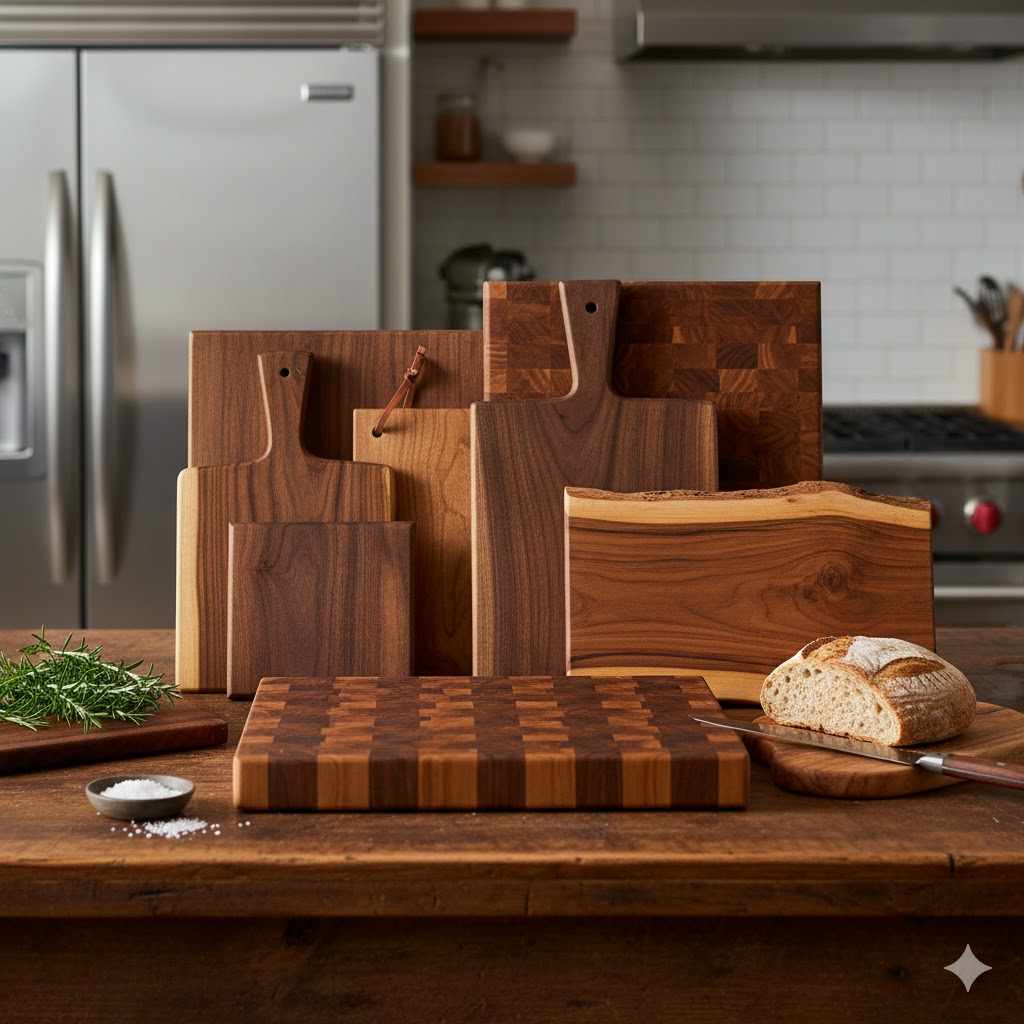

High Quality Wood Cutting Boards Top Picks

Finding the right cutting board can feel like a puzzle, especially when you’re just starting in the kitchen. You see so many options, and it’s hard to know which ones are truly great for chopping veggies or slicing bread. Many people wonder about the best choices for their needs.

This guide makes it easy. We’ll walk through exactly what makes a cutting board a winner, and by the end, you’ll know what to look for. Get ready to discover High-Quality Wood Cutting Boards: Top Picks that will make cooking a joy.

Choosing High Quality Wood Cutting Boards Top Picks

Selecting the right cutting board is more than just picking a surface to chop on. It’s about finding a tool that’s kind to your knives, hygienic, durable, and looks good in your kitchen. Wood cutting boards, in particular, have a special appeal.

