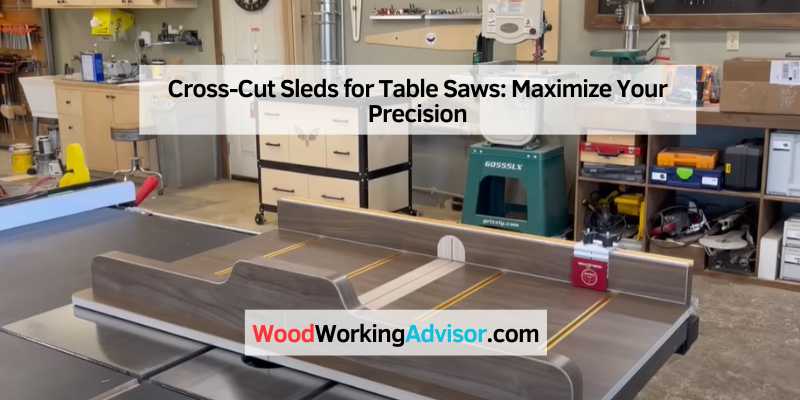

Cross-Cut Sleds for Table Saws: Maximize Your Precision

Cross-cut sleds for table saws provide precise and safe crosscuts for woodworking projects. They are essential for ensuring accurate and repeatable cuts on a table saw.

Whether you’re a professional woodworker or a hobbyist, a cross-cut sled can enhance the safety and quality of your work. By guiding the workpiece securely and allowing for controlled movement, cross-cut sleds minimize the risk of kickback and ensure clean, splinter-free cuts.

Additionally, they can be customized to accommodate various angles and sizes of workpieces, making them versatile tools in any woodworking shop. With the wide range of options available, including DIY kits and pre-made sleds, there’s a suitable choice for every woodworker’s needs and preferences.

Introduction To Cross-cut Sleds

A cross-cut sled is an essential tool for any woodworker, especially those who frequently use a table saw. It is a versatile and precise device that allows for accurate cross-cutting of wood, ensuring clean and straight edges. In this blog post, we will explore the benefits of using a cross-cut sled and discuss the role of precision in woodworking.

Benefits Of Using A Cross-cut Sled

A cross-cut sled offers several advantages over traditional methods of cross-cutting wood on a table saw. Let’s take a look at some of the benefits:

- Enhanced safety: The use of a cross-cut sled provides increased safety by offering better control and stability while cutting wood. It minimizes the risk of kickback and ensures that your hands are kept at a safe distance from the blade.

- Precision and accuracy: One of the primary advantages of a cross-cut sled is its ability to deliver precise and accurate cuts. The sled acts as a guide, allowing you to make consistent cuts at specific angles and lengths. This level of precision is crucial for projects that require tight-fitting joints or accurate measurements.

- Improved efficiency: With a cross-cut sled, you can save time and effort by eliminating the need to measure and mark each cut individually. The sled’s built-in stop blocks and measuring systems enable you to make repeatable cuts with ease.

- Reduced tear-out: Tear-out, which refers to the splintering or chipping of wood during the cutting process, is minimized when using a cross-cut sled. The sled provides support and stability to the workpiece, resulting in cleaner and smoother cuts.

- Versatility: Cross-cut sleds can be customized to fit the specific needs of your woodworking projects. You can add accessories such as hold-down clamps, featherboards, or even a miter gauge to enhance the sled’s functionality and versatility.

The Role Of Precision In Woodworking

In the world of woodworking, precision is paramount. Whether you are building furniture, cabinets, or intricate woodworking projects, achieving accurate and precise cuts is essential for a successful outcome. Precision ensures that all the components fit together seamlessly, resulting in a professional-looking final product.

Woodworkers rely on various tools and techniques to achieve precision in their work, and a cross-cut sled is undoubtedly one of the most valuable tools for this purpose. The sled’s design, combined with its ability to provide a stable cutting platform, enables woodworkers to make repeatable and accurate cuts with ease.

By using a cross-cut sled, woodworkers can elevate their craftsmanship and take their woodworking projects to the next level. The sled’s precision allows for the creation of intricate joinery, precise angles, and clean edges, ultimately leading to a superior finished product.

