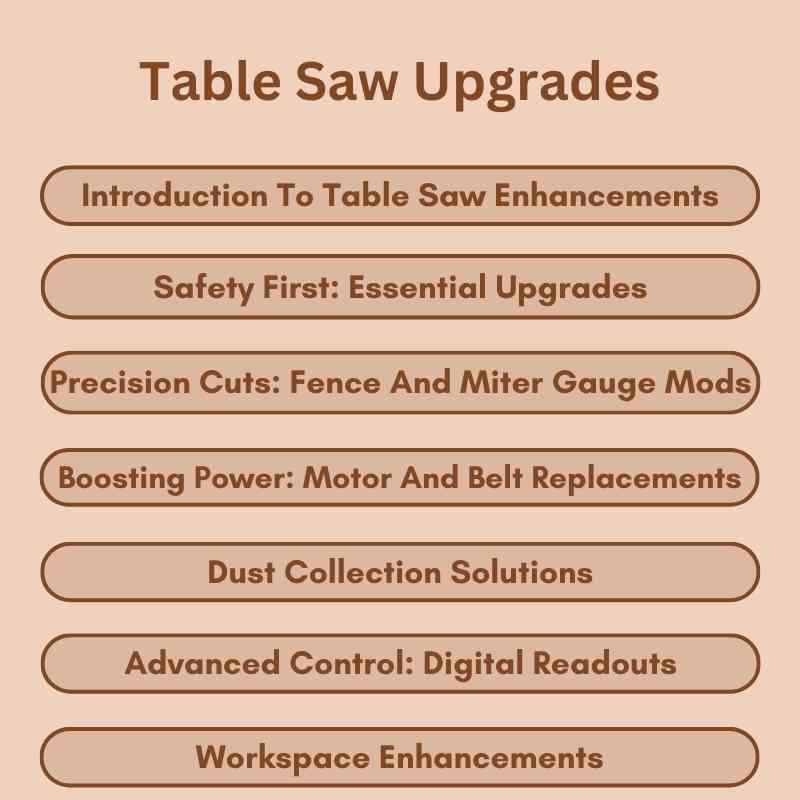

Table Saw Upgrades: Transform Your Woodworking Game!

Upgrading your table saw can significantly enhance its performance and safety. Key upgrades include a quality blade, fence system, and dust collection.

Table saws are essential tools for woodworkers, offering precision and versatility in cutting materials. As your skills progress, you may find that standard features no longer meet your needs. Upgrading your table saw can improve accuracy, efficiency, and safety, allowing you to tackle more complex projects with ease.

Whether you’re a hobbyist or a professional, investing in the right upgrades can make a noticeable difference. From better blades to advanced fences and enhanced dust collection systems, each modification can elevate your woodworking experience. Understanding these upgrades will help you make informed decisions that align with your woodworking goals.

Introduction To Table Saw Enhancements

Upgrading your table saw can transform your woodworking experience. Enhancements improve precision and safety. These upgrades can boost your creativity and efficiency. Let’s explore how upgrades impact woodworking and uncover your table saw’s potential.

The Impact Of Upgrades On Woodworking

Upgrades make a significant difference in your woodworking tasks. Here are some key benefits:

- Improved Accuracy: Upgraded saws cut more precisely.

- Enhanced Safety: Modern features reduce accident risks.

- Increased Efficiency: Faster cuts save time on projects.

- Better Versatility: New attachments expand capabilities.

Investing in table saw upgrades can elevate your projects. Better tools lead to better results. Consider these factors before upgrading:

| Factor | Impact |

|---|---|

| Blade Quality | Sharper blades lead to cleaner cuts. |

| Fence System | A sturdy fence improves alignment and safety. |

| Dust Collection | Better systems keep your workspace clean. |

Identifying Your Table Saw’s Potential

Understanding your table saw’s potential is crucial. Assess its current features and limitations. Check these areas:

- Power: Consider the motor size and horsepower.

- Blade Size: Ensure compatibility with common blade sizes.

- Table Size: A larger table offers more stability.

- Portability: Determine if you need a mobile option.

Assessing these factors helps you decide on upgrades. Identify what you need most. Prioritize enhancements that align with your woodworking goals.

Safety First: Essential Upgrades

Upgrading your table saw is crucial for safety. Every woodworker should prioritize safety features. Some upgrades can significantly reduce accidents. Let’s explore two essential upgrades: the riving knife and the blade guard.

Installing A Riving Knife

A riving knife is an important safety feature. It helps prevent kickback during cuts. Here are some benefits:

- Reduces the risk of blade binding.

- Keeps the material aligned.