They offer a natural warmth and a satisfying feel under the knife. But not all wood is created equal. This section helps you understand the differences between wood types and construction methods to ensure you pick a board that lasts and performs well.

Many home cooks are looking for that perfect balance of beauty and function. They want a board that can handle daily use without showing wear and tear quickly. The good news is, with a little knowledge, you can easily spot the features that make a wood cutting board a top choice.

We’ll break down the key factors that go into making a great wood cutting board, so you can feel confident in your selection.

Wood Types for Cutting Boards

The type of wood used for a cutting board significantly impacts its durability, appearance, and how it interacts with your knives. Different woods have varying densities, porosity, and natural oils, all of which play a role in the board’s performance and maintenance needs. Understanding these wood characteristics helps you choose a board that best suits your cooking habits and aesthetic preferences.

Hardwoods vs. Softwoods

Hardwoods are generally preferred for cutting boards because they are denser and less prone to damage from knife cuts. Softwoods, like pine, are too porous and soft, leading to deep scratches and a shorter lifespan. They can also absorb more moisture and bacteria.

Hardwoods also tend to be more resistant to warping and cracking.

Hardwoods like maple, walnut, and cherry are excellent choices. They offer a good balance of durability and knife-friendliness. Maple is especially popular for its light color and dense grain.Walnut provides a rich, dark aesthetic and is moderately hard. Cherry wood darkens with age, developing a beautiful patina over time. These woods are also naturally antimicrobial to some extent, which is a significant plus for food preparation surfaces.

Softwoods like pine and fir are generally not recommended for cutting boards. While they are cheaper, they are easily damaged by knife marks. These deep cuts can harbor bacteria, making them unhygienic.They also absorb liquids more readily, increasing the risk of warping and staining. For any serious cooking, sticking to hardwoods is essential for a long-lasting and safe cutting board.

Grain Structure and Porosity

The grain structure of wood affects its durability and how it holds up to moisture. Woods with closed, fine grains are less absorbent than those with open, coarse grains. This means they are more resistant to stains and bacteria.

A closed grain also means less likelihood of splintering or cracking over time, ensuring a smoother surface for chopping.

End grain construction is often considered the premium choice for wood cutting boards. In end grain boards, the wood fibers are oriented vertically, perpendicular to the cutting surface. This means that when a knife blade strikes the board, it parts the wood fibers rather than severing them.

This feature makes end grain boards incredibly kind to knife edges, keeping them sharper for longer. They also tend to be more forgiving of cuts, and minor knife marks can often self-heal. The construction also makes them very stable, reducing the chance of warping.

Edge grain construction is more common and often more affordable. Here, the wood is laid flat, with the grain running parallel to the cutting surface. While still durable, edge grain boards can show knife marks more readily than end grain boards.They are also more susceptible to warping if not properly maintained, especially with exposure to moisture. However, they are still a significant upgrade from plastic or composite boards and offer good value.

Construction Methods for Wood Cutting Boards

The way a wood cutting board is assembled is just as important as the type of wood used. Different construction methods affect the board’s stability, durability, and how it interacts with your knives. Understanding these methods helps you appreciate the craftsmanship and choose a board that will serve you well for years to come.

There are three main ways wood cutting boards are put together: face grain, edge grain, and end grain. Each has its own characteristics that influence its performance and longevity. We’ll explore these in detail so you can make an informed decision about which construction best fits your kitchen needs.

Face Grain Construction

Face grain cutting boards are the most common and usually the least expensive. They are made by joining planks of wood together along their widest faces. This method is straightforward and results in a visually appealing board with a broad, continuous wood grain pattern.

However, it’s also the least durable construction for heavy use.

Face grain boards showcase the natural beauty of the wood. The large, flat surfaces display the wood’s patterns prominently. This makes them very attractive for serving cheese or as a general-purpose board.The planks are typically glued together along their broad sides to create the board’s surface. This is a simpler manufacturing process, which contributes to their lower cost.

The main drawback of face grain boards is their susceptibility to knife marks. The wood fibers are cut directly by the knife, leading to deeper scratches over time. These scratches can harbor bacteria and make the board harder to clean.They are also more prone to warping and cracking, especially if exposed to prolonged moisture or extreme temperature changes. They require diligent care to maintain their condition.

