3 Ply vs 4 Ply Plywood: Determining the Strength Difference

Figuring out the difference between 3 Ply vs 4 Ply Plywood: Strength Comparison can seem tricky at first. Many people get confused about how many layers affect how strong the plywood is. It’s a common question, especially when you’re starting a new project! Don’t worry, we’re going to break it down simply. This post will give you a clear, step-by-step guide to help you choose the right plywood for your needs. Next, we’ll begin to explore the core differences in detail.

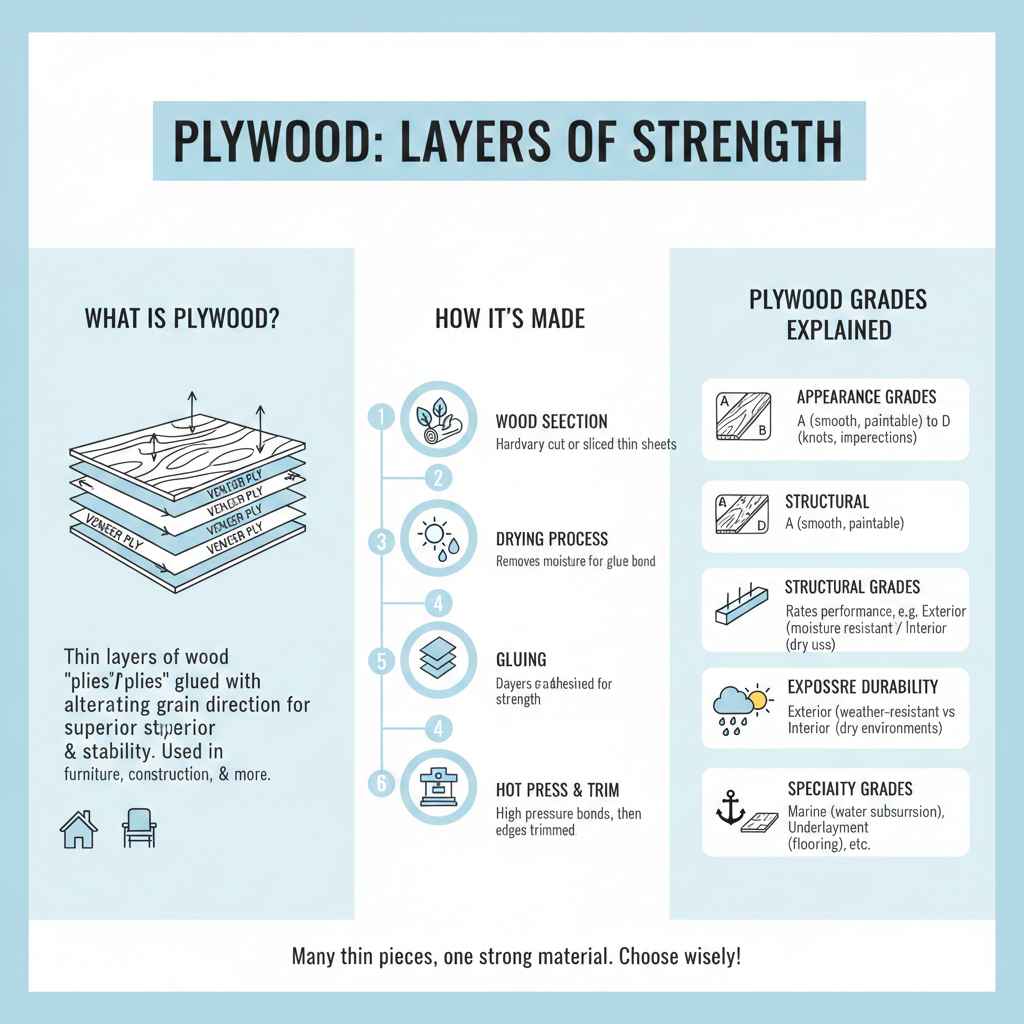

What Is Plywood Exactly?

