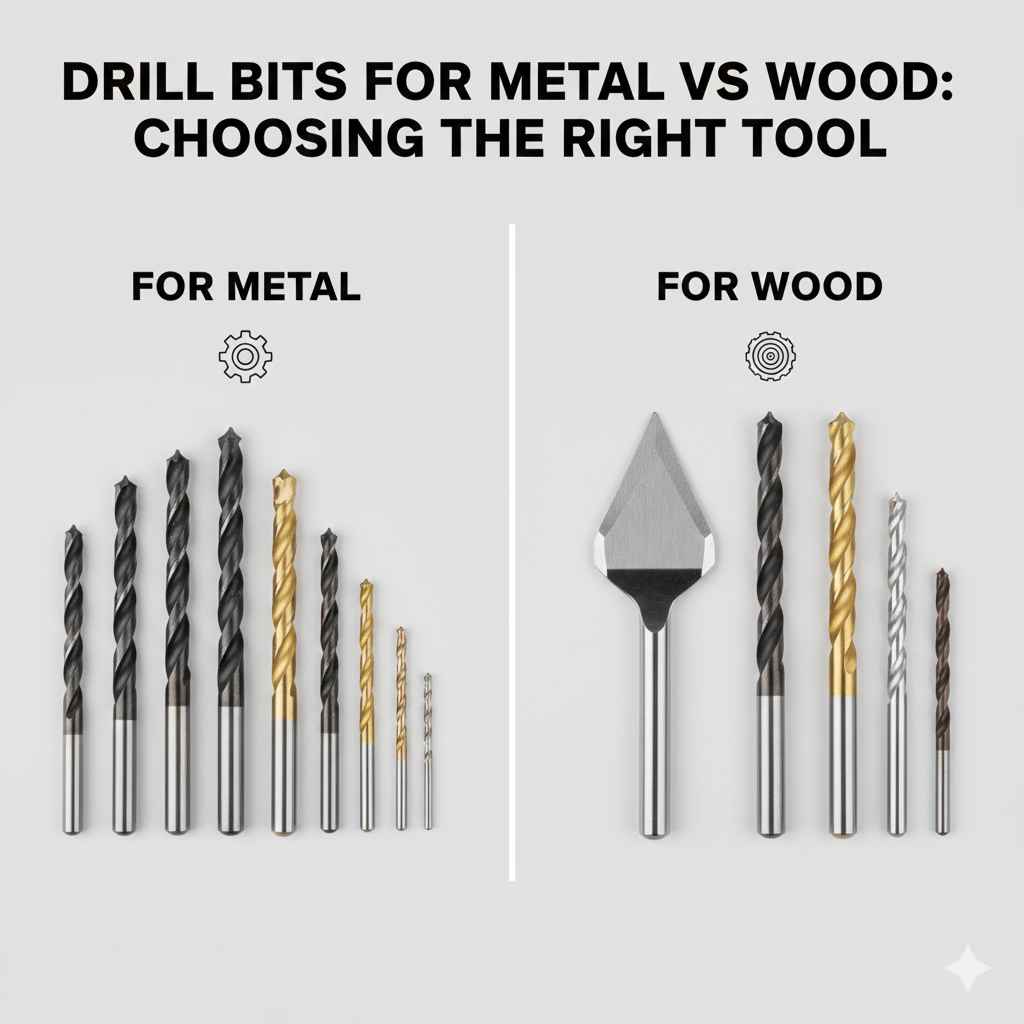

Drill Bits for Metal vs Wood: Choosing the Right Tool

Figuring out Drill Bits for Metal vs Wood: What to Use can seem tricky. Many people find it hard to know which bit to grab for the job. Don’t worry, it’s simpler than you might think. This guide will walk you through everything, making it easy to choose the right drill bit every time. We’ll explore the different types, materials, and when to use them. Let’s get started!

