DIY Drill Press Stand: Ultimate Guide for Stability & Precision

Are you tired of struggling to keep your drill steady while working on your projects? Imagine having a sturdy drill press stand that makes every hole precise and your work easier.

Building your own DIY drill press stand can save you money, give you full control over its size and features, and boost your workshop’s efficiency. You’ll discover simple steps and tips to create a reliable drill press stand that fits your needs perfectly.

Ready to upgrade your workspace and make drilling hassle-free? Keep reading, and let’s get started!

Choosing The Right Materials

Choosing the right materials for your DIY drill press stand is very important. The materials affect the stand’s strength, stability, and durability. Picking the right ones helps the stand last longer and work better. Understanding the pros and cons of different materials makes the building process easier.

Wood Vs Metal Options

Wood is easy to work with and widely available. It is lighter and can be cut with common tools. However, wood may not be as strong as metal. It can warp or crack over time.

Metal offers great strength and durability. It can hold heavy drills without bending. Metal stands last longer but need special tools to cut and weld. It is heavier and harder to move.

Essential Tools And Hardware

For wood stands, tools like saws, drills, and screwdrivers are needed. Screws, bolts, and brackets help hold parts together tightly. Sandpaper smooths rough edges.

Metal stands require a metal saw or grinder. Welding equipment may be necessary for strong joints. Nuts, bolts, and washers are important for secure assembly.

Safety Gear To Consider

Safety glasses protect eyes from dust and debris. Gloves keep hands safe from sharp edges and splinters. Hearing protection guards ears from loud tool noises.

Use masks to avoid breathing in dust or metal particles. Wear sturdy clothing to protect your body while working. Safety gear keeps you safe during the project.

Designing Your Drill Press Stand

Designing your drill press stand is an important step for a safe and efficient workspace. A good design supports your drill press firmly. It also makes your work easier and more precise. Keep the design simple but strong. Think about how you will use the stand daily. This helps you decide the best shape and size. Plan to make the stand stable and useful.

Key Dimensions And Measurements

Start by measuring your drill press carefully. Note its base size and height. The stand must fit the drill press perfectly. Add extra space for movement and adjustments. The height of the stand should match your working comfort. Too low or too high will cause strain. Keep a width that stops the stand from tipping. Measure the thickness of the wood or metal you plan to use. Strong materials help keep the stand steady.

Features For Enhanced Stability

Stability is the key to safe drilling. Use wide legs or a solid base to prevent wobbling. Consider adding cross braces to strengthen the frame. Rubber pads or non-slip feet keep the stand steady on smooth floors. Heavy materials at the bottom lower the center of gravity. Check all screws and bolts are tight. A stable stand reduces mistakes and accidents.

Incorporating Storage Solutions

Storage saves time and keeps your workspace neat. Add shelves or drawers under the drill press for tools and bits. Use small containers for screws and drill accessories. Keep everything close to your drill press for quick access. Design the storage to hold the weight of your tools. Open shelves work well for large items. Drawers protect smaller parts from dust and loss.

Building The Base

Building the base is the first and most important step in making a drill press stand. A solid base keeps the drill press steady and safe. Without a strong foundation, the drill press may wobble or tip over during use. This can cause mistakes and injuries. A good base also helps the stand last longer and work better.

Selecting A Stable Foundation

Choose a flat and strong material for the base. Wood like plywood or hardwood works well. The base should be large enough to support the drill press and stop it from tipping. Check the floor or table where you will place the stand. Make sure the base will sit evenly without rocking.

Cutting And Assembling Base Components

Cut the wood pieces to the right size. Use a saw to make clean, straight cuts. Sand the edges to avoid splinters. Fit the pieces together to form a square or rectangle base. Use wood glue on the joints for extra strength. Clamp the pieces until the glue dries. This makes the base sturdy and neat.

Securing The Base For Durability

Drill pilot holes to prevent wood from splitting. Use screws to fasten the pieces tightly. Check that all corners are square and the base is flat. Add corner braces or metal brackets for more support. Apply a finish or sealant to protect the wood from moisture. This helps the base last longer and stay strong.

Constructing The Upright Support

Constructing the upright support is a key step for a solid drill press stand. It holds the drill press steady during work. A strong and straight support prevents wobbling. This section explains how to build this part correctly.

Focus on choosing the right materials, fixing the upright to the base, and making sure it stands perfectly vertical.

Material Selection For Support

Choose wood or metal for the upright. Wood is easy to work with and strong enough for most projects. Use hardwood like oak or maple for best results. Metal offers more strength but needs special tools to cut and drill. Pick a material that fits your skills and tools.

