Brushless Drill vs Non Brushless: Essential Power

Brushless drill vs non-brushless drill: Brushless drills offer more power, longer battery life, and better durability thanks to their efficient motor design, making them a superior choice for most DIYers and professionals tackling tougher jobs.

Figuring out the right power tool can feel like navigating a maze, especially when you’re just starting out. You’ve probably seen “brushless” pop up on drill descriptions and wondered what it actually means. Does it really make a difference? Absolutely! Choosing between a brushless drill and a non-brushless (often called brushed) one can impact your projects, from how long your battery lasts to how easily you can power through tough materials. Don’t worry, we’ll break down exactly what these terms mean and what’s best for your needs, making your next tool purchase a confident one.

Understanding the Heart of the Drill: Motors

At the core of any power drill is its motor. This is what spins the chuck and drives the bits to drill holes or turn screws. The way this motor is built is the key difference between brushless and brushed drills.

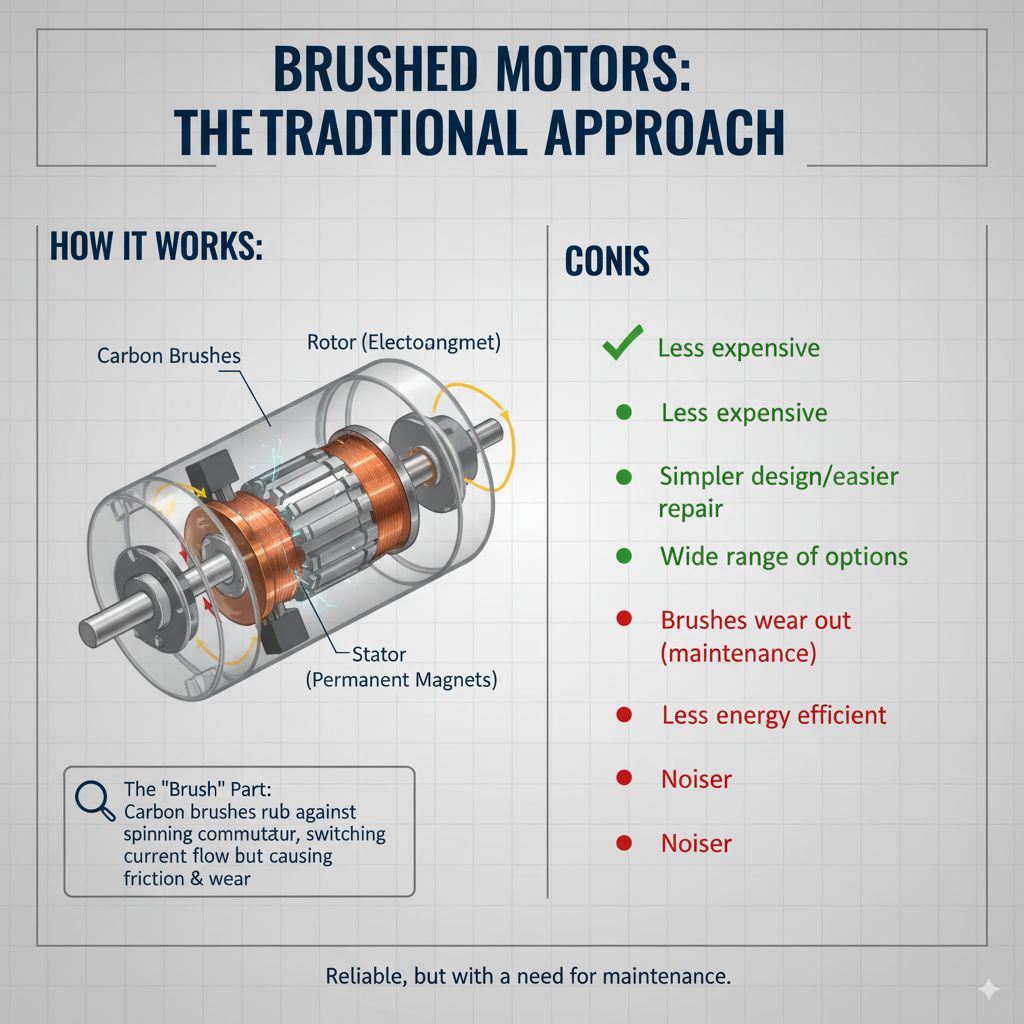

Brushed Motors: The Traditional Approach

Think of brushed motors as the reliable workhorses that have been around for a long time. They get their power transmitted through a clever system of carbon brushes and a commutator.

