Pro Tech Compound Miter Saw: Review Buying Guide

Choosing the right tools can feel a little tricky sometimes, especially when you’re just starting out. The Pro Tech Compound Miter Saw: Review & Buying Guide is something many folks search for when they want to make clean, accurate cuts for their projects. It might seem like a lot to take in at first, but don’t worry.

We’ll break it all down step-by-step to make it super simple. We’ll cover everything you need to know so you can feel confident about your choice. Get ready to learn about what makes a great saw and how to pick the perfect one for you.

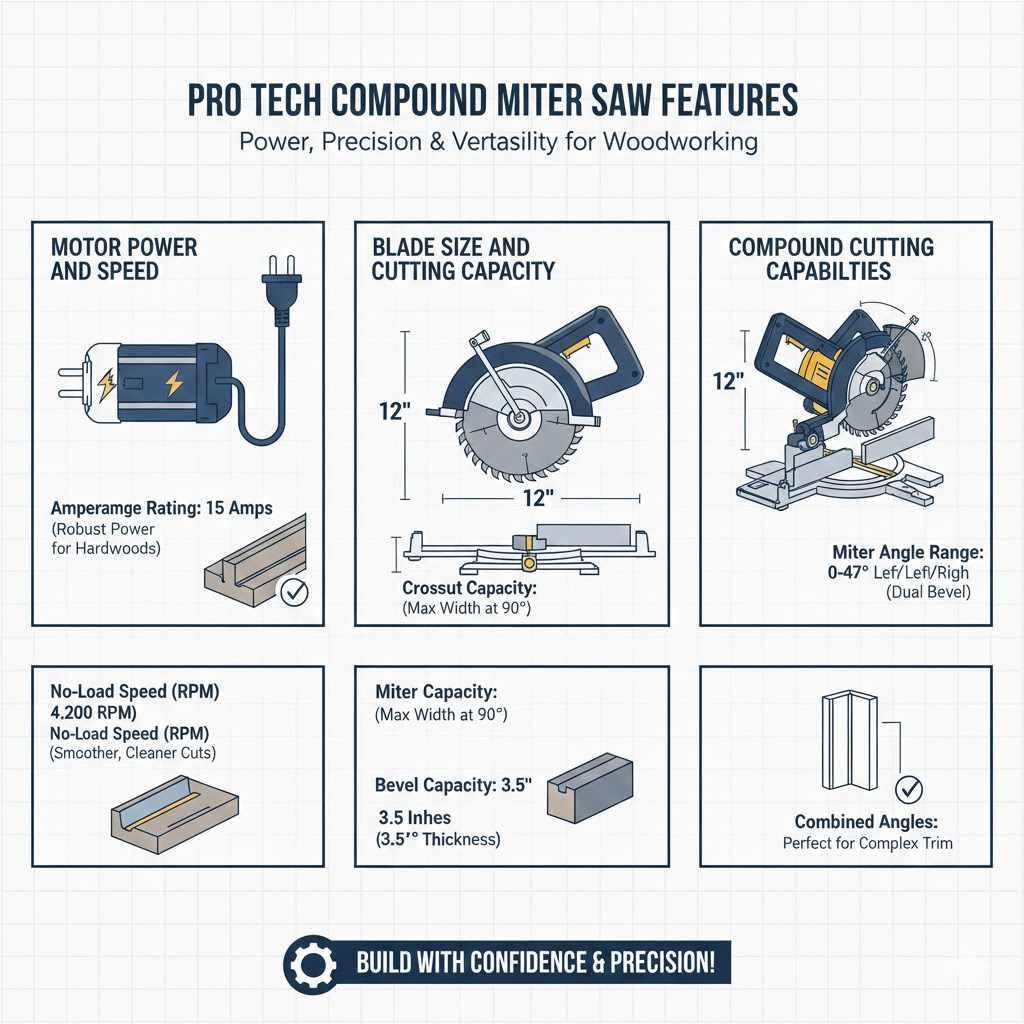

Pro Tech Compound Miter Saw Features

This section looks at the main parts and functions of the Pro Tech compound miter saw. We’ll talk about what makes it good for different kinds of woodworking tasks. Understanding these features helps you see why this saw is a popular choice for many people who build and create things.

We will go over its cutting power, accuracy, and ease of use, making sure you know what to expect.

Motor Power and Speed

The motor is the heart of any power tool, and for a compound miter saw, its power is really important. A stronger motor means the saw can cut through tougher materials without slowing down. This is crucial for making clean, smooth cuts, especially when you’re working with thicker wood or harder types of lumber.