- Improves cutting accuracy.

Installing a riving knife is simple:

- Turn off the saw and unplug it.

- Remove the existing splitter if needed.

- Attach the riving knife to the saw.

- Adjust the height to match the blade.

- Test the saw with scrap material.

Regularly check the riving knife for alignment. This ensures optimal performance and safety.

Upgrading The Blade Guard

A blade guard protects users from accidental contact with the blade. It covers the blade during operation. Here’s why you should upgrade:

| Benefit | Description |

|---|---|

| Increased Visibility | Modern guards offer clear visibility of the cut. |

| Easy to Use | New guards are simple to adjust and remove. |

| Enhanced Protection | They provide better coverage during cuts. |

Follow these steps to upgrade the blade guard:

- Turn off and unplug the saw.

- Remove the old blade guard.

- Install the new blade guard securely.

- Adjust it for proper positioning.

- Test the functionality before use.

Regular maintenance of the blade guard is key. This ensures it operates effectively.

Precision Cuts: Fence And Miter Gauge Mods

Upgrading your table saw enhances precision and accuracy. Two essential upgrades are the fence and miter gauge. These modifications improve your cutting experience and help achieve perfect cuts.

Choosing An Aftermarket Fence

Upgrading to an aftermarket fence can significantly increase your table saw’s performance. A quality fence provides better stability and precision. Here are key factors to consider:

- Material: Look for aluminum or steel for durability.

- Adjustability: Ensure it locks securely and adjusts easily.

- Length: Choose a fence that matches your saw’s size.

- Ease of Installation: Some fences are easier to install than others.

Popular aftermarket fences include:

| Fence Model | Material | Price Range |

|---|---|---|

| Incra TS-LS | Aluminum | $400 – $500 |

| Shop Fox W2005 | Steel | $300 – $400 |

| Biesemeyer | Steel | $200 – $300 |

Calibrating Your Miter Gauge

A well-calibrated miter gauge is vital for accurate cuts. Follow these steps to ensure yours is precise:

- Check the angle. Use a protractor or digital angle finder.

- Adjust the gauge. Loosen the screws to set the angle correctly.

- Test cuts. Make a few test cuts to verify accuracy.

- Tighten screws. Once calibrated, secure all screws tightly.

Regular calibration keeps your cuts sharp and accurate. This small upgrade can save time and material.

Boosting Power: Motor And Belt Replacements

Upgrading your table saw can greatly enhance its performance. Focusing on the motor and belt can lead to improved efficiency. This section highlights key aspects of these upgrades.

Selecting A Stronger Motor

Choosing a stronger motor is essential for better cutting power. A powerful motor can handle tougher materials. Here are some factors to consider:

- Horsepower: Look for at least 1.5 HP for general use.

- Type: Choose between induction or universal motors.

- Voltage: Ensure compatibility with your power supply.

- Size: Verify it fits your table saw’s specifications.

Upgrading to a stronger motor offers several benefits:

- Improved cutting speed.

- Increased durability.

- Better performance on dense materials.

Benefits Of A Poly-v Belt

Replacing your standard belt with a poly-V belt can enhance performance. Poly-V belts provide better power transfer. Here are key benefits:

| Benefit | Description |

|---|---|

| Efficiency | Reduced energy loss during operation. |

| Longevity | Longer lifespan compared to standard belts. |

| Less Vibration | Smoother operation with minimal noise. |

Switching to a poly-V belt can make a noticeable difference. Your table saw will operate smoother and quieter. Enjoy the benefits of enhanced power and efficiency.

Dust Collection Solutions

Dust collection is vital for safety and cleanliness in workshops. A good dust collection system reduces harmful particles. Upgrading your table saw can greatly enhance your dust control.

Custom Dust Collection Setups

Creating a custom dust collection setup can significantly improve airflow. Here are some ideas:

- Flexible Hoses: Use flexible hoses for easy movement.

- Adapters: Custom adapters fit different tool ports.

- Blast Gates: Control airflow to specific machines.

Building a custom system requires planning. Consider your workspace layout. You can use various materials:

| Material | Benefits |

|---|---|

| PVC Pipe | Lightweight and easy to install. |

| Metal Ducting | Durable and efficient for large setups. |

| Canvas Hoses | Flexible and easy to connect. |

Improving Factory Dust Ports

Factory dust ports often have limitations. Improving them boosts efficiency. Here are some tips:

- Increase Port Size: Larger ports allow better airflow.

- Seal Gaps: Use tape or caulk to seal leaks.

- Upgrade Filters: High-efficiency filters capture more dust.

