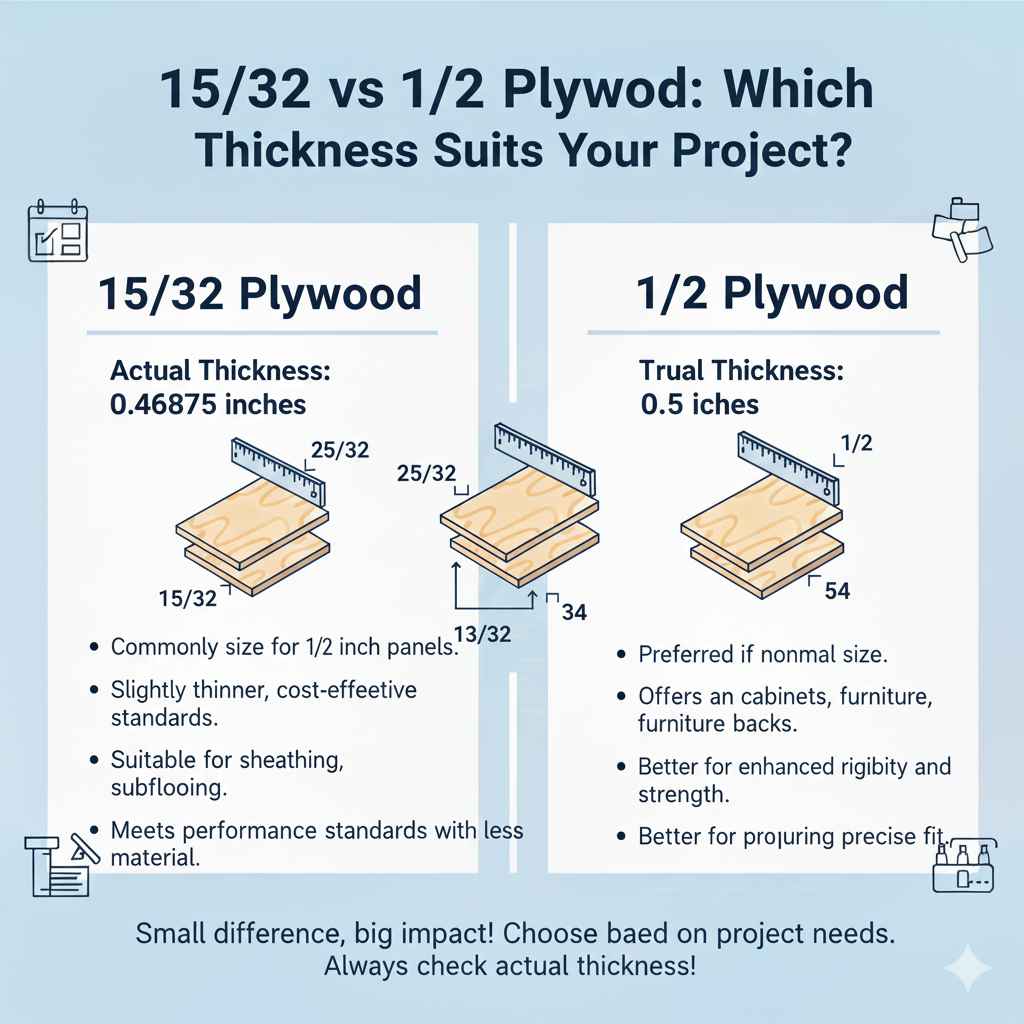

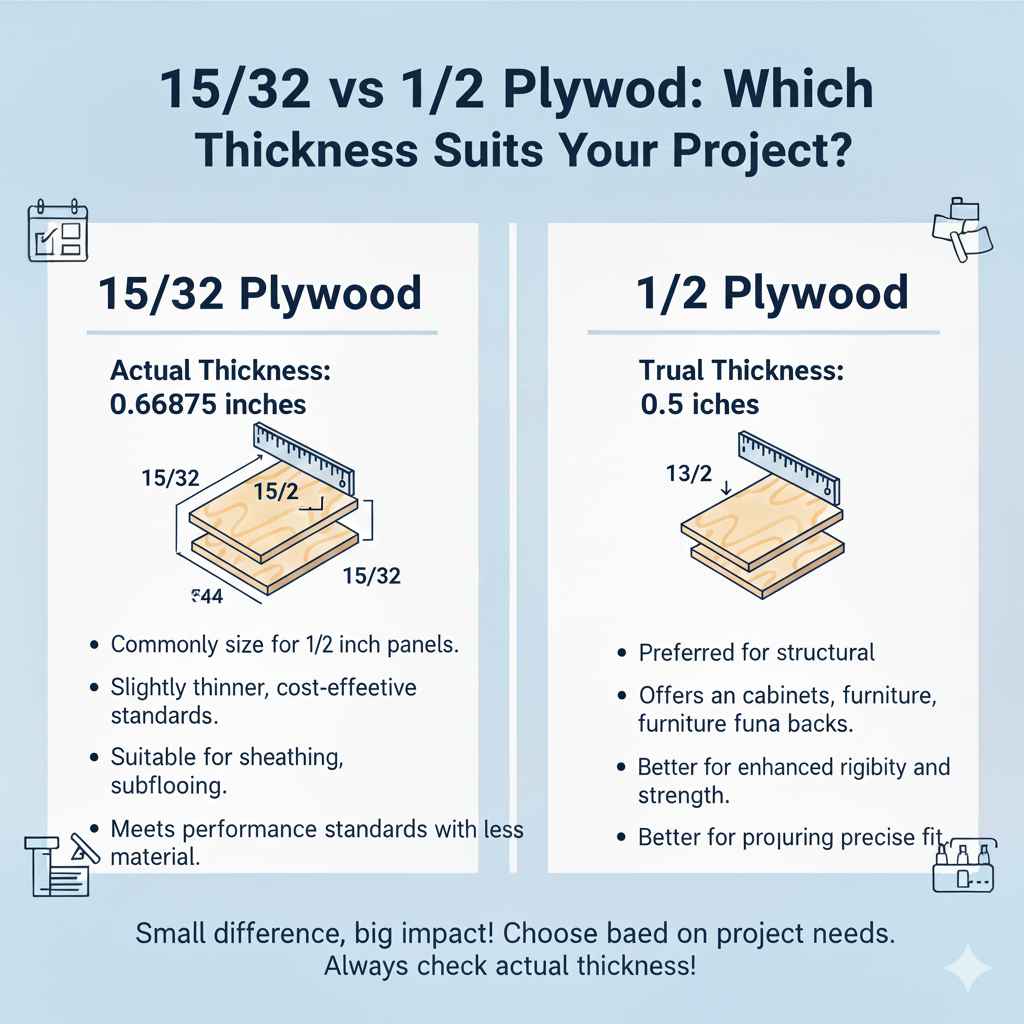

15/32 vs 1/2 Plywood: Which Thickness Suits Your Project?

Choosing the right plywood thickness can seem tricky at first, especially when you’re just starting. It’s common to wonder what the difference is between the sizes, and figuring out which one suits your project can be a challenge. Don’t worry! This guide will break down 15/32 vs 1/2 Plywood: What’s the Better Choice?, making it easy to understand. We’ll look at what each thickness offers, helping you pick the perfect one for your needs.

What is Plywood and Why Thickness Matters?

Plywood is a fantastic building material, composed of thin layers of wood veneer (called plies or layers) glued together. These layers are oriented with their grain running at right angles to each other. This construction method gives plywood its strength, flexibility, and resistance to warping. The thickness of plywood is a key factor, because it impacts its strength, how it performs, and even the price. Knowing the difference between thicknesses like 15/32″ and 1/2″ is important for the success of any project. Selecting the appropriate thickness is an essential skill for any builder, beginner or expert. The right plywood choice is essential for long-lasting, sturdy projects.

Understanding Plywood Layers

The construction of plywood directly influences its strength. Think of it like building a sturdy wall. Each layer of wood veneer adds to the overall resilience. The more layers, the stronger the plywood, and generally, the thicker it is. This construction also provides resistance to warping and splitting. This method creates a material that is exceptionally strong considering its weight. The orientation of the wood grain in each layer is crucial because it distributes stress across the panel, which improves the overall durability.

Here’s how to visualize it: imagine the grain of the wood running horizontally in one layer, then vertically in the next. This cross-graining approach is what makes plywood so strong in multiple directions. It’s a smart design, making plywood an excellent choice for a variety of tasks.

Plywood Measurement Explained

You’ll often see plywood described using fractions like 15/32” or 1/2”. These fractions represent the thickness of the plywood panel in inches. Sometimes, it can be a bit confusing. A general rule is the larger the number, the thicker the plywood. But how do you remember what 15/32” or 1/2” actually means? The best approach is to remember that the fractions are in inches. Using a ruler with fractional measurements will allow you to see the actual size. Always double-check your measurements to make sure you have the right size before you purchase any wood.

Different Types of Plywood

Plywood comes in several varieties, depending on its intended use. Each type has different qualities. For example, some plywood is designed for use in construction, such as sheathing for walls and roofs. Marine plywood, on the other hand, is built to withstand moisture, making it suitable for boats and outdoor projects. Then, there’s hardwood plywood, which is made with attractive hardwood veneers, often used for furniture and cabinetry. Understanding these differences will help you choose the right plywood for your project. Knowing the different types of plywood allows you to select the best choice for your needs. Always check the wood type before you buy to make sure you get the right materials.

