How Much Is a Wood Deck? Real Price Guide

Figuring out How Much Is a Wood Deck? Real Price Guide can feel tricky, especially when you’re just starting. There’s a lot to consider, from different wood types to labor costs. Don’t worry, it’s not as hard as it seems! We’re here to help you get a handle on the costs without the head-scratching. We’ll break down everything you need to know step-by-step. Let’s start with a look at what impacts the price of a deck.

Factors Influencing Decking Expenses

The total cost of building a deck varies widely. Several elements contribute to these fluctuations, making it essential to evaluate each aspect carefully. This gives you a clear picture of the budget you need. From the materials you choose to the size and the labor involved, every choice impacts the final price. Knowing these details upfront enables you to make informed decisions that match your budget and goals. You’ll then be able to prioritize what’s most important to you when designing your outdoor space.

Material Selection’s Impact on the Cost

The type of wood you select dramatically affects the overall cost. Different wood species boast unique properties, from durability to aesthetic appeal. This, in turn, influences the price tag. For example, pressure-treated lumber is often a budget-friendly option, offering decent weather resistance. However, it might not have the same natural beauty as a hardwood like Ipe. Similarly, composite decking, while more expensive initially, can save money on maintenance over time because it resists rot and fading. So, when calculating the cost of your project, compare the initial material price and the long-term upkeep.

Pressure-Treated Wood: This is the most common choice due to its affordability and resistance to rot and insects. It is treated with chemicals to withstand the elements.

Pressure-treated wood is manufactured by placing lumber in a pressurized tank containing preservatives. These chemicals are forced deep into the wood fibers, making it resistant to decay, termites, and fungal growth. The type of wood and the treatment process affect the lifespan and price. Common types include pine and fir. The initial cost is typically lower than other options like cedar or composite decking, making it an attractive choice for those on a budget. However, pressure-treated wood often requires regular maintenance, such as staining or sealing, to maintain its appearance and protect against moisture. This maintenance adds to the long-term expenses. It may also have less aesthetic appeal compared to other materials, but it is a sturdy, practical option.

Cedar Wood: Cedar is naturally resistant to decay and offers a beautiful, warm appearance. It resists insects and moisture well.

Cedar is a popular decking material that brings both beauty and natural resistance to decay. It offers a warm, reddish tone that enhances any outdoor space. This wood contains natural oils that make it resistant to insects, rot, and moisture. The price tends to be higher than pressure-treated wood. However, cedar requires less frequent maintenance. You can choose to leave it untreated, allowing it to weather naturally to a silver-gray, or protect it with stain. This makes it a great choice for those who value aesthetics and natural durability. Common varieties like Western Red Cedar are known for their rich color and pleasant aroma, adding a touch of luxury to your deck project.

Composite Decking: Made from a mix of wood fibers and plastics, composite decking is a low-maintenance option. It resists fading, staining, and warping.

Composite decking is a man-made material designed to mimic the appearance of wood while offering enhanced durability and reduced upkeep. It’s manufactured from a blend of recycled materials, often including wood fibers and plastic. This combination creates a deck that’s resistant to moisture, rot, and insects. Composite decking doesn’t require staining or sealing, reducing long-term maintenance costs. While the initial cost of composite decking is often higher than traditional wood options, the reduced maintenance can save you money over time. It is available in a wide range of colors and styles, allowing you to create a customized look for your outdoor space. Leading brands like Trex and TimberTech offer a variety of composite decking options. These options offer homeowners a beautiful, long-lasting deck solution.

Hardwood Decking (Ipe, Mahogany): These premium materials offer exceptional durability and a luxurious look, but they come with a higher price tag.

Hardwood decking, such as Ipe and Mahogany, represents the pinnacle of luxury and durability in decking materials. These hardwoods are prized for their exceptional resistance to weather, insects, and decay, ensuring a long-lasting deck. Ipe, in particular, is one of the densest woods available, making it incredibly strong and resistant to scratches and wear. Mahogany also offers a rich, beautiful appearance. It adds a touch of sophistication to any outdoor space. The higher cost reflects their premium quality, sourcing, and longevity. While the initial investment is more significant, hardwood decking typically requires less maintenance than traditional wood, reducing long-term upkeep expenses. Their stunning appearance and impressive durability make hardwood decks a great investment for homeowners who appreciate quality and want a deck that will stand the test of time.