Whether you are a beginner or a seasoned woodworker, incorporating a cross-cut sled into your workshop is a decision that will undoubtedly enhance your woodworking experience. Stay tuned for our next blog post, where we will delve deeper into the process of building and using a cross-cut sled.

Essential Features Of Cross-cut Sleds

When it comes to woodworking, a cross-cut sled for your table saw is an essential tool that can greatly enhance the accuracy and safety of your cuts. Whether you are a professional woodworker or a DIY enthusiast, investing in a high-quality cross-cut sled is a smart decision. In this article, we will explore the essential features of cross-cut sleds that you should consider when purchasing or building one for your table saw.

Material Construction And Durability

The material construction and durability of a cross-cut sled are crucial factors to consider. A sturdy and robust sled made from high-quality materials will ensure its longevity and provide consistent performance over time. Common materials used for cross-cut sleds include plywood, MDF (Medium Density Fiberboard), and even aluminum. These materials are known for their strength and stability, making them ideal for constructing durable cross-cut sleds.

Design Considerations For Stability

Stability is another vital aspect to consider when choosing a cross-cut sled. The design of the sled should prioritize stability to prevent any unwanted movement during the cutting process. Look for sleds that feature wide runners or miter bars that fit snugly into the table saw’s miter slots. This ensures a secure and stable connection, minimizing the risk of inaccuracies or accidents. Additionally, consider sleds that have anti-slip features such as rubberized surfaces or grip-enhancing materials to further enhance stability.

Moreover, a well-designed cross-cut sled should have built-in supports or backstops to prevent the workpiece from shifting or sliding during the cut. These features provide additional stability and ensure that your cuts are precise and consistent. Some sleds may also have adjustable fences or stops that allow for repeatable cuts at specific angles or lengths.

In conclusion, when selecting a cross-cut sled for your table saw, prioritize the material construction, durability, and stability of the sled. Look for sturdy materials such as plywood or MDF, and ensure that the sled has a design that promotes stability, including wide runners or miter bars and anti-slip features. By considering these essential features, you can choose a cross-cut sled that will greatly enhance the accuracy and safety of your table saw cuts.

Setting Up Your Cross-cut Sled

Setting up your cross-cut sled is a crucial step in ensuring its optimal performance and accuracy. Proper assembly and adjustments are key to achieving precise and safe cuts on your table saw.

Step-by-step Assembly Guide

Assembling your cross-cut sled requires attention to detail and precision. Here’s a step-by-step guide to help you set it up:

- Start by attaching the base of the sled to the runners, ensuring a snug fit.

- Secure the fence perpendicular to the saw blade, using a square to verify the alignment.

- Install the stop block to control the length of your cuts, adjusting it to your desired measurements.

- Double-check all connections and ensure everything is securely fastened before using the sled.

Adjustments For Optimal Performance

After assembling the cross-cut sled, it’s essential to make adjustments for optimal performance. Here are some key adjustments to consider:

- Fence alignment: Ensure the fence is perfectly square to the saw blade to prevent inaccuracies in your cuts.

- Smooth gliding: Lubricate the runners for smooth movement and reduced friction during operation.

- Zero-clearance support: Add a zero-clearance fence to minimize tear-out and enhance safety during cuts.

- Calibration: Regularly check and calibrate the sled to maintain accuracy and safety.

Safety Measures When Using Cross-cut Sleds

Cross-cut sleds are invaluable tools for making precise and safe cuts on a table saw. However, it’s crucial to adhere to specific safety measures when using cross-cut sleds to prevent accidents and ensure a secure working environment.

Proper Hand Placement And Technique

When using a cross-cut sled, proper hand placement and technique are essential for safety. Keep your hands a safe distance from the blade and use a push stick or push block to guide the material through the cut, ensuring your hands remain clear of the blade at all times.

Utilizing Safety Accessories

Utilizing safety accessories such as a blade guard and a riving knife can significantly reduce the risk of kickback and other potential hazards. Always ensure that these safety accessories are properly installed and adjusted before making any cuts with the cross-cut sled.