The speed of the blade, measured in revolutions per minute (RPM), also matters. Higher RPMs often lead to cleaner cuts because the blade moves through the wood faster.

For example, a saw with a 15-amp motor is generally more powerful than one with a 12-amp motor. This extra power can make a big difference when you’re doing a lot of cutting or working on demanding projects. Think about cutting through a 2×6 piece of oak; a more powerful motor will handle this with ease, while a less powerful one might struggle and leave a rough edge.

- Amperage Rating This tells you how much electrical current the motor uses, which is a good indicator of its power. Higher amperage usually means more cutting force. A rating of 15 amps or more is often considered robust for many tasks.

- No-Load Speed (RPM) This is the maximum speed the blade can spin without any resistance. A higher RPM can help create smoother cuts by reducing friction and tear-out. Look for saws with RPMs around 4,000 or higher for general use.

Blade Size and Cutting Capacity

The size of the blade on a miter saw directly affects how wide and deep it can cut. Common blade sizes are 10 inches and 12 inches. A 12-inch blade can typically cut a wider piece of wood in a single pass than a 10-inch blade.

This is super handy when you’re working with larger boards or need to make long crosscuts.

Beyond just the blade size, the saw’s design determines its “cutting capacity.” This refers to the maximum width and depth of material the saw can cut at various angles. For instance, a saw might state it can crosscut a 4×4 post or a 2×12 board. This information is vital for ensuring the saw can handle the types of projects you plan to do.

A Pro Tech compound miter saw with a 12-inch blade might offer a crosscut capacity of around 7.5 inches, while a 10-inch model might offer closer to 6 inches. The depth of cut is also important, especially for tasks like dado cuts or cutting thicker trim. Always check the specifications for both width and depth capacity.

- Blade Diameter The size of the blade, usually 10 or 12 inches, determines the maximum width of material that can be cut in a single pass. Larger blades offer greater capacity but can also be heavier.

- Crosscut Capacity This is the maximum width of a board the saw can cut straight across. It’s usually measured at a 90-degree angle.

- Miter Capacity This refers to how wide a board can be cut when the saw is angled to the left or right. Specs often show capacity at 45 degrees.

- Bevel Capacity This is the maximum thickness of material the saw can cut when the blade is tilted to the left or right. Compound miter saws can bevel in one or two directions.

Compound Cutting Capabilities

The “compound” in compound miter saw is a really important word. It means the saw can not only swivel left and right (miter cut) but also tilt its blade up and down (bevel cut) at the same time. This dual capability is what allows for those complex angled cuts you see in crown molding or intricate trim work.

Being able to make both a miter and a bevel cut simultaneously is what lets you create those perfectly fitted joints that look so professional. Without this feature, you’d have to make separate cuts and try to combine them, which is much harder and less accurate. For anyone doing interior finishing or custom cabinetry, the compound feature is a must-have.

Think about installing crown molding. You need to angle the molding in a way that it sits flush against both the ceiling and the wall. This requires a specific combination of miter and bevel angles, which a compound miter saw can achieve in one cut.

This saves a ton of time and frustration.

- Miter Angle Range This is how far the saw head can swivel left and right. Most saws offer up to 45 degrees in each direction. Some offer more, which is useful for specific applications.

- Bevel Angle Range This is how far the blade can tilt left or right. A single bevel saw tilts one way, while a dual bevel saw tilts both ways. Dual bevel is more convenient.

- Combined Angles Being able to set both the miter and bevel angles at the same time is what makes it a compound saw. This is key for complex trim work like crown molding.

Choosing the Right Pro Tech Compound Miter Saw

Selecting the correct Pro Tech compound miter saw involves thinking about your specific needs and the types of projects you’ll be tackling. It’s not a one-size-fits-all decision. We will walk through the factors to consider, so you can make a smart choice that will serve you well for a long time.

This part is all about matching the saw’s capabilities to your woodworking goals.

Project Scope and Frequency

Are you a weekend warrior building a birdhouse or a serious DIYer renovating your entire house? The scale and how often you plan to use the saw are key factors. For occasional, small projects, a less powerful saw with fewer features might be perfectly adequate and more budget-friendly.

However, if you’re doing a lot of woodworking or tackling large-scale renovations, you’ll want a more robust saw that can handle continuous use and tougher materials.

