Hardwood Deck Inserts: Proven Sailboat vs Balsa

Choosing between sailboat-grade hardwood deck inserts and balsa wood is crucial for your boat’s structural integrity. Sailboat-grade hardwoods offer superior strength, water resistance, and longevity, especially against rot, making them the preferred choice for demanding marine environments. Balsa is lighter and cheaper but less durable and prone to moisture issues without careful sealing.

Hey there, fellow DIYers and boat builders! Md Meraj here. Ever found yourself staring at a boat deck project, wondering which type of wood insert will hold up best? It’s a common puzzle, and getting this right means a stronger, safer, and longer-lasting vessel. We’ll cut through the confusion and figure out if fancy sailboat hardwood or simple balsa is the right path for you. Stick with me, and we’ll have your deck project sorted in no time!

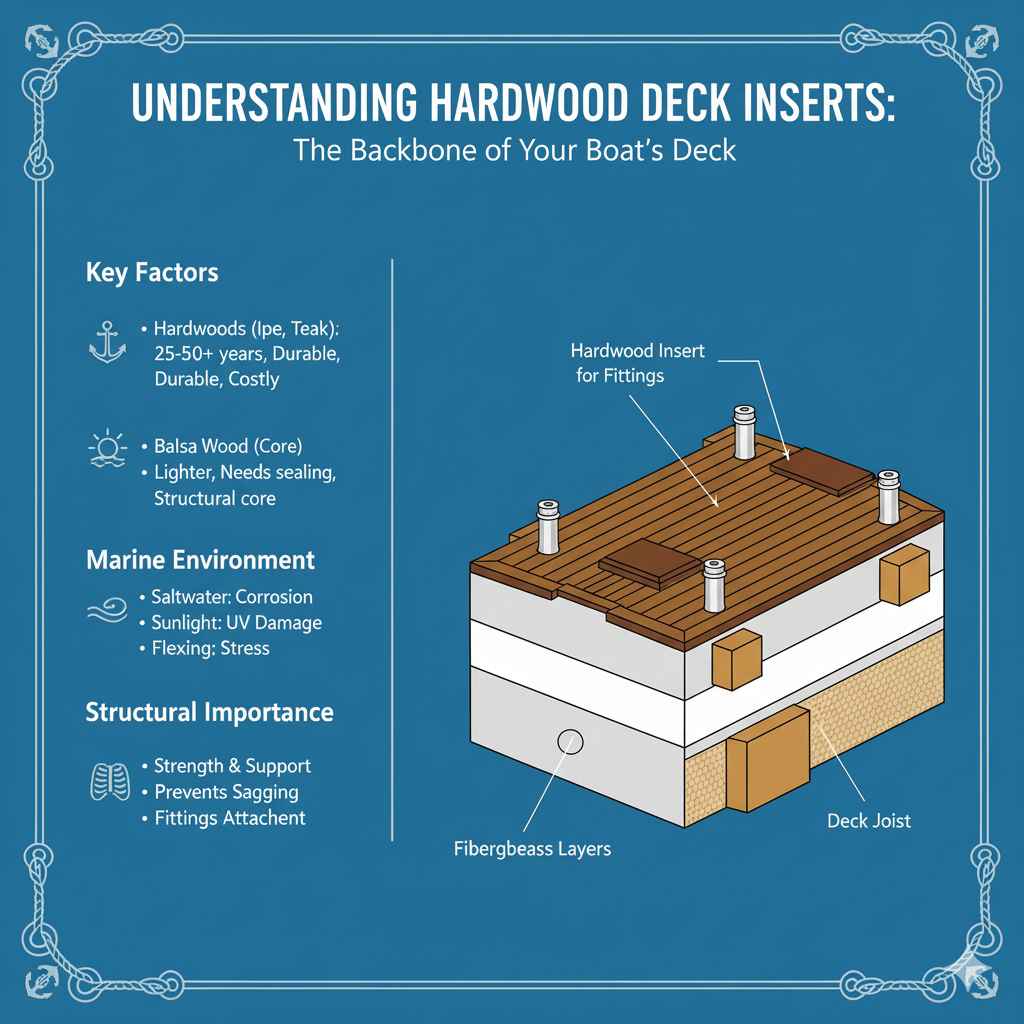

Understanding Hardwood Deck Inserts: The Backbone of Your Boat’s Deck

When we talk about hardwood deck inserts on a sailboat, we’re discussing the structural goodness hidden beneath the surface. These aren’t just decorative pieces; they’re fundamental to the deck’s strength and its ability to function in the tough marine world. Think of them as the strong bones that support the skin of your deck, giving you a solid place to walk, attach fittings, and withstand the forces of wind and waves. Without proper inserts, your deck can sag, crack, or worse, fail when you least expect it.

