How Hard Is Birch Wood: Proven Essential Facts

Birch wood is only moderately hard on the Janka scale (around 1,260–1,470 lbf), placing it firmer than maple but softer than oak. For beginners, this means birch is challenging enough to be durable for lighter uses yet soft enough for easier to handle, glue, and finish.

Hello makers! I’m Meraj, your guide to making sawdust the fun way. Many new woodworkers look at a piece of wood and only see beautiful grain pattern. But the real challenge is often knowing how it will act when you cut, drill, or sand it. If you are planning a cabinet face, a toy, or even simple shelving, you need to know: just how hard really is birch wood? Dealing with wood that’s too soft ruins projects quickly. Wood that is much too hard breaks beginner toolkit tools or wears out your sanity finishing it! Do not worry.

We will look at the official hardness ratings, what those numbers truly mean for your sandpaper choices, cutting speeds, finishing tips, and why birch is still a top choice for crafting beautiful projects, safely and easily. Let’s start by measuring this workhorse of the forest!

Understanding Wood Hardness for Beginners

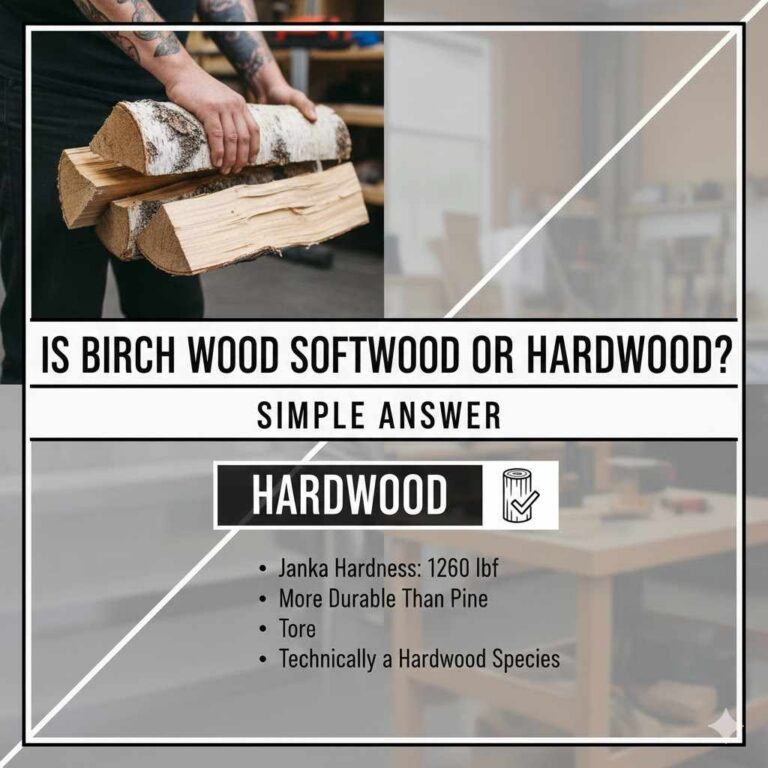

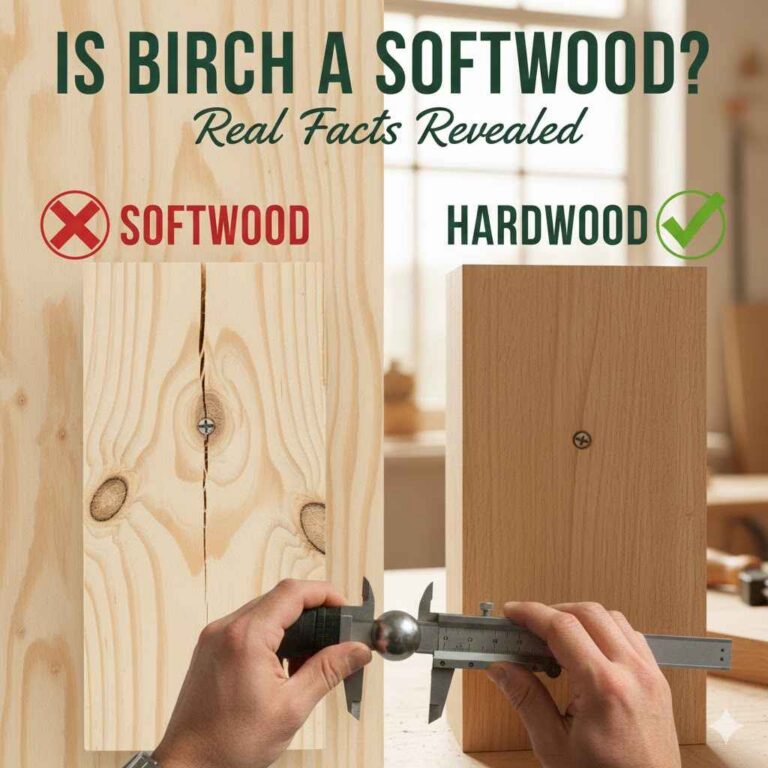

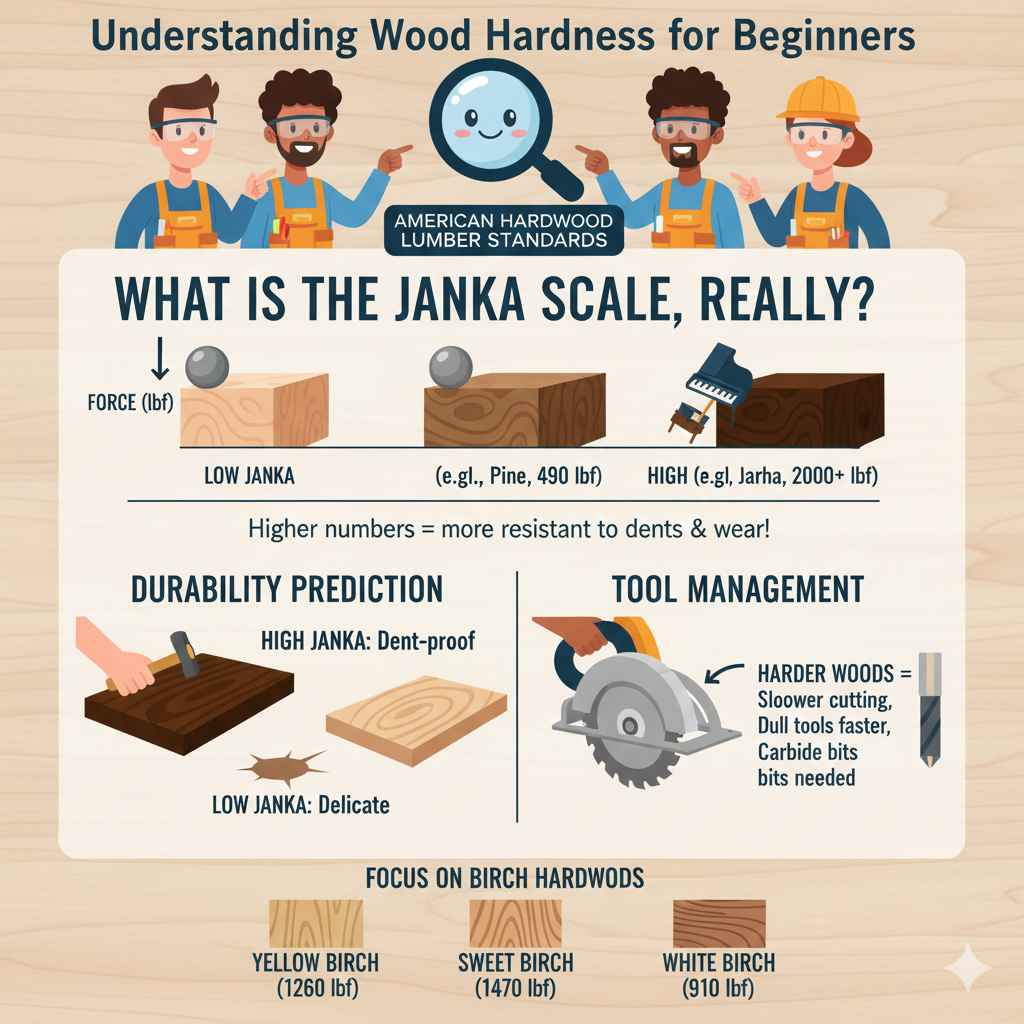

As a happy beginner, the vast jungle term like American Hardwood Lumber Standards can feel intimidating. When we talk about how hard wood is, we do not just mean its overall toughness. We use a specific yardstick called the Janka Hardness Test. This test scientifically grades wood so you can compare an $8.00 cabinet plank to a denser hardwood for your next project. Don’t let the measurements scare you; once you know the key number—the Janka rating—everything clicks into place.