Consider the types of wood you’ll be cutting. Softwoods like pine are easier to cut than hardwoods like oak or maple. If your projects involve a lot of hardwood, you’ll need a saw with a more powerful motor and a higher quality blade to ensure clean, efficient cuts without bogging down the motor.

The frequency of use also impacts durability; a saw used daily will need to be built to last much longer than one used once a month.

- Occasional Use For light DIY projects, a basic model might suffice. Look for ease of use and portability.

- Frequent Use If you’re a serious hobbyist or do small renovations regularly, consider a more durable model with a stronger motor and better blade. Features like dust collection become more important.

- Professional Use For commercial use, invest in a heavy-duty saw designed for continuous operation. Durability, precision, and advanced features are paramount.

Accuracy and Precision Features

When you’re building something, precision is everything. A good compound miter saw should offer features that help you make highly accurate cuts every time. This includes clear angle markings, reliable locking mechanisms for those angles, and a stable base to prevent movement during cuts.

Even small inaccuracies can add up, leading to gaps and a less professional finish.

Look for saws with positive stops at common angles like 0, 22.5, and 45 degrees. These stops help you quickly and accurately set the saw to frequently used angles without having to fiddle with a protractor. A laser guide can also be a fantastic feature, showing you exactly where the blade will cut, which greatly improves accuracy, especially for beginners.

The fence on the saw should be tall and sturdy enough to support your workpiece securely during cuts.

A common scenario where precision is critical is when cutting trim for a room. If your miter angles are slightly off, you’ll end up with noticeable gaps at the corners. A saw that allows for precise adjustments and holds those settings firmly is invaluable for achieving a clean, polished look.

Some high-end saws even offer digital readouts for angles, further enhancing precision.

- Positive Stops These are preset detents that help you quickly and accurately set common angles. They ensure repeatable accuracy for standard cuts.

- Laser Guide A laser line projected onto the material shows the path of the blade, allowing for precise alignment before cutting. This is a great visual aid.

- Adjustable Fences A tall, sturdy fence provides good support for your workpiece, especially for cutting taller trim pieces. Some fences can be adjusted or removed for different tasks.

- Blade Alignment Tools Some saws offer features that allow for fine-tuning blade alignment to ensure perfectly square cuts, even after some wear and tear.

Portability and Workspace

If you need to move your saw around the workshop, to different job sites, or just tuck it away when not in use, portability is a big deal. Some miter saws are quite heavy and bulky, while others are designed to be lighter and more compact. Consider the weight, size, and whether it has a built-in handle or a folding stand for easier transport.

Your workspace also plays a role. If you have a small garage or limited bench space, a compact saw or one with a folding stand might be ideal. Conversely, if you have a dedicated workshop, a larger, heavier saw might be perfectly fine and often offers more stability.

Make sure you have enough room to safely operate the saw, including space for long boards to pass through the cutting area.

Imagine you’re a contractor who needs to set up your saw at a different client’s house each day. A lightweight saw with a quick-deploy stand would be a lifesaver. On the other hand, if your workshop is your sanctuary, you might prefer a larger, more stationary saw that you don’t have to move often.

It’s all about what fits your lifestyle and work environment best.

- Weight and Size Look for saws that are manageable for you to lift and move. Compact designs are easier to store and transport.

- Integrated Stands Some saws come with stands that fold up, making them easy to move and set up. This is great for job sites or small workshops.

- Dust Collection A good dust collection system is crucial, especially if you work indoors or in a shared space. It keeps your workspace cleaner and healthier.

- Power Cord Length Consider where you’ll be using the saw. A longer power cord offers more flexibility if outlets are scarce.

Pro Tech Compound Miter Saw Performance Details

In this part, we’ll get into the real performance aspects of the Pro Tech compound miter saw. We’ll explore how well it cuts, how it handles different materials, and what users generally say about its reliability. This is where we look at the practical use of the saw and what you can expect when you start making cuts.

Cutting Smoothness and Accuracy

A hallmark of a great miter saw is its ability to make smooth, accurate cuts with minimal effort. When a Pro Tech compound miter saw performs well, you’ll notice that the blade passes through the wood cleanly, leaving a smooth surface without excessive splintering or tear-out. This is especially important for finish carpentry and cabinetry, where the appearance of the cuts is critical.

Accuracy comes from a combination of factors: a stable base, a well-aligned blade, and a fence that can hold the workpiece firmly. When these elements are in harmony, you can rely on the saw to repeat cuts precisely. For example, if you need to cut multiple pieces of trim to the exact same length, a precise saw will deliver consistent results, saving you time on adjustments later.