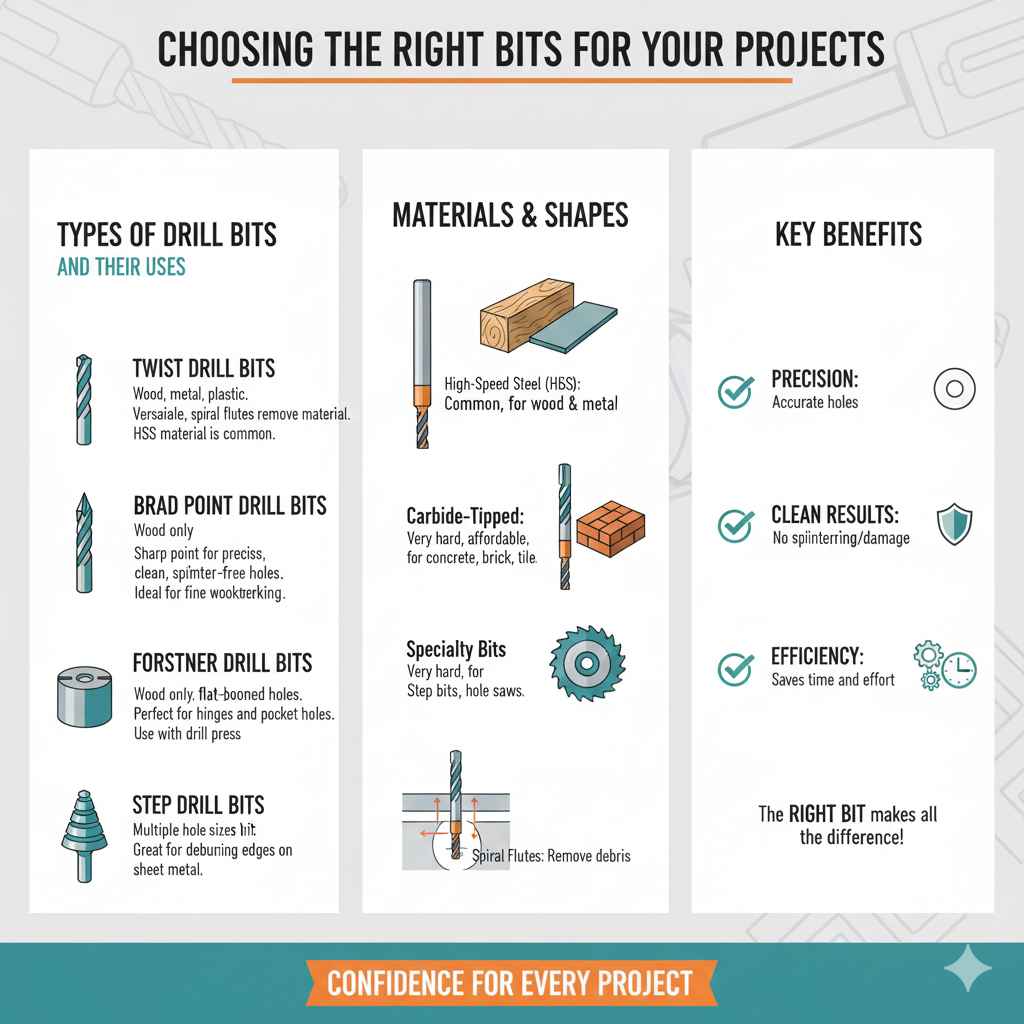

Choosing the Right Bits for Your Projects

Selecting the proper drill bit is vital for any project. Using the wrong bit can lead to poor results, damaged materials, or even injury. This section will highlight the major types of drill bits, explaining their materials, shapes, and uses. Recognizing the distinctions between bits designed for metal and wood is very important to complete any project safely and efficiently. By becoming familiar with these tools, you’ll be well-equipped to tackle various projects with confidence.

Types of Drill Bits and Their Uses

Drill bits come in a vast array of shapes and materials, each suited for different tasks. High-speed steel (HSS) bits are common for both wood and some metals, offering a balance of affordability and performance. Carbide-tipped bits excel when drilling into harder materials like tile or concrete. Specialty bits, such as step bits and hole saws, serve specific functions, like creating larger holes or precise openings. Understanding the strengths of each type ensures the best outcome for your project.

