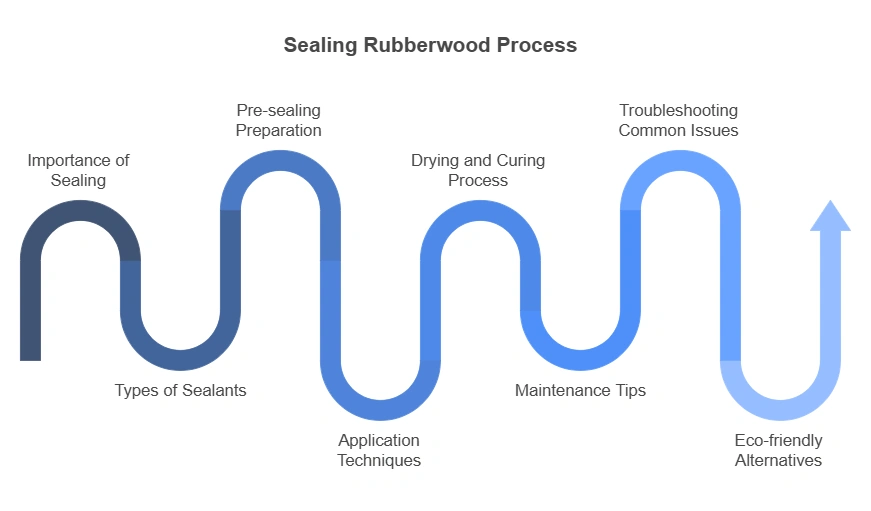

How to Seal Rubberwood: Ensure Longevity & Shine!

To seal rubberwood, first sand the surface to ensure a smooth finish. Then apply a suitable wood sealer or finish, following the manufacturer’s instructions.

Rubberwood, derived from the rubber tree, is known for its durability and eco-friendliness. Many homeowners and craftsmen appreciate its versatility in furniture and decor. Sealing rubberwood is essential to protect it from moisture and wear, enhancing its lifespan. Proper sealing prevents damage from spills and stains, ensuring your rubberwood pieces maintain their beauty.

Various sealers are available, including polyurethane, lacquer, and oil-based finishes. Each option has unique benefits, catering to different aesthetic preferences and functional needs. Understanding how to properly seal rubberwood will help you preserve its natural charm and extend its usability for years to come.

Introduction To Rubberwood

Rubberwood is a popular choice for furniture. It comes from the rubber tree, known for its durability. This wood is often light in color and has a fine grain.

The wood is resistant to warping and shrinking. It is eco-friendly and sustainable since it uses trees after they stop producing rubber. Rubberwood is also easy to work with, making it ideal for various projects.

Common uses include furniture, cabinets, and decorative items. Many people choose rubberwood for its affordability and strength. Its unique look adds a touch of elegance to any space.

Importance Of Sealing Rubberwood

Sealing rubberwood is crucial for its protection against wear and tear. This type of wood is prone to damage from moisture and scratches. A good sealant acts as a barrier, keeping it safe from daily use.

Sealing also enhances the aesthetic appeal of rubberwood. A smooth, glossy finish makes it more attractive. It brings out the natural grain and color of the wood. This can elevate the look of any room.

Types Of Sealants Suitable For Rubberwood

Choosing the right sealant for rubberwood is essential for durability. Here are three popular types:

| Sealant Type | Advantages |

|---|---|

| Polyurethane Coatings | Strong protection. Resistant to water and scratches. |

| Water-Based Sealants | Low odor. Quick drying. Eco-friendly option. |

| Oil-Based Sealants | Rich finish. Excellent for enhancing wood grain. |

Each sealant has unique benefits. Select one based on your project needs. Polyurethane is great for heavy use areas. Water-based options are better for indoor spaces. Choose oil-based for a warm look.

Pre-sealing Preparation

Cleaning the surface of rubberwood is very important. Start by using a mild soap and water solution. Wipe down the wood with a soft cloth to remove any dirt or grime.

Sanding the surface helps achieve smoothness. Use fine-grit sandpaper to gently sand the rubberwood. Always follow the wood grain for best results.