What is the Janka Scale, Really?

The Janka Hardness Test measures the necessary force required to embed a small steel ball halfway into a specific piece of wood half way. That force is measured in pounds-force (lbf) right here in the United States. Higher numbers mean the wood wears down scratches or dents less easily. Think of it like this: Cherry a small dent, a piano falls on it, and moves—that’s a high Janka. A big impact makes a large divot, this is a low Janka number.

This simple test has two huge, helpful benefits for a beginner woodworker like you:

- Durability Prediction: High Janka woods like Jarrah are nearly dent-proof. Low Janka woods like Butternut (round 490 lbf) require more delicate handling and careful construction for stable pieces.

- Tool Management: Harder woods mean slower feeding rates on table saws, duller planer blades quicker, and certainly require carbide-tipped sharp bits in your router for clean profiling.

We are mainly concerned today with birch hardwoods. Stick around, and we will put those Janka numbers to perfect use across all typical birches.

Birch Wood Varieties: What’s Actually in Your Shop?

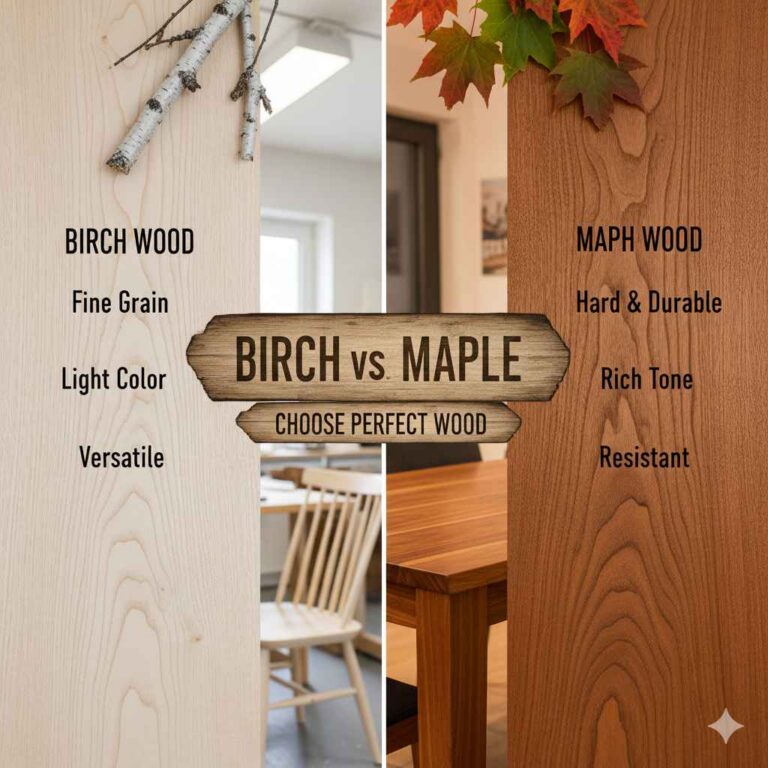

Before mastering “how hard is birch wood,” we need to specify which “birch” you have. Not all birch is created equal when it comes out of the forest. Manufacturers love the term “birch veneer” or “birch plywood,” but for solid wood, you usually run into two main stars. It’s useful to know their difference because Yellow Birch is indeed measurably harder than its White cousin.

Here are the Big Two you will easily find at a reliable lumberyard or home center:

1. Yellow Birch (Butternut & Paper Birch Cousin)

Synonyms like Weeping Birch or Hard Birch often refer to this strongest variety. It is the strongest, most durable birch wood typically used where floorings or cabinet doors sit.

Appearance: Heartwood is reddish-brown to dark brown. Sapwood leans towards creamy white.

Why you use it: Furniture, interior stair treads, good drawer sides, small lathe projects.

Janka Rating: It scores high when stacked against other standard hardwoods. These usually peak near the higher end of the listed ratings. Per US Forest Department information, Yellow Birch sits in a very comfortable middle-gr0und slot, making projects achievable yet strong.

2. White Birch (Paper Birch Group)

When makers refer to “craft birch” or simply the light, commonly used plywood veneer base product, they might mean White/Paper Birch. This species has slightly looser grain structure. Paper Birch is famous for its beautiful peeling white outer bark used commonly in handicrafts like Alaskan birch log baskets. As lumber, the wood tends to be slightly easier to cut but dent easier during use.