- Twist Drill Bits: These are the most common type and work well for both wood and metal. Their spiral flutes remove material efficiently. HSS is a common material.

Twist drill bits have a classic design and are used widely because of their versatility. They’re good for drilling pilot holes, but also for getting deep into thicker materials like plywood, or even aluminum and mild steel if using the right speed and applying cutting fluid. The spiral flutes help the drill to remove debris efficiently, preventing the bit from jamming and overheating. Choosing the right size and material ensures a clean, accurate hole.

- Brad Point Drill Bits: Primarily used for wood, these bits have a sharp point that helps guide the bit for precise drilling, reducing tear-out.

Brad point bits are a woodworker’s favorite because of their precision. The center point allows the bit to start drilling exactly where you want, and the sharp cutting edges ensure clean holes without splintering. These bits are very good when working with fine furniture or delicate materials, as they minimize damage around the hole. Make sure to use the correct speed to prevent burn marks.

- Forstner Drill Bits: Used for creating flat-bottomed holes in wood, perfect for hinges or pocket holes.

Forstner bits are excellent for making flat-bottomed holes. They excel when you need to drill a shallow hole that is perfectly flat at the bottom, which makes them ideal for recessed hinges and other woodworking jobs. The outer rim cuts the wood fibers cleanly, while the flat bottom is very important. Always use a drill press to get the most accurate results, as Forstner bits have a wide diameter, so precise alignment is important.

- Step Drill Bits: Ideal for creating holes of different sizes in thin metal, offering multiple hole diameters with a single bit.

Step drill bits are very useful when working with thin metal and they eliminate the need to switch bits when you need different hole sizes. They’re designed with stepped diameters, allowing you to drill progressively larger holes without changing the bit. They also work great for deburring edges of the drilled holes. Step bits are great for use in automotive repair or sheet metal projects where you need multiple sized holes quickly.

Understanding the Materials: Metal vs Wood Drill Bits

The materials that drill bits are made from greatly affect their performance and suitability for different tasks. Drill Bits for Metal vs Wood: What to Use depends on the material of the drill bit and the material you’re drilling into. High-speed steel (HSS) bits are a good choice for both wood and metal, while cobalt and titanium-coated bits provide extra durability and can drill through very hard metals. Wood bits are generally designed to cut wood efficiently and they might not work well on harder materials. This part of the guide will help you understand the core differences in materials.

High-Speed Steel (HSS) and Its Variations

HSS is a very common material for drill bits, offering a great balance of cost and performance. This steel holds up well against heat, which is generated during drilling. Cobalt and titanium-coated HSS bits provide enhanced performance. These bits are more heat-resistant and can drill through tougher metals. Cobalt is very suitable for high-speed drilling and dealing with hard metals like stainless steel. Titanium-coated bits are usually more durable and reduce friction, which prolongs their life.

- High-Speed Steel (HSS): A very common and versatile material, good for both wood and softer metals.

HSS bits are a good starting point for many projects. They are generally affordable and can handle a variety of tasks. They’re often used for drilling into wood, plastics, and softer metals like aluminum. Proper speed and the use of cutting fluid with metal can prevent overheating and extend the bit’s life. The quality of HSS bits varies, so consider brands with good reviews for better performance and durability.

- Cobalt Drill Bits: Designed for drilling very hard metals like stainless steel and other high-strength alloys.

Cobalt bits are an upgrade for those working with challenging metals. They contain cobalt, which makes the bit more heat-resistant and durable. Cobalt bits work well for drilling through hard alloys, and they maintain their cutting edge at high temperatures. These bits are a great choice for professionals who work with metal. Remember to use cutting fluid for maximum efficiency and to preserve the bit’s sharpness.

- Titanium-Coated Drill Bits: Provides increased hardness and heat resistance.