Consider replacing the factory ports. Custom options provide better performance. Investing in quality components pays off in the long run.

Advanced Control: Digital Readouts

Digital readouts (DROs) transform how woodworkers operate table saws. They offer precise measurements and quick adjustments. This technology improves accuracy and reduces waste.

The Advantages Of Digital Precision

Digital readouts provide many benefits for woodworkers. Here are some key advantages:

- Enhanced Accuracy: Digital displays show exact measurements.

- Time-Saving: Quick adjustments save valuable time.

- Easy to Read: Large numbers are easy to see.

- Consistent Results: Repeat cuts become simpler and more reliable.

- Less Stress: Reduces guesswork in measurements.

Installation Tips For Digital Readouts

Installing digital readouts can be straightforward. Follow these tips for a smooth setup:

- Choose the Right Model: Pick a DRO compatible with your saw.

- Read the Manual: Follow the manufacturer’s instructions closely.

- Clean the Surface: Ensure the mounting area is dust-free.

- Use Quality Tools: A drill and screwdrivers will be necessary.

- Double-Check Measurements: Verify all measurements before finalizing.

With these tips, you can enjoy the precision and efficiency of digital readouts. Upgrade your table saw today and experience the difference!

Workspace Enhancements

Upgrading your table saw workspace boosts efficiency and safety. Creating a well-organized area helps you focus. Two essential upgrades are building outfeed tables and adding side extensions.

Building Outfeed Tables

Outfeed tables support long workpieces as you cut. They prevent sagging and ensure smooth cuts. Here’s how to build one:

- Measure your table saw height.

- Choose a sturdy material like plywood.

- Cut the plywood to size. Make it wider than your table saw.

- Attach folding legs for easy storage.

- Secure the outfeed table to your table saw.

Benefits of an outfeed table:

- Improves cut accuracy.

- Increases safety by reducing accidents.

- Enhances workflow by providing extra support.

Adding Side Extensions

Side extensions expand your table saw’s cutting area. They allow for larger sheets and long boards. Follow these steps to add side extensions:

- Measure the width of your table saw.

- Choose the material. Plywood is a great choice.

- Cut the material to the desired size.

- Attach the extension securely to your saw.

Key advantages of side extensions:

- Stability for large pieces.

- Better control during cuts.

- Flexibility for various projects.

| Feature | Outfeed Table | Side Extensions |

|---|---|---|

| Supports Long Pieces | Yes | Yes |

| Improves Safety | Yes | No |

| Increases Cutting Area | No | Yes |

| Enhances Workflow | Yes | Yes |

Upgrading your workspace with these features improves your experience. You’ll work smarter and safer. Invest time in these enhancements for better results.

Accessory Add-ons

Upgrading your table saw with accessory add-ons can enhance its functionality. These upgrades improve precision and expand cutting capabilities. Consider investing in jigs, sleds, and other tools to make your projects easier and more accurate.

Selecting The Right Jigs

Jigs are essential for precise cuts. They help guide your workpiece securely. Here are some types of jigs to consider:

- Crosscut Jigs: Great for making straight cuts across the grain.

- Box Jigs: Perfect for creating boxes with uniform dimensions.

- Taper Jigs: Ideal for cutting angled pieces for furniture.

Choose a jig that matches your project needs. Look for features like:

- Adjustability

- Material quality

- Ease of use

Investing in a good jig can save time and improve accuracy.

Custom Sleds For Specialized Cuts

Custom sleds offer unique benefits for specific cutting tasks. They provide stability and accuracy. Here are some advantages of using sleds:

| Advantage | Description |

|---|---|

| Improved Stability | Holds the workpiece firmly during cutting. |

| Enhanced Accuracy | Ensures straight cuts without drift. |

| Versatility | Can be used for various angles and lengths. |

Building a custom sled is simple. Follow these steps:

- Measure your table saw’s dimensions.

- Cut a base from plywood.

- Add rails for smooth sliding.

- Attach a stop block for repeat cuts.

With a custom sled, achieve precision like never before.

Maintaining Your Upgraded Saw

Keeping your table saw in top shape is essential. Proper maintenance enhances performance and extends its lifespan. Here’s how to maintain your upgraded saw effectively.

Routine Maintenance Checklist

Follow this checklist for regular maintenance:

- Clean the table: Remove dust and debris.

- Inspect the blade: Look for wear and damage.

- Check alignment: Ensure the blade is parallel to the miter slot.

- Lubricate moving parts: Use appropriate oils or greases.

- Tighten screws and bolts: Keep everything secure.

- Test safety features: Ensure they work properly.