How it works: The motor has an electromagnet (rotor) that spins inside a stationary set of magnets (stator). To keep the rotor spinning, the electrical current needs to switch direction as it spins. This is where the brushes and commutator come in. The brushes, made of carbon, physically rub against a spinning metal part called the commutator on the rotor. As the rotor turns, the brushes make contact with different sections of the commutator, precisely switching the current flow.

The “Brush” Part: These carbon brushes are the namesake. They are essential for the motor’s function but also wear down over time.

Pros of Brushed Motors:

Generally less expensive upfront.

Simpler design, which can sometimes make them easier to repair for those with electrical knowledge.

Historically, they’ve been the standard, so there’s a vast range of options available.

Cons of Brushed Motors:

The physical contact between brushes and the commutator creates friction. This friction leads to heat, sparks, and wear.

The brushes themselves wear down and will eventually need replacement. This means a maintenance cost and potential downtime.

Less energy efficient due to friction and heat loss.

Can be noisier due to the sparking and friction.

Brushless Motors: The Modern Upgrade

Brushless motors are a more recent innovation in power tools, and they’ve revolutionized performance. Instead of physical brushes, they use electronics to control the flow of electricity.

How it works: In a brushless motor, the magnets are on the rotor, and the electromagnets are on the stator. An electronic controller, often integrated into the drill’s circuitry, directs the power to the stator coils in the correct sequence to create the magnetic field that turns the rotor. There are no carbon brushes to wear out.

The “Brushless” Part: This means no physical contact for electrical transfer—just smart electronics managing it all.

Pros of Brushless Motors:

More Efficient: Without friction from brushes, more battery power goes directly to the motor, meaning longer runtimes on a single charge.

More Power & Torque: They can deliver more consistent power and higher torque, allowing you to tackle tougher jobs.

Longer Lifespan: No brushes to wear out means less maintenance and a longer tool life.

Less Heat: Reduced friction means less heat buildup, which is better for the motor’s longevity and for comfortable tool usage.

Quieter Operation: Generally run more quietly due to the absence of sparking and friction.

Better Control: Electronic control allows for more precise speed and torque management.

Cons of Brushless Motors:

Typically more expensive upfront.

The electronic controller can be more complex to repair if it fails, sometimes requiring replacement of the entire motor unit.

Brushless Drill vs Non-Brushless: The Key Differences

Let’s bring it all together and compare the two types side-by-side. When you’re standing in the tool aisle, this is what you need to know.

Performance and Power Output

Brushless: These drills often feel more powerful. They can maintain their speed and torque even under heavy load, like drilling into a dense piece of hardwood or driving a long screw through multiple studs. This is because the electronic controller can precisely manage power delivery, optimizing it for the task at hand.

Brushed: While capable, brushed drills can struggle more under heavy load. You might notice a drop in speed or power. They can also be more prone to overheating during extended, heavy-duty use.

Battery Life and Efficiency

Brushless: This is a major advantage. Because there’s no energy lost to friction and heat from brushes, brushless motors are significantly more energy-efficient. This translates directly to longer runtimes on a single battery charge. You can get more holes drilled or screws driven before needing to swap batteries or recharge.

Brushed: Brushed motors lose a noticeable amount of energy as heat and through friction. Consequently, they consume battery power faster, leading to shorter runtimes compared to their brushless counterparts, especially under demanding use.

Durability and Lifespan

Brushless: The absence of wearing parts like carbon brushes means brushless motors are inherently more durable. They are less prone to overheating, which is a common cause of motor failure. This typically results in a longer overall lifespan for the tool.

Brushed: The constant friction and potential for sparking from the brushes can cause wear over time. The brushes will eventually need to be replaced, and consistent overheating can shorten the motor’s life.