Titanium-coated bits offer improved performance and longevity. The titanium coating reduces friction and allows the bit to drill through harder materials with less effort. These bits are good for drilling into a wide range of materials, including metal and wood. The coating also helps prevent the bit from wearing down quickly. Although these bits are more expensive than standard HSS bits, their longer lifespan and better performance often make them worth the cost.

Drill Bits for Wood Material

Drill bits for wood have very unique designs. Brad point bits have a sharp tip for clean holes, and Forstner bits are good for flat-bottomed holes. The fluting on the bits is designed to remove wood chips efficiently, preventing the bit from getting stuck. Choosing the right wood bit depends on the project. Using the proper bit can reduce splintering and achieve professional-looking results. Here are some examples of wood drill bit materials.

- Brad Point Drill Bits: Made from HSS or carbon steel, designed for wood with a center point for precise drilling.

Brad point bits are designed for clean and precise holes in wood. The sharp center point helps in positioning the bit exactly where you need it, and the spurs cut cleanly around the hole, reducing tear-out and splintering. These are perfect for fine woodworking and furniture making, where a clean finish is important. These bits work best at moderate speeds and can be found in various sizes.

- Spade Bits: Commonly made from carbon steel, and are designed for fast drilling in wood and creating larger holes.

Spade bits are very useful when you need to make larger holes quickly in wood. They have a flat paddle-shaped head with a sharp point in the center to guide the bit. Spade bits are great for drilling through studs and other wood framing components, where speed is more important than a perfectly clean finish. Choose the correct speed to prevent burning the wood and to improve the lifespan of the bit.

- Forstner Bits: Generally made from carbon steel and designed for creating flat-bottomed holes in wood, often used for hinges.

Forstner bits are excellent for creating flat-bottomed holes in wood. They have a cylindrical shape with cutting edges on the sides and a center point. This design enables the bit to cut a very clean hole with a flat bottom, making them ideal for drilling recessed holes for hinges or other applications where a flush or precise fit is needed. These bits are best used with a drill press to ensure accuracy.

Choosing the Right Bit for Metal: A Detailed Guide

When drilling into metal, the choice of drill bit becomes even more important. Metal is a much tougher material than wood, requiring bits made from harder materials and specific techniques. This section will go over selecting the correct drill bit. Additionally, it will cover important things like cutting fluids and drilling speeds that will help ensure a successful outcome. Correct preparation and correct use of equipment will help reduce the risk of bit breakage.

Key Features of Metal Drill Bits

Metal drill bits are designed to cut through hard materials efficiently. They have specific features such as a sharper point angle, stronger materials, and durable fluting. The point angle, often 118 or 135 degrees, helps the bit bite into the metal. Materials like cobalt and titanium are often used, as they can resist heat and abrasion. The fluting removes the chips as the bit drills, so the bit doesn’t jam. The proper features will lead to cleaner, more precise holes in metal.

- Point Angle: The angle of the drill bit’s tip affects how well it cuts into the metal.

The point angle is an important factor when selecting a metal drill bit. A point angle of 118 degrees is good for general use, while a 135-degree angle is better for harder metals. The sharper the angle, the better the bit will bite into the metal. The right angle helps to center the bit and prevents it from wandering. Using the correct point angle improves drilling efficiency and reduces the chance of damaging the material or breaking the bit.

- Material: Cobalt, titanium, and HSS are common materials for metal drill bits, with each offering different levels of hardness and heat resistance.

The material of the drill bit is very important for drilling metal. Cobalt bits are suitable for hard metals like stainless steel, as they maintain their cutting edge and resist high temperatures. Titanium-coated bits offer additional hardness and reduce friction. The HSS bits are a good starting point for general use. The correct material choice will extend the bit’s life and ensure cleaner, more accurate holes. Consider the type of metal and the demands of your project.

- Fluting: The flutes help to remove chips, preventing the bit from getting stuck and overheating.