The marine environment is unforgiving. Saltwater, sun, and constant flexing can take a toll on any material. That’s why choosing the right insert material is so vital. It’s not just about making something look good; it’s about ensuring safety, durability, and a reliable structure for years to come. We’re going to explore two common players in this game: specially selected hardwoods, often referred to as “sailboat grade,” and balsa wood. Each has its own story, its own strengths, and its own weaknesses.

For beginners, this might sound a bit intimidating, but I promise it’s straightforward once you understand the basics. We’ll break down what makes each material tick, how they perform in a boat deck, and how to decide which one is the champion for your specific project. By the end, you’ll feel confident in making an informed decision that will serve your boat well.

Sailboat-Grade Hardwood Inserts: Strength and Durability

When builders talk about “sailboat-grade” hardwood for deck inserts, they’re referring to specific types of dense, durable woods chosen for their exceptional strength and resistance to the elements. These aren’t just any hardwoods; they are the “heavyweights” of the wood world, carefully selected for their ability to handle the unique stresses of a marine environment. Think of woods like teak, mahogany, or white oak. These are known for their natural oils and dense grain, which make them incredibly resistant to rot, decay, and insect damage.

The primary advantage of using these hardwoods is their sheer strength. They provide a robust core that can handle significant loads. When you’re drilling into your deck to install cleats, winches, or even just walking on it, the hardwood insert gives your fasteners something solid to grip onto. This prevents pull-out and distributes stress effectively, preventing the deck from delaminating or cracking under pressure. This is absolutely critical in marine construction where structural integrity can be a matter of safety.

Why Sailboat-Grade Hardwoods Shine:

- Exceptional Strength: They can bear heavy loads and resist impacts.

- Superior Water Resistance: Natural oils and dense structure help repel moisture, preventing rot.

- Durability: They withstand UV exposure, temperature fluctuations, and constant flexing better than many other materials.

- Longevity: Properly treated and installed, hardwood inserts can last for the lifetime of the boat.

- Excellent Fastener Holding: Screws and bolts have a very strong grip in dense hardwoods.

However, this premium performance often comes at a price. Sailboat-grade hardwoods can be more expensive than other materials, and they are also heavier. This extra weight might be a consideration for performance-oriented sailboats, though for many cruising or recreational boats, the trade-off for durability is well worth it. Cutting and shaping these dense woods can also require more effort and sharper tools compared to softer woods or composites.

Common Sailboat-Grade Hardwoods Used:

While many hardwoods can be robust, some are favored in traditionally built or high-performance sailboats:

- Teak: The gold standard. Naturally oily, incredibly durable, and resistant to rot and slip. It’s beautiful but expensive.

- Mahogany: Another excellent choice, offering good strength and stability. It’s generally easier to work than teak and more cost-effective.

- White Oak: Very strong and rot-resistant, especially when kept dry once sealed. It’s a more traditional choice and can be more affordable.

Balsa Wood Inserts: The Lightweight Alternative

Now, let’s talk about balsa wood. This material is quite different from our dense hardwoods. Balsa is a lightweight, low-density wood harvested from the balsa tree. It’s known for its excellent strength-to-weight ratio, meaning it’s strong for how little it weighs. This makes it a popular choice, especially in modern composite boat construction where weight saving is a significant factor.

Balsa is typically used as a core material in sandwich constructions. This means it’s sandwiched between layers of fiberglass and resin. The fiberglass provides the stiffness and strength, while the balsa core provides insulation, some stiffness, and a lightweight filler that maintains the shape and provides a surface for attachment. When drilling into a balsa-cored laminate, the balsa itself isn’t providing the primary strength; it’s the surrounding fiberglass and epoxy that hold things together. The balsa simply spaces the fiberglass layers apart.

