What Size Chainsaw for Milling? Ultimate Guide

For milling, a chainsaw with a bar length of at least 20 inches is recommended. Now, let’s delve into the details of selecting the right chainsaw size for milling.

Chainsaw milling is a cost-effective way to create lumber from logs, and it’s a popular hobby for many woodworkers. However, selecting the appropriate chainsaw size is critical for the success of your milling project. Chainsaws with shorter bars are suitable for light-duty tasks, while longer bars can handle larger logs and more extensive milling projects.

This article will assist you in selecting the appropriate chainsaw size for your milling needs, ensuring that you get the most out of your equipment.

Choosing The Right Chainsaw For Milling

If you’re planning on milling lumber, you’ll need a chainsaw that’s up to the task. But with so many different options available, it can be difficult to know where to start. Here are some factors to consider when choosing the right chainsaw for milling.

Factors To Consider

- Engine Power: The power of the engine is an important consideration when choosing a chainsaw for milling. A more powerful engine will be able to handle larger logs and tougher cuts.

- Bar Length: The length of the chainsaw’s bar determines the maximum size of log that can be cut. A longer bar will be able to cut larger logs but can be more difficult to handle.

- Weight: The weight of the chainsaw is an important factor to consider, as a heavier saw can be more difficult to handle for extended periods of time.

- Price: Chainsaws for milling can range in price from a few hundred dollars to several thousand. Consider your budget when choosing a saw.

Types Of Chainsaws Suitable For Milling

When it comes to milling lumber, there are two types of chainsaws that are suitable: gas-powered and electric-powered chainsaws.

| Gas-Powered Chainsaws | Electric-Powered Chainsaws |

|---|---|

| More powerful | Less powerful |

| Can handle larger logs | Best for smaller logs |

| More expensive | Less expensive |

| Require more maintenance | Require less maintenance |

In general, gas-powered chainsaws are better suited for milling larger logs, while electric-powered chainsaws are better for smaller logs and lighter-duty milling.

Understanding Chainsaw Power And Milling Capacity

When it comes to milling wood with a chainsaw, understanding the chainsaw’s power and milling capacity is crucial. Two key factors that determine a chainsaw’s suitability for milling are the engine size and power output, as well as the bar length and its impact on milling. Let’s explore these factors in more detail.

Engine Size And Power Output

The engine size of a chainsaw directly influences its power output. Chainsaws with larger engines generally deliver more power, allowing for more efficient milling. The power output is typically measured in horsepower (HP) or cubic centimeters (cc). A chainsaw with a higher horsepower or larger cc rating can handle larger logs and cut through them more easily.

When choosing a chainsaw for milling, consider the size of the logs you plan to work with. If you’re milling small to medium-sized logs, a chainsaw with an engine size between 40cc and 60cc should suffice. For larger logs, you may need a chainsaw with an engine size of 60cc or higher.

Bar Length And Its Impact On Milling

The bar length of a chainsaw refers to the length of the cutting blade or guide bar. It plays a crucial role in determining the maximum width of the logs you can mill. Chainsaws with longer bars have a greater cutting capacity, allowing for milling larger logs.

When choosing a chainsaw for milling, consider the bar length that suits your milling needs. A shorter bar length, typically between 16 and 20 inches, is suitable for smaller logs. If you plan to mill larger logs, opt for a chainsaw with a longer bar length, typically between 20 and 36 inches.

It’s important to note that longer bar lengths require more power to operate effectively. Therefore, ensure that the chainsaw’s engine size is compatible with the chosen bar length to achieve optimal milling performance.

In conclusion, understanding the chainsaw’s power and milling capacity is essential for successful wood milling. By considering the engine size and power output, as well as the bar length and its impact on milling, you can select the right chainsaw for your milling needs.

Guide Bar Considerations For Effective Milling

When it comes to milling with a chainsaw, choosing the right guide bar is crucial for achieving optimal results. The guide bar is the part of the chainsaw that holds the saw chain and determines the size of the logs that can be milled. In this guide, we will explore the key considerations for selecting the ideal guide bar length and ensuring quality and durability.

Ideal Guide Bar Length

The ideal guide bar length for milling depends on the size of the logs you plan to mill. A longer guide bar allows you to cut through larger logs, while a shorter guide bar is more maneuverable and suitable for smaller logs. It is important to choose a guide bar length that matches your milling needs.

Here is a table outlining the recommended guide bar lengths based on log size:

| Log Size | Recommended Guide Bar Length |

|---|---|

| Small logs (up to 12 inches in diameter) | 12-16 inches |

| Medium logs (12-20 inches in diameter) | 16-20 inches |

| Large logs (20+ inches in diameter) | 20+ inches |

Guide Bar Quality And Durability

Choosing a high-quality guide bar is essential for durability and longevity. A durable guide bar not only lasts longer but also ensures smoother and more precise cuts. Here are some factors to consider when evaluating guide bar quality:

- Material: Look for guide bars made from hardened steel, as they are more resistant to wear and provide better performance.

