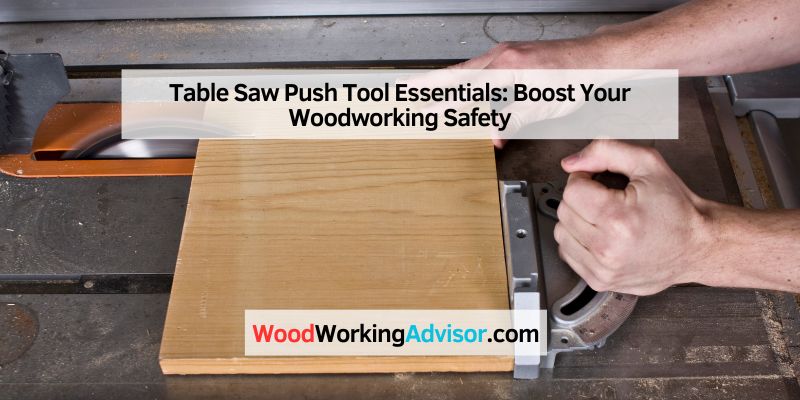

Table Saw Push Tool Essentials: Boost Your Woodworking Safety

A table saw push tool is an essential accessory for safely guiding wood through a table saw. It minimizes the risk of injury while ensuring precise cuts.

Using a table saw can be intimidating, especially for beginners. A push tool enhances safety by keeping hands away from the blade. It allows for better control over the workpiece, resulting in cleaner cuts. Whether you’re ripping boards or making crosscuts, a push tool improves accuracy and reduces the chance of kickback.

Various designs are available, catering to different woodworking needs. Investing in a quality push tool not only protects you but also enhances your woodworking experience. Choose a tool that fits comfortably in your hand for optimal performance. Prioritize safety and efficiency in every project.

Introduction To Table Saw Push Tools

Table saw push tools are essential for safe and accurate woodworking. They help users guide material through the saw. This prevents accidents and improves precision. Understanding these tools enhances your woodworking experience.

The Role Of Push Tools In Woodworking

Push tools serve multiple functions in woodworking. They help in:

- Guiding the material safely.

- Keeping hands at a safe distance from the blade.

- Improving cutting accuracy.

Using a push tool reduces the risk of kickback. Kickback occurs when the material is forcefully thrown back. This can cause injuries. Push tools create a barrier between your hands and the blade.

Key Benefits For Safety And Precision

Push tools offer several benefits:

| Benefit | Description |

|---|---|

| Enhanced Safety | Minimizes hand exposure to the saw blade. |

| Increased Accuracy | Helps maintain a straight cut. |

| Reduced Fatigue | Lessens strain on hands and arms. |

| Better Control | Offers improved guidance for tricky cuts. |

Using push tools leads to better results. They allow for consistent and clean cuts. Investing in a good push tool is wise for any woodworker.

Types Of Table Saw Push Tools

Table saw push tools enhance safety and accuracy. Different types cater to various cutting needs. Understanding each type will improve your woodworking experience.

Push Sticks And Their Variations

Push sticks are essential for guiding wood through the saw blade. They keep fingers away from the blade, preventing injuries. Here are some common variations:

- Standard Push Stick: Simple design, effective for most cuts.

- Notched Push Stick: Provides better grip on the wood.

- Ergonomic Push Stick: Comfortable handle for extended use.

Push Blocks For Better Grip

Push blocks offer a secure grip on the material. They help stabilize wood while cutting. This tool is especially useful for smaller pieces. Key features include:

- Flat surface for stability.

- Handle for better control.

- Non-slip bottom for added safety.

Using a push block minimizes the risk of kickback. It also ensures a smoother cut.

Featherboards For Consistent Pressure

Featherboards apply constant pressure to the wood. They help maintain even contact with the blade. This feature improves cut quality and safety. They come in various forms:

| Type | Description |

|---|---|

| Adjustable Featherboard | Can be set to different angles and pressures. |

| Fixed Featherboard | Stays in one position for consistent use. |

| Portable Featherboard | Easy to move and adjust for different setups. |

Featherboards boost safety by keeping hands away from the blade. They ensure precise cuts every time.

Material Choices For Push Tools

Choosing the right material for your table saw push tool is vital. Each material offers unique benefits. Understanding these options helps you make the best choice for your needs.

