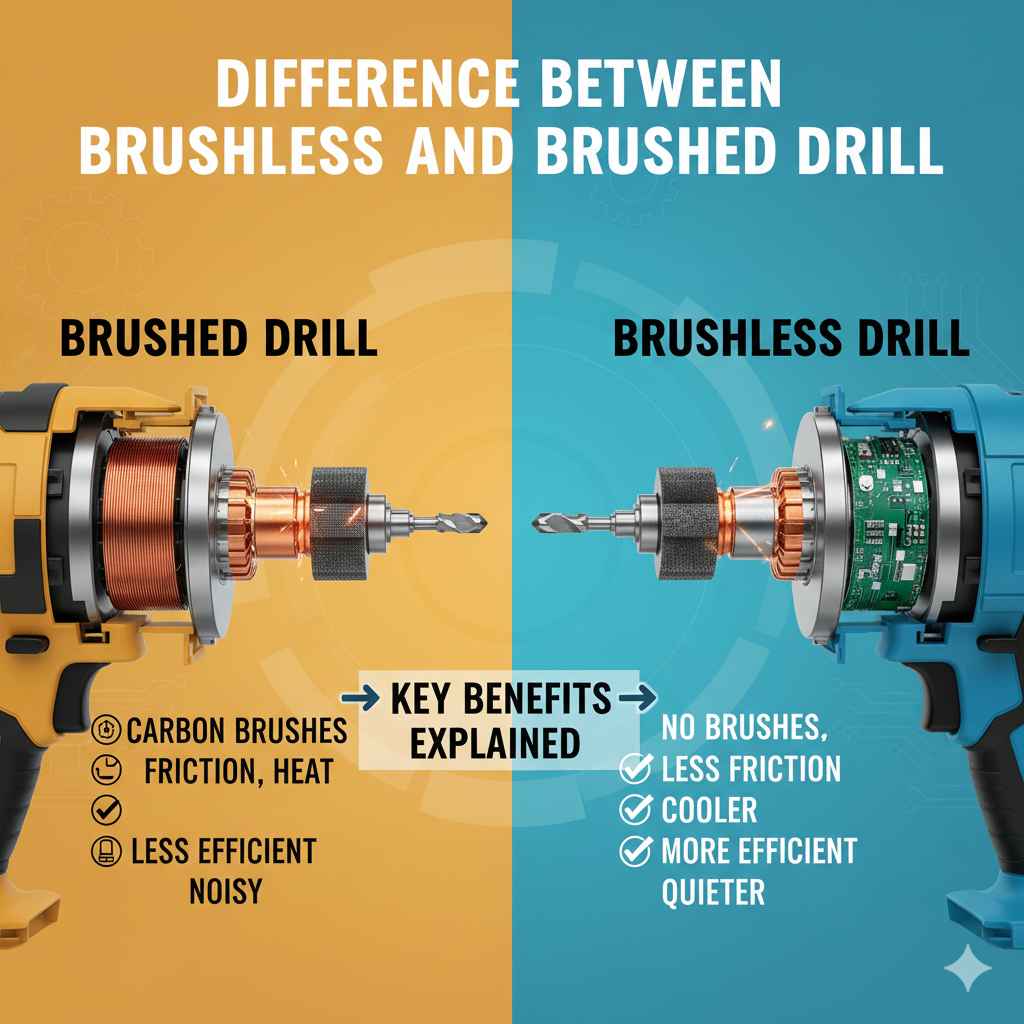

Difference between Brushless And Brushed Drill: Key Benefits Explained

When it comes to choosing the right drill for your projects, understanding the difference between a brushless and a brushed drill can make all the difference. You might be wondering which one will give you better power, longer life, or more efficiency.

This guide will clear up the confusion and help you make a smart choice that fits your needs. Keep reading, and by the end, you’ll know exactly which drill is the best match for your work and budget.

Brushless Drill Basics

Brushless drills have changed the way people work with power tools. They use a different motor type than traditional drills. This type makes them more efficient and longer lasting. Understanding how brushless drills work helps choose the right tool for your tasks.

These drills do not use brushes to transfer electricity. This simple change brings many benefits. It affects power, weight, and tool life. Here is a closer look at brushless drill basics.

How Brushless Motors Work

Brushless motors use magnets and electronic controllers. They replace the brushes found in older motors. The electronic controller sends power to the motor coils. This creates a magnetic field that spins the drill’s rotor.

No physical contact happens inside the motor. This reduces friction and heat. Less heat means the motor runs cooler and lasts longer. The system adjusts power based on what the drill needs. This improves battery life and performance.

Advantages Of Brushless Design

Brushless drills offer many advantages over brushed models. They run more quietly and generate less heat. The motor parts wear out slower. This means less maintenance and longer tool life.

The design also makes the drill lighter. Users can work longer without feeling tired. Battery life improves because the motor uses power more efficiently. This saves time and money on charging.

Brushed Drill Essentials

Brushed drills are a common choice for many DIYers and professionals. These drills use a traditional motor design that has been around for decades. Understanding their basics helps in choosing the right tool for your tasks.