Maximizing Accuracy With Cross-cut Sleds

Cross-cut sleds are an essential tool for table saws that allow woodworkers to make accurate cuts safely and efficiently. With the right calibration and fine-tuning, cross-cut sleds can help maximize accuracy and minimize mistakes. Here are some tips for getting the most out of your cross-cut sled:

Calibration Tips For Precise Cuts

Before you start cutting, it’s important to calibrate your cross-cut sled to ensure precise cuts. Here are a few calibration tips:

- Check that your blade is square to the table saw’s miter slot by using a combination square.

- Make sure your sled’s fence is square to the blade by using a framing square.

- Check that your sled’s runners fit snugly in the miter slot to prevent any wiggle or wobble.

- Use a dial indicator to fine-tune the fence’s position and ensure it’s parallel to the blade.

Fine-tuning For Squareness And Alignment

Once your sled is calibrated, you can fine-tune it for squareness and alignment. This is important to ensure that your cuts are accurate and consistent. Here are some tips:

- Use a square to check that your sled’s fence is 90 degrees to the table saw’s blade.

- Check that your sled’s fence is parallel to the blade by using a dial indicator.

- Ensure that your sled’s runners are parallel to each other and fit snugly in the miter slot.

- Check that your sled’s stop block is square to the fence and the blade.

By following these calibration and fine-tuning tips, you can maximize the accuracy of your cross-cut sled and make precise cuts with ease.

Advanced Techniques And Tips

Discover advanced techniques and tips for using cross-cut sleds with table saws. Maximize the accuracy and safety of your cuts with these innovative tools, ensuring a smooth and precise woodworking experience. Improve your woodworking skills with the help of these cross-cut sleds for table saws.

Making Repetitive Cuts With Stop Blocks

One of the most useful techniques for cross-cut sleds is to make repetitive cuts with stop blocks. This technique involves setting up a stop block at a specific distance from the blade and then sliding the workpiece against it to make the cut. By doing this, you can ensure that each cut is the same length and the work is done quickly and efficiently.

To set up a stop block, measure the distance from the blade to the desired cut and clamp the block in place on the sled. Make sure that the stop block is securely fastened and that the workpiece is held tightly against it during the cut. For even more precision, you can use a micro-adjustable stop block to make small adjustments to the cutting distance.

Handling Small Parts Safely

When working with small parts on a cross-cut sled, safety is of utmost importance. One way to ensure safety is to use a hold-down clamp to keep the workpiece in place during the cut. This helps prevent the workpiece from shifting or flying off the sled, which can cause injury or damage to the saw.

Another technique for handling small parts is to use a sacrificial fence. This is a separate piece of wood that is clamped onto the sled and acts as a barrier between the blade and the workpiece. By using a sacrificial fence, you can prevent the blade from accidentally cutting into the sled or workpiece, which can ruin both.

Cross-cut sleds for table saws are an essential tool for any woodworker. By using the advanced techniques and tips outlined in this article, you can make precise cuts quickly and safely. Whether you’re working on a small project or a large one, a cross-cut sled can help you achieve the accuracy and efficiency you need to get the job done right.

Cross-cut sleds are indispensable tools for achieving precision and safety when making crosscuts on a table saw. When it comes to acquiring a cross-cut sled, woodworkers have two primary options: building their own DIY sled or purchasing a commercial model. Each approach has its own set of advantages and drawbacks that should be carefully considered before making a decision.

Building Your Own Sled: Pros And Cons

Opting to construct your own cross-cut sled provides several benefits, including:

- Customization: Tailor the sled to fit the specific dimensions and requirements of your table saw.

- Cost-effectiveness: Building a DIY sled can be more budget-friendly, especially if you already have suitable materials on hand.

- Learning experience: Constructing your own sled can be a valuable learning opportunity, allowing you to develop your woodworking skills.

However, there are also potential drawbacks to building your own sled:

- Time-consuming: Crafting a high-quality sled from scratch may require a significant time investment.

- Skills required: Building a precise and effective sled demands a certain level of woodworking proficiency and attention to detail.

- Tools and materials: Acquiring the necessary tools and materials, if not already available, could add to the overall cost and effort.

