Ash Wood Dowel: Essential & Proven Guide

Mastering Ash Wood Dowels: A Simple Guide for Beginners. Learn what ash wood dowels are, their incredible strength, versatility, and how to use them effectively in your DIY projects for durable, beautiful results. This guide breaks down everything you need to know in easy-to-understand steps.

Hey there, fellow woodworkers! Md Meraj here, your go-to mentor for all things DIY and woodworking. Ever look at a beautifully crafted piece of furniture or a sturdy shelf and wonder about the strong, hidden connections holding it all together? Often, it’s the humble yet mighty dowel rod that does the heavy lifting. Today, we’re diving into the wonderful world of the ash wood dowel. If you’re new to woodworking and find yourself a bit lost about which materials to trust for strength and reliability, you’re in the right place. We’ll explore why ash is such a fantastic choice for dowels and how you can confidently use them in your own projects to achieve professional-looking, long-lasting results. Stick around, and let’s get building!

What is an Ash Wood Dowel?

An ash wood dowel is essentially a smooth, cylindrical rod made from ash wood. Ash trees are known for their impressive strength, density, and shock resistance, making their wood a top-tier material for many applications, including dowels. Unlike some softer woods, ash has a tight grain pattern and a beautiful, natural appearance that can even be a visual feature in your projects. Think of these dowels as nature’s own reinforcing bars for your woodworking creations. They are used to strengthen joints, create decorative elements, or even serve as handles and pins.

Why Choose Ash for Dowels? The Unbeatable Strengths

When it comes to selecting wood for dowels, especially for projects where strength and longevity are paramount, ash stands out. Its inherent properties make it a superior choice for a variety of woodworking tasks. Let’s break down why ash wood dowels are a favorite among hobbyists and professionals alike.

- Exceptional Strength and Durability: Ash wood is renowned for its high tensile strength and resistance to impact. This means dowels made from ash can withstand significant force without breaking or bending. This is crucial for joints that will experience stress, like in furniture legs or structural supports. You can find detailed wood property comparisons on resources like The Wood Database, which often highlight ash’s robust nature.

- Good Shock Resistance: If your project involves any kind of movement or potential impact, ash’s ability to absorb shock is a huge advantage. This makes ash dowels ideal for tool handles, sporting equipment components, or even children’s furniture where durability is key.

- Straight Grain and Workability: While strong, ash wood generally has a straight grain pattern that makes it relatively easy to work with. It cuts cleanly, sands smoothly, and accepts finishes well. This ensures that when you’re drilling holes for your dowels or fitting them, you’ll have a much smoother experience.

- Attractive Appearance: Ash wood has a natural beauty. Its grain can range from straight to wavy or irregular, and it typically has a light color with distinct growth rings. This makes ash dowels a great choice when they might be visible in the final project, adding a touch of natural elegance.

- Resilience to Splitting: Compared to some other hardwoods, ash is less prone to splitting, especially when fasteners are used. This is a significant benefit when driving dowels into place or when they are used in scenarios where they might be bumped or stressed.

These qualities combine to make ash wood dowels a reliable and high-performing choice for anyone looking to build strong, beautiful, and lasting woodworking projects. Whether you’re a beginner or have been crafting for years, understanding these benefits will help you make informed material choices.