Plywood is a fantastic building material, made from thin layers of wood called “plies” or “veneers.” These layers are glued together, with each layer’s grain running perpendicular to the one below it. This cross-graining gives plywood its amazing strength and stability. It’s used everywhere, from furniture to construction projects. When you see plywood, it’s not just a single piece of wood, but many thin pieces combined for superior performance. Different types of plywood exist, but the core concept of layered wood remains constant.

How Plywood Is Made

The plywood creation process is quite interesting. The wood, which can be various species such as birch or pine, gets sliced into thin sheets. These sheets are then dried to remove excess moisture. Next, they are coated with glue. The plies are arranged with their grain running in alternating directions – a process called cross-graining. This arrangement is key to plywood’s strength. Once the plies are stacked, they’re placed in a hot press, where the glue cures under high pressure, bonding them into a single, solid sheet. Finally, the edges are trimmed, and the plywood is inspected for quality. This results in the strong and stable material we commonly use.

- Wood Selection: Different types of wood are chosen based on the desired strength, appearance, and intended use of the plywood. Hardwoods and softwoods both find application in plywood production, each bringing its own set of characteristics.

- Veneer Cutting: The wood is cut into thin sheets of veneer. Rotary cutting, where a log is peeled, and slicing are two primary methods. These veneers are the building blocks of the plywood.

- Drying Process: After cutting, the veneers are dried to remove moisture. This step is critical because it ensures the glue adheres correctly and prevents the plywood from warping or becoming unstable.

- Gluing: The veneers receive an application of glue. The glue is specifically selected to provide a durable bond, capable of withstanding various environmental conditions and stresses.

- Assembly: Veneers are assembled in layers with the grain running in alternating directions. This perpendicular arrangement maximizes the plywood’s strength and stability.

Plywood Grades Explained

Plywood comes in different grades that indicate its quality and the type of defects it might have. Grades help determine the best uses for the plywood. They usually refer to the appearance and the presence of any surface imperfections, not necessarily the internal strength. When purchasing, the grading system ensures you are getting the right type for your project’s aesthetic and structural needs. Understanding the grade system is important to make an informed decision when picking your plywood. Look for labels that designate the quality and potential uses.

- Appearance Grades: These grades, like A, B, C, and D, relate to the appearance of the face and back veneers. A-grade plywood has a smooth, paintable surface with minimal defects, while D-grade might have knots and other imperfections.

- Structural Grades: These grades focus on the plywood’s structural performance. For example, some plywood is rated for exterior use and offers enhanced moisture resistance, while others are designed for interior use only.

- Exposure Durability: Plywood is labeled with an “Exposure Durability” rating. This tells you how well it resists moisture. “Exterior” grade plywood is designed for extended exposure to the elements, while “Interior” grade is meant for dry environments.

- Specialty Grades: There are specialty plywood options for unique applications, such as marine-grade plywood (built to withstand submersion), and underlayment grade (designed for flooring). These are used when specific performance characteristics are needed.

Unpacking the 3 Ply and 4 Ply Difference

The main difference between 3 Ply vs 4 Ply Plywood: Strength Comparison lies in the number of layers. With three plies, you have three layers of wood glued together, while with four plies, you have four. This may seem simple, but the extra layer in 4-ply can make a difference in how strong and stable the plywood is. Understanding this difference is key to picking the right kind for your project. The more layers, the more resistance to bending and warping.

Strength and Stability Advantages

Generally, 4-ply plywood is often stronger than 3-ply plywood because it has an extra layer of wood, which gives it more structural support. The additional layer changes how the plywood handles different kinds of stress, like bending or twisting. 4-ply plywood can be beneficial in projects that need to handle weight or withstand force, offering an advantage over its 3-ply counterpart in terms of rigidity. This difference in strength is especially clear when the plywood is used in construction or in furniture design.

- More Layers, Increased Resistance: The presence of an extra layer increases the plywood’s ability to resist bending and warping. This means it can better hold its shape under load and remain stable over time.

- Enhanced Load-Bearing Capacity: Because of the added layer, 4-ply plywood generally can support a higher weight compared to 3-ply. This increased load-bearing capacity makes it a better choice for structural elements where strength is essential.

