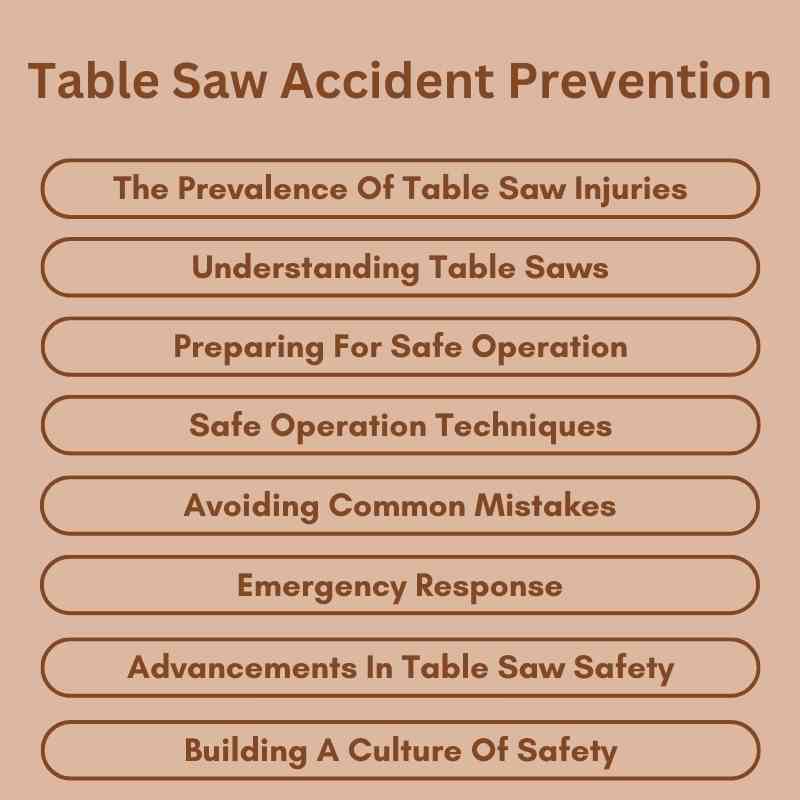

Table Saw Accident Prevention: Essential Safety Tips

A table saw accident can lead to severe injuries, including amputations and lacerations. Proper safety measures significantly reduce these risks.

Table saws are powerful tools essential for woodworking and construction. Despite their usefulness, they pose serious safety hazards if not handled correctly. Many accidents occur due to lack of attention, improper use, or inadequate safety equipment. Common injuries include finger amputations, deep cuts, and other traumatic injuries.

Understanding the risks associated with table saws is crucial for anyone using them. Implementing safety protocols, such as using push sticks and blade guards, can prevent many accidents. Education on proper techniques and equipment maintenance plays a vital role in ensuring a safer work environment. Awareness and caution can make a significant difference in preventing table saw accidents.

The Prevalence Of Table Saw Injuries

Table saws are powerful tools used in woodworking. They can cause serious injuries. Understanding the prevalence of these accidents is crucial. Knowing the statistics and personal stories can help raise awareness.

Statistics And Reports

Table saw injuries are more common than many realize. The following statistics highlight the severity of this issue:

| Year | Injuries Reported | Fatalities |

|---|---|---|

| 2018 | 4,000 | 10 |

| 2019 | 4,500 | 12 |

| 2020 | 5,000 | 15 |

These numbers show a steady rise in injuries. Most injuries oc

Understanding Table Saws

Table saws are powerful tools. They are essential for woodworking. Knowing about them can prevent accidents. Understanding their types and uses is crucial.

Types Of Table Saws

Table saws come in various types. Each type serves different needs. Here are the main types:

- Cabinet Saws: Heavy and stable. Best for serious woodworkers.

- Contractor Saws: Portable and versatile. Suitable for job sites.

- Jobsite Saws: Lightweight and easy to move. Ideal for construction work.

- Benchtop Saws: Compact and affordable. Good for small projects.

Common Uses And Applications

Table saws have many uses in woodworking. Here are some common applications:

- Ripping Lumber: Cutting wood along the grain.

- Cross-Cutting: Cutting wood across the grain.

- Bevel Cuts: Cutting at an angle.

- Dado Cuts: Creating grooves for joints.

