Riving Knife Table Saw Safety: Essential Tips & Tricks

A riving knife is a safety feature on table saws that prevents kickback. It keeps the kerf open while making cuts.

Table saws are essential tools in woodworking, offering precision and versatility. A riving knife enhances safety, reducing the risk of accidents during cutting. Unlike traditional splitter systems, it moves with the blade, ensuring consistent alignment. This feature allows for smoother cuts and minimizes material binding.

Many woodworkers prefer table saws equipped with riving knives for these benefits. Understanding how to use a riving knife effectively can improve your woodworking experience. As you navigate various projects, knowing the importance of this component can boost both safety and efficiency. Embrace this technology to elevate your craftsmanship and protect yourself from potential hazards.

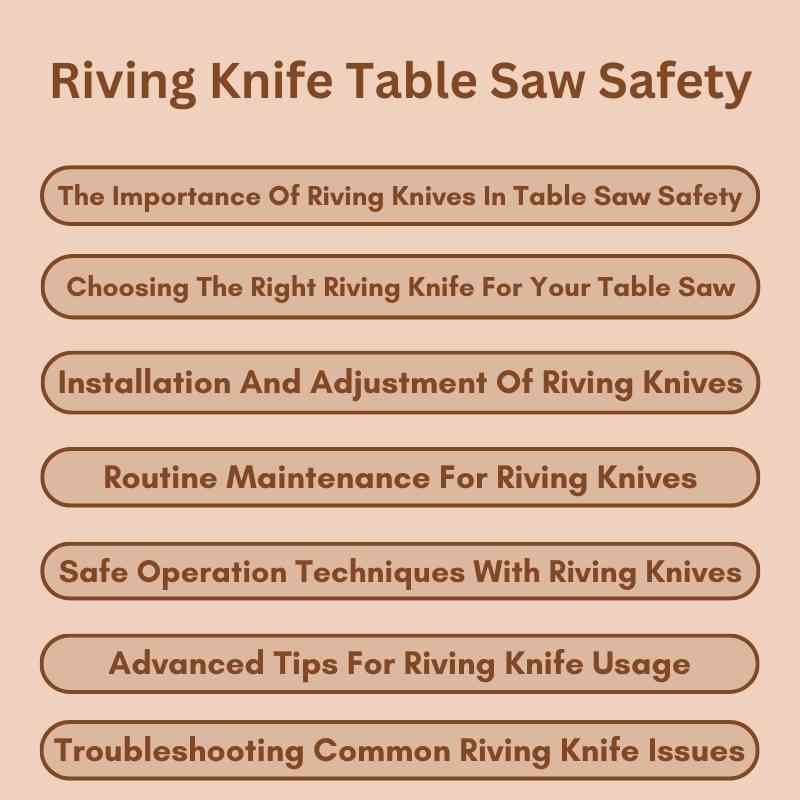

The Importance Of Riving Knives In Table Saw Safety

The riving knife is a key safety feature in a table saw. It helps to prevent kickback, which can cause serious injuries. A riving knife keeps the wood from binding against the blade. This reduces the chance of the wood being thrown back at the operator. Proper setup of the riving knife is very important for safety.

Understanding the anatomy of a table saw accident helps in preventing injuries. Most accidents happen due to a lack of safety measures. The riving knife plays a crucial role in avoiding these accidents. Always check that the riving knife is aligned with the blade. This simple step can save lives.

Choosing The Right Riving Knife For Your Table Saw

Choosing the right riving knife is essential for safety and accuracy. Compatibility with your saw blades is crucial. Measure the thickness of your blades. The riving knife should match this measurement closely.

Check the saw’s manual for specifications. Some saws require specific riving knife models. Always ensure the knife fits snugly to prevent kickback.

Adjustability is important. Many riving knives can be raised or lowered. This feature allows you to use different blade heights easily.

Installation should be simple. Follow the manufacturer’s instructions carefully. Make sure to secure the riving knife properly before use.

Installation And Adjustment Of Riving Knives

Installing a riving knife on your table saw is essential for safety. Follow these steps for proper installation:

- Turn off the table saw and unplug it.

- Remove the blade guard and any other attachments.

- Position the riving knife just behind the blade.

- Ensure it is aligned with the blade’s width.

- Tighten the screws securely.

For optimal performance, fine-tuning is important. Adjust the height of the riving knife. It should be slightly lower than the blade. Check the alignment again after adjustments. Test the saw with scrap wood. This ensures everything works correctly.