The flutes are the spiral grooves on the drill bit, which play a major role in removing the metal chips. These flutes ensure that the metal shavings are carried away from the cutting edge, which prevents the bit from getting jammed or overheating. A well-designed flute also helps to improve drilling efficiency and extends the life of the bit. Make sure to clean the flutes during drilling to prevent chip build-up.

Cutting Fluid and Drilling Speed for Metal

Using cutting fluid and selecting the proper drilling speed are essential for successful metal drilling. Cutting fluid is a lubricant and coolant that reduces friction, prevents overheating, and extends the drill bit’s life. The correct drilling speed varies depending on the metal and the drill bit material. Too fast, and the bit will wear out quickly or break; too slow, and you risk glazing the metal. Using these techniques will improve the quality of the holes.

- Cutting Fluid: Lubricates and cools the bit, extending its life and improving cutting performance.

Cutting fluid, such as cutting oil or a lubricant, is crucial when drilling into metal. It lubricates the bit and cools it down, reducing friction and heat. This prevents the bit from overheating and wearing out prematurely. Cutting fluid also helps to improve the chip removal, providing cleaner and more precise holes. Choose the proper cutting fluid for the type of metal you are drilling. Always apply the cutting fluid liberally.

- Drilling Speed: Different metals and bit materials require different speeds. Too fast and the bit will wear quickly; too slow, and it can glaze the metal.

The speed at which you drill is very important for metalworking. The ideal drilling speed depends on the metal type and the bit material. Softer metals, like aluminum, can often be drilled at higher speeds, while harder metals like stainless steel require slower speeds. Using the wrong speed can cause the bit to wear down, break, or even cause damage. Always consult a speed chart for the material and the bit type. Start slow and increase as needed.

- Drilling Techniques: Apply even pressure, start with a pilot hole, and clear chips frequently to maintain the cut.

Proper techniques for drilling into metal are very important to achieving good results. Make sure to apply steady, even pressure and avoid forcing the bit. Always start with a pilot hole to guide the drill bit and prevent it from wandering. Clear the metal chips frequently to prevent clogging and overheating. Using the right drilling techniques increases precision and the life of your drill bits, and improves your safety.

Making the Correct Drill Bit Choice

Choosing the correct drill bit is very important for success in any project. Choosing the right bit requires careful consideration of the materials, the equipment used, and the desired outcome. The materials should be assessed, and the type of bit needed should be determined. Understanding these factors will ensure that the user gets the best results and avoids potential issues like damaged materials or injuries. The next part will help you make the right choice.

Matching the Bit to the Material

The main key to success is pairing the drill bit with the materials being worked on. For wood, brad point bits deliver clean, precise holes. For metal, using HSS, cobalt, or titanium bits is a great choice. Considering both the hardness and thickness of the material is important to the proper function of the bit. Also, taking note of special features like coatings or flute designs is important. If you select the right bit, the outcome will be perfect, and the life of the bit will be extended.

- Wood: Brad point, spade, and Forstner bits are used for the job, with an emphasis on clean cuts and chip removal.

For wood, brad point bits are a great choice for their precise and clean holes. They’re very good for tasks where accuracy is key, such as furniture making. Spade bits are great when speed is very important, good for larger diameter holes. The Forstner bits are a great choice when a flat-bottomed hole is required. Ensure your choice matches the project’s requirements, and that the chosen bit can deliver the required outcome.

- Metal: HSS, cobalt, and titanium-coated bits are the best choices, selected based on metal hardness and thickness.

When working with metal, HSS bits are a good starting point for general use. For harder metals, cobalt bits are a great choice. Always check for the proper coatings for additional strength and longevity. Make sure to choose the right material based on the metal’s hardness and thickness. Always use cutting fluid and use the correct speed for the material.