Comparing 15/32 Inch vs. 1/2 Inch Plywood

Now, let’s dig into the main topic: the difference between 15/32 vs 1/2 Plywood: What’s the Better Choice?. While these two thicknesses seem similar, there are key distinctions that affect your project. Both are great options, and often the best choice depends on the specific job. Knowing the pros and cons of each helps you make a better decision. Let’s look at the qualities of each to help you choose the correct option.

15/32 Inch Plywood: Overview and Uses

15/32 inch plywood (which is nearly half an inch thick) is a popular option for several reasons. It offers a good blend of strength and cost. It is often used in construction for subflooring, wall sheathing, and roofing. Its thickness offers enough strength to support weight and resist bending. Also, it’s a good choice for projects where you need a balance between cost and performance. Think of it as a middle-of-the-road choice. It can handle many tasks without being too expensive or too heavy.

- Subflooring: It can serve as a strong base for floors, supporting weight and withstanding foot traffic.

- Wall Sheathing: Because of its durability, it’s suitable for covering wall frames.

- Roofing: It can handle the weight of roofing materials and resist the elements.

1/2 Inch Plywood: Overview and Uses

1/2 inch plywood is slightly thicker than 15/32 inch plywood, so it provides a bit more strength and rigidity. It is often preferred for projects where extra sturdiness is important. It is used in cabinetry, furniture making, and projects where a more robust material is needed. While it might cost a bit more, the added strength is sometimes worth the investment. 1/2 inch plywood offers additional support for those situations. It gives you some extra confidence for weight and stress. Its durability makes it suitable for projects that must last.

- Cabinetry: It provides a solid foundation for cabinets, resisting wear and tear.

- Furniture Making: It is often used in furniture construction because it offers a sturdy frame.

- Shelving: The added strength is ideal for shelving units that will hold heavier items.

Comparing Strength and Durability

When you consider 15/32 vs 1/2 Plywood, a key difference is strength and durability. 1/2 inch plywood generally provides more strength and is able to handle more weight. It’s less likely to bend or flex under pressure. 15/32 inch plywood is still strong, but it might flex more. For some projects, this won’t matter, but in others, the extra durability of 1/2 inch plywood is essential. Consider the expected load and stress your project will face to decide on the proper plywood thickness. In the long run, the choice depends on your specific needs.

| Feature | 15/32 Inch Plywood | 1/2 Inch Plywood |

|---|---|---|

| Strength | Good | Better |

| Durability | Good | Better |

| Cost | Typically less | Typically more |

| Flexibility | More flexible | Less flexible |

| Common Uses | Subflooring, wall sheathing, roofing | Cabinetry, furniture, shelving |

Project Considerations: What to Think About

To choose between 15/32 vs 1/2 Plywood, you must consider the project’s specific needs. Think about the purpose of the project, the amount of weight it needs to hold, and the amount of wear it will face. Also, think about the budget. It may be easier to choose once you’ve considered these factors.

Weight and Load-Bearing Capacity

If your project must hold a significant amount of weight, 1/2 inch plywood is usually the better choice. It can handle heavier loads. If the item will experience a lot of stress, the added strength will provide peace of mind. For projects that have lighter loads, 15/32 inch plywood can work well. Always ensure your project meets any safety standards. Consider not just the initial weight, but also the potential for any additional stress.

Environmental Conditions

If your project is exposed to moisture or extreme weather, you must think about the plywood’s resistance to these conditions. While both 15/32 inch and 1/2 inch plywood can be treated with waterproof coatings, 1/2 inch might have a slight advantage simply due to its greater thickness. If the project is outdoors or in an environment with high humidity, choose plywood made for exterior use. This will improve its lifespan. Remember, proper preparation and maintenance are also important to protect your project, no matter which plywood thickness you choose.

Cost and Budget Constraints

The cost difference between 15/32 inch and 1/2 inch plywood can affect your budget. 15/32 inch plywood is often a little less expensive than 1/2 inch. This can be an important factor, particularly for larger projects. Decide how much you can spend, and consider whether the added strength of 1/2 inch plywood is worth the added cost. Sometimes, saving a little money is essential, and 15/32 inch plywood is adequate. In other cases, investing in the slightly more expensive 1/2 inch plywood can save you money in the long run. Making the best decision depends on your budget constraints.

Real-World Examples and Scenarios

Let’s look at a few examples to see how these plywood thicknesses are used in real-world scenarios. Seeing how people apply them to tasks is helpful to show which option works best.

Case Study 1: Building a Bookshelf

Imagine you’re building a bookshelf. If the shelves will hold many heavy books, 1/2 inch plywood would be the better choice. Its strength would prevent the shelves from bending over time. For a smaller bookshelf, or one that will only hold lighter items, 15/32 inch plywood might be sufficient. This shows how the project’s purpose will influence your decision.