Edge Grain Construction

Edge grain boards are made by gluing strips of wood together along their edges. This creates a denser, more durable surface that is more resistant to knife marks than face grain boards. The strips of wood are oriented so the grain runs vertically, parallel to the cutting surface.

This structure offers a good compromise between durability and cost.

In edge grain construction, shorter strips of wood are glued together along their long edges. This creates a visually appealing pattern of stripes or parquet. The grain of the wood runs parallel to the cutting surface, meaning that knife cuts are less likely to penetrate deeply into the wood.This makes the board more resistant to scratches and wear compared to face grain boards.

Edge grain boards are a popular choice for home cooks. They offer good durability without the higher cost associated with end grain boards. They are also relatively stable and less prone to warping than face grain boards, provided they are cared for properly.Regular oiling is still important to protect the wood and maintain its integrity. Many chefs and home cooks find them to be an excellent balance of performance, aesthetics, and value.

End Grain Construction

End grain boards are considered the gold standard by many chefs and woodworking enthusiasts. They are constructed from wood blocks where the end of the grain is exposed on the cutting surface. This unique orientation allows knife blades to pass between the wood fibers, rather than cutting through them.

This results in a board that is exceptionally gentle on knives and remarkably resistant to deep scratches.

The defining feature of end grain boards is the orientation of the wood fibers. Blocks of wood are arranged so that the cut surface is the end grain. When a knife blade strikes this surface, it pushes the fibers apart, which then spring back into place.This makes end grain boards incredibly “self-healing” and significantly extends the life of your knife edges. It’s a superior cutting experience for anyone who values their cutlery.

This type of construction requires more labor and skill to produce, which is why end grain boards are typically the most expensive. However, their longevity, knife-friendliness, and visual appeal often justify the investment for dedicated cooks. They are also known for their stability, being less prone to warping and cracking than other types of wood construction.Proper maintenance, including regular oiling, will ensure an end grain board lasts for a lifetime.

Maintaining Your High-Quality Wood Cutting Board

To ensure your cutting board serves you well for years, proper care is essential. Wood is a natural material that requires a little attention to stay in top condition. Regular cleaning and conditioning will protect it from drying out, cracking, and staining, keeping it hygienic and beautiful.

Think of it like caring for a good pair of leather shoes. A little effort goes a long way in preserving its quality and appearance. We’ll cover the simple steps to keep your board looking and functioning at its best.

Cleaning Your Wood Cutting Board

Cleaning a wood cutting board is a straightforward process. The key is to avoid soaking the board in water, as this can cause the wood to warp, crack, or split. Prompt cleaning after each use is the best way to prevent stains and bacteria buildup.

After each use, wash your wood cutting board with warm water and mild dish soap. Use a soft brush or sponge to gently scrub the surface. Rinse thoroughly with warm water.For a quick sanitization, you can rub the board with a cut lemon or sprinkle it with coarse salt and let it sit for a few minutes before rinsing. This helps lift any lingering odors and provides a gentle abrasive cleaning action.

Avoid using harsh detergents or abrasive scrubbers, as these can damage the wood’s surface. Never put your wood cutting board in the dishwasher. The high heat and prolonged exposure to water in a dishwasher will inevitably lead to warping, cracking, and potential delamination of the wood.Always air dry the board completely, standing it up on its edge to allow air to circulate around all sides.

Oiling and Conditioning

Oiling your wood cutting board regularly is crucial for its longevity and appearance. It replenishes the natural oils in the wood, creating a protective barrier against moisture, stains, and bacteria. It also prevents the wood from drying out and cracking.

For best results, use a food-grade mineral oil. Other oils, like vegetable or olive oil, can go rancid over time, leaving an unpleasant odor and potentially sticky residue on your board. Apply the mineral oil liberally to all surfaces of the board, including the edges and ends.Allow the oil to soak in for at least a few hours, or ideally overnight. Wipe off any excess oil with a clean cloth.

How often you should oil your board depends on how often you use it and the climate you live in. A good rule of thumb is to oil it once a month, or whenever the board starts to look dry or dull. You can also use specialized cutting board conditioners, which are often a blend of mineral oil and beeswax.The beeswax adds an extra layer of protection and a nice sheen.

Dealing with Stains and Odors

Wood cutting boards can sometimes pick up stains or odors from strongly colored or aromatic foods. Fortunately, there are simple ways to address these issues and restore your board to its pristine condition.