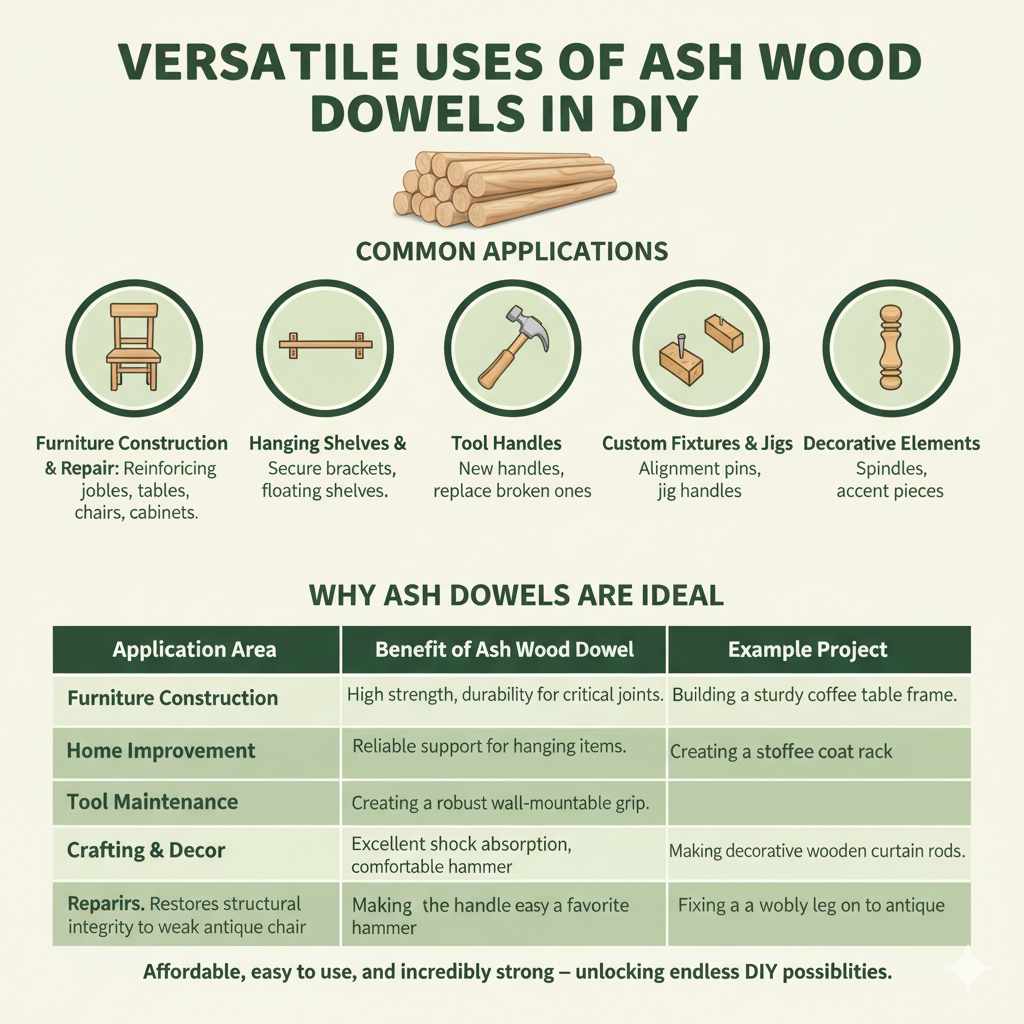

Applications of Ash Wood Dowels in DIY Projects

Ash wood dowels are incredibly versatile and can be used in countless DIY projects. Their strength and reliability make them suitable for both structural and decorative purposes. Here are some of the most common and effective ways you can use ash wood dowels:

- Furniture Construction and Repair: This is perhaps the most common use. Ash dowels are perfect for reinforcing joints in bookcases, tables, chairs, and cabinets. They are excellent for reattaching loose table legs, reinforcing chair stretchers, or adding strength to shelf supports.

- Hanging Shelves and Racks: Need to create robust shelving? Ash dowels can be used to securely attach shelf brackets to wall studs or to create the internal structure for floating shelves.

- Tool Handles and Replacements: From hammers to chisels, ash is a traditional material for tool handles due to its shock absorption. You can use ash dowels to create new handles or replace broken ones on your favorite tools.

- Creating Custom Fixtures and Jigs: For any woodworking enthusiast, custom jigs can make projects much easier. Ash dowels are great for creating alignment pins or handles for your homemade woodworking jigs.

- Decorative Elements: The natural beauty of ash means dowels can be used decoratively. They can form part of the design in modern furniture, be turned into decorative spindles, or used as accent pieces.

- Hanging Heavy Items: Need to hang a quilt, a heavy mirror, or even a sturdy curtain rod? A strong ash wood dowel can provide the necessary support and stability.

- Rod or Clamping Applications: They can serve as simple rods for various purposes or be incorporated into clamping systems for specific projects.