Users often report that higher-quality blades also contribute significantly to cutting smoothness. While the saw itself is important, pairing it with a good blade makes a noticeable difference. A saw that consistently produces clean edges means less sanding and less chance of material waste.

This translates to better finished projects and a more satisfying woodworking experience.

- Blade Quality The type and sharpness of the blade have a huge impact on cut quality. A good quality blade designed for the material you’re cutting will yield much better results.

- Blade Speed and Power A strong motor and appropriate blade speed ensure the blade doesn’t bog down, which prevents rough cuts and burning.

- Fence Stability A solid fence that keeps the workpiece steady is crucial for accurate, straight cuts. Any wobble in the fence can transfer to the cut itself.

- Angle Settings Precision in the miter and bevel angle detents ensures that when you set the saw to 45 degrees, it’s truly 45 degrees, leading to tight joints.

Durability and Build Quality

When you invest in a tool like a Pro Tech compound miter saw, you want it to last. Durability comes down to the quality of the materials used and how well the saw is assembled. A well-built saw will feel solid and sturdy, with no excessive flex or looseness in its components.

This not only contributes to accuracy but also means the saw can withstand the rigors of regular use.

Look for features like a heavy-duty base, robust metal construction where appropriate, and high-quality bearings for smooth operation. A saw that is built to last will continue to perform accurately for years, even with demanding use. For instance, a contractor who uses their miter saw daily needs a tool that is built like a tank, whereas a hobbyist might be fine with a slightly less robust, but still reliable, option.

Many reviews of Pro Tech tools mention their solid construction. This means the saw is less likely to break down or require frequent repairs. A durable saw also tends to maintain its accuracy over time, unlike cheaper models that can become loose and imprecise after only a few months of work.

Investing in a durable saw is an investment in your long-term woodworking projects.

- Material Construction Saws made with more metal components and high-impact plastics tend to be more durable than those relying heavily on lighter, less sturdy materials.

- Component Quality The quality of motors, bearings, and adjustment mechanisms affects longevity. Higher-quality parts will last longer and perform more reliably.

- User Reviews Check what other owners say about the saw’s longevity and any common issues they’ve encountered over time.

- Warranty A good warranty can be an indicator of the manufacturer’s confidence in their product’s durability.

Ease of Use and Adjustments

Even the most powerful and accurate saw is no good if it’s difficult to operate. Ease of use on a Pro Tech compound miter saw means that making adjustments for different cuts should be straightforward. This includes how easily you can change miter and bevel angles, lock them in place, and adjust the depth of cut if needed.

All the controls should be intuitively placed and easy to reach.

A user-friendly saw also features clear, easy-to-read markings for angles. The blade guard should be easy to move out of the way for cuts and should return to its protective position automatically. Blade changes should also be a simple process, not requiring special tools or a lot of effort.

This all adds up to a more efficient and less frustrating user experience.

Imagine you’re in the middle of a project and need to switch from a 45-degree miter cut to a 30-degree bevel cut. If the adjustment levers are stiff or hard to find, it slows you down considerably. A saw designed for ease of use will allow these changes to be made quickly and smoothly, letting you focus on the task at hand rather than fighting with the tool.

- Angle Adjustment Levers Controls for changing miter and bevel angles should be smooth, easy to grip, and lock securely. Quick-release levers are a bonus.

- Visibility of Markings Clear, large markings for angles and measurements are essential for quick and accurate settings. Backlighting can help in low-light conditions.

- Blade Guard Operation The blade guard should move smoothly without getting in the way of the cut and should automatically cover the blade when not in use.

- Blade Change Mechanism A tool-less blade change system or a simple hex key system makes swapping blades much faster and more convenient.

Pro Tech Compound Miter Saw Buying Guide Tips

Now that we’ve explored the features and performance, this guide will offer some practical tips for actually buying your Pro Tech compound miter saw. We’ll cover where to look, what to compare, and how to get the best value for your money. Following these tips can help you make a confident purchase and ensure you get the right saw for your needs.