Comparing Popular Models On The Market

For those who prefer the convenience of a ready-made solution, there is a wide array of commercial cross-cut sleds available on the market, each with its own features and benefits:

| Model | Price | Features |

|---|---|---|

| Rockler CrossCut Sled | $191.98 – $250 | Drop-Off Platform, Accurate, Easy to set up |

| Table Saw Crosscut Sled | $89.78 | Free shipping, Easy to use, Well made |

| Incra Miter Sled Miter Express | $179.99 | Accurate, Easy to set up, Well made |

On the other hand, DIY enthusiasts may prefer to explore options such as:

- DIY Crosscut Table Saw Sled Kit with a Specific Guide Booklet

- Crosscut Sled Plans – Build Plans /Table Saw Sled

- POWERTEC Crosscut Sled Kit for Table Saw Small Parts

Ultimately, the choice between DIY and commercial cross-cut sleds depends on individual preferences, skill level, and available resources. Whether you decide to build your own or invest in a pre-made sled, the key is to ensure that it meets your specific woodworking needs and enhances the accuracy and safety of your table saw operations.

Maintenance And Longevity

Cross-cut sleds are essential accessories for table saws, providing stability and precision for various woodworking projects. To ensure their optimal performance and longevity, it’s crucial to prioritize routine maintenance and timely component replacements.

Routine Care For Lasting Use

Proper maintenance is key to extending the lifespan of your cross-cut sled. Here are some essential maintenance tips to ensure lasting use:

- Regularly clean the sled to remove sawdust and debris that can affect its performance.

- Inspect the runners and ensure they are clean, smooth, and free from any damage.

- Apply a lubricant to the sled’s runners to minimize friction and promote smooth operation.

- Check the squareness of the sled’s fence to maintain accuracy in cross-cutting operations.

- Inspect the sled’s components for signs of wear and tear, and address any issues promptly.

When To Replace Components

While routine maintenance can significantly prolong the lifespan of your cross-cut sled, certain components may eventually require replacement. Knowing when to replace these parts is crucial for ensuring the sled’s continued effectiveness. Here are the key components to monitor for potential replacement:

- Runners: If the runners show signs of excessive wear, such as deep grooves or unevenness, consider replacing them to maintain smooth movement along the table saw’s miter slots.

- Fence: A warped or damaged fence can compromise the sled’s accuracy. Replace the fence if it no longer maintains perfect squareness with the saw blade.

- Sled Base: Any structural damage or weakening of the sled’s base can compromise its stability. Replace the base if it shows signs of deterioration.

- Hardware: Check all nuts, bolts, and fasteners for signs of corrosion or damage. Replace any compromised hardware to ensure the sled’s structural integrity.

Accessories And Upgrades

When it comes to cross-cut sleds for table saws, there are a variety of accessories and upgrades available to enhance their functionality and versatility. These add-ons can help you customize your sled to meet specific project requirements and ensure accurate and safe cuts. Whether you’re looking to improve precision, efficiency, or overall performance, investing in the right accessories can take your cross-cut sled to the next level.

Enhancing Your Sled With Add-ons

If you want to expand the capabilities of your cross-cut sled, there are several add-ons you can consider. These accessories are designed to provide additional features and functionalities that can make your woodworking tasks easier and more efficient. Here are some popular add-ons:

- Hold-down clamps: Adding hold-down clamps to your sled can help secure the workpiece firmly in place, preventing any movement during the cutting process. This ensures greater accuracy and safety.

- Stop blocks: Stop blocks are useful for repetitive cuts, allowing you to set consistent lengths without the need for measuring each time. They provide precise and repeatable results, saving you time and effort.

- Measurement systems: Installing a measurement system, such as a tape measure or a digital readout, on your sled can help you achieve precise and consistent cuts. This eliminates the need for manual measurement and reduces the chances of errors.

- Sled extensions: Sled extensions are useful when working with large or long workpieces. They provide additional support and stability, allowing you to make accurate cuts across the entire length of the workpiece.

Custom Modifications For Unique Projects

For those special projects that require unique cuts or angles, you may need to make custom modifications to your cross-cut sled. These modifications can be tailored specifically to the requirements of your project, ensuring that you achieve the desired results. Here are some examples:

- Angle cutting jigs: If your project involves angled cuts, you can create custom jigs that attach to your sled to guide the workpiece at the desired angle. This allows you to achieve precise and accurate angled cuts with ease.

