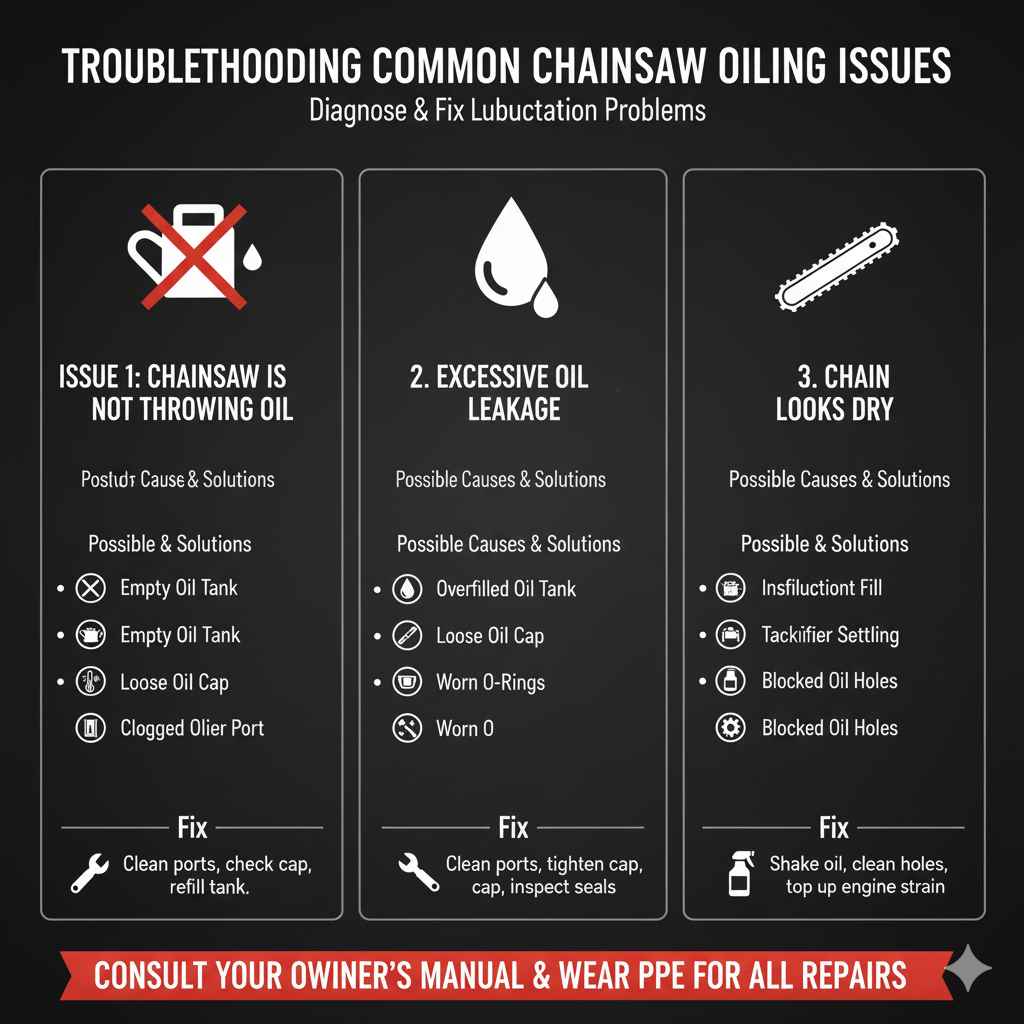

Troubleshooting Common Chainsaw Oiling Issues

Even with the best intentions, you might run into a snag. Here are a few common problems and how to fix them:

Issue 1: Chainsaw is Not Throwing Oil

This is usually the most worrying problem for users.

Problem: You start the saw, and there’s no oil line on your test surface.

Possible Causes & Solutions:

Empty Oil Tank: Did you forget to fill it completely? Double-check the reservoir.

Oil Cap Loose or Improperly Sealed: The pump might not be able to create enough pressure to move the oil. Ensure the cap is tight.

Clogged Oiler Port: The small hole on the saw’s body where the oil flows from the tank to the bar can get blocked by dirt or sawdust.

Fix: Turn off the saw, remove the bar and chain (if comfortable doing so), and clean the port with a thin pick or a bit of wire. A good blast of compressed air can also help. Use your owner’s manual for guidance on bar removal.