They offer reliable performance for simple drilling and driving jobs. Their design is straightforward, making them easier to repair and maintain. Let’s explore what makes brushed drills unique.

Mechanics Of Brushed Motors

Brushed motors use carbon brushes to deliver electricity. These brushes press against the spinning part called the commutator. This contact creates friction, which causes some wear over time.

The motor’s spinning action powers the drill bit. The brushes help switch the electric current’s direction inside the motor. This process keeps the motor running smoothly.

Common Features Of Brushed Drills

Brushed drills usually have a simpler and cheaper design. They come with a visible motor part that needs occasional brush replacement. These drills tend to be heavier than brushless models.

They offer good torque and speed for everyday jobs. Brushed drills often have basic speed control and variable torque settings. Many users prefer them for their straightforward use and lower price.

Performance Comparison

Performance is a key factor when choosing between brushless and brushed drills. Both types have unique strengths and limitations. Understanding how they compare helps you pick the right drill for your needs.

We will compare power and efficiency, durability and maintenance, plus noise and heat levels.

Power And Efficiency

Brushless drills offer better power output. They use electronic controls to deliver consistent torque. This means they perform well under heavy loads. Brushed drills lose some power due to friction inside the motor. They also use more battery energy, which reduces runtime. Brushless models run longer on a single charge. They convert battery power into work more efficiently.

Durability And Maintenance

Brushless drills last longer. They have fewer moving parts inside the motor. This reduces wear and tear over time. Brushed drills have carbon brushes that wear down. These brushes need regular replacement to keep the drill working well. Maintenance costs can add up for brushed drills. Brushless drills need less care and fewer repairs.

Noise And Heat Levels

Brushless drills run quieter than brushed drills. The lack of brushes reduces friction noise. They also produce less heat during use. Cooler motors prevent overheating and extend the drill’s life. Brushed drills generate more noise and heat. This can cause discomfort during long tasks. Cooler and quieter operation makes brushless drills easier to handle.

Cost And Value

Choosing between brushless and brushed drills often depends on cost and value. Understanding these aspects helps you pick the right tool for your needs and budget. The price difference is clear, but long-term benefits also matter. Let’s explore both points.

Initial Price Differences

Brushed drills usually cost less upfront. They have simpler motors and fewer parts. This lowers manufacturing costs and retail prices. Brushless drills tend to be pricier due to advanced technology inside. The higher initial cost might seem like a barrier for some users. However, the price gap reflects different features and performance levels.

Long-term Investment

Brushless drills last longer and need less maintenance. They generate less heat and use energy more efficiently. This reduces wear and tear on the tool. Over time, you may save money on repairs and battery replacements. Brushed drills may wear out faster and require more upkeep. Spending more initially on a brushless drill can pay off in the long run.

Best Uses For Each Drill

Choosing the right drill depends on the task. Both brushless and brushed drills have unique strengths. Knowing their best uses helps you pick the perfect tool. This guide explains where each drill shines.

Ideal Applications For Brushless Drills

Brushless drills work well for tough jobs. They last longer and use battery power efficiently. These drills suit heavy-duty tasks like drilling into metal or hardwood. Professionals often prefer them for long work hours. They handle repeated use without overheating. Brushless drills also run quieter than brushed models.

These drills perform best in projects requiring precision and power. They fit well for construction, woodworking, and automotive repairs. Their longer battery life means fewer breaks during work. For users who want strong, reliable drills, brushless models are ideal.

When To Choose Brushed Drills

Brushed drills are simpler and cost less. They work fine for light to medium tasks. Homeowners often choose them for occasional jobs. Tasks like assembling furniture or drilling into soft wood suit brushed drills. They offer enough power for small repairs and DIY projects.

These drills need more maintenance and have shorter battery life. Still, they are good for users with a tight budget. If the drill use is rare and not heavy, brushed drills fit well. Easy to find and repair, they remain popular for basic needs.

Frequently Asked Questions

What Is The Main Difference Between Brushless And Brushed Drills?

Brushless drills use electronic controllers without brushes, offering higher efficiency and less wear. Brushed drills rely on physical brushes, causing more friction and maintenance.

Are Brushless Drills More Efficient Than Brushed Drills?

Yes, brushless drills consume less power and generate less heat. This leads to longer battery life and better performance compared to brushed drills.

Which Drill Type Lasts Longer, Brushless Or Brushed?

Brushless drills generally last longer due to reduced friction and less mechanical wear. Brushed drills have shorter lifespans because brushes wear out over time.

Do Brushless Drills Cost More Than Brushed Drills?

Typically, brushless drills are more expensive upfront due to advanced technology. However, they save money long-term with lower maintenance and better durability.

Conclusion

Choosing between brushless and brushed drills depends on your needs. Brushless drills run cooler and last longer. Brushed drills cost less and work well for light tasks. Both types have strengths and limits. Think about how often and where you will use the drill.

This helps pick the best tool for your work. Understanding these differences saves money and effort. Make your choice based on what fits your projects best. Simple and smart decisions bring better results.