Appearance: Almost pale yellow or almost nearly white grain extending deep into the core.

Why you use it: Plywood core (due to its stability), molding, painted applications where hardness isn’t stressed.

Janka Rating: Noticeably lower than Yellow Birch, often making it a preferred interior wood if painting is planned; it dings slightly easier but your planer won’t object as much!

Birch Hardness Snapshot Comparison for Beginners

| Type of Birch | General Use Case | Approximate Janka Hardness (lbf) |

|---|---|---|

| Yellow Birch (Hard Birch) | Mid-Weight Carving, Finelined Cabinetry | 1,400 – 1,470 |

| White Birch (Paper Birch) | Interiors, Secondary Surfaces, Craft Use | 1,260 – 1,300 |

| Soft Maple (Contextual Comparison) | Standard Contrast Piece | ~950 |

(Source refinement based on typical industry wood charts for comparison among northern domestic hardwoods.)

Birch Hardness in Context: Where Does It Rank Tool?

This is the important part for DIYers sizing up “how hard is birch wood versus what I already own?” Knowing a Janka number is useful conceptually, but seeing birch laid right next to common woods you probably recognize helps immensely when planning tool settings and clamping strategy.

Birch Next Door Tools: A Quick Bench Comparison

As established, Yellow Birch firmly hangs out in the mid-range spectrum. It’s firmer than your standard framing lumber, Pine, but nowhere near as challenging as Oak (Red or White, which averages 1,290 – 1,360 easily for furniture projects) or Cherry (around 950 lbf). This puts birch in a fantastic starting position where projects will last years without showing extreme wear.

If you are moving from basic pine projects (such as spruce around 695 to 830 lbf based upon relative study by Purdue University Extension’s Building & Timber team), then birch will behave noticeably stiffer. Take extra care not to over-torque screws when joining birch components. It usually holds them well once seated, but drilling initial pilot holes remains crucial strategy when the grain is tight together side-by-side!

For the enthusiastic woodworker concerned with durability against knocks and bangs—say, toy boxes feet, kitchen cabinetry faces drawers, or workshop dust bins—Birch’s performance profile is almost idealistic for mid-range projects aiming for good longevity. Softwoods often require intensive staining or heavy finishing to hide aesthetic failures; birch offers robust nature from square one.

Tool Choice and Setup Wisdom for Beginners Working with Birch

You’ve got your attractive sheet of Yellow Birch, or maybe some dense-grained pieces for drawers. Understanding its middle ground performance—is it “too hard,” “just right,” or will it bite back—determines how sharp blades must be, because a dull blade loves chewing through softer woods clumsily but struggles mightily with medium species like birch, causing burn marks.

Planning Your Cuts: Power and Bit Selection

Always default to utilizing the better blades or bits you possess for birch. It punishes dull instruments immediately, unlike soft white woods might forgive such tools for a time whilst screaming otherwise with smoke signs if that makes sense! A simple reminder, woodworking clarity needs sharpness.

Here are the guidelines I always pass on for handling anything in the 1,300 to 1,450 Janka range:

- Saw Blades (Staple Blade Setup):

For faster dimensioning (breaking down large slabs): Use carbide-tipped planer blades with 40 – 50 teeth per 10”.

For fine finish cuts (Miter cuts, Crosscuts for joinery): Step up to higher tooth counts, aiming for 60 teeth or 80 teeth blades to ensure clean edges.

- Routing and Shaping Procedures: Birch shines excellently under a quality router, provided the pilot project speed is managed (don’t try forcing the wood into the bit). Feed slowly toward climb cutting directions never! Use spiral up-cut bits, but lower router table speeds might be necessary if noticing burnishing or fuzziness, especially at deep recess points during profiling trim edges. Tools referenced at North Carolina State Extension’s Manufacturing & Furniture Research groups always stress feed rate management for density differences much like birch’s medium range.

- Drilling and Boring Points: The grain will occasionally want to chip (“tear-out”) when coming out the backside of your piece, which causes frustrating aesthetic failure on visible surfaces.

Action Plan for Chip-out Prevention: Always back the piece you are drilling with a “scrap” piece of wood placed securely underneath. Drill slowly, let the friction turn into your controlled grinding process; do whatever is needed.