Table saws can handle various materials:

| Material | Application |

|---|---|

| Wood | Furniture, cabinets, and more. |

| Plywood | Wall panels and flooring. |

| MDF | Craft projects and shelving. |

Fundamental Safety Features

Table saws are powerful tools. They can also be dangerous. Understanding fundamental safety features is essential. These features help prevent accidents and injuries.

Blade Guards

Blade guards are crucial for safety. They cover the blade when not in use. Here are some key points about blade guards:

- They prevent accidental contact with the blade.

- Guards can be adjustable for different cuts.

- Always check if the guard is in place before use.

Anti-kickback Devices

Anti-kickback devices are vital for safety. They prevent the wood from being pushed back toward the user. Here’s how they work:

| Feature | Function |

|---|---|

| Riving Knife | Keeps the wood from pinching the blade. |

| Anti-Kickback Paws | Holds the wood in place during cutting. |

Safety Switches

Safety switches are essential for quick shutdowns. They protect users from accidental starts. Important aspects include:

- Easy access for quick operation.

- Some models have a removable switch.

- Look for a switch with a large, visible button.

Preparing For Safe Operation

Operating a table saw safely requires careful preparation. Proper steps minimize risks. Follow these guidelines to ensure safety.

Proper Attire And PPE

Wearing the right clothing is crucial. Here are some tips:

- Wear snug clothing: Loose clothes can catch on the saw.

- Use closed-toe shoes: Protect your feet from falling objects.

- Use hearing protection: Table saws can be loud.

- Wear safety goggles: Protect your eyes from flying debris.

- Use dust masks: Prevent inhalation of harmful dust.

Workspace Organization

A tidy workspace reduces accidents. Organize your area with these steps:

- Clear the table saw of any clutter.

- Keep tools in designated spots.

- Ensure the floor is free of tripping hazards.

- Maintain clear access to emergency exits.

- Store materials securely away from the saw.

Pre-use Inspection

Always inspect the table saw before use. Follow this checklist:

| Item | Status |

|---|---|

| Blade condition | Sharp and clean |

| Guard functionality | In place and operational |

| Power cord | No damage or frays |

| Switch operation | Works correctly |

| Table stability | Secure and level |

Completing this inspection helps ensure safe operation. Always prioritize safety before cutting.

Safe Operation Techniques

Using a table saw safely is crucial for every woodworker. Proper techniques can prevent accidents and injuries. Here are some essential safe operation techniques to follow.

Correct Posture And Handling

Maintaining the right posture while using a table saw is vital. Here are some tips:

- Stand straight with feet shoulder-width apart.

- Keep your body behind the saw blade.

- Use both hands for better control.

- Keep your elbows close to your body.

These practices help you maintain stability and control over the saw.

Feed Rate And Direction

The feed rate and direction significantly affect safety. Follow these guidelines:

- Feed wood slowly to avoid kickback.

- Always feed wood against the blade’s rotation.

- Use the right size wood for the blade.

A proper feed rate reduces the chance of accidents.

Use Of Push Sticks And Featherboards

Push sticks and featherboards enhance safety while cutting. Here’s how:

| Tool | Purpose |

|---|---|

| Push Stick | Keep hands away from the blade. |

| Featherboard | Hold wood against the fence. |

Always use these tools for added protection.

Avoiding Common Mistakes

Table saws are powerful tools. They can also be dangerous. Knowing how to avoid common mistakes is essential. This helps prevent accidents and injuries.

Bypassing Safety Features

Many users ignore built-in safety features. This can lead to serious injuries. Always use these safety tools:

- Blade guards: Protect hands from the blade.

- Riving knife: Prevents kickback.

- Emergency stop button: Quickly turn off the saw.

Never disable or remove these features. Doing so increases your risk. Always prioritize safety over convenience.

Improper Blade Selection

Choosing the wrong blade can lead to accidents. Different materials require different blades. Here’s a quick guide:

| Material | Recommended Blade Type |

|---|---|

| Wood | General-purpose blade |

| Plywood | Fine-tooth blade |

| Metal | Specialized metal-cutting blade |

Select the right blade for the job. A proper blade ensures clean cuts. It also reduces the risk of kickback.

Neglecting Maintenance

Regular maintenance keeps your table saw safe. Neglect can lead to accidents. Follow these simple steps:

- Check the blade for wear.

- Clean the saw after every use.

- Lubricate moving parts regularly.

A well-maintained saw operates smoothly. It also lasts longer. Make maintenance a part of your routine.