Routine Maintenance For Riving Knives

Regular cleaning of the riving knife keeps it effective. Use a soft cloth to wipe off dust and debris. Lubrication is important for smooth operation. Apply a light machine oil to moving parts.

Check the riving knife for damage or wear every few weeks. Look for cracks or bends that can affect safety. If any issues arise, replace the riving knife immediately.

| Inspection Type | Frequency | Action |

|---|---|---|

| Visual Inspection | Every 2 weeks | Check for damage |

| Cleaning | Weekly | Wipe with a cloth |

| Lubrication | Monthly | Apply light oil |

| Replacement | As needed | Replace if damaged |

Safe Operation Techniques With Riving Knives

Using a riving knife improves safety while cutting wood. Always maintain a firm grip on the workpiece. Feed the wood slowly and steadily to avoid kickback. Keep hands away from the blade while feeding.

Different wood types require special attention. For softwoods, use a straight edge for clean cuts. For hardwoods, ensure the blade is sharp to prevent binding. Always adjust the saw settings for the wood’s thickness.

Practice makes perfect. Take time to master each technique. Safety should always be the top priority when using a table saw.

Advanced Tips For Riving Knife Usage

Using a riving knife with thin kerf blades requires special care. Always check the alignment of the riving knife. It should match the blade height. This helps prevent kickback during cuts.

For custom modifications, consider adjusting the riving knife’s position. This can enhance cutting performance. Make sure to maintain a secure fit when adjusting. Test cuts on scrap wood can help fine-tune settings.

Always prioritize safety. Wear proper protective gear and follow manufacturer guidelines. Regular maintenance of your tools is also essential. Keep the riving knife clean and free from resin build-up.

Troubleshooting Common Riving Knife Issues

Riving knife issues can cause safety risks and poor cuts. Alignment problems often arise due to improper installation. Check the riving knife’s position against the blade. It should be parallel and aligned with the kerf.

Fit and finish errors may occur from using the wrong tools. Ensure the riving knife fits snugly in the mounting bracket. Loosen screws slightly, adjust the position, and then retighten for a better fit.

Regularly inspect the riving knife for any wear and tear. Replace it if damaged to maintain safety and performance. Keeping the knife clean helps prevent debris buildup.

Safety Practices Beyond The Riving Knife

Using Personal Protective Equipment (PPE) is vital for safety in the workshop. Always wear safety goggles to protect your eyes from flying debris. Hearing protection is essential when operating loud machinery. Use dust masks to avoid inhaling harmful particles. Wearing steel-toed boots can protect your feet from heavy objects.

Creating a culture of safety in the workshop encourages everyone to follow guidelines. Regular training sessions help workers understand safety practices. Discussing safety concerns openly can prevent accidents. Encourage using safety gear at all times, not just during risky tasks. Make safety a part of daily activities.

| Type of PPE | Purpose |

|---|---|

| Safety Goggles | Protects eyes from debris |

| Hearing Protection | Reduces noise exposure |

| Dust Masks | Prevents inhalation of dust |

| Steel-Toed Boots | Protects feet from heavy items |

Frequently Asked Questions

What Is A Riving Knife On A Table Saw?

A riving knife is a safety feature on table saws. It helps prevent kickback by keeping the wood from binding against the blade. Positioned just behind the blade, it moves with the blade’s height adjustment. This ensures a consistent cut and enhances user safety during operation.

How Does A Riving Knife Improve Safety?

The riving knife improves safety by reducing the risk of kickback. It keeps the material aligned and prevents it from pinching the blade. By maintaining a gap between the wood and blade, it allows for smoother cuts. This feature significantly enhances the overall safety of table saw operations.

Can I Use A Table Saw Without A Riving Knife?

Using a table saw without a riving knife is not recommended. It increases the risk of kickback, which can lead to serious injuries. Many modern table saws are designed to operate safely with a riving knife. Always prioritize safety features to ensure a secure woodworking experience.

What Are The Benefits Of Using A Riving Knife?

The benefits of using a riving knife include enhanced safety, improved cut quality, and reduced risk of blade binding. It allows for more precise cuts and minimizes kickback incidents. Additionally, it helps maintain consistent feed rates during cutting, making your woodworking projects more efficient and safer.

Conclusion

A riving knife is essential for safe and accurate table saw operation. It reduces kickback and enhances cutting precision. Investing in a quality riving knife improves your woodworking experience. Always prioritize safety by using this feature. Embrace the benefits it offers for better results in your projects.

Happy woodworking!