How to Screw Mitered Corners: Master Perfect Joints Easily

Screwing mitered corners can be tricky. But with the right steps, it’s manageable.

Mitered corners are a popular choice in carpentry for achieving a clean, professional look. Whether you’re working on a picture frame, molding, or a piece of furniture, knowing how to screw mitered corners securely is essential. This guide will walk you through the process, ensuring your corners are tight and durable.

By the end, you’ll have the confidence to tackle any mitered corner project with ease. Let’s dive in and learn how to perfect those beautiful mitered joints!

Credit: www.reddit.com

Tools And Materials

You need a few basic tools for mitered corners. A miter saw is very important. It helps cut angles precisely. A clamp will hold pieces together while you work. A measuring tape ensures accuracy. Wood glue and screws are needed to secure the corners.

A screwdriver or drill makes screwing easier. Sandpaper will smooth rough edges. A protractor helps measure angles. Safety glasses protect your eyes. Hearing protection is also good to have.

Choose high-quality wood for strong mitered corners. Pine and oak are good choices. Hardwood is more durable. Choose wood that is straight and smooth.

Use wood glue that is strong and dries clear. Choose screws that are the right length. They should not be too long or short. Finishing nails can also help secure the corners.

Preparing Your Workspace

Clear your workspace. Remove any clutter. Make sure you have enough room. Get all your tools ready. Keep a clean cloth nearby. It’s good to wipe off sawdust. Double-check your saw. Ensure it’s sharp and ready. Safety first! Wear protective goggles.

Use a ruler and a pencil. Mark your wood pieces clearly. Double-check your measurements. This prevents mistakes. Line up your wood properly. Use clamps to hold them steady. This keeps the pieces from moving. Use a square tool. This helps you get perfect angles. Accurate measurements make the job easier.

Cutting Techniques

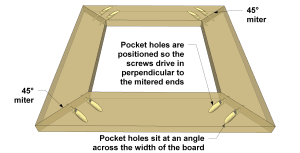

Align mitered corners perfectly by using screws. Secure the edges tightly for a clean, professional finish. Ensure stability by pre-drilling holes before inserting screws.

Mastering The Miter Saw

A miter saw is key to clean mitered corners. Align the blade with your mark before cutting. Hold the wood firmly to avoid movement. Make sure the wood is flat against the fence and table. This keeps cuts straight.

Tips For Clean And Precise Cuts

Use a sharp blade for smooth cuts. Check the angle settings on the saw. Small errors can cause gaps. Cut slowly to avoid splintering. Practice on scrap wood before making final cuts. This helps in getting comfortable with the saw.

Assembly Process

Secure mitered corners by aligning pieces precisely. Use screws to join the corners tightly, ensuring a strong bond.

Gluing Techniques

Apply glue to the mitered edges. Make sure to cover the entire surface. Too much glue can cause a mess. Use a brush for even spreading. The glue should be strong and quick-drying.

Clamping For A Seamless Joint

Place clamps on the corners. Tighten them gently. Ensure the edges align perfectly. Too much pressure can damage the wood. Use soft pads to protect the surface. Leave the clamps on until the glue dries. This usually takes a few hours.

Fine-tuning And Adjustments

Start by checking the alignment of the mitered corners. Use a square tool to do this. Place the tool against the corners. The tool should fit snugly. Gaps mean poor alignment. This must be fixed before proceeding. Good alignment is key for strong joints.

Fixing alignment involves sanding or trimming the edges. Use sandpaper for minor adjustments. For larger gaps, use a saw. Trim small amounts at a time. Recheck with the square tool after each adjustment. Patience is important here. Align the corners until there are no gaps. This ensures a tight fit and a neat finish.

Sanding And Finishing

Use fine-grit sandpaper to make the wood smooth. Remove any rough spots. Sand along the grain. Do not press too hard. Clean the surface after sanding. Wipe away dust with a damp cloth. Let it dry completely before moving on.

Pick a finish that matches your project. Oil-based finishes are durable. Water-based finishes dry faster. Apply a thin coat with a brush. Let it dry as per the instructions. Lightly sand between coats. Add more coats for a smoother finish. Always work in a well-ventilated area.

Common Mistakes To Avoid

Precise measurements are crucial. Small errors can cause big problems. Always double-check your measurements. Use a reliable measuring tool. Make sure corners align perfectly. Incorrect cuts lead to gaps and misalignment. Measure twice, cut once. This saves time and materials. Accurate cuts ensure a clean finish.

Take your time with assembly. Rushing can cause mistakes. Ensure each piece fits well. Check the alignment before final assembly. Secure each piece properly. Use clamps if needed. Proper assembly ensures durability. Hasty work leads to weak joints. Patience is key for quality results.

Credit: www.reddit.com

Credit: www.youtube.com

Frequently Asked Questions

How Do You Screw Mitered Corners?

To screw mitered corners, align the pieces, pre-drill holes, and use wood screws. Ensure the screws are evenly spaced. This provides strong joints.

What Tools Are Needed For Mitered Corners?

You need a miter saw, wood screws, a drill, clamps, and wood glue. These tools ensure precise cuts and strong joints.

Why Pre-drill Holes For Mitered Corners?

Pre-drilling prevents wood from splitting. It ensures screws go in smoothly and aligns correctly. This enhances joint strength.

How To Ensure Mitered Corners Are Tight?

Use clamps to hold pieces together while screwing. Apply wood glue before screwing for added strength. Check alignment regularly.

Conclusion

Screwing mitered corners requires patience and precision. Practice ensures perfect results over time. Use the right tools and follow the steps closely. Your projects will look professional and sturdy. Remember, accuracy matters. Take your time with each corner. Consistent effort leads to better craftsmanship.

Happy woodworking and enjoy creating beautiful mitered corners!