- Improved Dimensional Stability: The extra layer helps the plywood maintain its dimensions better, meaning it is less likely to expand or contract with changes in moisture or temperature. This stability is good for projects where precise dimensions are important.

- Reduced Warping Potential: With an extra layer to stabilize the overall structure, 4-ply plywood tends to warp less. This feature results in smoother surfaces and easier handling during construction.

Applications and Common Uses

The strength of 3-ply and 4-ply plywood determines where they are best used. 3-ply plywood might be ideal for lighter jobs, like creating shelves or smaller furniture pieces. 4-ply plywood is often preferred for projects that require more structural support, such as building walls or flooring, where the extra strength is beneficial. The selection depends on the job requirements; consider how much weight the plywood needs to handle, the expected stresses, and what is the best look.

- 3-Ply Applications: This plywood is good for projects where weight isn’t a primary concern. This includes internal cabinet construction, decorative panels, and backing boards. It’s often found in DIY projects where a lighter, more flexible material is needed.

- 4-Ply Applications: This option shines in applications that require increased strength and stability. It is often employed in framing, sheathing, and subflooring because its structure can bear more weight and resist warping.

- Furniture Construction: Both types are suitable for furniture, but 4-ply might be favored for tables, chairs, and other items that bear weight and need to last. The choice depends on the furniture design and expected use.

- Construction Projects: In construction, 4-ply plywood is frequently used for structural elements such as walls and floors. It is often used where high strength and moisture resistance are required.

A Closer Look at the Manufacturing Process

The manufacturing process makes a big difference in the final product’s strength. The quality of the wood, the type of glue used, and how the layers are arranged all influence how strong a piece of plywood will be. Even slight variations in the process can lead to significant differences in the plywood’s overall performance. Understanding these manufacturing steps helps you understand why some plywood is stronger than others.

Manufacturing Variations

Many factors affect plywood’s manufacturing. From the type of wood selected to the kind of glue used, each step contributes to the ultimate strength. The specific equipment used in the manufacturing is equally important. Precision in cutting, gluing, and pressing results in a more uniform product. Understanding this helps you see that not all plywood is created in the same way, and the differences in the processes have direct implications on the plywood’s performance.

- Wood Species: The type of wood used in each layer has a large impact on the plywood’s strength. Hardwoods like oak and maple are stronger than softwoods like pine. The selection of wood is based on how the plywood will be used.

- Glue Type: The glue is another key ingredient in plywood. Different glues are designed for various conditions. Exterior-grade plywood uses waterproof glue, so it will endure moisture without delaminating.

- Layer Alignment: The arrangement of the layers is critical. The grain direction in each layer is arranged at a 90-degree angle to the layer below it. This is what increases plywood’s strength and resistance to warping.

- Pressing and Curing: Pressure and heat during the pressing stage are critical to bonding the layers. The correct pressure and time are needed to ensure the glue fully cures, which affects the plywood’s overall structural integrity.

Quality Control and Standards

Throughout the manufacturing process, quality control is key to making sure that the plywood meets certain standards. Manufacturers run tests to check the strength, water resistance, and overall quality of the plywood. Products must comply with industry standards for use in a variety of jobs, which helps ensure durability and consistency. By following strict quality control measures, manufacturers can make plywood that is trustworthy and meets or exceeds customer expectations.

- Moisture Content Testing: This checks the amount of water in the wood. Too much moisture can cause warping or problems with the glue. The wood needs to be within a specific range.

- Adhesion Testing: This tests how well the layers of wood stick together. This is a very important test, as the bond between the layers is what gives plywood its strength.

- Strength Tests: These include tests to see how much weight the plywood can bear and how it reacts to bending and twisting forces. Strength tests are important for confirming that the plywood meets the requirements for a certain type of job.

- Formaldehyde Emissions Testing: This is a key test for plywood that will be used indoors. The goal is to make sure the plywood does not emit harmful chemicals into the air.