Deck Size and Design Considerations

The size and complexity of your deck significantly influence the overall cost. A larger deck naturally requires more materials, increasing expenses. Complex designs, such as multi-level decks or those with intricate features, demand more labor. They also need more specialized materials. Simple, rectangular decks are usually more affordable. They require less planning and can be built more quickly. Before starting the project, consider how the design impacts both material and labor costs.

Simple vs. Complex Designs: Basic rectangular decks are generally less expensive to build than multi-level decks or those with curves.

The design complexity has a direct impact on the cost of building a deck. Simple, rectangular designs are easier and faster to construct, requiring fewer materials and less labor. This simplicity keeps the costs down. Complex designs, such as those with curves, multiple levels, built-in seating, or custom features, increase the cost. They require more planning, more intricate cuts, and potentially specialized tools. These features also demand greater skills from the builders. This leads to higher labor costs. The time it takes to complete the project increases with complexity. So, when planning, weigh the desired design against the budget and consider the impact of intricate features.

Deck Height and Accessibility: Decks built higher off the ground will require more supports and safety features, adding to the cost.

The height of the deck above the ground is a key factor in determining costs. Decks built close to the ground are generally more affordable because they require less foundational support. Higher decks, however, need more extensive and stronger support structures to ensure safety and stability. This includes posts, beams, and railings. Building a deck above a certain height often requires adherence to local building codes. These codes might mandate features like additional guardrails or staircases. This increases material and labor costs. Accessibility is also essential. If you want to include ramps or wider stairs for ease of access, these features will also impact the cost. The height, combined with accessibility requirements, plays a large role in the overall project expense.

Additional Features (Railing, Lighting, Built-in Seating): Adding extras like railings, lighting, or built-in seating increases the overall cost.

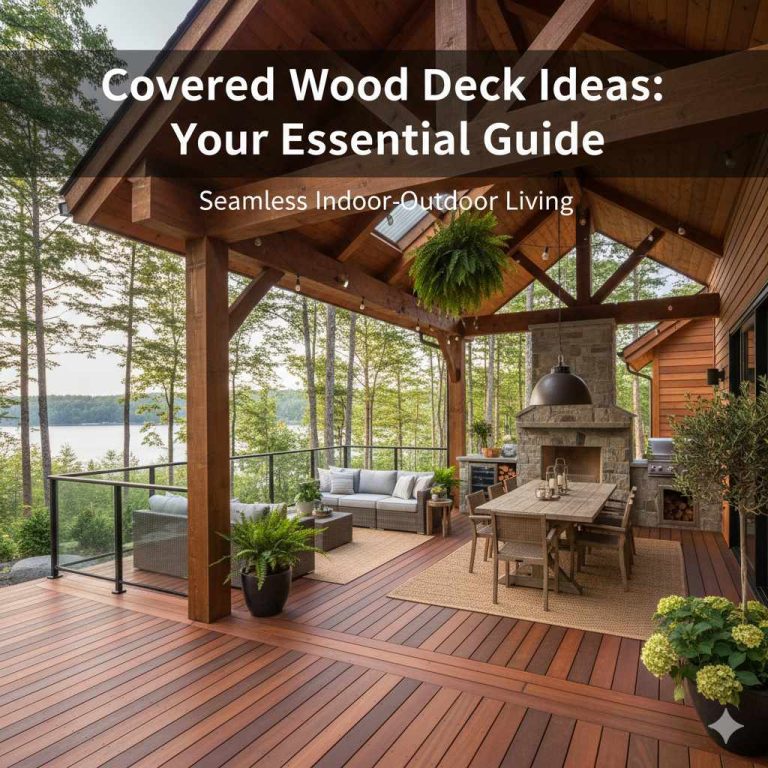

Adding features elevates the deck’s aesthetic appeal and functionality but also increases the project cost. Railings, essential for safety, can be made from various materials, each with different price points. Lighting adds ambiance and extends the deck’s usability into the evening. These lights can range from simple post lights to more elaborate setups. Built-in seating offers convenience and style, but it requires extra planning and construction. Other elements, like pergolas, built-in planters, or outdoor kitchens, can add significant costs. These enhancements will enhance your outdoor space and reflect your personal preferences. These additions should be considered within the total budget to ensure a design that balances aesthetics, functionality, and affordability.