The simplicity of a dowel, combined with the strength of ash, opens up a world of possibilities for both repair and new creation. Their affordability and ease of use make them a beginner-friendly yet highly effective woodworking solution.

| Application Area | Benefit of Ash Wood Dowel | Example Project |

|---|---|---|

| Furniture Construction | High strength, durability for critical joints. | Building a sturdy coffee table frame. |

| Home Improvement | Reliable support for hanging items. | Creating a robust wall-mounted coat rack. |

| Tool Maintenance | Excellent shock absorption, comfortable grip. | Replacing the handle on a favorite hammer. |

| Crafting & Decor | Natural aesthetics, easy to shape. | Making decorative wooden curtain rods. |

| Repairs | Restores structural integrity to weak joints. | Fixing a wobbly leg on an antique chair. |

How to Use Ash Wood Dowels: A Step-by-Step Guide for Beginners

Working with ash wood dowels is straightforward, even for beginners. The key to success lies in careful measurement, precise drilling, and proper gluing. I’ll guide you through the process so you can confidently incorporate dowels into your projects.

Step 1: Planning Your Joint

Before you cut anything, decide where and how you’re going to use the dowels. This usually involves joining two pieces of wood. Mark the points where the dowel will connect the two pieces. For simple butt joints, you’ll often place two dowels for stability. For more complex joints, you might need a diagram or template.

Step 2: Selecting the Right Dowel Size

Ash wood dowels come in various diameters. The size you choose depends on the thickness of the wood you’re joining and the strength required. A general rule of thumb is that the dowel diameter should be about half to two-thirds the thickness of the thinnest piece of wood being joined. It’s always better to err on the side of slightly larger for more strength, but make sure it fits comfortably within the wood.

Step 3: Marking and Drilling Your Holes

This is the most critical step. Precision here ensures a tight, strong joint.

- Marking: Carefully measure and mark the exact center points for your dowel holes on both pieces of wood that will be joined. Use a pencil and a ruler or a marking gauge for accuracy.

- Drilling Accurately: Use a drill bit that is the same diameter as your dowel. To ensure your holes are straight and at the correct depth, use a drill guide or a drill press if you have one. If using a hand drill, attach a depth stop to your drill bit or wrap tape around it to mark the required depth.

- Depth: Drill the holes about halfway through the thickness of the dowel you plan to use. So, if using a 1-inch dowel, drill the hole about 1⁄2 inch deep. This allows enough surface area for glue and ensures the dowel doesn’t bottom out.

Pro-Tip for Alignment: If you’re drilling holes in two separate pieces that need to align perfectly, drill one set of holes, insert a dowel (or a sacrificial piece of dowel) into one hole, apply a bit of craftsman’s chalk or sawdust to the end of the dowel, and then carefully press the second piece of wood onto it. This will leave a mark showing you exactly where to drill the corresponding holes in the second piece.

Step 4: Preparing the Dowels

Once you have your ash wood dowels cut to the desired length (they should be slightly shorter than the combined depth of the two holes you drilled, allowing for glue squeeze-out), you might want to break the sharp edges slightly with sandpaper. This helps them slide in easier and prevents them from acting like wedges that could split the wood.

Step 5: Gluing and Assembly

- Apply Glue: Apply a generous amount of wood glue into both drilled holes and a thin layer on any mating surfaces of the joint.

- Insert Dowels: Insert the ash wood dowels into the holes on one of the pieces of wood.

- Join the Pieces: Bring the two pieces of wood together, ensuring the dowels engage with the corresponding holes.

- Clamp: Use clamps to hold the joint tightly together while the glue dries. Ensure there’s a little bit of glue squeezing out around the joint – this is a good sign that you have enough glue. Wipe away any excess glue with a damp cloth before it hardens.

Step 6: Curing and Finishing

Allow the glue to cure fully according to the manufacturer’s instructions (usually 24 hours for maximum strength). Once dry, you can proceed with sanding and finishing your project as usual. If the dowel ends are visible, you can sand them flush with the surface or leave them exposed for a more rustic look.