- Tip Design: Guide bars with sprocket-nose tips are ideal for milling as they offer reduced friction and increased cutting speed.

- Bar Rails: Opt for guide bars with thick and sturdy bar rails, as they provide stability and reduce vibrations during milling.

- Compatibility: Ensure the guide bar is compatible with your chainsaw model and chain pitch to guarantee a proper fit.

By considering these factors and choosing a guide bar that meets your specific milling requirements, you can enhance the efficiency and effectiveness of your milling operations.

Chain Types And Their Role In Milling

When it comes to milling with a chainsaw, the right chain type plays a crucial role in ensuring efficiency and accuracy. Different chain types are designed to suit specific milling applications, and understanding their roles is essential for achieving optimal results.

Selecting The Right Chain Pitch

The chain pitch refers to the distance between three consecutive rivets divided by two. For milling, choosing the appropriate chain pitch is vital as it determines the size of the wood that can be cut. Smaller chain pitches are suitable for smaller logs, while larger chain pitches are ideal for larger logs.

Chain Gauge And Its Importance

Chain gauge is the thickness of the drive link and is a critical factor in milling. Selecting the correct chain gauge ensures stability and precision during the milling process. It is imperative to match the chain gauge with the guide bar to maintain optimal performance and safety.

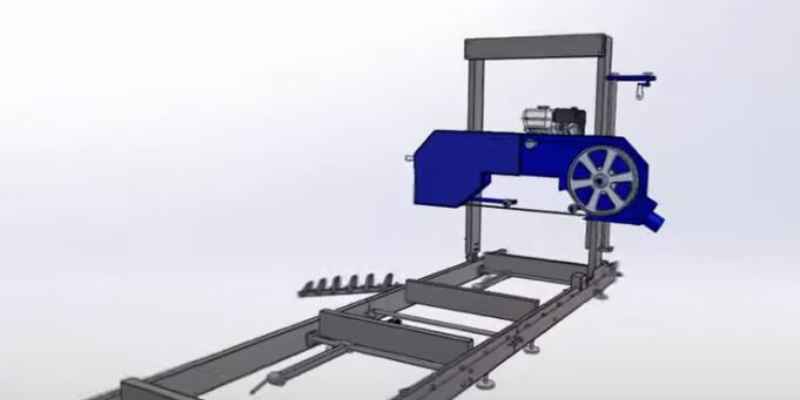

Milling Attachments And Accessories

When it comes to milling, having the right attachments and accessories can make all the difference in ensuring efficient and precise results. Whether you are a seasoned professional or a DIY enthusiast, understanding the essential milling attachments and additional accessories available is crucial for getting the most out of your chainsaw mill.

Essential Milling Attachments

When setting up your chainsaw mill for milling, there are a few essential attachments that you should consider:

- Guide Rails: Guide rails help to maintain a straight and level cut, ensuring consistent and accurate milling results. They provide stability and support for the chainsaw mill as it moves along the log.

- Depth Gauge: A depth gauge is used to control the depth of the cut. It allows you to adjust the cutting depth according to your desired specifications, ensuring precision and uniformity in each pass.

- Chain Sharpener: Keeping your chainsaw chain sharp is essential for efficient milling. A chain sharpener attachment allows you to easily sharpen the chain on the go, ensuring optimal cutting performance and prolonging the lifespan of your chain.

Additional Accessories For Efficient Milling

In addition to the essential attachments, there are several other accessories that can greatly enhance the efficiency and productivity of your milling process:

- Log Clamps: Log clamps securely hold the log in place during milling, preventing any movement or shifting that could affect the accuracy of the cut. They provide stability and ensure a safer working environment.

- Log Lifter: A log lifter attachment helps in lifting heavy logs onto the milling platform. It reduces strain on your back and allows for easier maneuvering of larger logs, making the milling process more manageable.

- Dust Collection System: Milling produces a significant amount of sawdust, which can obstruct your view and affect the overall efficiency. A dust collection system attachment helps to collect and remove the sawdust, keeping your work area clean and improving visibility.

By investing in these additional accessories, you can streamline your milling process, increase productivity, and achieve more accurate and professional results. Each attachment serves a specific purpose, contributing to the overall efficiency and ease of use of your chainsaw mill.