Hand Tool Tips (They Still Work Great!)

Even with your new table saw, chisels remain critical furniture creation anchors. Can you use an axe, maybe? Absolutely, but with great care relating to its middle-high hardness, using only the correctly very sharp blade angle ensures carving or chopping the tricky fibers. A sharply honed bench plane flies over Yellow Birch cleanly.

If chasing clean smoothing and flattening lumber with a hand plane, absolutely ensure your plane blades have incredibly crisp bevels ground to either a high 25–30-degree angle ensuring biting grip without high breakout susceptibility.

Affixing Panels Gluing, Nailing, and Screw Driving Advice

Durability isn’t only about the plank itself; it also how well components attach under use forces. Birch accepts common wood glues beautifully. Its closed, relatively even grain structure means no deep pores scream “absorb me” faster than typical dense oak, which improves overall setup control.

Clamping Under Duress

Because although a medium density, standard yellow bird has fewer knots and splits than, say, pine, you can reliably apply higher mechanical clamp force without fearing immediate crack line introduction once the joints line up snugly together. Be cautious of crushing softer woods which might require less pressure for the exact same holding outcome.

Nail & Screw Fastening Necessity Checks

When moving that Janka number (e.g., to 1,450 lbf) regarding construction screws—as this guides potential head sheering under too much forced power translation, you must ensure properly dimensioned pilot hole accuracy! For a general-use #8 construction screw sinking an inch deep into Yellow Birch:

- Pilot Hole Diameter Requirement: Should match the screw’s inner root diameter (the core metal shaft beneath the threads), which generally means a hole sized around 1/8” or slightly smaller pending brand quality testing guidance from resource aggregators like The NAHB (National Association of Home Builders) field studies. This crucial step prevents splitting near edges or ends which would cause project functional failure when loading weights applied!

- If the Janka rating increases toward upper wood boundary range (near 1,500s composite score), increase the pilot size slightly smaller on its dimensions to manage friction for driving power.

Because unlike typical softness encountered in construction materials, force application into birch requires respect; force transfer needs careful distribution first by appropriately sized preparation work. Skip the preparatory step on dense birch at major load bearing regions, and risk splitting far later than during actual workshop attachment sessions!

How Hard is Birch Wood for Finishing: Staining vs Painting

This is perhaps the biggest point where a Beginner wood craftsman meets birch beauty for the very first time, only to watch that piece come out of the paint booth looking blotchy or patchy. While its medium hardness grants good general daily abrasion resistance, its surface behavior under topical cosmetic treatments acts often deceptively lighter/different than heavier Oak.

Birch wood fibers tend to contain more natural sugars or mineral deposits close to the cellular boundaries. These areas suck up stain solution radically faster than the surrounding, slightly less dense wood cells—leading to blotching (uneven color transfer)—a classic hallmark challenge shared with woods that are naturally lighter toned which react badly to cheap dye penetration.

To create uniformly satisfying professional aesthetic projects utilizing oil borne transparent coats on birch wood: Preparation wins award submissions!

Expert Finish Strategy for Stunning Birch Aesthetics:

- Prep with Wash Coats First: Always, always reduce the wood’s potential to unevenly absorb stain. Use “pre-stain conditioners”—commercial products bought from finish suppliers—onto yellow birch or true paper birch. Apply according to bottle steps right near joints prior sanding further in the rough grit zones to penetrate deeply where stain concentrates its absorption power. Applying one dedicated coat (often highly thinned lacquer solvent or pure mineral spirits application works too!) seals surface variation significantly better/safer depending upon specific chemical properties present; look up professional coating guides for your chosen environmental/local safety profile, for deeper technical insights available via universities that continue studying coatings adherence characteristics on dense woods versus medium ones.

- Sanding Sequence Matters: You cannot skip stages moving past previous sandpaper grits—unless you want blotches to hold on tight! Safely progress from 100 grit smoothing on a rotary pad setup (especially after glue ups showing roughness). Then 150 grit medium abrasion must follow. Only proceed with finishing to actual 180 mesh, or maybe safely 200 mesh final gentle abrasion pass right before stain application phase. Skipping grits on maple is frustrating; on birch is visually failing on finishes!