After sanding, dust removal is crucial. Use a vacuum or a tack cloth to eliminate dust particles. This step ensures a clean surface for sealing.

Application Techniques For Sealants

The Brush Application Method is simple and effective. Use a quality brush to apply the sealant. Start at one end and work your way to the other. Make sure to cover all surfaces evenly. This method allows for better control over the amount of sealant used.

Using a Spray System can save time. It provides a fine mist that evenly coats the rubberwood. Ensure the area is well-ventilated during application. Hold the sprayer about 12 inches away from the wood. Move in steady, even strokes for best results.

The Wipe-On Method is great for small projects. Use a clean cloth to apply the sealant. Dip the cloth lightly and spread it on the wood. This method works well for touch-ups and small areas. It allows for quick adjustments if needed.

Drying And Curing Process

To achieve the best results with rubberwood, drying is crucial. Ideal drying conditions include a temperature of 70-80°F and humidity around 30-40%. This helps prevent warping and cracking.

For optimal curing, allow 4-6 weeks for the wood to dry completely. Thicker pieces may require longer curing times. Always check moisture levels using a moisture meter to ensure proper drying.

Maintaining these conditions will ensure a strong and durable finish.

Maintenance Tips For Sealed Rubberwood

Regular cleaning is vital for maintaining sealed rubberwood. Use a soft cloth to remove dust. For deeper cleaning, a damp cloth with mild soap works well. Avoid harsh chemicals that can damage the sealant.

Spills should be wiped immediately to prevent stains. Use a dry cloth to blot, not rub. For stubborn stains, a gentle cleaner can help. Always test it on a small area first.

Sealants wear over time. Periodic reapplication is necessary to protect the wood. Check the surface every six months. If it looks dull, apply a new coat of sealant.

Troubleshooting Common Issues

Bubbles and blotches can occur while sealing rubberwood. Use a fine sandpaper to smooth the surface. Apply a thin coat of sealant to avoid these issues. Let it dry completely before applying another layer.

Peeling or flaking happens if the sealant isn’t applied properly. Ensure the wood is clean and dry before sealing. Apply a primer if necessary. This helps the sealant stick better.

Discoloration can result from UV exposure or moisture. Use a UV-resistant sealant for outdoor items. For indoor items, keep them away from direct sunlight. Regular maintenance can prevent these problems.

Eco-friendly Alternatives For Sealing

Natural oil finishes are great for sealing rubberwood. They protect the wood and enhance its beauty. Common options include linseed oil and tung oil. These oils soak into the wood, creating a strong seal. They are safe for the environment and easy to apply.

Environmentally safe varnishes offer another sealing option. These varnishes do not contain harmful chemicals. Look for products labeled water-based or low-VOC. They dry quickly and provide a durable finish. Apply a thin coat and let it dry before adding more.

Frequently Asked Questions

How Do I Prepare Rubberwood For Sealing?

Preparing rubberwood for sealing involves cleaning and sanding the surface. Start by removing any dirt or dust with a damp cloth. Next, sand the wood using fine-grit sandpaper to create a smooth surface. This helps the sealant adhere better and ensures a more even finish.

What Type Of Sealant Is Best For Rubberwood?

The best sealants for rubberwood are polyurethane or water-based finishes. These sealants offer durability and protection against moisture. They also enhance the wood’s natural beauty. Choose a sealant that suits your project needs, whether for indoor or outdoor use.

How Long Does It Take To Seal Rubberwood?

Sealing rubberwood typically takes about 1 to 2 hours. This includes the application time for the sealant. However, drying times can vary depending on the product used and environmental conditions. Always check the manufacturer’s instructions for specific drying times to ensure optimal results.

Can I Use Oil-based Finishes On Rubberwood?

Yes, you can use oil-based finishes on rubberwood. These finishes penetrate the wood effectively and provide a rich, warm appearance. However, oil-based products may take longer to dry compared to water-based options. Ensure proper ventilation during application for best results and safety.

Conclusion

Sealing rubberwood enhances its durability and appearance. A proper sealant protects against moisture and wear. By following the steps outlined, you can achieve a professional finish. Regular maintenance will keep your rubberwood projects looking their best. Enjoy the beauty and longevity of your sealed rubberwood items for years to come.