Maintenance and Longevity

Brushless: Generally maintenance-free. Since there are no brushes to replace, you can expect fewer trips back to the store for parts or service related to the motor itself.

Brushed: Requires occasional maintenance. The carbon brushes wear down and will eventually need to be replaced. For a DIYer, this might mean a trip to a hardware store and a bit of tinkering, or for a professional, it means unplanned downtime on a job.

Cost

Brushless: The advanced technology comes at a higher price point. Brushless drills are usually more expensive than brushed models with similar features.

Brushed: They are the more budget-friendly option. If you’re on a tight budget or only use a drill for very light, occasional tasks, a brushed drill can be a perfectly adequate and cost-effective choice.

Weight and Size

This can vary greatly between specific models, but brushless motors can sometimes be designed to be more compact given their efficiency. However, the electronics and battery technology can also influence overall weight and balance. It’s best to hold a drill in your hand to assess comfort and weight for your specific needs.

Comparing Performance: A Table View

To make the differences even clearer, let’s look at them in a table.

| Feature | Brushless Drill | Brushed Drill |

|---|---|---|

| Motor Type | Electronic speed control, no physical brushes. | Carbon brushes physically contact a commutator. |

| Power & Torque | Higher, more consistent power, especially under load. | Good for basic tasks, can drop under heavy load. |

| Battery Efficiency | Up to 50% more runtime per charge. | Shorter runtime due to friction/heat loss. |

| Durability | More durable, less prone to overheating. | Brushes wear out; can overheat. |

| Maintenance | Virtually maintenance-free. | Brushes need eventual replacement. |

| Lifespan | Generally longer lifespan. | Potentially shorter due to wear and tear. |

| Noise Level | Quieter. | Can be noisier due to sparking. |

| Cost | Higher upfront cost. | Lower upfront cost. |

Who Needs a Brushless Drill?

If you find yourself doing a variety of projects, from simple household fixes to more involved DIY builds, a brushless drill is likely the best investment.

The Weekend Warrior: If you enjoy tackling home improvement projects regularly, building furniture, or any DIY that requires more than occasional screw-driving, the extra power and battery life of a brushless drill will save you time and frustration.

The Woodworker: For those who enjoy woodworking, drilling into hardwoods, or driving long fasteners, the consistent power and torque of a brushless drill are invaluable. It makes tougher cuts and installations much easier.

The Professional: Tradespeople who rely on their tools daily need the durability, efficiency, and power that brushless technology offers. Downtime and battery management are critical considerations in professional settings.

Anyone Seeking Long-Term Value: While the initial cost is higher, the extended lifespan, improved performance, and reduced maintenance make a brushless drill a better value over the long haul for many users.

For more information on tool performance and electrical considerations, you can refer to resources like the U.S. Department of Energy’s Office of Energy Efficiency & Renewable Energy, which discusses electric motor efficiency in various applications, offering a broader understanding of why efficient motors matter.

Who Might Be Okay with a Brushed Drill?

A brushed drill can still be a great tool for certain situations and users.

The Occasional DIYer: If you only need a drill for very occasional tasks, like hanging a picture, assembling flat-pack furniture, or changing a light fixture once a year, a brushed drill will serve you well without breaking the bank.

The Budget-Conscious Buyer: When budget is the primary concern, a brushed drill offers a functional solution at a lower price.

Light-Duty Tasks Only: If your definition of “drilling” involves only small holes in soft materials and driving short screws, the benefits of brushless might be overkill for your needs.

Essential Features to Look For (Regardless of Motor Type)

While the motor is a huge factor, other features make a drill a joy to use.