Here’s a look at the results. A builder used 1/2 inch plywood to build a sturdy bookshelf, and its strength and durability have made it a favorite in the home for years. Another builder used 15/32 inch plywood for a lighter-duty shelf. It holds books but shows a slight bend over time. This shows the difference between the two choices.

Case Study 2: Constructing a Shed Floor

Building a shed floor requires a strong, supportive base. Because the shed floor needs to withstand both weight and exposure to the elements, 15/32 inch plywood can be used, and it offers a good mix of strength and cost. If you’re building a shed that must handle very heavy items or one that is subject to more extreme weather conditions, 1/2 inch plywood might be a better idea. This will give you greater peace of mind.

Sample Scenarios

- Building a Desk: For a desk, 1/2 inch plywood would likely be the better option for its strength. It will need to handle the weight of a computer, books, and other items. 15/32 inch plywood could be used, but it might be less sturdy.

- Making a Toy Box: For a toy box, 15/32 inch plywood could be perfectly fine, particularly if it’s for smaller toys. If it’s for larger toys or will be used by children who are likely to climb on it, 1/2 inch plywood might offer better durability.

Working with Plywood: Tips and Tricks

No matter which plywood thickness you choose, there are some tips to help with your project. With a little forethought and preparation, you can get great results. Follow these suggestions to help you get professional-looking results.

Cutting and Measuring

Accurate cutting and measuring are essential for any woodworking project. Start by measuring your plywood precisely. Then, mark your cutting lines clearly. When cutting plywood, use the right tools. A circular saw or table saw is ideal for straight cuts. If you do not have those, a hand saw with a sharp blade can also work. Always cut with the good side of the plywood facing up to minimize tear-out. Also, remember to support the plywood well to prevent it from flexing during the cutting process.

Fastening Techniques

The right fastening techniques are essential for holding your plywood pieces together. Screws and nails are the most common choices. Screws give a stronger hold. Choose screws that are long enough to go through both pieces of plywood. Consider using wood glue in addition to screws or nails for extra strength. For larger projects, or for pieces that must be assembled in difficult positions, using clamps is also useful. Clamps help hold the pieces in place until the glue and screws dry or set.

Finishing and Protecting Plywood

Protecting your plywood project is very important. Begin by sanding the surface. This removes any rough edges and prepares the plywood for paint or stain. You can choose from paints, stains, or sealants. Paints and stains can add color and beauty. Sealants protect the wood from moisture and the elements. Make sure you use a sealant made for the specific type of plywood. Always apply your finish correctly. Always follow the manufacturer’s directions for best results. Correct finishing extends the life of your project. Applying finish products will also make it look better.

Frequently Asked Questions

Question: Is 15/32 inch plywood the same as 1/2 inch plywood?

Answer: Not exactly, but they are very close. 15/32 inch plywood is just under 1/2 inch. The slight difference doesn’t often matter in practice, but 1/2 inch plywood is slightly thicker and, in some cases, stronger.

Question: Which plywood is best for outdoor use?

Answer: For outdoor projects, choose exterior-grade plywood. This plywood is specifically designed to resist moisture and the elements. Marine plywood is an excellent choice for projects exposed to a lot of water.

Question: Can I use 15/32 inch plywood for building cabinets?

Answer: Yes, you can use 15/32 inch plywood for cabinets, especially for the sides and backs. For shelves and areas that hold a lot of weight, 1/2 inch plywood might be better.

Question: What’s the difference between plywood and OSB?

Answer: Plywood is made of layers of wood veneer, glued together with the grain of each layer running at right angles to the next. OSB (Oriented Strand Board) is made from wood strands that are compressed and glued together. Plywood is typically stronger and more water-resistant.

Question: How do I know which side of plywood is the “good” side?

Answer: The “good” side is usually the one with fewer knots, imperfections, and a smoother surface. Check the edges and surface carefully. It’s usually the side you’ll want to display.

Final Thoughts

When you’re deciding between 15/32 vs 1/2 Plywood: What’s the Better Choice?, remember that both have their place. 15/32 inch plywood offers a good balance of cost and strength, making it suitable for many general construction tasks. 1/2 inch plywood provides a bit more durability and is best used for projects needing a more sturdy base. The best option hinges on the specific project requirements, including load-bearing needs, environmental conditions, and budget.

Assess the project’s demands, think about your resources, and select the plywood thickness that will best meet the needs of your project. Understanding the nuances of each option empowers you to make informed decisions that ensure your project’s success. With some thought, you can easily choose the right material for all of your construction plans. So, go ahead and start your next building project with confidence, knowing you’ve made the right decision about your plywood choice.