What Angle Do I Cut Wood to Make an Octagon?: Precision Tips

To make an octagon, cut wood at a 22.5-degree angle. This angle allows for eight equal sides, creating a perfect octagon shape.

Creating an octagon can be a rewarding woodworking project. Whether building furniture or crafting decorative pieces, understanding the right angle is crucial. An octagon consists of eight equal sides, making it distinct and visually appealing. Accurate cutting ensures that all sides meet correctly, resulting in a professional-looking finish.

This guide provides the necessary angle and tips for successful cuts. With the right tools and techniques, anyone can create stunning octagonal designs. Master this skill to elevate your woodworking projects and impress others with your craftsmanship. Embrace the challenge and enjoy the process of creating your octagon.

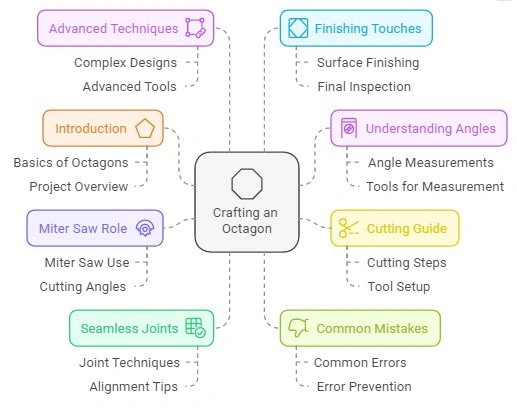

Introduction To Crafting An Octagon

Octagonal designs are both unique and beautiful. They add a special touch to any project. Many enjoy crafting octagons for tables and frames. Understanding the right cutting angle is essential for success.

Basic tools can make this task easier. A miter saw or a hand saw works well. A protractor helps measure angles accurately. Using a square ensures straight cuts. Lastly, having sandpaper smooths edges for a polished finish.

Understanding Angles And Measurements

Understanding the geometry of an octagon is essential. An octagon has eight sides and eight angles. Each interior angle measures 135 degrees. The total of all angles is 1080 degrees.

To create an octagon, cutting wood requires specific angles. Each exterior angle measures 45 degrees. This angle helps in achieving the correct shape. Use a protractor to measure angles accurately.

| Side | Exterior Angle | Interior Angle |

|---|---|---|

| 1 | 45° | 135° |

| 2 | 45° | 135° |

| 3 | 45° | 135° |

| 4 | 45° | 135° |

| 5 | 45° | 135° |

| 6 | 45° | 135° |

| 7 | 45° | 135° |

| 8 | 45° | 135° |

Step-by-step Guide To Cutting Wood For An Octagon

To create an octagon, marking your wood accurately is key. Start by measuring the length of each side. Use a square to ensure your lines are straight. Then, mark the angle at 22.5 degrees for each cut. This angle divides the circle into eight equal parts.

For cutting techniques, use a miter saw for precise angles. Make sure to secure the wood properly before cutting. This prevents slipping and ensures safety. Always wear safety goggles to protect your eyes. Check your measurements twice to avoid mistakes.

| Step | Description |

|---|---|

| 1 | Measure the length of each side. |

| 2 | Mark a 22.5-degree angle. |

| 3 | Use a miter saw for clean cuts. |

| 4 | Secure wood and wear safety goggles. |

The Role Of A Miter Saw In Octagonal Cuts

Using a miter saw is essential for making precise octagonal cuts. Start by setting the saw to a 22.5-degree angle. This angle allows for eight equal sides in your octagon. Ensure the blade is sharp for clean cuts.

To set up your miter saw, follow these steps:

- Place the saw on a stable surface.

- Adjust the miter angle to 22.5 degrees.

- Secure the wood firmly against the fence.

- Double-check measurements before cutting.

For the best results, keep the wood steady during the cut. This prevents any slippage or mistakes. Regularly maintain your miter saw for optimal performance.

Tips To Achieve Seamless Joints

To achieve seamless joints, start with proper sanding. Use fine-grit sandpaper for smooth edges. Sand each piece until it feels soft to the touch.

For gluing techniques, apply glue evenly along the edges. Press pieces together firmly. Use clamps to hold them in place while drying. This ensures strong bonds.

Check alignment before the glue sets. Adjust as needed for perfect fit. After drying, sand again for a polished look.

Common Mistakes And How To Avoid Them

Miscalculating the angle is a common mistake. The correct angle for cutting wood to make an octagon is 22.5 degrees. Double-check your measurements before cutting. Using a protractor can help ensure accuracy.

Improper tool use can lead to poor cuts. Always use the right tool for the job. A miter saw is ideal for cutting angles. Ensure the blade is sharp for clean cuts.

Practice on scrap wood before starting your project. This helps you get comfortable with the tools. Avoid rushing, as this can lead to mistakes.

Advanced Techniques For Complex Octagons

Creating an octagon for your project requires precise angles. For a regular octagon, each internal angle measures 135 degrees. To achieve this, cut each wood piece at 22.5 degrees. This angle allows for perfect alignment.

Incorporating angles in 3D projects can enhance depth and visual interest. Use a protractor to measure angles accurately. Mark your cuts clearly for better results. Always ensure wood pieces fit snugly together.

Decorative edging adds charm to your octagon. Consider using molding or trim for a polished look. Experiment with different styles to match your project’s theme. Detailing can make a simple octagon look extraordinary.

Finishing Touches For Your Octagonal Project

Choosing the right finish for your octagonal project is essential. A good finish protects wood and enhances its beauty. Consider using water-based finishes for easy cleanup. Oil-based finishes provide a rich color and durability.

For outdoor projects, use weather-resistant options. Sealants can prevent moisture damage and UV fading. Test finishes on scrap wood first to see how they look. Always follow the manufacturer’s instructions for the best results.

Protecting your creation is vital. Proper care ensures the longevity of your work. Regularly check for scratches or wear. Reapply the finish as needed to keep your octagon looking great.

Frequently Asked Questions

What Is The Angle For Cutting Octagon Wood?

To create an octagon, you need to cut wood at a 22. 5-degree angle. This angle allows you to form the eight equal sides required for a perfect octagon. Using a miter saw can help achieve this precise angle efficiently.

How Many Sides Does An Octagon Have?

An octagon has eight sides. This geometric shape is commonly used in design and architecture. Each side of the octagon is equal in length, contributing to its symmetrical appearance.

What Tools Are Needed To Cut An Octagon?

To cut an octagon, you will need a miter saw, measuring tape, and a square. A miter saw provides the precision required for the 22. 5-degree cuts. Measuring tape ensures accurate lengths for each side, while a square helps maintain straight edges.

Can I Make An Octagon Without Power Tools?

Yes, you can make an octagon without power tools. Hand saws and a miter box can effectively create the necessary angles. Accurate measurements and patience are essential for achieving a clean cut with manual tools.

Conclusion

Cutting wood to create an octagon is a rewarding project. By using a 22. 5-degree angle, you can achieve precise cuts. This technique is essential for various woodworking tasks. Whether you’re building furniture or crafting decorations, mastering this skill enhances your craftsmanship.

Start your project today and enjoy the creative process!