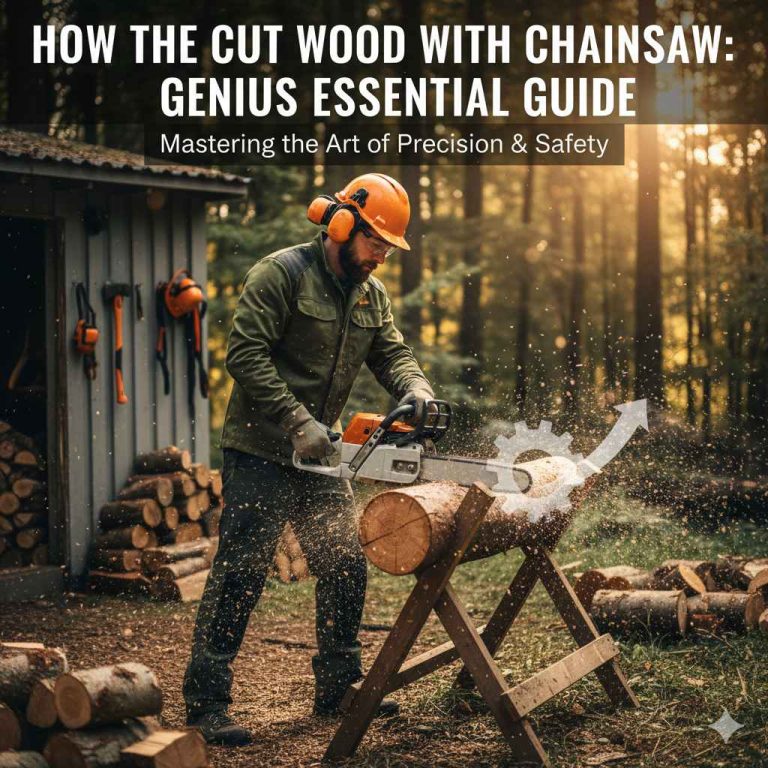

Safety Gear And Best Practices

When using a chainsaw for milling, safety should be the top priority. Proper safety gear and adherence to best practices are crucial for preventing accidents and ensuring a smooth milling process. In this section, we’ll cover the must-have safety equipment and operating procedures for safe milling.

Must-have Safety Equipment

Before starting any milling operation, it’s essential to have the right safety gear in place. The following table outlines the must-have safety equipment for chainsaw milling:

| Equipment | Description |

|---|---|

| 1. Chainsaw Safety Gear | Includes a chainsaw helmet with face shield, hearing protection, chainsaw chaps, and steel-toed boots. |

| 2. Personal Protective Equipment (PPE) | Includes gloves, eye protection, and appropriate clothing to protect against sawdust and debris. |

| 3. First Aid Kit | Should be readily available in case of minor injuries. |

Operating Procedures For Safe Milling

Following proper operating procedures is essential for safe chainsaw milling. Here are some key best practices to ensure safe and efficient milling:

- Inspect the chainsaw and safety equipment before each use.

- Ensure the work area is clear of obstacles and bystanders.

- Secure the log to prevent movement during cutting.

- Position yourself correctly to maintain balance and control while milling.

- Keep bystanders at a safe distance from the milling area.

Maintenance Tips For Chainsaw Milling

When it comes to chainsaw milling, proper maintenance is crucial for optimal performance and longevity.

Routine Chainsaw Maintenance

- Regularly clean the chainsaw to prevent buildup.

- Check chain tension and sharpness before each use.

- Lubricate the chain and bar after milling sessions.

Post-milling Care For Longevity

- Inspect the chainsaw for any damage or wear after milling.

- Store the chainsaw in a dry and secure place.

- Sharpen the chain regularly to maintain cutting efficiency.

Real World Examples: Milling Projects And Chainsaw Sizes

Discover the ideal chainsaw size for milling projects to ensure efficient and precise cutting. Proper chainsaw sizes are crucial for successful milling operations, delivering optimal results and enhancing productivity. Matching the right chainsaw size with your milling project is key to achieving superior outcomes.

Case Studies Of Successful Milling

Real-world examples showcase the effectiveness of specific chainsaw sizes in milling projects.

Chainsaw Sizes In Action

Different chainsaw sizes are utilized based on the scope and nature of milling projects.

In a recent milling project, a 20-inch chainsaw was used to cut large logs efficiently.

16-inch chainsaws are ideal for smaller milling projects that require precision cutting.

Milling projects vary, requiring specific chainsaw sizes for optimal results.

Key Points:

– 20-inch chainsaw for large logs

– 16-inch chainsaw for precision cutting

Frequently Asked Questions

What Size Chainsaw Is Ideal For Milling Purposes?

A chainsaw with a bar length of 24 to 36 inches is recommended for milling. This size allows for cutting larger logs efficiently while providing stability and control during the milling process.

How Does Chainsaw Size Impact Milling Efficiency?

The size of the chainsaw directly affects milling efficiency. Larger chainsaws with longer bar lengths can cut through bigger logs in fewer passes, increasing productivity. However, smaller chainsaws are more maneuverable and suitable for smaller milling projects.

What Features Should I Look For In A Milling Chainsaw?

When choosing a chainsaw for milling, consider features like high engine power, longer bar length, adjustable oiler, and ergonomic design for comfort. These features ensure smooth operation, precise cuts, and enhanced safety during milling tasks.

Can I Use A Smaller Chainsaw For Occasional Milling Projects?

While smaller chainsaws can be used for occasional milling projects, they may not be as efficient as larger ones. For optimal results and productivity, it is advisable to invest in a chainsaw with a suitable bar length and power for consistent milling performance.

Conclusion

Choosing the right chainsaw for milling is crucial for efficiency and safety. By considering the size, power, and features, you can ensure optimal performance. Remember to prioritize safety measures and maintenance to prolong the chainsaw’s lifespan. With the right equipment, you can achieve professional-quality milling results.