1/4 Pressure Treated Plywood: Durable Building Solution

Are you planning a DIY project or looking to enhance your home’s durability with quality materials? If so, you might want to consider 1/4 pressure treated plywood.

This versatile and sturdy material is a game-changer for anyone needing a reliable solution for both indoor and outdoor projects. Imagine creating structures that stand the test of time, resisting elements that would otherwise cause wear and damage. With 1/4 pressure treated plywood, you can do just that.

Whether you’re building a new deck, reinforcing your shed, or crafting a unique piece of furniture, this plywood offers the strength and resilience you need. But why is it so effective? And how can you make the most of it in your next project? We’ll dive into the benefits, uses, and tips for working with 1/4 pressure treated plywood, helping you make informed choices and achieve outstanding results. Don’t miss out on discovering how this material can elevate your projects to new heights.

Benefits Of Pressure Treated Plywood

Pressure treated plywoodlasts longer than regular wood. It can handle tough weather. Rain and sun do not damage it easily. Builders trust this wood. It stays strong for many years. Good for outdoor projects. Decks and fences use this wood often.

This plywood fights decay. Rot does not affectit quickly. Wet conditions do not harm it much. Better than untreated wood. It keeps shape even in water. Ideal for gardens and patios. No need for constant care.

Termites and pestsavoid this plywood. Chemicals in the wood keep them away. Homes stay safe from bugs. Good choice for basements. Protects against wood-eating insects. Saves money on pest control.

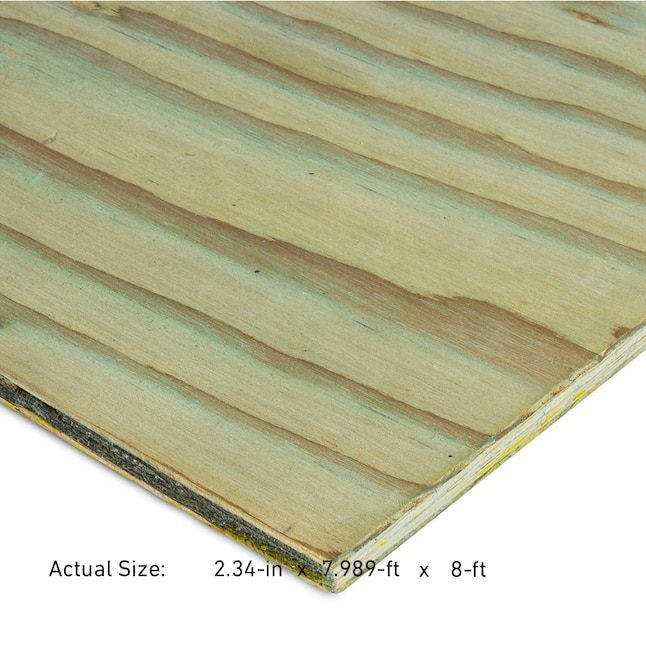

Credit: www.homedepot.com

Applications In Construction

Pressure treated plywood is strong and lasts long. It is often used in floors and walls. Builders like it because it does not rot easily. This plywood keeps homes safe and strong. It also helps in keeping moisture away.

In commercial buildings, pressure treated plywood is vital. It supports heavy structures and roofing systems. It is used in office buildings and shopping centers. This plywood offers extra strength and durability. It is perfect for places with lots of people.

Outdoor sheds and structures need strong material. Pressure treated plywood is ideal. It handles rain and sun well. It is great for garden sheds and tool storage. Builders use it for decks and fences too. It resists insects and weather damage.

Manufacturing Process

Plywood is treated with special chemicals. These chemicals protect the wood from bugs and rot. The wood is placed in a big tank. High pressure pushes the chemicals deep into the wood. This process makes the plywood last longer. It also makes it safe for outdoor use.

Each sheet of plywood is checked carefully. Workers look for cracks and defects. Machines test the strength of the plywood. Only the best pieces pass the test. This ensures that the plywood is strong and reliable.

Making plywood should be safe for nature. Companies use eco-friendly chemicals. These do not harm the environment. They also recycle water used in the process. This helps save valuable resources.