The Appeal of Balsa Wood:

- Lightweight: Its primary advantage. Reduced weight can improve a boat’s performance, fuel efficiency, and handling.

- Cost-Effective: Balsa is generally less expensive than high-grade hardwoods.

- Good Insulation: It offers decent thermal and acoustic insulation properties.

- Easy to Shape: Balsa can be easily cut and formed to fit curves and complex shapes.

However, balsa wood has a critical vulnerability: moisture. It’s like a sponge if not meticulously sealed. If water penetrates the balsa, it can lead to rot, delamination, and a significant loss of structural integrity. Unlike dense hardwoods that have natural oils to resist water, balsa is porous. This means that any fittings or structural points that penetrate the fiberglass and reach the balsa core must be perfectly sealed with epoxy or a similar waterproof sealant to prevent this moisture ingress. Repairing water-damaged balsa core can be a significant undertaking.

Furthermore, balsa doesn’t offer the same robust, direct fastener-holding strength as a hardwood. When you screw into a balsa core, you’re essentially screwing into the fiberglass and the balsa spacing. A specialized epoxy potting or a reinforcement like a hardwood block is often required around screw holes to ensure a secure and long-lasting attachment that won’t leak or fail under load. For more information on composite construction techniques, resources from reputable marine organizations like the BoatUS Foundation for Boating Safety can offer valuable insights.

Hardwood Deck vs. Balsa Core: A Direct Comparison

Let’s put these two materials head-to-head to see how they stack up for your deck insert needs. Understanding their differences will help you choose the best option for your boat project.

When considering deck inserts, the primary functions are providing strength, holding fasteners securely, and resisting the harsh marine environment. Here’s how our contenders measure up:

Key Differences Table

| Feature | Sailboat-Grade Hardwood Inserts | Balsa Wood Inserts (as core) |

|---|---|---|

| Primary Function | Direct structural reinforcement, strong fastener anchor | Lightweight core material, spaces fiberglass layers |

| Strength | Very High (dense, solid material) | Moderate (relies on surrounding fiberglass for bulk strength) |

| Weight | High | Very Low |

| Moisture Resistance | Excellent (natural oils, dense grain) | Poor (highly porous, susceptible to rot if water enters) |

| Fastener Holding | Excellent (direct, strong grip) | Poor (requires epoxy pot or hardwood block reinforcement) |

| Durability/Longevity | Very High (resists decay and wear) | Moderate to High (dependent on perfect sealing against moisture) |

| Cost | Higher | Lower (material cost itself) |

| Ease of Working | Can be harder (dense, requires sharp tools) | Easy to cut and shape (soft, lightweight) |

| Typical Application | Traditional builds, high-load areas, transom, keel areas | Modern composite construction, general deck coring |

As you can see, they serve slightly different purposes. Hardwood inserts are like adding concrete pillars where you need the most support. Balsa, when used as a core, is more about creating a lightweight, rigid sandwich structure that relies on the fiberglass skins for its overall strength and integrity.

When to Choose Sailboat-Grade Hardwood:

- You need maximum strength in specific areas.

- You are drilling many holes for deck fittings where a very secure anchor is paramount.

- You are working on a traditional boat build or a restoration where hardwoods are standard.

- You want the absolute best in rot and water resistance without relying on perfect sealing everywhere.

- Weight is not a primary concern for your project.

When to Consider Balsa Wood:

- You are building a modern composite boat where weight saving is critical.

- You are creating large, flat deck panels where consistent, lightweight core material is needed.

- You are experienced and meticulous with epoxy work to ensure all potential water ingress points are sealed.

- Cost is a significant factor, and you are opting for a full composite build.