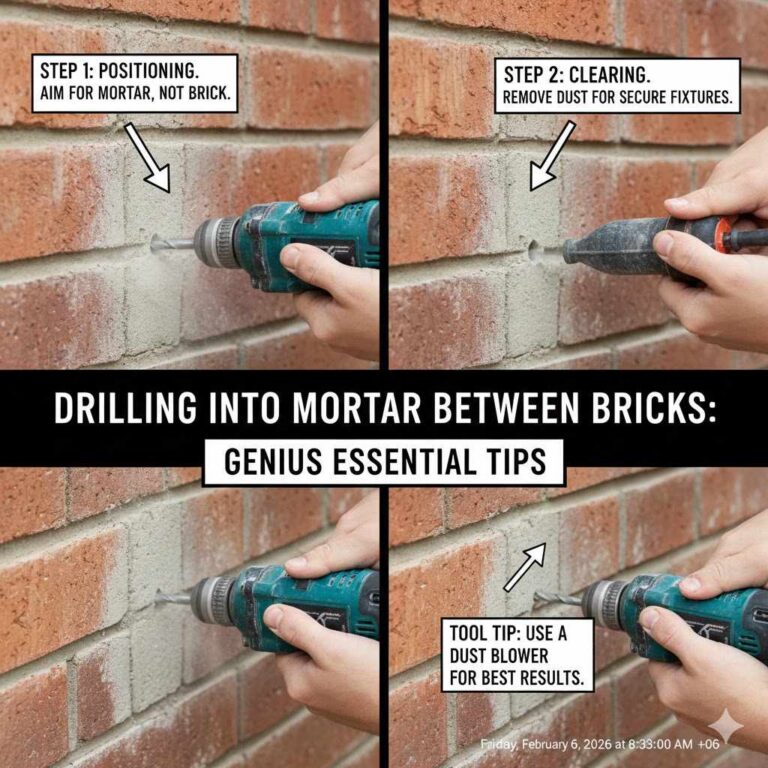

Attaching Upright To Base

Secure the upright firmly to the base. Use screws or bolts for a tight connection. Drill pilot holes to avoid splitting wood. Check that the upright stands straight before tightening all fasteners. A strong attachment keeps the drill press safe during use.

Ensuring Vertical Alignment

Use a level or square to check the upright’s position. Place the tool against the support to confirm it is perfectly vertical. Adjust the upright before final fixing if needed. Correct alignment helps in accurate drilling and prevents damage to workpieces.

Mounting The Drill Press

Mounting the drill press on your DIY stand is a key step. It keeps the tool steady and safe during use. Proper mounting helps you work with more accuracy and control. This section guides you through the process.

Preparing The Drill Press

Start by cleaning the base of the drill press. Remove dust and grease for better grip. Check the base for any damages or loose parts. Tighten screws and bolts to make sure everything is firm. Measure the drill press base to match the stand surface.

Attachment Techniques

Use bolts and nuts to secure the drill press to the stand. Drill holes in the stand surface that align with the drill press base. Place washers under the bolt heads for strong hold. Tighten the bolts evenly to avoid wobbling. Use lock washers or thread-locking glue for extra security.

Testing For Secure Fit

Once attached, test the stability of the drill press. Push and shake gently to check for movement. If it shifts, tighten the bolts more. Run the drill press at low speed to listen for vibrations. No shaking means the drill press is securely mounted and ready.

Enhancing Precision And Stability

Enhancing precision and stability is key for a DIY drill press stand. A steady stand helps keep your drill steady. This means cleaner, more accurate holes. It also makes your work safer by reducing wobble and slips. Small tweaks can make a big difference in how well your drill press performs. Focus on three main upgrades to boost stability and precision.

Adding Adjustable Clamps

Adjustable clamps hold your workpiece firmly in place. They stop movement during drilling. Clamps that can be moved allow for different sizes and shapes. This flexibility makes your stand useful for many projects. Tight clamps reduce vibrations and improve drilling accuracy. Use strong materials for the clamps to ensure durability.

Incorporating Vibration Dampeners

Vibration dampeners absorb shaking and reduce noise. These help keep the drill steady during use. You can add rubber pads or foam strips under the drill base. This cuts down on small shakes that affect precision. Less vibration also makes your workspace more comfortable. Choose dampeners that fit well and last long.

Using Leveling Feet

Leveling feet keep your drill press stand balanced on uneven floors. These feet can be adjusted to different heights. This adjustment prevents rocking and tilting while you work. A level stand ensures the drill bit goes in straight every time. Use sturdy materials to support the weight and maintain stability.

Maintenance Tips

Keeping your DIY drill press stand in good shape ensures it works well for years. Regular care prevents damage and improves safety. Simple maintenance tasks save time and money by avoiding big repairs.

Regular Inspection Points

Check all bolts and screws to keep the stand stable. Look for cracks or wear in the wood or metal parts. Ensure the drill holder moves smoothly without wobbling. Inspect the base for signs of damage or unevenness. Make sure the clamps hold the drill securely in place.

Cleaning And Lubrication

Remove dust and debris after each use with a soft cloth. Clean the moving parts to avoid buildup that slows them down. Use light oil to lubricate hinges and sliding tracks. Wipe away excess oil to prevent dirt sticking. Avoid harsh chemicals that can damage the finish.

Troubleshooting Common Issues

If the drill stand wobbles, tighten loose screws and check the base. Stiff movement may need extra lubrication or cleaning of the tracks. Strange noises often mean parts need oil or realignment. If clamps do not hold, adjust or replace worn parts. Regular checks catch problems before they get worse.

Frequently Asked Questions

What Materials Are Needed For A Diy Drill Press Stand?

You need plywood or MDF, screws, wood glue, bolts, and a drill. Optional items include clamps and a measuring tape for precision.

How Do I Ensure Stability In A Drill Press Stand?

Use thick, sturdy wood and secure all joints tightly. Adding a wide base and cross supports enhances stability.

Can I Customize The Height Of My Drill Press Stand?

Yes, measure your preferred working height before building. Adjustable legs or platforms allow easy height customization.

How Do I Attach The Drill Press To The Stand?

Use bolts and matching nuts through pre-drilled holes in the base. Ensure the drill press is firmly secured to prevent movement.

Conclusion

Building a DIY drill press stand saves space and adds stability. It helps keep your work precise and safe. You can customize it to fit your tools and needs. Using simple materials makes the project affordable and quick. This stand improves your workshop’s organization and efficiency.

Give your drill press a solid home with this easy project. Enjoy better results and smoother work every time. Try making your own stand and see the difference.