Clogged Bar Groove: The channel in the guide bar where the chain runs can get packed with sawdust.

Fix: Remove the bar and chain. Use a toothpick or a thin, pointed tool to clear out the groove. Make sure the oil holes leading to the groove are also clear.

Faulty Oil Pump: In some rare cases, the internal oil pump might be malfunctioning. This usually requires professional attention.

Issue 2: Excessive Oil Leakage

Sometimes, a chainsaw can seem to drip or leak more oil than expected.

Problem: Oil pools under the chainsaw, or it looks like there’s oil everywhere.

Possible Causes & Solutions:

Overfilled Oil Tank: If you fill it right to the brim without leaving any air space, the pump can push oil out.

Fix: Ensure you fill only to the indicated “max” line.

Loose Oil Cap: Not screwed on tightly.

Fix: Tighten the oil cap.

Worn or Damaged O-Rings: The seals around the oil cap or in the pump system might be deteriorating.

Fix: Inspect the O-ring on the cap. If it’s cracked or flattened, it may need replacement. Major internal leaks often require professional repair.

Bar and Chain Not Mounted Correctly: If the bar or chain is on crooked, it can create gaps where oil escapes.

Fix: Realign the bar and chain according to your owner’s manual.

Normal “Drip”: It’s normal for a small amount of oil to drip from the bar tip after the saw has been sitting for a while, especially if it was recently filled. This is a sign the oiler is working.

Issue 3: Chain Looks Dry Even After Oiling

You’ve done everything right, but the chain still looks like it’s not getting enough lubrication.

Problem: The chain appears dry, and you might hear a squeaking sound during operation.

Possible Causes & Solutions:

Insufficient Fill: Did you really fill it sufficiently? Sometimes, oil settles, and the level drops. Top it up again.

Tackifier Settling: The sticky agents in bar oil can sometimes settle in the bottle. Give the bottle a good shake before filling.

Bar Oil Holes Blocked: As mentioned earlier, sawdust can plug the small holes in the bar that feed oil to the chain groove.

Fix: Clean these holes meticulously with a toothpick or a piece of wire.

Chain Brake Engaged: If the chain brake is slightly engaged without you realizing it, it can impede chain movement and oil flow perception.

Fix: Ensure the chain brake is fully disengaged.

Maintaining Your Chainsaw for Peak Performance

Oiling the chain is just one piece of the puzzle. Regular maintenance keeps your chainsaw running safely and efficiently. Here are a few key areas to focus on:

Chain Sharpening: A sharp chain cuts faster, requires less effort, and is safer. Learn how to sharpen your chain or have it done regularly. A dull chain also puts more strain on the oiling system.

Chain Tension: Ensure your chain is correctly tensioned. Too loose, and it can derail; too tight, and it puts excessive stress on the engine and bar. The general rule is that the chain should be snug enough to not sag away from the underside of the bar, but you should still be able to pull it around by hand (with gloves on, for safety!). For detailed instructions, check out resources from reputable outdoor power equipment providers, like this guide on Stihl’s chain adjustment principles.

Air Filter: A dirty air filter restricts airflow, reducing engine power and overheating. Clean or replace it regularly as per your owner’s manual.

Spark Plug: Ensure the spark plug is clean and properly gapped. A fouled spark plug can cause starting problems and poor running.

* General Cleaning: After each use, clean off sawdust and debris from all parts of your chainsaw, especially around the engine, air filter, and bar.

Frequently Asked Questions (FAQ)

Q1: Can I use any type of oil in my chainsaw chain oiler?

A1: No. It’s crucial to use only dedicated chainsaw bar and chain oil. Regular motor oil or cooking oil will not work correctly, can damage your saw, and may even create a safety hazard.

Q2: How do I know if my chainsaw is getting enough oil?

A2: The best way is to perform the oil flow test: start the saw, engage the throttle briefly, and aim the bar at a light-colored surface. You should see a consistent line of oil being thrown off the chain. Also, listen for squealing sounds, which indicate a lack of lubrication.

Q3: What happens if I don’t oil my chainsaw chain?

A3: Without proper oiling, the chain and guide bar will experience extreme friction and heat. This leads to rapid wear, dulling of the chain cutters, damage to the guide bar groove, and potential seizing or overheating of the entire saw. It significantly shortens the lifespan of your chainsaw.