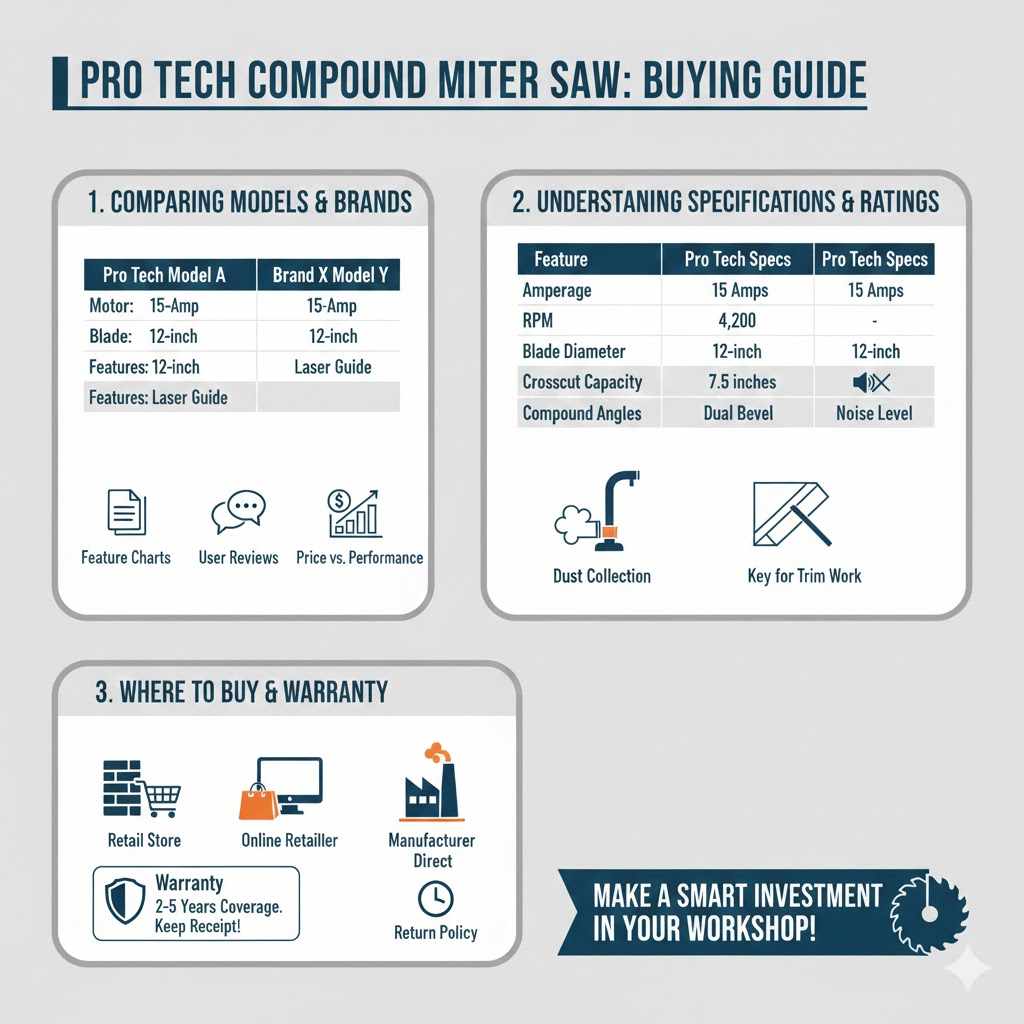

Comparing Models and Brands

When you’re in the market for a Pro Tech compound miter saw, it’s wise to compare different models within the Pro Tech line, and also to see how they stack up against other brands. Each model might have slight variations in motor power, cutting capacity, or added features like lasers or improved dust collection. Knowing these differences helps you pinpoint the one that best fits your requirements.

Don’t be afraid to read reviews from multiple sources. User reviews on retail websites, woodworking forums, and dedicated tool review sites can offer invaluable insights into real-world performance and potential issues. Comparing specifications side-by-side on paper is a good start, but understanding how those specs translate to actual cutting performance is key.

Think about what features are most important to you and prioritize those.

For example, if you know you’ll be doing a lot of crown molding installation, you’ll want to compare the bevel capacities and angle accuracy of different saws. If portability is your main concern, you’ll focus on weight and size. Looking at a few top contenders from Pro Tech and maybe one or two other well-regarded brands can give you a solid basis for your decision.

- Feature Comparison Charts Many retailers and review sites provide comparison charts that list the specifications of various saws side-by-side, making it easy to spot differences.

- User Review Analysis Look for patterns in user feedback. Are multiple users praising the saw’s accuracy, or are there common complaints about durability?

- Price to Performance Ratio Evaluate whether a higher price point for a particular model or brand truly translates into better performance and durability for your specific needs.

- Brand Reputation Consider the overall reputation of the brand for quality, customer service, and warranty support.