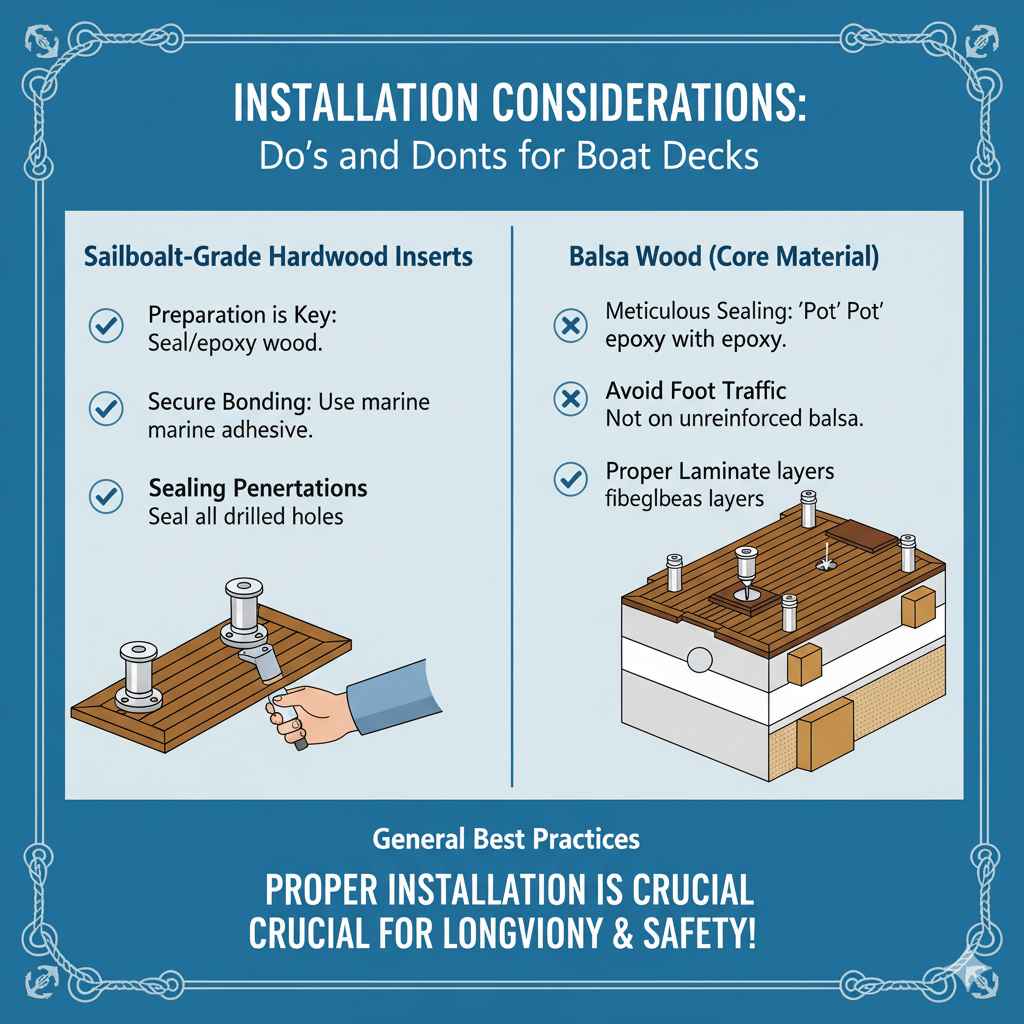

Installation Considerations: Do’s and Don’ts for Boat Decks

No matter which material you choose, proper installation is key to its success and the longevity of your deck. A few smart practices will make all the difference.

For Sailboat-Grade Hardwood Inserts:

- Preparation is Key: Ensure the hardwood is properly dried and treated with a marine-grade sealant or epoxy before installation. This adds an extra layer of protection.

- Secure Bonding: Use a reliable marine adhesive like epoxy or a strong polyurethane adhesive to bond the hardwood insert to the deck structure. Don’t just rely on fasteners unless they are specifically designed for that purpose and you understand the load distribution.

- Drilling for Fittings: When drilling through the deck and into the hardwood for fittings, use sharp drill bits. For ultimate security, consider drilling and tapping holes directly into the hardwood, or use appropriately sized machine screws with backing plates.

- Sealing Penetrations: Always seal around any drilled holes with a good quality sealant to prevent water from getting trapped between the wood and the deck structure.