For stubborn stains, you can try a paste made of baking soda and water. Apply the paste to the stained area and let it sit for 10-15 minutes. Then, gently scrub with a soft brush or sponge and rinse thoroughly.This abrasive yet gentle cleaning method can often lift the stain without damaging the wood.

To combat odors, a quick rub with a cut lemon or a sprinkle of coarse salt can work wonders. For persistent smells, you can also try wiping the board down with diluted vinegar (equal parts white vinegar and water). Let it sit for a few minutes, then rinse and dry thoroughly.Ensure the board is completely dry before oiling it.

Best High-Quality Wood Cutting Boards Top Picks For Your Kitchen

When it comes to choosing the best high-quality wood cutting boards, a few key features stand out. Durability, knife-friendliness, aesthetics, and ease of maintenance are all important factors. Many brands offer excellent options, but understanding what makes them great will help you find the perfect match for your culinary needs.

We’ll highlight some of the top contenders that consistently receive praise for their quality and performance.

This section is all about showcasing the boards that truly shine. We’ll look at different styles, materials, and what makes them a worthwhile investment for any kitchen. Whether you’re a seasoned chef or just enjoy cooking at home, finding a reliable cutting board can elevate your entire experience.

Top Wood Cutting Board Brands and Models

Several brands have established themselves as leaders in producing high-quality wood cutting boards. These companies often focus on using premium materials, expert craftsmanship, and thoughtful design. When you invest in a board from a reputable brand, you’re often getting a product that’s built to last and perform exceptionally well in the kitchen.

Let’s explore some of the most respected names in the world of wood cutting boards and what makes their offerings stand out. These are the brands that home cooks and professionals alike trust for their durability, beauty, and functionality.

Boos Blocks are arguably one of the most recognized names in high-quality wood cutting boards. They offer a wide range of options, including maple, cherry, and walnut, in various constructions like end grain and edge grain. Their boards are often found in professional kitchens due to their robust build and attractive finishes.They are known for their dedication to quality materials and craftsmanship, making them a consistent top pick.

John Boos Maple Wood Cutting Board is a prime example of their excellence. This particular model is often lauded for its thick maple construction and reversible design, making it a versatile tool. It’s a substantial board that can handle serious chopping and dicing.The durable maple is gentle on knives and develops a beautiful patina with age. It’s a testament to why Boos Blocks are so highly regarded.

Teakhaus is another brand that consistently receives high marks for its wood cutting boards. They specialize in teak wood, which is naturally resistant to water and bacteria due to its high oil content. Their boards often feature beautiful grain patterns and elegant designs.Teakwood is a durable and attractive option that holds up well to frequent use. Many of their boards are made in the USA, reflecting a commitment to quality manufacturing.

The Teakhaus Edge Grain Reversible Cutting Board is a popular choice from this brand. Its edge grain construction provides good durability and stability, while the teak wood offers natural water resistance. The reversible design offers flexibility, and the board’s natural beauty makes it suitable for serving as well.It’s a great option for those looking for a stylish yet functional cutting surface.

Catskill Craftsmen offers a variety of wood cutting boards, often emphasizing traditional craftsmanship and durable hardwoods like maple. They provide both end grain and edge grain options, catering to different needs and budgets. Their products are known for being solid, reliable, and made in the USA, ensuring a high standard of quality.

Key Features to Look For in Top Picks

When you’re hunting for High-Quality Wood Cutting Boards: Top Picks, certain features are non-negotiable if you want a board that will perform well and last. Beyond just the wood type, consider how the board is put together and what practical aspects it offers. These details can make a big difference in your daily cooking experience.

Focusing on these specific attributes will help you sift through the options and find a board that truly meets your expectations for quality and utility. It’s about more than just aesthetics; it’s about functionality and longevity.

Size and Thickness

The right size and thickness for your cutting board depend on your kitchen space and typical cooking tasks. A larger, thicker board is generally more stable and offers more room to work. However, it can also be heavier and harder to store.

A board that is at least 12 inches by 18 inches provides ample space for most common food preparation tasks, such as chopping vegetables, slicing meat, or dicing fruit. Smaller boards might be suitable for occasional use or limited counter space, but they can feel cramped for larger jobs. Consider the volume of food you typically prepare.