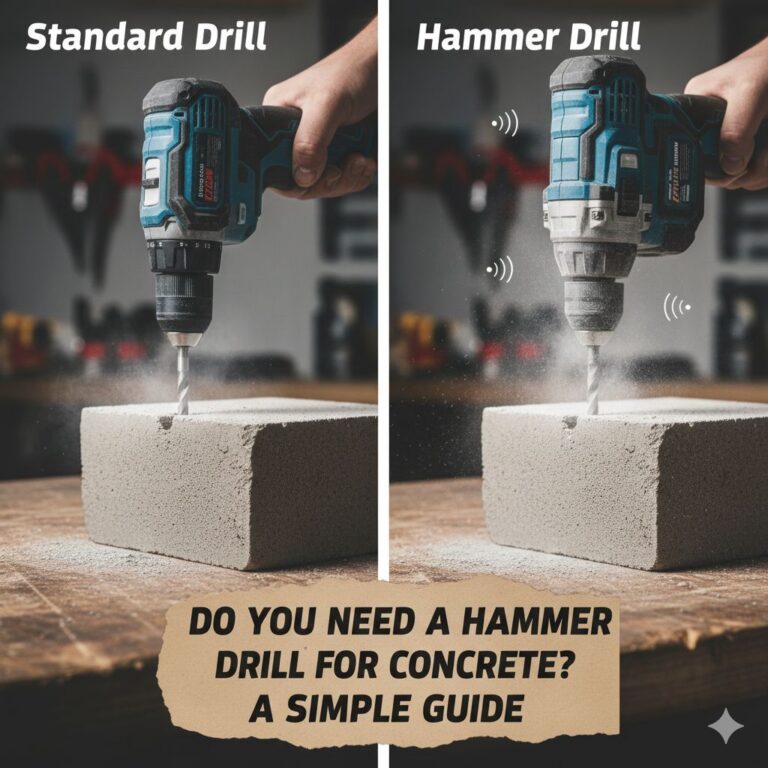

- Specialty Materials: Carbide-tipped bits for tile and glass, and masonry bits for concrete.

For special materials, the correct bit is essential. Carbide-tipped bits are very good for drilling tile and glass, because they can handle the hardness and reduce the risk of cracking. For concrete and masonry, a masonry bit with a special tip designed for these abrasive materials is a must-have. When working with specialized materials, always review the bit specifications to make sure it is suitable. Using the correct bit makes projects more efficient.

Selecting the Proper Drill Bit Size

Selecting the proper drill bit size is crucial for any project, and making this decision will depend on what the project is. Using a bit that is too small can lead to issues, while using a bit that is too large can compromise the accuracy. The size of the hole you want, the material you’re working with, and any related hardware play a very important role in determining the right size. Accuracy will improve as a result of using the correct size, which is important for the desired functionality.

- Hole Size Requirements: Know the exact diameter needed for screws, bolts, or other hardware.

The first step is to determine the hole size you need for the hardware you’re using. If you plan to use screws or bolts, then you must get the correct diameter so that they fit properly. It’s often helpful to consult a chart that shows the right drill bit size for common screws and fasteners. Always make sure the hole is just big enough to allow the hardware to fit comfortably, not too tight or too loose.

- Material Thickness: Choose the right drill bit length based on the depth needed for the hole.

The material’s thickness dictates the length of the drill bit that you will need. If you’re drilling into thin materials, a standard-length bit is usually sufficient. But if you need to go deeper, you’ll need a longer bit. Make sure the bit is long enough to fully drill through the material, but not so long that it’s difficult to control or that it flexes too much. Checking the material’s thickness before starting helps to avoid mistakes.

- Pilot Holes: Use a pilot hole, particularly for harder materials, to guide the larger bit and prevent it from wandering.

When drilling into harder materials, a pilot hole is often helpful. A pilot hole is a small hole drilled first to guide the larger drill bit. This helps the larger bit start in the right place and makes it easier to control. The pilot hole also reduces the chance of the bit wandering off-center. When the pilot hole is complete, you can then use the larger bit to finish the job. Pilot holes are very useful in metalworking.