Following these steps will help you create strong, seamless joints with ash wood dowels that you can be proud of!

Tools and Materials You’ll Need

To successfully use ash wood dowels in your projects, you’ll want a few essential tools and materials. Don’t worry, they are quite common for most DIYers!

Essential Tools:

- Measuring Tape or Ruler: For precise marking of your dowel locations and lengths.

- Pencil: For marking your wood clearly.

- Drill: A corded or cordless drill is necessary for creating the holes.

- Drill Bits: You’ll need a bit that matches the diameter of your ash wood dowels.

- Drill Guide or Drill Press (Recommended): For ensuring perfectly straight holes. This is essential for strong joints.

- Depth Stop (or Tape): To control the depth of your drilled holes.

- Saw: To cut your ash wood dowels to the exact length needed. A handsaw, miter saw, or band saw will work.

- Sandpaper: To smooth the dowels and any rough edges.

- Clamps: To hold your project pieces together firmly while the glue dries.

- Hammer or Mallet (Optional): To gently tap dowels into place if they are a snug fit.

Materials:

- Ash Wood Dowels: Of course! Choose the appropriate diameter and length for your project.

- Wood Glue: A good quality wood glue is crucial for strong joints. Titebond and Gorilla Wood Glue are popular, reliable brands.

- Safety Glasses: Always protect your eyes when drilling, cutting, or sanding.

- Dust Mask: Especially important when sanding.

Having these items ready will make your doweling projects go smoothly. If you’re just starting out, a basic drill, a few bits, a tape measure, and some clamps are a great foundation.