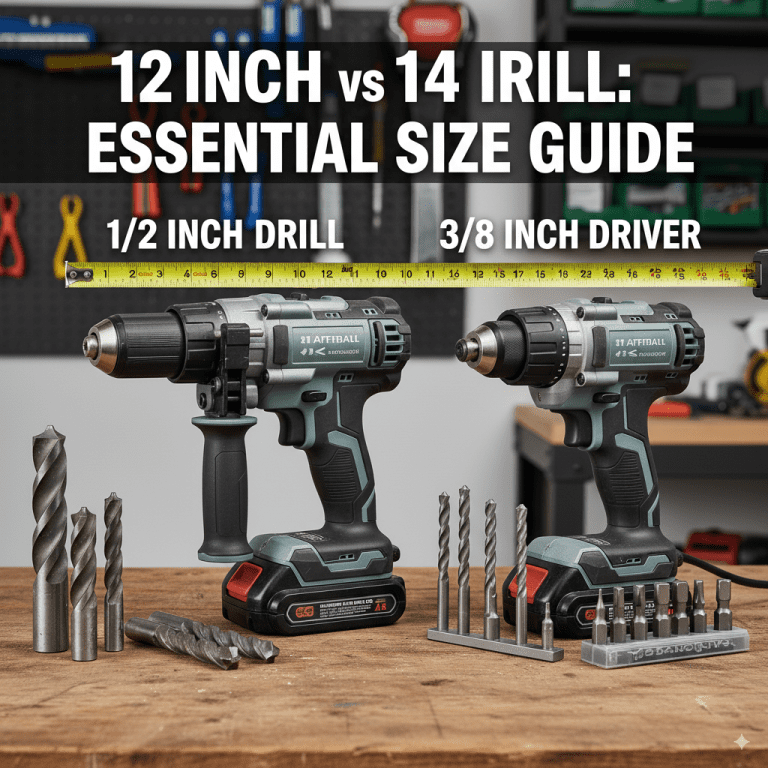

Chuck Size: Most drills have a 3/8-inch or 1/2-inch chuck. A 1/2-inch chuck can accept larger drill bits and provides a more secure grip, generally preferred for more robust tasks.

Variable Speed Trigger: This is standard on most modern drills. It allows you to control the speed by how hard you squeeze the trigger, which is crucial for precision and avoiding stripping screws or damaging materials.

Torque Settings (Clutch): Most drills have a numbered collar around the chuck. This allows you to set the maximum torque (twisting force) the drill will apply. When the screw reaches that resistance, the clutch will slip, preventing over-driving or damaging the screw head and material. This is invaluable for driving screws.

LED Light: A built-in LED light that illuminates the work area is a game-changer, especially in dimly lit spaces. Look for one that stays on for a few seconds after you release the trigger.

Ergonomics and Grip: A comfortable handle and good weight balance are essential for reducing fatigue during longer use. Try to hold the drill if possible.

Battery Platform: If you have other tools from a specific brand, sticking with that brand’s battery platform can save you money, as batteries and chargers are often interchangeable.

Getting the Most Out of Your Drill: Essential Tips

Whether you have a brushless or brushed drill, using it correctly will extend its life and improve your results.

