Table Saw Vs Bandsaw: Which Cuts Best for Woodwork?

Are you standing in front of a choice between a table saw and a bandsaw, feeling a bit overwhelmed? You’re not alone.

Choosing the right tool for your woodworking projects can be a game-changer. The table saw and bandsaw are both powerful, but they offer different strengths that can make or break your project. Imagine effortlessly slicing through wood with precision and ease.

That’s what the right saw can do for you. By understanding the unique benefits of each, you can transform your woodworking experience and bring your creative visions to life. So, are you ready to make the best choice for your next masterpiece? Let’s dive in and discover which saw is your perfect match.

Table Saw Features

Table saws use different blade types for various cuts. A rip blade has few teeth. It cuts quickly. A crosscut blade has many teeth. It gives a smooth finish. Combination blades can do both. Choose the right blade for your task.

Table saws offer high cutting precision. They make straight cuts easily. Use a fence for guidance. This helps keep cuts accurate. Adjust the blade height for different materials. Precision is key for quality work.

Safety is important with table saws. They have guards for protection. A riving knife prevents kickback. Push sticks help keep hands safe. Always follow safety guidelines. Never rush when using a saw.

Credit: landmarktools.com

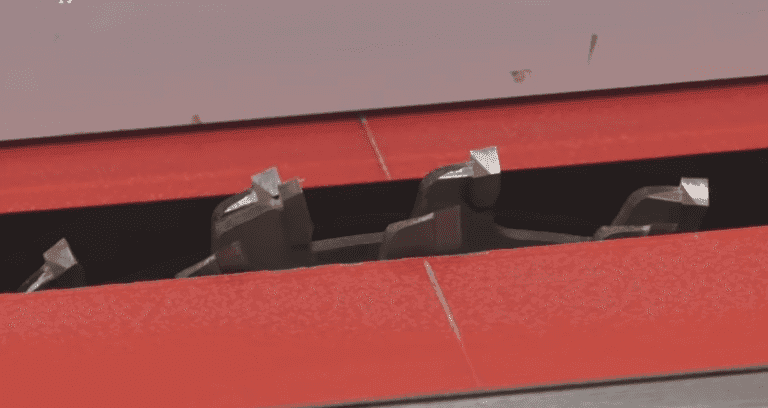

Bandsaw Features

A bandsaw offers precise cuts with its narrow blade, ideal for curves and intricate details. The table saw, with its broad blade, excels in straight cuts and ripping large boards. Understanding these distinctions helps in choosing the right tool for woodworking projects.

Blade Variability

The bandsaw offers various blade types. Each blade suits different tasks. Thinner blades make curves easily. Wider blades cut straight lines better. Blades come in different tooth sizes too. Small teeth cut slowly but smoothly. Large teeth cut faster but rougher.

Cutting Versatility

Bandsaws can cut many materials. Wood is common, but metal too. Plastic cuts well with bandsaws. You can make straight cuts or curves. They handle thick and thin pieces. Bandsaws are ideal for creative projects.

Safety Considerations

Bandsaws have important safety features. Blade guards protect fingers. Always wear safety glasses. Keep hands away from the blade. Use a push stick for small pieces. Ensure the blade tension is correct. Bandsaws need regular checks for safety.

Comparing Cutting Techniques

Table saws make straight cuts easy. They have a flat surface for wood. The blade moves up and down. This helps cut wood evenly. Table saws are great for cutting long boards. They are fast and accurate. Safety is important, so use guards.

Bandsaws are different. They have a looped blade. This blade moves in one direction. Bandsaws can make curved cuts. The blade bends to follow shapes. Bandsaws are perfect for craft projects. They offer a lot of control. Curved cuts are smooth and precise.

Rip cuts split wood lengthwise. Table saws shine here. They cut straight lines quickly. Bandsaws can rip too, but slower. Table saws handle big boards well. Bandsaws are better for smaller pieces. Both tools need care and attention. Always measure twice and cut once.

Credit: schoolofwoodwork.com

Material Efficiency

Table saws cut hard and soft woods well. Their straight cuts are neat. Bandsaws handle curved cuts better. They work on thicker wood and tough types. Choose based on your wood project needs.

Thick wood is easy for bandsaws. They cut through it smoothly. Table saws may struggle with very thick wood. They are better for thinner pieces. Decide based on your wood thickness.

Bandsaws create less waste. Their blade is thin and precise. Less wood is lost in cuts. Table saws have a thicker blade. They may waste more wood. Choose bandsaws for less waste.