Wooden Vs. Plastic Push Tools

Wooden and plastic push tools serve different purposes. Here’s a quick comparison:

| Feature | Wooden Push Tools | Plastic Push Tools |

|---|---|---|

| Weight | Heavier, provides stability | Lighter, easier to maneuver |

| Grip | Natural texture, often provides better grip | Varies, can be slippery |

| Cost | Generally more expensive | More affordable options available |

| Maintenance | Requires regular oiling | Low maintenance |

Durability And Maintenance Considerations

Durability impacts how long your tool lasts. Different materials react differently over time.

- Wooden Tools:

- Can warp or crack with moisture.

- Need periodic maintenance to stay effective.

- Plastic Tools:

- Resistant to moisture and rot.

- Durable under various conditions.

Think about how often you use your push tool. A wooden tool may require more care. A plastic tool offers convenience with less upkeep. Choose wisely based on your needs.

Proper Grip And Hand Placement

Using the right grip and hand placement on a table saw push tool is essential. It enhances safety and improves accuracy. A secure grip allows better control over the material being cut. This section will highlight effective techniques and common mistakes.

Techniques For Effective Control

Mastering grip techniques ensures safe and accurate cuts. Here are key tips:

- Use a firm grip: Hold the push tool tightly. This prevents slipping.

- Position your hands: Keep hands clear of the blade. Use the push tool to guide the wood.

- Keep arms straight: Maintain a straight arm for better leverage. It helps in pushing the material forward.

- Stand to the side: Position yourself beside the saw. This keeps you away from the blade’s path.

Avoiding Common Gripping Mistakes

Setting Up For Safe Cuts

Using a table saw requires careful setup. Proper adjustments ensure safety and accuracy. A push tool enhances safety while cutting. Follow these steps to set up your table saw correctly.

Adjusting The Table Saw For Optimal Use

Start with these adjustments:

- Blade Height: Set the blade height to just above the wood.

- Angle Adjustments: Ensure the blade is at the right angle for your cut.

- Table Alignment: Check the alignment of the table with the blade.

Use a ruler to measure the distance from the blade to the fence. Adjust the fence to achieve the desired width. Keep the work area clear of debris to avoid accidents.

The Importance Of Blade Guards And Splitters

Blade guards and splitters are crucial for safety:

- Blade Guards: Protect hands from accidental contact with the blade.

- Splitters: Prevent wood from pinching the blade during cuts.

Always keep the blade guard in place. This helps minimize injuries. Check that the splitter aligns with the blade. Regular maintenance ensures they function properly.

Remember, safety is key. Always wear protective gear. Use your push tool to keep hands away from the blade.

Custom Push Tool Creation

Creating a custom push tool can enhance your table saw experience. A well-designed push tool improves safety and control. It helps you make precise cuts while keeping your hands away from the blade.

Designing Your Own Push Tools

Designing a push tool is simple and fun. Start by considering your specific needs.

- What size materials do you usually cut?

- Do you need extra grip?

- Will you cut small or large pieces?

Sketch your design on paper. Focus on features like:

- Comfortable handle

- Stable base

- Durable construction

Think about adding slots for better grip. This will make handling easier.

Materials And Tools Needed For DIY Push Tools

Gathering the right materials is crucial for your project. Here’s a list of what you need:

| Materials | Description |

|---|---|

| Wood | Use hardwood for durability. |

| Rubber grip | For better handling and comfort. |

| Glue | Strong adhesive for assembly. |

| Sandpaper | To smooth rough edges. |

Here are the tools you will need:

- Saw for cutting wood

- Drill for making holes

- Clamps to hold pieces together

- Measuring tape for accuracy

With these materials and tools, you can create a custom push tool. Your design will improve your woodworking projects and keep you safe.

Maintenance And Care Of Push Tools

Proper maintenance of your table saw push tools is essential. Regular care extends their life and ensures safe operation. This section covers cleaning, storage, and replacement tips for push tools.

Cleaning And Storage Tips

Keep your push tools clean and dry. Here are some effective tips:

- Wipe Down: Use a damp cloth to remove dust and residue.

- Check for Debris: Inspect for wood shavings or sawdust.

- Dry Thoroughly: Ensure tools are completely dry before storage.

Store push tools in a dry place. Avoid exposure to moisture. Use a dedicated toolbox or drawer. Keep them organized to prevent damage.

When To Replace Your Push Tools

Monitor your push tools regularly. Replace them when you notice:

- Cracks or Splits: These can lead to accidents.