Thickness also plays a significant role in stability and durability. Boards that are 1.5 inches to 2 inches thick are ideal. They are heavy enough to stay put while you chop vigorously, reducing the risk of accidents.Thicker boards are also more robust and less likely to warp over time. Extremely thin boards can flex and may not offer the same level of stability or longevity.

Weight and Stability

A cutting board that moves around on the counter while you’re chopping is not only annoying but also a safety hazard. High-quality wood cutting boards are often designed with weight and stability in mind. This ensures they remain firmly in place during intensive use.

The weight of a cutting board comes primarily from its thickness and density of the wood. Heavier boards are less likely to slide, especially when dealing with wet ingredients or vigorous chopping. If a board feels too light, consider using a damp cloth or a non-slip mat underneath it to improve its grip on the countertop.

For end grain boards, the construction itself contributes to stability. The way the wood is laminated together creates a very solid and flat surface. Look for boards that are free of any warping or cupping.A perfectly flat board will sit flush on your countertop, providing maximum stability and a safe cutting surface.

Edge Finishes and Features

The edges and any additional features of a cutting board can enhance its usability and aesthetic appeal. Simple details can make a big difference in how you interact with your board.

Many high-quality wood cutting boards feature rounded or beveled edges. This not only adds a touch of visual appeal but also makes the board easier to handle and less prone to chipping. It also prevents sharp corners from snagging on clothing or towels.

Some boards come with built-in juice grooves. These are channels carved along the perimeter of the board to catch any liquids that run off your food. This is incredibly useful when slicing juicy fruits, meats, or vegetables, keeping your countertop clean.Others might have handles or cut-outs for easier carrying and maneuvering, especially for larger boards.

When to Consider Different Types of Wood Cutting Boards

While hardwoods are generally the go-to for quality, there are specific situations and preferences where one type of wood or construction might be more suitable than another. Understanding these nuances helps you tailor your choice to your personal needs and cooking style.

It’s not always about picking the “best” overall, but rather the best for you. Let’s explore some scenarios where different wood cutting board options might be the ideal fit.

For the Serious Home Cook

For those who spend a lot of time in the kitchen and are passionate about cooking, investing in a top-tier cutting board is a natural progression. They appreciate tools that perform well, protect their knives, and look good doing it. This is where premium materials and construction methods truly shine.

End Grain Construction: A serious home cook will likely appreciate the benefits of end grain construction the most. The self-healing properties are gentle on expensive knives, keeping them sharper for longer. This is a significant advantage for anyone who values their cutlery collection.The aesthetic appeal of an end grain board also adds to the kitchen’s ambiance.

Dense Hardwoods: Maple, walnut, and cherry are favored for their durability and resistance to stains and odors. Maple provides a bright, clean look, while walnut offers a sophisticated dark contrast. Cherry wood deepens in color with age, adding character.

These woods are dense enough to withstand heavy use without showing excessive wear.

Sufficient Size and Thickness: A generous size (18×24 inches or larger) and substantial thickness (1.5-2 inches) are preferred. This provides ample workspace for prepping multiple ingredients and ensures the board remains stable during vigorous chopping. A larger, heavier board also feels more professional and durable.

For Everyday Versatility

Many home cooks need a reliable, all-purpose cutting board that can handle a variety of tasks without demanding excessive maintenance. Versatility and a good balance of durability and cost are key. Edge grain boards often fit this bill perfectly.

Edge Grain Construction: This construction method offers a great balance of durability and affordability. It’s more resistant to knife marks than face grain boards and generally more stable. Edge grain boards are excellent for everyday chopping, slicing, and dicing of all kinds of ingredients.

Hardwoods like Maple or Bamboo: While bamboo isn’t technically a wood but a grass, it’s often used in cutting boards and is known for its hardness and sustainability. Maple remains a classic choice for its light color and durability. These materials are relatively easy to maintain and offer good resistance to wear and tear for daily use.

Moderate Size and Thickness: A board around 14×20 inches and about 1 inch thick is usually sufficient for most everyday tasks. It’s large enough to be practical but not so big that it’s cumbersome to store or clean. Features like a juice groove can add to the practicality for everyday use

For Special Occasions and Serving

Some cutting boards are designed not just for preparation but also for serving. These boards often prioritize visual appeal and unique wood grains, making them beautiful additions to a table setting. They might be less about heavy-duty chopping and more about presentation.