Perform these tasks monthly. Use a calendar to remind yourself. This habit keeps your saw running smoothly.

Long-term Care For Enhanced Components

Upgraded components need special attention. Here are tips for long-term care:

| Component | Care Tips |

|---|---|

| Blade | Sharpen regularly. Replace when dull. |

| Motor | Check for overheating. Clean vents often. |

| Fence | Adjust for accuracy. Lubricate sliding parts. |

| Table | Prevent rust. Wipe with a protective oil. |

Regularly monitor these components. Address issues quickly to avoid bigger problems. A well-maintained saw ensures safety and efficiency.

Case Studies: Successful Upgrades

Upgrading a table saw can transform your woodworking experience. Many woodworkers have shared their success stories. These upgrades can improve safety, accuracy, and efficiency.

Real-life Upgrade Experiences

Here are a few real-life stories from woodworkers:

- John’s Dust Collection System: John added a dust collector. His shop stayed cleaner, and he breathed easier.

- Sarah’s Fence System: Sarah upgraded to a Biesemeyer fence. Her cuts became more precise and repeatable.

- Mike’s Blade Upgrade: Mike switched to a carbide-tipped blade. His cuts were smoother, and the blade lasted longer.

Quantifying The Benefits

Upgrading a table saw brings measurable benefits. Let’s take a look at some key metrics:

| Upgrade Type | Before Upgrade | After Upgrade | Improvement (%) |

|---|---|---|---|

| Dust Collection | 70% Effective | 95% Effective | 35% |

| Fence System | 1/8″ Accuracy | 1/16″ Accuracy | 50% |

| Blade Quality | 50 Cuts | 150 Cuts | 200% |

These upgrades lead to better efficiency and quality. They enhance the overall woodworking experience. Successful upgrades create a more enjoyable workspace.

Conclusion: Unleashing Your Saw’s Full Potential

Upgrading your table saw transforms it into a powerful tool. Simple enhancements can boost performance and safety. Let’s explore key tips and future trends for your table saw upgrades.

Recap Of Key Upgrade Tips

- Blade Upgrade: Choose high-quality blades for cleaner cuts.

- Fence System: Install a reliable fence for accuracy.

- Dust Collection: Improve dust management for a cleaner workspace.

- Table Extensions: Add extensions for larger workpieces.

- Digital Displays: Use digital readouts for precision measurements.

| Upgrade | Benefit |

|---|---|

| Blade Upgrade | Cleaner and smoother cuts. |

| Fence System | Enhanced cutting accuracy. |

| Dust Collection | Safer and cleaner environment. |

| Table Extensions | Support for larger projects. |

| Digital Displays | Improved measurement precision. |

Future Trends In Table Saw Upgrades

Technology shapes the future of table saws. Smart features will enhance user experience. Here are some trends to watch:

- Smart Sensors: Detect and prevent blade contact.

- Remote Control: Adjust settings from a distance.

- Automatic Height Adjustment: Simplifies blade height changes.

- Integration with Apps: Monitor performance and maintenance.

- Eco-Friendly Materials: Sustainable options for construction.

Frequently Asked Questions

What Are Essential Upgrades For Table Saws?

Essential upgrades for table saws include improved blades, dust collection systems, and fence systems. A high-quality blade enhances cutting precision. Dust collection keeps your workspace clean. An upgraded fence system allows for better accuracy and repeatability. These upgrades can significantly improve your overall woodworking experience.

How Can I Improve Safety On My Table Saw?

Improving safety on your table saw involves using a riving knife and a blade guard. A riving knife prevents kickback, while a blade guard protects your hands. Additionally, consider installing a push stick for safer handling of small pieces. Always follow safety protocols and wear appropriate protective gear.

What Is The Benefit Of A Table Saw Fence Upgrade?

Upgrading your table saw fence increases accuracy and efficiency. A high-quality fence ensures straight cuts and minimizes adjustments. It allows for easier measurement and repeat cuts, saving time and reducing errors. This upgrade can greatly enhance your woodworking projects’ quality and consistency.

Are There Dust Collection Upgrades For Table Saws?

Yes, there are various dust collection upgrades available for table saws. You can add a dedicated dust port or connect to a shop vacuum system. Some models come with built-in dust collection options. Effective dust collection keeps your workspace cleaner and promotes a healthier working environment.

Conclusion

Upgrading your table saw can significantly enhance your woodworking experience. With the right improvements, you’ll achieve better accuracy and efficiency. Whether it’s a new blade or advanced safety features, investing in upgrades pays off. Embrace these enhancements to elevate your craftsmanship and enjoy the process even more.

Happy woodworking!