Machine Screw Vs Wood Screw: Key Differences Explained

Imagine you’re in the middle of a DIY project or tackling some home repairs. You reach for a screw, but wait—are you using the right one?

Choosing between a machine screw and a wood screw might seem straightforward, yet it can make all the difference in the success and durability of your project. Each type of screw serves a unique purpose, and using the wrong one could lead to frustration, wasted time, and even damage.

You might wonder why this matters, but consider this: the right screw can ensure your project stands the test of time and functions as intended. Dive into this article to uncover the subtle yet crucial differences between machine screws and wood screws. Discover how these tiny components can transform your projects from ordinary to extraordinary. Your next masterpiece awaits, and understanding these distinctions is your first step to achieving it.

Types Of Screws

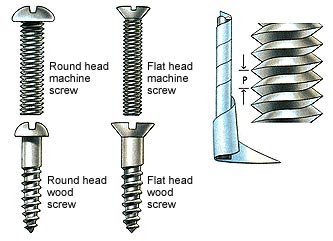

Machine screws hold metal pieces together. They have a uniform thread. This thread matches with a nut or hole. Sizes vary. Some are small. Others are big. They come in many shapes. Flat heads. Round heads. Even hex heads. Made from steel or brass. Strong and durable. Often used in machines. Also found in electronics.

Wood screws are different. They have a sharp point. This helps them go into wood. The thread is not uniform. It is wider at the top. Designed for wood. They are often shorter. Heads vary too. Flat heads. Oval heads. They are easy to use. Good for furniture. Perfect for wooden crafts. Made from steel or brass. Sometimes coated for protection.

Material And Composition

Machine screws are often made from steel or alloys. These materials make them strong and durable. They are used in metal and machines. Steel is tough and can handle high pressure. Alloys are a mix of metals. They are even stronger than regular steel. This makes them perfect for heavy-duty tasks.

Wood screws are used for wood projects. They are made of softer metal. This helps them grip the wood better. The shape of wood screws is different too. They have a pointy end. This helps them go into wood easily. Wood screws are not as strong as machine screws. But they are perfect for woodwork.

Thread Design

Fine threads are used for precise tasks. They grip tightly. Ideal for metal surfaces. They offer more holding power. Less likely to loosen. Used in machinery and electronics. They are not good for soft materials. Avoid using them in wood. Wood splits easily. Fine threads have narrow gaps. They need careful handling.

Coarse threads work well with wood. They have larger gaps. Easy to install. Provide strong grip in wood. Ideal for carpentry tasks. Less prone to stripping. They work in plastic too. Not suitable for thin metal sheets. Coarse threads hold tight in soft materials. Less stress on the surface.

Head Shapes

Flat head screws lay flush with the surface. They have a flat top. These screws are perfect for a smooth finish. People use them in furniture and cabinets. Flat heads are easy to hide. They are good for projects needing a clean look.

Round head screws have a rounded top. They sit above the surface. These screws are easy to see. People use them for decorative purposes. Round heads are often shiny. They are good for projects needing a visible screw head.

Applications

Machine screws and wood screws serve distinct purposes in construction. Machine screws fasten metal parts together, requiring a pre-drilled hole. Wood screws, designed for wood, feature a sharp tip for easy penetration without pre-drilling. Choosing the right type ensures stability in projects involving wood or metal.

Industrial Uses

Machine screws are vital in industrial machinery. They hold parts tightly. Their metal threads fit into nuts or tapped holes. This design ensures strong connections. Wood screws serve different needs. They are used in furniture assembly. Their sharp threads grip wood well. They offer strong support in wooden structures.

Construction Uses

Builders rely on wood screws. They are perfect for wooden frames. Their design prevents splitting wood. Machine screws are used in metal structures. They provide stability. Both screws are crucial in construction projects. Each has unique benefits. Choose wisely for best results.

Credit: www.thepipefittings.com

Installation Techniques

Machine screws often need pre-drilled holes. It helps them fit better. Wood screws can dig into wood by themselves. Sometimes, a small hole helps. This stops the wood from splitting. Use a drill bit smaller than the screw.

Machine screws need a nut or a tapped hole. They don’t hold alone. Wood screws can go straight into wood. Their sharp tip helps them grip. A screwdriver turns them in. This makes them stay tight.

Load Bearing Capacity

Machine screws are strong. They hold parts together tightly. Their tensile strength is high. Wood screws are different. They work best in wood. Machine screws use nuts or tapped holes. This gives them strength. Wood screws cut into wood. They grip well, but not as strong as machine screws. Both have important uses.

Shear strength matters a lot. Machine screws are better here. They resist cutting forces well. Wood screws are good in wood. But shear strength is lower. This is due to their design. They are sharp and grip wood. Machine screws are smooth. They hold tight in metal or plastic. Each has its role in projects.

Credit: www.mbdirect.co.uk

Durability And Longevity

Machine screws often have a coating. This coating prevents rust. Wood screws lack this feature. They may rust faster. Stainless steel is popular for machine screws. It is resistant to corrosion. Wood screws may be zinc-plated. This gives some protection. But not as much as stainless steel.

Machine screws are very strong. They can handle heavy loads. They last longer. Wood screws are weaker. They break easily under pressure. Wood screws wear down faster. Friction affects them more. They lose threads quickly. This reduces lifespan. Machine screws keep their shape longer. They resist wear bette

Cost Considerations

Machine screws often have a higher price tag than wood screws. This is because they are made of stronger materials. Wood screws are usually cheaper. They are designed for softer materials like wood. Bulk buying can lower costs for both types. Quality and size also affect the price. Larger screws usually cost more.

Higher quality screws tend to last longer. They may reduce the need for replacements. Cheaper screws might wear out fast. This can lead to more expenses over time. Investing in good quality is wise. It ensures durability and strength. Choose wisely based on your project needs. Balance quality and cost for best results.

Credit: home.howstuffworks.com

Frequently Asked Questions

What Is The Difference Between A Machine Screw And A Wood Screw?

Machine screws have uniform threads for metal or plastic. Wood screws feature pointed ends for easy penetration into wood. Machine screws use nuts or tapped holes, while wood screws grip wood directly.

What Is The Difference Between A Wood Screw And A Production Screw?

Wood screws have a tapered shank for fastening wood securely. Production screws feature a uniform diameter, ideal for automated assembly.

What Is The Difference Between A Wood Screw And A Regular Screw?

Wood screws have a pointed tip and coarse threads for gripping wood. Regular screws have different tips and threads for various materials.

When Should You Use Machine Screws?

Use machine screws for fastening metal parts securely. They work best in tapped holes or with nuts. Ideal for precision assembly, they ensure stability in machinery and electronics. Choose them for applications requiring consistent torque and reliability. Ensure compatibility with materials and environmental conditions for optimal performance.

Conclusion

Choosing the right screw matters for your project. Machine screws fit metal tasks well. They work best with nuts or tapped holes. Wood screws suit woodwork perfectly. Their sharp threads grip wood tightly. Both types have unique benefits. Consider your material needs.

This ensures durability and strength. Remember, selecting the wrong screw can cause issues. Always match the screw to your material. This small step makes a big difference. So, next time, choose wisely. Your project will thank you!