Face Grain or Charcuterie Style Boards: Boards made with beautiful face grains, often featuring intricate patterns or contrasting wood colors, are ideal for serving. These are frequently called charcuterie boards or cheese boards. Their flat, broad surfaces are perfect for arranging meats, cheeses, fruits, and other appetizers.

Exotic or Decorative Woods: Woods with unique natural patterns, like olive wood or acacia, are often used for serving boards. These woods can add a touch of elegance and warmth to any gathering. The natural beauty of the grain is the star here.

Smaller, Thinner Designs: Serving boards don’t need to be as thick or heavy as preparation boards. Smaller, thinner designs are often more practical for carrying and arranging food on a table. Some might even include handles or decorative cut-outs for easy transport.

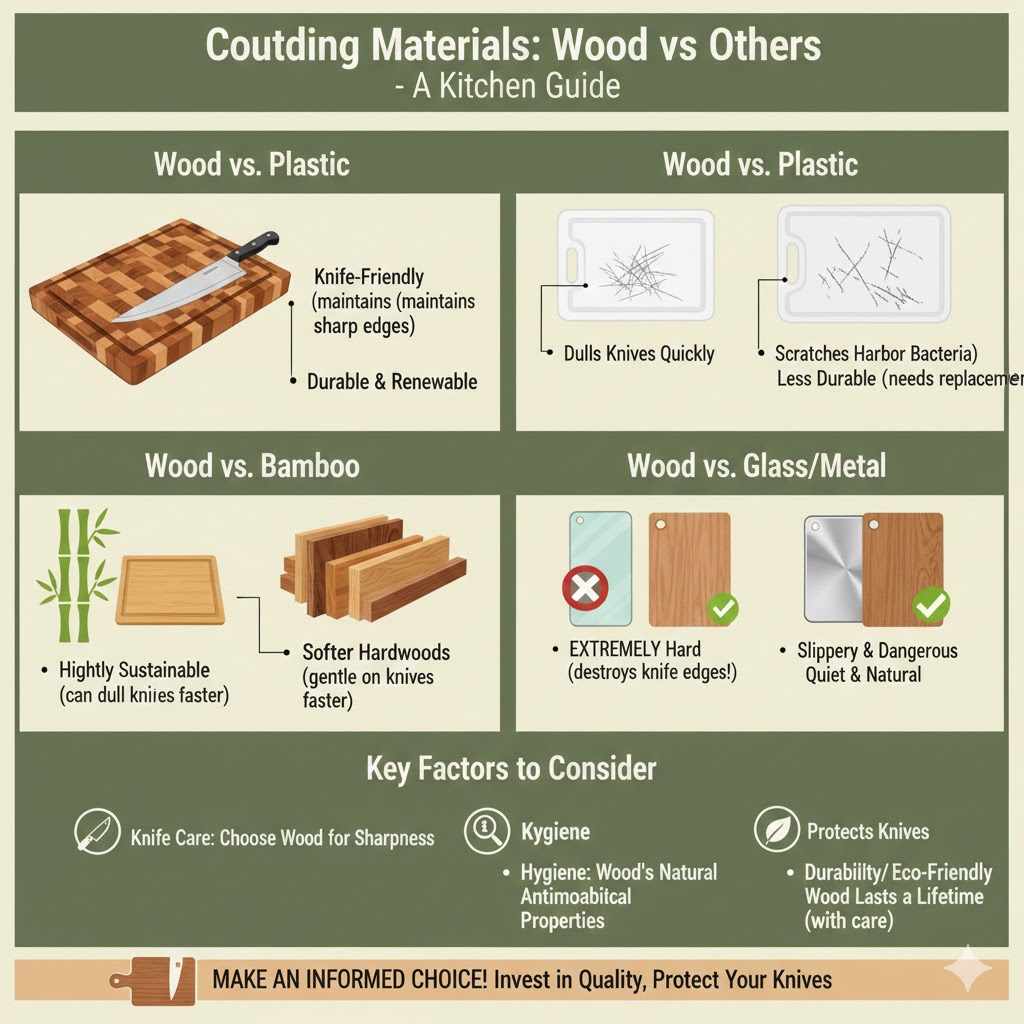

Comparing Wood Cutting Boards to Other Materials

When you’re looking at High-Quality Wood Cutting Boards: Top Picks, it’s helpful to understand how they stack up against other common cutting board materials. Each material has its own set of pros and cons, influencing its suitability for different kitchen tasks and preferences.