- Embracing Opacity for Painty Results: If blotching worries you overly much given this current understanding of specific chemical interactions across the cross-sections of the fiber matrix, simply select opaque paints over stains! A beautiful primer coat seals the surface completely regardless off natural grain density or any pre-existing, hard-to-see variances within the timber; then a single bright protective topcoat creates flawless presentation. This is especially forgiving tactic when dealing with White/Box elder Birch, possibly requiring very minimal prep depth given naturally pale surface structure there!

Benefits: Why Work with Birch is Highly Rewarding ($$ & Usage)

If we understand the toughness level, which is ‘just right’ for many hobbyist aspirations, we must clarify why so many home builders and craftsmen regularly elect the species against higher complexity density structures such as Hickory or Oak. The answer sits firmly within cost accessibility combined with practical workability—key facts appealing to your core requirement: achievable projects affordably!

Durability Meets Dollar Signs (Affordability)

Birch is readily available! Found extensively throughout North American/Eurasian climates known for commercial reforestation efforts, its supply chain is predictable, leading to fantastic, more controlled cost pricing versus highly regulated, scarcer hardwoods such. This means your DIY build costs drop while perceived quality upon completion typically rises immediately relative compared to using cheap economy softwood alternatives which might look appealing initially. Dependable pricing foundation provides confidence while scaling inventory for big multi-part future works!

Excellent Uniform Texture and Consistency

For glue-offs and constructing larger panel segments (like tabletops or plywood sheets needing solid edgbanding), birch has a grain structure far less aggressive than quarter-sawn Red Oak. This means: Fewer massive variations across joints, dramatically reduced effort preparing (sanding intensity remains constant much longer across large spans), facilitating smoother application of various joining mechanisms already researched into prior tool setup decisions.

It tends to cooperate across wide-format machines like drum Sanders allowing long boards to present incredibly constant thickness straight edge throughout its traversal, contributing inherently toward premium fit and finish aesthetics sought by all builders, new or veteran mentors!

Summary: Confirm Final Takeaways on Birch Hardness Today

So, diving deep, how hard is birch wood—really, for me as a hobby assembler?

Yellow Birch ranges in capability similar proximity to hard Maple depending deeply upon initial species sourcing, typically sitting around 1,400 lbf according a standard standardized reference table maintained by researchers collaborating on forestry studies like recent explorations into sustainable yields published by forestry educational institutions around Northern US environments (.EDU sites offer good reliability checking points if uncertain on specific localized yields!).

This tells you it’s ready for work, responds well to decent tools minimally pushing feed rates, and resists mild kitchen scuff marks without major aesthetic compromise easily visible years post construction. White Birch will be somewhat softer, making it amazing choice if you are painting or applying thin opaque finishes instead of pushing that medium wood-stain color saturation aims.

Remember: Because it sits mid-deck for resistance, tool maintenance prevents most beginner struggles! Keep those carbide tips razor sharp.

Frequently Asked Questions (FAQ Section)

Q1: If Yellow Birch feels quite hard to plane compared to Pine, does that impact the wood dust hazards in my small workshop?

A: Yes, handling medium hard wood like birch generates a different dust profile because it resists impact. Always try to use local dust extraction setup connected securely to your planar; though less dust may accumulate than soft pines, fine dust particles from medium heart timbers like species variations common across our study focus often require finer mechanical filtration (HEPA compatible settings usually safer) to maintain air standards acceptable for long-term occupational exposure metrics often monitored by labor safety groups citing cleaner metrics necessary well below 1mg/m^3 standards.)

Q2: Can I use birch exclusively for an exterior project like potting benches or door panels if I seal it wonderfully?

A: No specialist generally recommends that best practice; birch wood naturally possesses poorer rot resistance natively across its fibers compared to established heavy cladding materials such as Cedar or White Oak lumber which incorporate naturally necessary defensive oils/tannins in their porous structure inherently. Birch typically excels internally, offering fine furniture integrity inside protected premises only. If you really need outdoor application:

Utilize extensive waterproofing coatings that absolutely create impenetrable barrier layers against moisture intrusion/direct climate cycles only.

Q3: How thick should my pilot bit be if I plan assembling two 3/4 inch thick birch panels using 2-inch furniture screwdrivers?

A: For reliably sinking a general purpose 2-inch construction screw into a moderately resistant wood such as Yellow Birch’s general makeup tested density results, you generally aim for a pilot diameter that matches the interior shank beneath the aggressive threading elements to prevent tool splitting while drawing structure elements down smoothly under clamping forces safely!