For Balsa Wood (as a core material):

- Meticulous Sealing: This cannot be stressed enough. Every single penetration through the fiberglass and into the balsa core must be “potted” with epoxy. This involves drilling out the hole slightly larger, filling it with thickened epoxy, and then drilling a new pilot hole for your fastener. This creates a waterproof collar. A great resource for understanding epoxy use in composites is Massachusetts Maritime Academy’s material science pages.

- Avoid Foot Traffic on Unreinforced Balsa: Do not walk directly on balsa-cored panels without a very strong outer fiberglass layup. The balsa will crush.

- Proper Laminate Schedule: Ensure the fiberglass layers above and below the balsa are of adequate thickness and properly laid up according to the design to provide the necessary structural strength.

- Tapering and Shaping: Balsa can be easily cut and sanded. Ensure a smooth, consistent surface for fiberglass layup. Tapering edges where panels meet can help create stronger joints.

General Best Practices for Deck Inserts:

- Understand Your Loads: Know what the deck needs to support and where the highest stress points will be. This dictates the size and type of insert you need.

- Ventilation: While not directly related to the insert itself, good deck ventilation helps keep the entire structure dry and prevents moisture buildup, which is detrimental to both wood and composites.

- Regular Inspections: Periodically inspect your deck, especially around fittings, for any signs of water intrusion, cracking, or looseness. Early detection is key to preventing major repairs.

FAQ: Your Beginner Questions Answered

Q1: Can I use regular lumber for deck inserts?

A: It’s highly discouraged for any structural deck component. Regular lumber lacks the rot resistance and strength needed for the marine environment. Stick to specifically chosen hardwoods or materials designed for marine use.

Q2: Is balsa wood actually strong enough for a boat deck?

A: Balsa itself isn’t the primary strength component; it’s the fiberglass and resin sandwich, with balsa acting as a lightweight core. When properly laminated and sealed, it’s very effective, but its strength comes from the composite system, not the balsa alone.

Q3: How do I prevent my hardwood inserts from rotting?

A: Use hardwoods naturally resistant to rot (like teak, mahogany), seal them thoroughly with marine-grade epoxy or varnish before and after installation, and ensure any drilled holes are also well-sealed.

Q4: What does “potted” mean when talking about balsa core?

A: “Potted” refers to the process of filling a hole drilled into a core material (like balsa) with thickened epoxy. This creates a solid, waterproof plug that your fastener can be screwed into, preventing water from reaching the balsa.

Q5: Will hardwood inserts make my boat too heavy?

A: Hardwoods are denser and heavier than balsa. For a performance sailboat where weight is critical, it might be a factor. For most cruising or recreational boats, the added weight of strategically placed hardwood inserts is often a worthwhile trade-off for superior strength and durability.

Q6: Can I mix hardwood inserts and balsa core in the same deck?

A: Yes, this is common. High-load areas like where winches or cleats are mounted might use solid hardwood blocks (sometimes called “backing blocks”) within a balsa-cored deck structure to provide extra strength for the fasteners.

Conclusion: Your Smart Choice for a Sturdy Deck

So, there you have it! We’ve journeyed through the world of hardwood deck inserts and the lightweight charm of balsa. For beginners and seasoned builders alike, understanding these materials is your first step toward a robust and reliable boat deck. Sailboat-grade hardwoods offer unmatched density, strength, and natural resistance to the elements, making them a fantastic choice for critical structural areas and where fastener strength is paramount. On the other hand, balsa wood shines in modern composite builds where saving weight is a priority, but it demands meticulous attention to waterproofing to prevent its Achilles’ heel: moisture.

Think about your project: what are your priorities? Is it absolute, unwavering strength and longevity, even at a bit more weight and cost? Then dense hardwood inserts are likely your champion. Or are you aiming for a lighter, more performance-oriented build, and are you prepared to be diligent with your sealing techniques? Balsa could be a great fit. Often, a smart approach involves using both – hardwood for high-stress points like transom corners or mast steps, and balsa for larger, lighter deck panels. Whichever path you choose, by applying these principles and focusing on good craftsmanship, you’ll build a deck that you can trust for countless voyages. Happy building, and may your boat always stay afloat!