- Specialized fences: Depending on the shape or size of your workpiece, you may need to modify the fence on your sled. By adding adjustable or custom-shaped fences, you can securely hold the workpiece in position and achieve accurate cuts.

- Zero-clearance inserts: To minimize tear-out and splintering, you can create zero-clearance inserts for your sled. These inserts are custom-made to match the width of your saw blade, providing support around the cutting area and reducing the risk of tear-out.

With these accessories and custom modifications, you can transform your cross-cut sled into a versatile and efficient tool that meets your specific woodworking needs. Whether you’re a professional woodworker or a DIY enthusiast, investing in these upgrades can greatly enhance the performance and functionality of your table saw sled.

Real-world Applications

A cross-cut sled is an essential tool for any woodworking enthusiast or professional. Its versatility and precision make it invaluable for various applications in the workshop. Let’s explore some case studies of cross-cut sled use and gather feedback from the woodworking community.

Case Studies Of Cross-cut Sled Use

1. Improved Safety: Woodworkers who have incorporated a cross-cut sled into their table saw setup have reported a significant improvement in safety. The sled allows for precise control over the workpiece, reducing the risk of kickback and accidental injuries.

2. Accurate and Repeatable Cuts: One of the main advantages of using a cross-cut sled is its ability to consistently produce accurate and repeatable cuts. Woodworkers can rely on the sled’s fence and stop block to ensure precise measurements and angles for every cut.

3. Enhanced Efficiency: By utilizing a cross-cut sled, woodworkers can streamline their workflow and complete projects more efficiently. The sled eliminates the need for constant readjustment and repositioning of the workpiece, saving valuable time and effort.

Feedback From The Woodworking Community

Woodworkers from around the world have shared their experiences with cross-cut sleds and the positive impact they have had on their projects. Here are some testimonials:

- “The cross-cut sled has revolutionized my woodworking. I can now make precise cuts with ease, ensuring the highest quality in my projects.” – John D.

- “I was amazed at how much safer I felt using a cross-cut sled. It provides excellent control and eliminates the fear of kickback. I highly recommend it to all woodworkers.” – Sarah M.

- “The accuracy achieved with a cross-cut sled is unmatched. It has greatly improved the overall quality of my work, and my clients have noticed the difference.” – Michael W.

Woodworkers of all skill levels have embraced the cross-cut sled for its versatility, safety, and precision. Whether you’re a hobbyist or a professional, incorporating a cross-cut sled into your table saw setup can elevate your woodworking projects to the next level.

Frequently Asked Questions

What Is The Best Material For A Table Saw Crosscut Sled?

The best material for a table saw crosscut sled is usually a high-quality plywood or MDF board, as they are stable, durable, and provide a smooth surface for the sled to slide on. It’s important to choose a material that won’t warp or twist over time and can withstand the pressure of the saw blade.

Using hardwood can also be an option for a more durable sled, but it can be more expensive.

How Big Should A Table Saw Crosscut Sled Be?

A table saw crosscut sled should be big enough to accommodate the largest workpiece you plan to cut. It should extend beyond the blade on both sides to provide stability and support for the material.

Why Use A Crosscut Sled For Table Saw?

A crosscut sled for a table saw helps make precise and safe crosscuts. It provides stability and reduces the risk of kickback.

Can You Cross Cut On A Table Saw?

Yes, you can cross cut on a table saw. However, it is recommended to use a cross cut sled for safety and accuracy. A cross cut sled is a jig that slides on the table saw and holds the workpiece perpendicular to the blade, making it easier and safer to cut.

You can purchase pre-made cross cut sleds or make your own using plans or kits.

Conclusion

Cross-cut sleds for table saws are an essential tool for any woodworker looking to make precise and accurate cuts. With a variety of options available on the market, it’s important to choose a sled that fits your specific needs and budget.

Whether you opt for a ready-made sled or decide to build your own, the benefits of using a cross-cut sled are clear: safer operation, increased accuracy, and improved efficiency. So why wait? Invest in a cross-cut sled and take your woodworking to the next level.