Understanding these differences can help you make the best choice for your kitchen, whether you’re deciding on your first board or adding to your collection.

Wood vs. Plastic Cutting Boards

Wood and plastic cutting boards are the most common types found in kitchens. They differ significantly in terms of hygiene, durability, and impact on knife edges. Wood is often favored for its aesthetic appeal and knife-friendliness, while plastic is known for its ease of cleaning and lower cost.

Hygiene and Bacteria

One of the most debated aspects is hygiene. While plastic boards might seem easier to sanitize, research suggests that wood, especially hardwoods, can be naturally antimicrobial. The porous nature of wood can trap bacteria, but the wood’s natural compounds can kill them over time.

Plastic boards, however, develop knife marks that can harbor bacteria, and these are harder to sanitize thoroughly.

Wood: Studies have shown that wood cutting boards can actually inhibit bacterial growth. For example, experiments have found that bacteria like E. coli and Salmonella die off on wooden surfaces within hours, whereas they can survive much longer on plastic.This is attributed to the natural antimicrobial properties of certain woods and the way bacteria get trapped within the wood’s micro-structure, making them inaccessible.

Plastic: Plastic boards are non-porous, making them appear easier to clean initially. However, knife cuts create microscopic crevices where food particles and bacteria can lodge. Even with vigorous washing, these areas can remain contaminated.

Repeated washing in dishwashers can sanitize them to some extent, but the damage from knives is cumulative and problematic.

Knife Edge Preservation

The impact on your knife’s sharpness is a major consideration. A cutting board’s surface can either help maintain your knife’s edge or dull it rapidly. This is where wood boards typically have a significant advantage over their plastic counterparts.

Wood: The grain of wood, especially in end grain construction, is designed to yield slightly when a knife blade passes through it. This means the blade parts the wood fibers rather than being abruptly stopped or severed. This gentle interaction helps your knives stay sharper for much longer periods, reducing the need for frequent sharpening.It’s a key reason why many chefs prefer wood.

Plastic: Plastic is often a harder material than wood and provides a less forgiving surface for knife blades. Each cut made on a plastic board can dull your knife edge more quickly. Over time, this can significantly reduce the effectiveness of your knives, leading to frustration and a need for more frequent professional sharpening or honing.

Durability and Maintenance

The lifespan of a cutting board and the effort required to keep it in good condition are also important factors. Wood boards, when properly cared for, can last a lifetime. Plastic boards, while sometimes dishwasher-safe, tend to wear out more quickly and require replacement.

Wood: With regular oiling and proper cleaning, wood cutting boards can last for decades. They are renewable resources and can often be resurfaced if they become deeply scratched or warped. The maintenance, while present, is straightforward and contributes to the board’s longevity and beauty.They are a sustainable, long-term investment.

Plastic: Plastic boards are less durable overall. They are prone to deep scratches and can become stained or discolored over time. While some are dishwasher safe, this can also degrade the plastic, leading to warping or cracking.

Generally, plastic boards have a shorter lifespan and will need to be replaced more frequently than a well-maintained wood board.

Wood vs. Bamboo Cutting Boards

Bamboo cutting boards have gained popularity due to their sustainability and hardness. While often grouped with wood, bamboo is technically a grass, but it shares many characteristics with hardwood cutting boards. It offers a good alternative for those seeking eco-friendly options.

Sustainability and Environmental Impact

Bamboo is a highly renewable resource, growing much faster than most trees. This makes bamboo cutting boards an attractive option for environmentally conscious consumers. The rapid growth cycle means that harvesting bamboo has a lower impact on deforestation.

Bamboo: Bamboo forests can regenerate quickly after harvesting, making it a highly sustainable material. It requires minimal pesticides and fertilizers to grow, further reducing its environmental footprint. Many bamboo products are also biodegradable, breaking down naturally at the end of their lifespan, unlike plastic which persists in landfills for centuries.

Wood: While hardwoods are also natural and renewable, the time it takes for trees to mature means their sustainability depends on responsible forestry practices. High-quality wood cutting boards are often made from sustainably harvested timber, ensuring that forests are managed for long-term health. The longevity of a well-maintained wood board also contributes to its overall sustainability, as it requires less frequent replacement.