- Loose Parts: Ensure all components are secure.

- Worn Edges: Dull edges can cause slips.

Check your push tools every few months. Keep your workspace safe by replacing worn tools promptly.

Advanced Safety Techniques

Table saws are powerful tools. Safety should always be a priority. Using a push tool enhances control and minimizes risks. This section discusses advanced safety techniques to protect you while woodworking.

Combining Push Tools With Other Safety Gear

Using a push tool is effective, but it’s not the only measure. Combine it with other safety gear for maximum protection:

- Safety Glasses: Protect your eyes from flying debris.

- Hearing Protection: Reduce noise exposure from the saw.

- Dust Masks: Prevent inhaling harmful dust particles.

- Cut-Resistant Gloves: Protect your hands from cuts.

Consider the following table for a complete safety gear checklist:

| Safety Gear | Purpose |

|---|---|

| Safety Glasses | Protects eyes |

| Hearing Protection | Reduces noise |

| Dust Masks | Prevents dust inhalation |

| Cut-Resistant Gloves | Protects hands |

Developing A Safety-first Mindset In Woodworking

Building a safety-first mindset is crucial. Awareness and preparation prevent accidents. Here are steps to develop this mindset:

- Stay Focused: Concentrate on your task at hand.

- Plan Your Cuts: Measure twice, cut once.

- Check Your Tools: Ensure all tools are functioning well.

- Keep Your Workspace Clean: A tidy area reduces hazards.

- Practice Regularly: Familiarize yourself with tools.

Remember, safety is everyone’s responsibility. Make safety a habit.

Case Studies: Push Tool Success Stories

The table saw push tool is a game-changer in woodworking. It enhances safety and boosts efficiency. Let’s explore real-life examples where push tools made a difference.

Real-life Examples Of Injury Prevention

Many woodworkers have shared stories about avoiding injuries. Here are some notable examples:

- John’s Workshop: After using a push tool, John avoided a serious hand injury. He felt more in control while cutting.

- Lisa’s Project: Lisa was able to make accurate cuts without risking her fingers. The push tool helped her stay safe.

- Mark’s Experience: Mark used to have close calls. Since he started using a push tool, his confidence increased.

These stories highlight the importance of safety. Push tools can greatly reduce the risk of accidents.

Efficiency Gains With Proper Push Tool Use

Push tools not only enhance safety but also improve efficiency. Here are the efficiency gains reported by users:

| User | Before Push Tool | After Push Tool | Efficiency Increase |

|---|---|---|---|

| Sam | 10 cuts per hour | 15 cuts per hour | 50% |

| Kate | 8 cuts per hour | 12 cuts per hour | 50% |

| Tom | 5 cuts per hour | 9 cuts per hour | 80% |

These users reported significant time savings. The push tool made their work smoother and faster.

- Less fatigue: Users felt less tired after long sessions.

- Better focus: They could concentrate on cuts without distractions.

- Improved quality: Cuts were straighter and more precise.

Overall, push tools transform how woodworkers operate. Safety and efficiency go hand in hand.

Frequently Asked Questions

What Is A Table Saw Push Tool?

A table saw push tool is a safety device designed to help users maneuver wood while cutting. It keeps hands away from the blade, reducing the risk of injury. Using a push tool enhances accuracy and control during cuts, making it an essential accessory for any woodworker.

Why Use A Push Tool For Table Saw?

Using a push tool for a table saw is crucial for safety. It helps maintain a safe distance from the blade, preventing accidental contact. Additionally, it ensures greater precision in cuts. This tool is particularly useful for handling narrow or small pieces of wood.

How Does A Table Saw Push Tool Work?

A table saw push tool works by providing leverage and control. Users can push the wood through the blade without placing their hands close to it. The tool often features a handle and a flat surface to stabilize the wood.

This design ensures smooth, accurate cuts while prioritizing safety.

Can I Make My Own Table Saw Push Tool?

Yes, you can make your own table saw push tool. Many woodworkers create custom tools using scrap wood or other materials. Ensure it has a comfortable handle and a flat base for stability. A DIY push tool can be effective and cost-efficient, enhancing your woodworking experience.

Conclusion

Choosing the right table saw push tool enhances safety and precision in your woodworking projects. Investing in a quality push tool can significantly improve your cutting accuracy. Remember, safety should always be your top priority. Explore different options and find the tool that best suits your needs for optimal results.