Emergency Response

Table saw accidents can happen quickly. Knowing how to respond can save lives. Immediate action is crucial to minimize injuries. This section covers basic first aid and when to seek professional help.

First Aid Basics

In the event of a table saw accident, follow these first aid steps:

- Stay Calm: Keep a clear mind to assess the situation.

- Turn Off the Saw: Ensure the power is off to prevent further injury.

- Assess Injuries: Look for bleeding or severe injuries.

- Control Bleeding: Apply direct pressure to the wound.

- Clean the Wound: Use water and mild soap if possible.

- Dress the Wound: Use a clean bandage to protect the area.

- Keep the Person Calm: Offer reassurance and support.

When To Seek Professional Help

Advancements In Table Saw Safety

Table saws are essential tools for woodworking. They can also be dangerous. Recent advancements in safety technology aim to reduce accidents. This section explores key innovations that enhance table saw safety.

Sawstop Technology

SawStop technology is a groundbreaking safety feature in table saws. It uses a special brake system to stop the blade instantly. This occurs upon contact with skin. The saw blade retracts below the table in milliseconds.

- Prevents serious injuries.

- Reduces hospital visits.

- Enhances user confidence.

This technology has saved many fingers and hands. Its effectiveness has led to increased adoption in homes and workshops.

Future Innovations

Future innovations promise even more safety features. Some ideas in development include:

- Smart Sensors: Detects objects near the blade.

- Automatic Blade Guards: Deploys when the saw is not in use.

- Remote Monitoring: Alerts users about unsafe conditions.

These advancements could drastically lower accident rates. Safety will always be a top priority in woodworking.

| Innovation | Benefit |

|---|---|

| Smart Sensors | Prevents accidental contact with the blade. |

| Automatic Blade Guards | Enhances safety when not in use. |

| Remote Monitoring | Informs users of hazards in real-time. |

Such innovations will make woodworking safer for everyone. Users can focus more on creativity and less on danger.

Building A Culture Of Safety

Creating a culture of safety is vital in every workshop. It protects workers from accidents, especially with table saws. A proactive approach reduces risks and promotes awareness. Everyone shares the responsibility for safety.

Training And Education

Effective training ensures all workers understand safety measures. Regular education helps maintain a safe environment. Here are key training points:

- Understanding the table saw’s functions

- Recognizing common hazards

- Learning emergency procedures

- Practicing safe operating techniques

Use hands-on demonstrations to reinforce learning. Encourage questions to clarify doubts. Regular workshops keep safety fresh in everyone’s mind.

Safety Protocols And Checklists

Implementing safety protocols is crucial. Checklists help ensure all safety measures are followed. Here’s a simple checklist for table saw safety:

| Safety Check | Status |

|---|---|

| Blade guard installed | ✔️ |

| Emergency stop accessible | ✔️ |

| Proper push sticks available | ✔️ |

| Area free of clutter | ✔️ |

Encourage workers to use checklists daily. Regularly review and update protocols. This builds a culture of safety that everyone values.

Frequently Asked Questions

What Are Common Causes Of Table Saw Accidents?

Table saw accidents often occur due to operator error, lack of focus, or improper setup. Other causes include inadequate safety measures and malfunctioning equipment. Understanding these risks can help users take preventive actions. Always stay vigilant and follow safety protocols to minimize the chances of an accident.

How Can I Prevent Table Saw Injuries?

To prevent table saw injuries, always use safety equipment like push sticks and guards. Maintain a clean workspace to avoid distractions. Educate yourself on proper techniques and take breaks to stay focused. Regularly check the saw for any malfunctions. Awareness and preparation are key to safe operation.

What Should I Do After A Table Saw Accident?

If an accident occurs, first assess the injury and call for medical help if necessary. Apply pressure to any bleeding wounds and keep the person calm. Document the incident for safety reviews and future prevention. Lastly, evaluate the equipment and workspace to identify hazards and improve safety measures.

Are Table Saw Safety Features Effective?

Yes, table saw safety features like blade guards, riving knives, and anti-kickback devices are effective. These features significantly reduce the risk of accidents. However, they must be used correctly and consistently for maximum protection. Regular maintenance also ensures these safety features function properly.

Conclusion

Table saw accidents can lead to severe injuries. Understanding safety precautions is crucial for every woodworker. Always prioritize protective gear and proper techniques. Regular maintenance of your equipment also plays a key role in preventing mishaps. Stay informed and vigilant to ensure a safer woodworking experience for yourself and others.