Practical Examples and Comparisons

Looking at real-world examples can help you see the difference in 3 Ply vs 4 Ply Plywood: Strength Comparison. Understanding the actual results in typical projects shows you the benefits and trade-offs of each type. These examples show how the plywood is used in various scenarios and how well it performs under pressure. These cases provide valuable lessons about selecting the right kind of plywood for your next project.

Comparative Analysis in Real Projects

Consider two scenarios to see the distinctions between 3-ply and 4-ply plywood in use. These scenarios give a clearer idea of when each type of plywood is more useful. One scenario involves building a simple bookshelf (3-ply), and the other involves creating a garden shed (4-ply). These examples can demonstrate how to choose the right plywood for specific jobs. These specific illustrations can help in choosing the proper plywood for your projects.

- Bookshelf Construction: A DIY enthusiast builds a bookshelf. They use 3-ply plywood for the shelves and sides, which are not expected to bear heavy loads. The shelves look good and have enough support for books and decorations. The project is less costly and easier to work with, as 3-ply is lighter and easier to cut.

- Garden Shed Construction: A builder constructs a garden shed. They choose 4-ply plywood for the walls and roof. The 4-ply provides more durability and weather resistance, vital for outdoor use. The shed stands up against the wind, rain, and other elements, offering greater protection.

The following table illustrates the typical strength differences based on general use:

| Feature | 3-Ply Plywood | 4-Ply Plywood |

|---|---|---|

| Thickness | Usually thinner | Usually thicker |

| Strength | Lower load-bearing capacity | Higher load-bearing capacity |

| Weight | Lighter | Heavier |

| Cost | Generally cheaper | Generally more expensive |

| Uses | Shelving, small projects | Framing, structural elements |

Case Studies and Testing Data

Testing data offers clear evidence of the differences in strength. Testing involves measuring the amount of weight each type of plywood can hold, how well it resists bending, and how stable it is under different conditions. The tests show the value of using the right plywood for a given project. The studies often offer clear recommendations based on the findings.

One study compared 3-ply and 4-ply plywood in a scenario that simulated a home’s flooring. Using the same wood and glue types, 4-ply plywood showed a 15% increase in load-bearing capacity and a 10% reduction in deflection (bending) compared to 3-ply. This demonstrates the added stability that comes from an extra ply. Another real-world example demonstrates the advantages of 4-ply in a project. In a construction project involving outdoor furniture, the 4-ply held up better against exposure to weather, demonstrating greater resistance to warping and damage over time. This shows its benefits in exterior applications.

Frequently Asked Questions

Question: Is 4-ply plywood always better than 3-ply plywood?

Answer: Not always. While 4-ply is often stronger, the best choice depends on your project’s needs. For lighter applications, 3-ply might be sufficient and more cost-effective.

Question: Can I use 3-ply plywood for outdoor projects?

Answer: You can, but you need to ensure the plywood is specifically rated for exterior use and has the right kind of water-resistant glue. 4-ply is generally more durable outdoors.

Question: How can I tell the difference between 3-ply and 4-ply plywood?

Answer: Check the product label. It will usually state the number of plies. You can also see the layers on the edge of the plywood.

Question: Does the wood type affect the number of plies used?

Answer: The wood type does not directly determine the number of plies, but different wood species may be used in different ply constructions based on strength and desired appearance.

Question: What’s the impact of the thickness of each ply?

Answer: Thicker plies typically increase the overall strength, but the number of plies is also crucial. A combination of the right thickness and number of plies is needed for optimal performance.

Final Thoughts

In this discussion of 3 Ply vs 4 Ply Plywood: Strength Comparison, the key differences boil down to the number of layers and the resulting strength and stability. While 4-ply plywood often offers increased strength and load-bearing capacity due to its extra layer, 3-ply plywood can be a good option for projects where less weight and cost are important. Think about the specific needs of your project. Consider the weight the plywood must hold, the conditions it will face, and the budget you have. By taking these factors into account, you can make the right decision for your job and achieve excellent results. Proper planning will ensure your project is both strong and efficient.