Examples and Scenarios

Real-life examples can help to show how important the correct choice of drill bits is and to give users an advantage. From simple DIY tasks to professional applications, the right tool makes the job easier and improves the result. These examples will illustrate how the right bit choice affects the project’s quality, efficiency, and safety. Each example reveals a unique scenario and shows what outcomes and performance can be achieved.

- Scenario: You’re building a wooden bookshelf and need to assemble it with wood screws.

In this case, you will want to choose a drill bit that is just a bit smaller than the screw’s diameter to ensure the screw has a tight grip. You can use a twist drill bit for this task, selecting the proper size based on the wood screw’s specifications. A pilot hole is highly recommended to prevent the wood from splitting and to help guide the screw straight.

- Scenario: You are installing new door handles and need to drill through a metal door.

For this job, you would need a drill bit designed for metal, like an HSS bit or a cobalt bit. Because you’re working with metal, it is very important to use a cutting fluid to prevent overheating and to extend the bit’s life. The drill bit’s size should match the size of the handle’s mounting screws, and start with a pilot hole to make it easier to drill through the metal.

- Scenario: You want to install a picture frame on a drywall and you do not have any studs.

In this scenario, you would need to know the proper dimensions of the wall anchors. After selecting the appropriate size for the anchor, use a drill bit that is the same diameter as the anchor. Make sure the bit is designed for use on drywall. You will then insert the anchor, and then insert your screw. Drywall is a very soft material, so the task should be simple and easy.

Consider the story of a furniture maker, Sarah. Sarah, known for her craftsmanship, was designing a new line of solid oak coffee tables. She needed to drill perfectly aligned holes for the legs and the tabletop. She initially tried using standard HSS bits, but they kept wandering, causing misaligned holes and damaging the oak. After doing more research, she switched to brad point bits, known for their precision. The result? Perfectly straight holes, clean edges, and tables that were not only beautiful but also very strong. Sarah’s business saw a boost in customer satisfaction and also the reduction of material waste, because of the correct drill bit choice.

| Bit Type | Material | Use | Best For |

|---|---|---|---|

| Twist Bit | HSS | General Drilling | Wood and Soft Metals |

| Brad Point | HSS | Wood Drilling | Wood |

| Cobalt | Cobalt | Metal Drilling | Hard Metals, Stainless Steel |

| Forstner | Carbon Steel | Flat Bottom Holes | Wood |

Frequently Asked Questions

Question: Can I use the same drill bit for wood and metal?

Answer: Yes, you can use some drill bits for both wood and metal, like twist drill bits made from HSS. However, you need to use the right speed and technique for each material. It’s often best to use bits designed specifically for the material you are working with.

Question: What’s the difference between HSS and titanium drill bits?

Answer: HSS (High-Speed Steel) bits are good for general use in both wood and metal. Titanium-coated bits have a titanium nitride coating that makes them harder, more durable, and more resistant to heat, making them a great choice for harder metals.

Question: What is cutting fluid and why should I use it?

Answer: Cutting fluid is a lubricant and coolant used when drilling metal. It reduces friction, prevents the drill bit from overheating, and improves the quality of the cut. Using cutting fluid extends the life of the bit and helps to create cleaner, more precise holes.

Question: What is the best drill bit to use for concrete?

Answer: The best drill bit to use for concrete is a masonry bit. These bits are designed with a hardened tip that can withstand the abrasive nature of concrete. They are often used with a hammer drill function.

Question: How do I know what size drill bit to use for a screw?

Answer: To determine the right size drill bit for a screw, check the screw’s specifications or consult a screw size chart. The hole should be slightly smaller than the screw’s outer diameter. This ensures the screw grabs the material properly and securely.

Final Thoughts

Choosing the right drill bit is important for any project. Whether working with wood, metal, or other materials, knowing the differences between bit types and materials helps ensure success. Understanding the role of factors like material composition, size requirements, and application techniques leads to better results. By taking into consideration the specifics and following the guidance of the correct bit choices, you’ll greatly improve both the efficiency and the outcome of your work. Consider these insights to your future projects, building confidence, accuracy, and skill with every job.