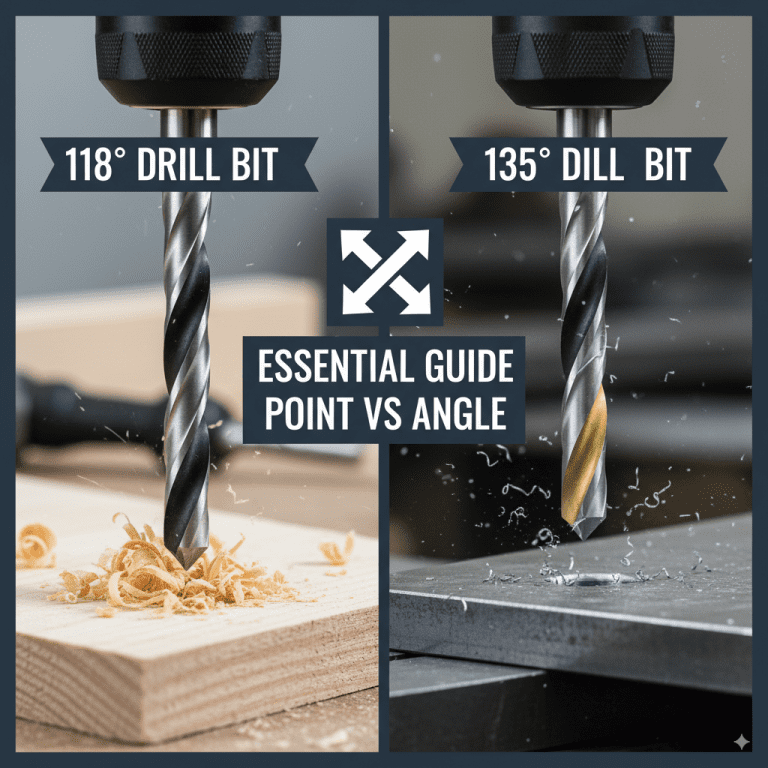

1. Use the Right Bit for the Job: Always select the correct type and size of drill bit or screwdriver bit for the material and task.

2. Set Torque Wisely: For driving screws, start with a lower torque setting and gradually increase it until the screw is snug but not stripped. This is especially important in softer woods.

3. Master the Variable Speed: Use slower speeds for starting holes, precise work, or driving screws, and higher speeds for drilling larger holes or in softer materials.

4. Drill Straight: Keep the drill, and thus the drill bit, perpendicular to the surface for clean holes and to prevent bit breakage.

5. Clear Debris: Periodically remove wood shavings or dust from the drilled hole to prevent binding.

6. Battery Care: Follow the manufacturer’s recommendations for charging and storing batteries. Avoid extreme temperatures.

Frequently Asked Questions

Here are some common questions beginner DIYers have about brushless and brushed drills.

Q1: What does “brushless” actually mean for me as a user?

For you, “brushless” means your drill will likely be more powerful, run significantly longer on a single battery charge, and last longer overall. It’s a more efficient and robust motor technology that makes tough jobs easier.

Q2: Can a brushed drill still do a good job?

Absolutely! A brushed drill is perfectly capable for many common DIY tasks like hanging shelves, assembling furniture, or drilling small- to medium-sized holes in wood or drywall. They are a great entry point into power tools.

Q3: Is a brushless drill worth the extra cost?

For most people who do more than just very occasional light DIY, yes, a brushless drill is often worth the extra investment. The improved performance, battery life, and durability provide better value over time and make projects more enjoyable.

Q4: How often will I need to replace brushes on a brushed drill?

This depends heavily on how often and how hard you use the drill. For light DIY use, brushes might last several years. For heavy professional use, they might need replacement annually or even more frequently. It’s normal wear and tear.

Q5: Are brushless drills faster than brushed drills?

They can be, but it’s more about sustained power and torque. A brushless drill can often maintain its optimal speed under load better than a brushed one, making it feel faster and more capable when you encounter resistance.

Q6: Can I upgrade my old drill by just getting a brushless battery?

No, you cannot interchange batteries between brushed and brushless drills if they are from different tool lines or if your drill is not designed to accept brushless-specific batteries. The motor technology is different, and the battery voltage/communication systems may not be compatible.

Q7: Do brushless drills get hot?

Brushless drills still generate some heat, as all motors do when working. However, they generate significantly less heat than brushed motors because there is no friction from carbon brushes. This makes them more comfortable to hold for extended periods and contributes to their longer lifespan.

Conclusion: Making the Right Choice for Your Workshop

Choosing between a brushless drill and a brushed drill doesn’t have to be complicated. Think of it this way: brushed drills are like reliable sedans – they get the job done for everyday commuting. Brushless drills are more like performance SUVs – they offer more power, handle tougher terrain with ease, and go further on a tank of gas (or a battery charge!).

For the beginner DIYer or homeowner who wants a tool that will last, perform well across a variety of tasks, and make your projects smoother and more enjoyable, a brushless drill is usually the way to go. You’ll appreciate the extended battery life during those longer weekend projects and the extra grunt when you tackle a more challenging build.

However, if your needs are very basic and your budget is tight, a well-made brushed drill can still be a fantastic starting point. The most important thing is to get a tool that fits your projects, feels comfortable in your hand, and helps you build confidence in your DIY abilities. Whichever you choose, remember to always prioritize safety, use the right accessories, and enjoy the process of creating and fixing with your own two hands! Happy building!