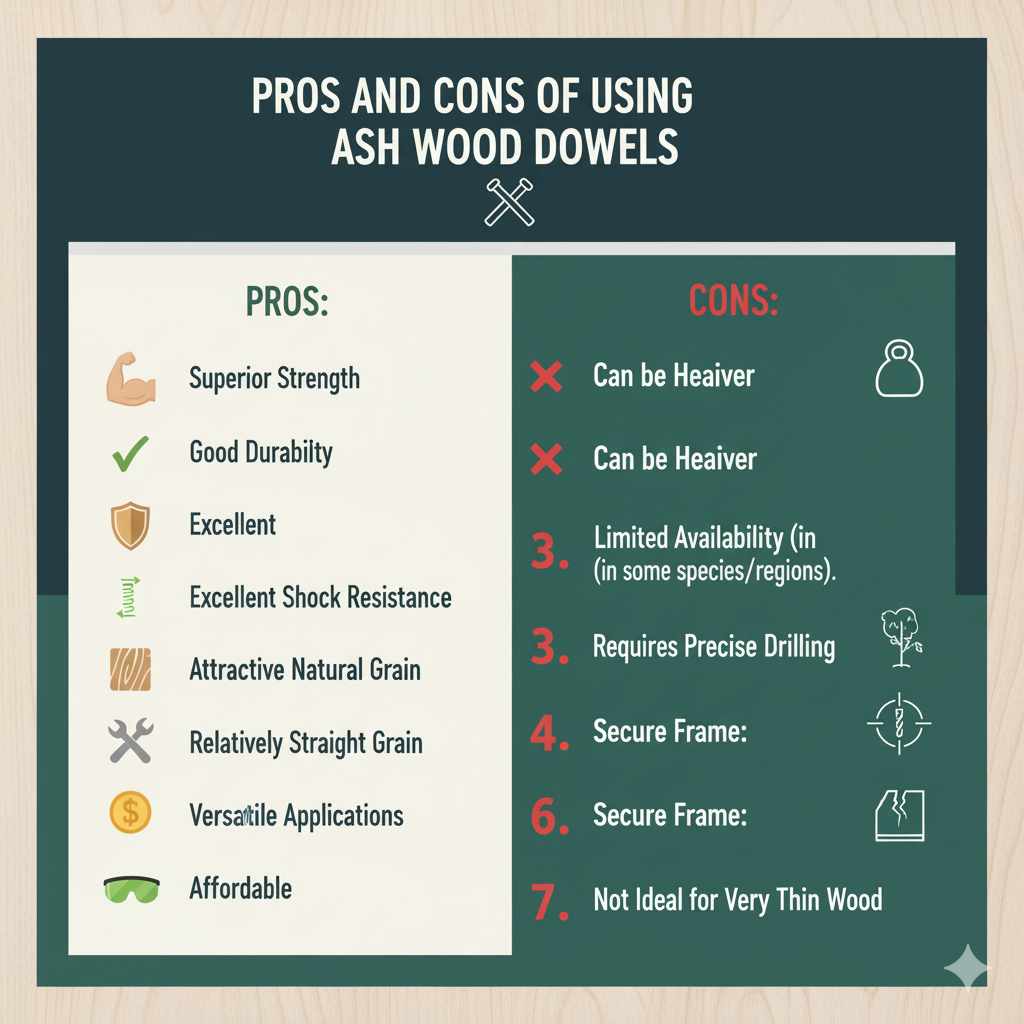

Pros and Cons of Using Ash Wood Dowels

Like any woodworking material, ash wood dowels have their advantages and disadvantages. Understanding these will help you decide if they’re the right choice for your specific needs.

Pros:

- Superior Strength: Ash is a hardwood known for its excellent strength and durability, making it ideal for structural joints.

- Good Durability: It holds up well to wear and tear, ensuring your projects last longer.

- Excellent Shock Resistance: Perfect for handles or items that might experience impacts.

- Attractive Natural Grain: Can add a visual appeal if the dowel is exposed.

- Relatively Straight Grain: Generally easy to work with and less prone to splitting than some other woods.

- Versatile Applications: Suitable for furniture, repairs, tools, and decorative elements.

- Affordable: Compared to some other hardwoods, ash is often quite budget-friendly.

Cons:

- Can be Heavier: Due to its density, ash is heavier than softer woods, which might be a consideration for very large or portable projects.

- Limited Availability (in some species/regions): While common, certain types of ash might be harder to find depending on your location, especially with concerns about the emerald ash borer impacting ash populations. For information on tree conservation, you can consult resources like the US Forest Service.

- Requires Precise Drilling: Like all doweling, success depends on accurate hole placement and depth. This can be a learning curve for beginners.

- Not Ideal for Very Thin Wood: The strength of ash might be overkill, and drilling holes for dowels could weaken very thin pieces of wood.

Overall, the pros of using ash wood dowels significantly outweigh the cons for most common DIY applications, especially when strength and durability are key.

Frequently Asked Questions (FAQ) About Ash Wood Dowels

Got more questions about ash wood dowels? Here are some common ones answered by your friendly woodworking mentor!

Q1: How strong is an ash wood dowel compared to other wood dowels?

Ash wood is a hardwood known for its high tensile strength and shock resistance. It’s generally stronger and more durable than softwoods like pine or poplar. While other dense hardwoods like oak can be comparable, ash often strikes a great balance between strength, weight, and workability, making it a top choice for dowels.

Q2: Can I use ash wood dowels outdoors?

Ash wood is moderately durable but not naturally resistant to decay or insects like some other woods (e.g., cedar or redwood). For outdoor use, it’s highly recommended to use an exterior-grade sealant or finish to protect the dowels from moisture and weathering.

Q3: What’s the best way to cut ash wood dowels to length?

For clean, accurate cuts, a miter saw or a band saw is ideal. If you don’t have power tools, a sharp handsaw and a miter box will work well. Always ensure your saw blade is sharp to prevent splintering the wood.

Q4: My dowel holes aren’t lining up perfectly. What can I do?

This is a common beginner challenge! For future projects, invest in a drill guide or a drill press for straighter holes. For a quick fix on a current project with slightly misaligned holes, you can carefully enlarge one of the holes slightly with a doweling jig or by hand, working slowly and checking the fit often. Sometimes, a little bit of sanding on the dowel itself can also help it seat properly.

Q5: Do I need to pre-drill holes for ash wood dowels?

Yes, absolutely. Dowels are used to reinforce joints by fitting into pre-drilled holes in the mating pieces of wood. You never drive a dowel directly into solid wood without any hole; it will almost certainly split the wood.