Hardness and Knife Wear

Bamboo is known for its exceptional hardness, which can be both a pro and a con. While this hardness makes it durable and resistant to knife marks, it can also be harder on knife edges compared to softer hardwoods.

Bamboo: The density of bamboo means it is quite hard. This makes it very resistant to scratches and cuts. However, this same hardness can also dull knife edges more quickly than softer woods like maple or walnut.

If knife sharpness is a top priority, a softer hardwood might be a better choice.

Wood: Softer hardwoods like maple offer a better balance. They are still durable enough for everyday use but are more forgiving on knife edges. The natural give in the wood fibers helps to preserve the sharpness of your blades.

This makes them a more preferred choice for chefs and home cooks who want to maintain their knives’ cutting ability.

Wood vs. Glass or Metal Cutting Boards

Glass and metal cutting boards are primarily chosen for their ease of cleaning and modern aesthetic. However, they present significant drawbacks, particularly concerning knife damage and overall usability.

Impact on Knife Edges

This is where glass and metal cutting boards fall drastically short. Their extreme hardness means they will rapidly dull and damage even the sharpest knives. They are essentially abrasive surfaces for your blades.

Glass/Metal: These materials are significantly harder than steel knife blades. When a knife comes into contact with a glass or metal surface, it will dull very quickly. This negates the purpose of having sharp knives, and you’ll find yourself needing to sharpen them constantly.They are not recommended for any serious food preparation where knife care is a concern.

Wood: As discussed, wood’s natural give protects knife edges. This is the fundamental difference that makes wood a far superior choice for protecting your cutlery. The ability to maintain knife sharpness is a key benefit that glass and metal simply cannot offer.

Hygiene and Durability

Glass boards are often praised for being easy to wipe clean and non-porous. Metal boards can also be hygienic and durable. However, both can chip or scratch, and their hardness can lead to other issues.

Glass: While glass is non-porous and easy to wipe down, it can chip or shatter if dropped. Knife marks on glass can be less visible initially but can still dull knives severely. They also tend to be slippery, posing a safety risk.

Metal: Metal boards can be durable but can also scratch, and some metals can react with certain foods. They also tend to be very slippery and can create a lot of noise when used. Their primary advantage is ease of sanitization, but this is often outweighed by the damage to knives.

Frequently Asked Questions

Question: What is the best type of wood for a cutting board?

Answer: The best types of wood for cutting boards are dense hardwoods like maple, walnut, and cherry. Maple is a popular choice for its hardness, light color, and ability to resist stains. Walnut offers a rich, dark aesthetic, and cherry wood develops a beautiful patina over time.

These woods are durable, gentle on knives, and naturally antimicrobial to some extent.

Question: How do I clean my wood cutting board?

Answer: Clean your wood cutting board by washing it with warm water and mild dish soap using a soft brush or sponge. Rinse thoroughly. Never soak the board or put it in the dishwasher.

Always air dry it completely, standing it on its edge.

Question: How often should I oil my wood cutting board?

Answer: You should oil your wood cutting board about once a month, or whenever it starts to look dry or dull. If you live in a very dry climate or use your board frequently, you might need to oil it more often. Using a food-grade mineral oil is recommended.

Question: Can wood cutting boards harbor bacteria?

Answer: While wood is porous, studies suggest that dense hardwoods can actually inhibit bacterial growth. Bacteria can get trapped within the wood’s micro-structure, where they die off due to the wood’s natural antimicrobial properties. However, proper cleaning and oiling are still essential to maintain hygiene.

Question: What’s the difference between end grain and edge grain cutting boards?

Answer: End grain boards have wood fibers oriented vertically, so knives part the fibers, making them gentler on edges and self-healing. Edge grain boards have wood strips glued with grain running parallel to the surface; they are durable but show knife marks more readily. End grain is generally considered superior for knife longevity and board resilience.

Conclusion

Choosing high-quality wood cutting boards involves looking at wood type, construction, and care. Dense hardwoods like maple, walnut, and cherry are excellent. End grain construction offers the best protection for knives and the board itself.

Proper cleaning and regular oiling with mineral oil are key to longevity. These steps ensure your cutting board remains a beautiful, functional, and safe tool in your kitchen for many years.