Understanding Specifications and Ratings

Decoding the technical specifications of a Pro Tech compound miter saw is crucial for making an informed purchase. We’ve touched on some of these, but it’s worth reinforcing. Pay close attention to amperage (motor power), RPM (blade speed), and the maximum cutting capacities (crosscut, miter, and bevel).

These numbers give you a quantitative idea of the saw’s capabilities.

Also, consider ratings related to dust collection efficiency, noise levels, and the type of blade included. While a saw might boast impressive cutting capacity, if its dust collection is poor, it can make your workspace unpleasant. Similarly, a saw that is excessively loud might require extra hearing protection and could be a nuisance in a residential setting.

For instance, a saw might be rated for 90 degrees at 0 degrees (crosscut) and 45 degrees at 0 degrees (miter cut). This tells you its standard capabilities. However, the true measure comes when you look at its compound cutting abilities, like 45 degrees at 45 degrees (both miter and bevel).

This specification is vital for crown molding and other complex joinery. Always read the fine print on the specifications list.

| Feature | What It Means | Why It Matters |

|---|---|---|

| Amperage | Motor power output. Higher is generally more powerful. | Handles tougher materials and more demanding cuts. |

| RPM (Revolutions Per Minute) | Blade speed. Higher RPM can lead to cleaner cuts. | Reduces friction and tear-out for a smoother finish. |

| Blade Diameter | Size of the blade (e.g., 10″ or 12″). | Determines the maximum width of material that can be cut. |

| Crosscut Capacity | Maximum board width at 90 degrees. | Essential for cutting wider boards. |

| Miter/Bevel Capacity | Maximum angles for angled cuts. | Crucial for fitting complex joinery and trim. |

Where to Buy and Warranty Information

When it comes to purchasing your Pro Tech compound miter saw, you have several options. Big box home improvement stores are common places, offering hands-on viewing and immediate purchase. Online retailers provide wider selection, competitive pricing, and convenience, with reviews often readily available.

Specialty tool shops can offer expert advice and sometimes higher-end or specialized models.

Regardless of where you buy, always check the warranty. A longer warranty period often signifies the manufacturer’s confidence in their product’s durability and reliability. Understand what the warranty covers (e.g., parts, labor, specific components) and for how long.

This information is vital should any issues arise after your purchase. Keep all receipts and warranty documentation in a safe place.

Consider the return policy as well. If you buy online, ensure you can return the item if it doesn’t meet your expectations or if it arrives damaged. For physical stores, understand their in-store return process.

A good warranty and a fair return policy offer peace of mind, making your purchase of a Pro Tech compound miter saw a more secure investment.

- Retail Stores Offers the chance to see and feel the saw before buying. Staff may offer assistance.

- Online Retailers Often provide better prices and a wider selection. Read customer reviews carefully.

- Manufacturer Direct Some brands offer direct sales, which can sometimes come with unique bundles or support.

- Warranty Coverage What is covered (e.g., motor, moving parts) and for how long is critical. A 2-year warranty is good, 5 years is excellent.

Frequently Asked Questions

Question: What is the main advantage of a compound miter saw over a standard miter saw

Answer: The main advantage is its ability to make both miter (angled side-to-side) and bevel (angled up-and-down tilt) cuts simultaneously. This compound action is essential for complex trim work like crown molding.

Question: How do I ensure my Pro Tech compound miter saw is cutting accurately

Answer: Regularly check that the fence is square, the blade is sharp and properly aligned, and that angle locks are secure. Use the saw’s positive stops for common angles and a laser guide if available for precise alignment.

Question: What is the typical cutting capacity for a 10-inch Pro Tech compound miter saw

Answer: A typical 10-inch model can crosscut boards around 5.5 to 6 inches wide at a 90-degree angle and can handle miter cuts on boards up to about 4 inches thick at a 45-degree angle.

Question: Is a laser guide on a miter saw really necessary

Answer: A laser guide is not strictly necessary, but it greatly improves accuracy and speed by providing a clear visual of where the blade will cut. It’s especially helpful for beginners.

Question: How often should I replace the blade on my Pro Tech compound miter saw

Answer: Blade life depends on usage and material. Replace the blade when you notice it’s dull, causing tear-out, or requiring more force to cut. For frequent use, consider replacing every 6-12 months or sooner if performance degrades.

Summary

Choosing a Pro Tech compound miter saw is simpler when you know its features and your project needs. We’ve covered motor power, blade size, compound cutting, accuracy needs, and portability. Comparing models, understanding specs, and checking warranties helps you get the best saw.

Now you can confidently select the right tool to make your projects turn out great.