Ease Of Use

Table saws need more time to set up. Align the blade. Fix the table. Bandsaws are quicker. Just adjust the blade tension. Set the guide. Ready to cut. Less fuss. Simple steps save time. You start faster.

Table saws are easy. Straight cuts mostly. Bandsaws can curve. They need practice. Different skills. More control is needed. Beginners find table saws easier. Bandsaws require learning. Cutting shapes needs patience.

Table saws need blade cleaning. Check motor often. Bandsaws need blade tension checks. Oil the wheels. Both need regular care. Keeps them working well. Simple tasks avoid problems. Make sure parts are clean. Tools last longer.

Cost Considerations

Table saws usually cost more than bandsaws. Most table saws are bigger. They have more parts. This makes them more expensive. Bandsaws are smaller. They have fewer parts. So, they are cheaper to buy.

Table saws need more care. They have more parts to check. This means spending more money on them over time. Bandsaws have fewer parts. They need less fixing. So, they cost less to keep working.

Replacement parts for table saws are more costly. They have bigger blades and motors. Bandsaw parts are smaller. This makes them cheaper to replace. Keeping a bandsaw running costs less.

User Experience

Woodworkers often share their thoughts on table saws and bandsaws. Many find table saws useful for straight cuts. Bandsaws are praised for cutting curves. Some users like the power of table saws. Others prefer the precision of bandsaws. Both tools have fans. Some woodworkers use both. Each tool has its own charm.

Woodworkers face challenges with both tools. Dust can be a problem. Safety is crucial. Table saws need space. Bandsaws require adjustments. Blades can break. Changing blades takes time. Some find noise annoying. Understanding these tools is key. Practice makes perfect.

Many woodworkers share success stories. They make beautiful furniture. Some build toys for kids. Others craft musical instruments. Table saws help with clean edges. Bandsaws shape unique designs. Creativity shines with these tools. Woodworkers enjoy their achievements. Their hard work pays off.

Making The Right Choice

Choosing the right saw depends on your project needs. Table saws are great for straight cuts. They handle large sheets of wood easily. Bandsaws are better for curves and intricate shapes. Think about the type of cuts you need. A table saw offers precision for furniture. Bandsaws work well for sculptures or unique designs.

Skill level is important when picking a saw. Table saws are simpler to use. Beginners find them easier to manage. Bandsaws need more practice. They require skill for tight curves. Consider your experience before choosing. Start with a table saw if you are new.

Space matters in your workshop. Table saws are bulky. They need more room to operate safely. Bandsaws are compact. They fit into tighter spaces. Assess your workshop area. Choose a saw that fits comfortably. Ensure there is enough space for the saw and for you.

Credit: www.youtube.com

Frequently Asked Questions

What’s Better, A Band Saw Or A Table Saw?

A band saw excels at cutting curves and intricate shapes. A table saw is ideal for precise straight cuts and larger wood pieces. Choose a band saw for versatility, and a table saw for accuracy and power, depending on your woodworking needs.

Why Do Most Woodworkers Buy A Bandsaw As Their First Machine?

Most woodworkers choose a bandsaw first due to its versatility in cutting curves, resawing, and intricate designs. Compact size and affordability make it ideal for small workshops. Its ability to handle various materials and thicknesses ensures efficient and precise cuts, enhancing craftsmanship and productivity in woodworking projects.

What Are The Disadvantages Of A Bandsaw?

Bandsaws can be expensive to purchase and maintain. They often require regular blade replacements. Noise and dust generation can be significant. They may lack portability due to size and weight. Limited cutting capacity restricts use on large materials. Safety risks exist if not used properly.

What Is The #1 Danger When Using A Table Saw?

The #1 danger when using a table saw is kickback. It occurs when wood suddenly gets caught and propelled. This can cause severe injuries. Always stay focused, maintain control, and use proper safety gear to prevent accidents. Regularly check the saw for any mechanical issues or malfunctions.

Conclusion

Choosing between a table saw and bandsaw depends on your needs. Table saws excel at straight cuts and are versatile for various projects. Bandsaws are perfect for curved cuts and handling thick materials. Consider your space and budget when deciding.

Some projects may need both tools for best results. Safety is crucial with either choice, so always follow guidelines. Each tool offers unique benefits. Determine which suits your woodworking style best. Both have their place in a workshop. Make your choice based on the tasks you aim to achieve.