Credit: www.lowes.com

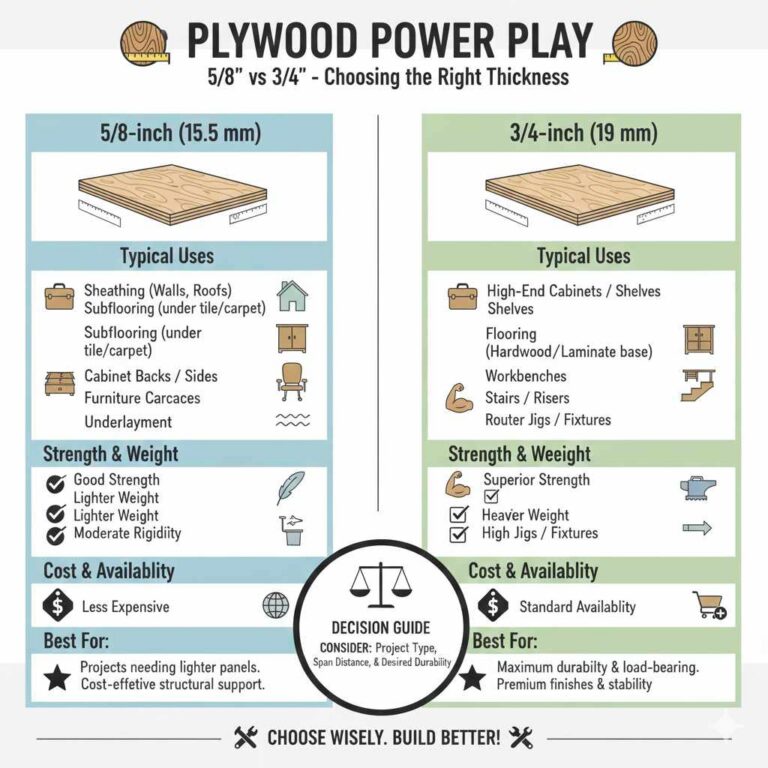

Comparing To Other Materials

Pressure treated plywood is stronger than untreated wood. It lasts longer in wet conditions. Bugs and fungus do not harm it easily. This makes it a good choice for outdoor projects. Untreated wood can rot and break faster. Pressure treated wood also resists fire better.

Other plywood types may not last as long outdoors. They do not have the same treatment for water. This makes them weak in rain or snow. Pressure treated plywood is better for decks and fences. It can handle bad weather without breaking.

Pressure treated plywood costs more than regular wood. But it lasts much longer. This makes it a smart buy for long-term projects. You save money because you do not have to replace it often. Its durability adds value over time.

Installation Tips

Wearing protective gearis a must. Gloves and masks help keep you safe. Ensure ventilationin the work area. Avoid breathing in dust. Keep a first-aid kitnearby. Be ready for small accidents. Check toolsbefore use. Ensure they are in good condition.

A sawcuts the plywood. Drillshelp in fixing. Measuring tapeensures accurate sizes. Safety glassesprotect eyes. Sandpapersmoothens edges. Keep a pencilfor marking. Use a square rulerfor straight lines.

Measure twice, cut once. Mark linesclearly before cutting. Use sharp bladesfor clean cuts. Join piecessecurely. Use screws and nailsfor strong bonds. Leave space for expansion. Plywood can change shape. Keep edges smoothto prevent splinters.

Credit: www.homedepot.com

Maintenance And Care

Inspect pressure treated plywood often. Look for cracks or damage. Fix small cracks quickly. Use wood filler for minor repairs. Replace damaged sections if needed. This keeps the plywood strong. Regular checks help avoid bigger issues. Clean the plywood every few months. Use a soft brush and mild soap. Rinse with water. Let it dry completely before using again. This cleaning prevents mold and rot.

Apply a sealant to the plywood. This stops water from entering. Use a waterproof sealant. Apply it once a year. Sealant keeps the wood safe from rain. Choose a UV-resistant sealant. This stops sun damage. Good weatherproofing extends the life of the plywood. Use paint for extra protection. Choose exterior paint for best results. Paint adds a layer of defense. It looks nice too.

Pressure treated plywood is strong. It lasts a long time. Sustainable practices are key. Use environmentally friendly sealants. This protects nature. Recycling old plywood helps. Don’t throw it away. Reuse in new projects. This saves resources. Always choose quality materials. They last longer and need less upkeep. Quality plywood is worth the cost. It stays strong over time.

Frequently Asked Questions

What Is 1/4 Pressure Treated Plywood?

1/4 pressure treated plywood is a type of wood panel. It is treated with preservatives to resist rot and decay. This makes it ideal for outdoor applications. It offers durability and longevity in projects exposed to moisture and insects. It’s commonly used in decks, fences, and garden structures.

How Is Pressure Treated Plywood Made?

Pressure treated plywood is made by infusing wood with chemicals. These chemicals help resist rot and insects. The process involves placing plywood in a vacuum chamber. This allows preservatives to penetrate deep into the wood fibers. The treatment enhances durability and extends the wood’s lifespan.

Where Can I Use 1/4 Pressure Treated Plywood?

1/4 pressure treated plywood is versatile for outdoor use. It’s perfect for garden structures, sheds, and fences. The plywood is also suitable for decking and outdoor furniture. It resists moisture and decay, making it ideal for humid environments. Always check local building codes before use.

Is Pressure Treated Plywood Safe For Indoor Use?

Pressure treated plywood is generally safe for outdoor use. It contains chemicals that may not be ideal indoors. For indoor applications, consider untreated or kiln-dried plywood. If used indoors, ensure proper ventilation. Always follow manufacturer guidelines for safe usage.

Conclusion

1/4 pressure treated plywood is a versatile choice. It offers durability and resistance to decay. Perfect for both indoor and outdoor projects. Its affordability makes it a smart option for budget-conscious buyers. This plywood supports various applications, providing long-lasting results.

Remember to handle it safely and follow guidelines. Proper care ensures its longevity and performance. Suitable for DIY enthusiasts and professionals alike. Consider it for your next project. It could be just what you need. Make informed decisions and enjoy the benefits.

Quality results without breaking the bank.