Labor Costs and DIY vs. Professional Installation

Labor costs can be a significant part of your deck-building expenses. These costs can vary based on your area and the complexity of the project. Choosing to build the deck yourself can save on these costs. However, it requires time, skills, and the right tools. Hiring a professional ensures quality work and compliance with local building codes. You can also save money by comparing quotes from different contractors and understanding the details of each estimate. This helps you get the best value for your investment.

Local Labor Rates: Labor costs fluctuate depending on your area’s cost of living and the demand for skilled labor.

Local labor rates are a major element of the overall project cost. These rates can vary significantly depending on where you live. Metropolitan areas and regions with a higher cost of living tend to have higher labor rates compared to rural areas. Factors like the demand for skilled workers also impact these rates. During peak construction seasons, when demand increases, labor costs may go up. It’s always good to research local labor costs. This lets you budget accurately. Getting quotes from multiple contractors provides a good idea of prevailing rates in your area. This helps you compare costs effectively.

Complexity of the Project: Intricate deck designs demand more skilled labor and, therefore, higher costs.

The complexity of your deck’s design directly influences the labor costs. Simple, rectangular designs require less skill and time to construct, leading to lower labor costs. Complex designs, however, such as those with multiple levels, curves, or custom features, demand more specialized skills and increased time to complete. This complexity increases the labor costs. More intricate builds involve detailed cutting, precise measurements, and a higher level of craftsmanship. When planning your deck, consider how your design choices affect labor expenses. A simpler design can help reduce costs. It still lets you enjoy a beautiful outdoor space. If you have a detailed design, ensure that the contractor is experienced in similar projects to ensure quality work.

DIY vs. Hiring a Contractor: Building your deck yourself can save on labor costs, but it requires time, skill, and tools.

Deciding between DIY and hiring a contractor greatly impacts project expenses. Building your deck yourself can save you the labor costs, which can be a significant portion of the total. However, it demands time, effort, skills, and the necessary tools. It’s crucial to evaluate your abilities and time commitment. If you are inexperienced, the project might take longer. It might also lead to mistakes. Hiring a contractor ensures that the deck is built to code. It often comes with warranties and professional expertise. While the initial investment is higher, you can get a high-quality finished product. Carefully consider your skills, time availability, and budget when making this choice.

Breaking Down Decking Costs: A Detailed Look

Understanding the costs involves breaking down expenses. This breakdown provides transparency and allows you to pinpoint where your money goes. Knowing the cost of materials, labor, and additional features helps you create a budget. It also helps you make informed choices that align with your financial goals. You can decide where to save and where to splurge. This ensures you get the deck that perfectly suits your needs and tastes.

Material Expenses

Material costs depend on your chosen materials. Pressure-treated lumber is often the most cost-effective. Cedar and composite decking are more expensive. Hardware, like screws, nails, and fasteners, is a small but important part of the materials budget. Always get quotes from several suppliers to compare prices.

Lumber Costs: The price varies widely based on the wood species, with pressure-treated lumber being the most affordable.

Lumber costs are a major expense. The price varies widely based on the wood species and the quality. Pressure-treated lumber is typically the most affordable option. It is a practical choice for those watching their budgets. Cedar is another option. It offers natural resistance to the elements. Composite decking and hardwood options like Ipe and Mahogany are more expensive. They provide durability and aesthetic appeal. Comparing prices from various lumber suppliers is essential. It lets you find the best deals. Be sure to account for waste. You should also consider any additional costs for specialized lumber. The right choice combines your personal preferences and budget.

Fasteners and Hardware: Screws, nails, and other fasteners add to the overall material cost.

The cost of fasteners and hardware is a crucial, though sometimes overlooked, aspect of material expenses. These items, including screws, nails, brackets, and connectors, are essential for the deck’s structural integrity. Even though they may seem insignificant individually, the combined cost can add up. The type of fasteners you choose also influences the cost. Stainless steel screws and specialized connectors are more expensive than standard options. However, they provide enhanced corrosion resistance and long-term durability. When budgeting, always include these items. Factor in the quantities needed. This helps you get an accurate material cost and ensures your deck is securely built.

Waste Factor: It’s essential to account for material waste when calculating costs, usually around 5-10%.

Accounting for material waste is critical to accurate cost planning. When building a deck, it’s inevitable that some materials will be cut, damaged, or left over. This is particularly true with complex designs. Estimating a waste factor ensures that you buy sufficient materials to complete the project without delays. A typical waste factor for decking projects is around 5% to 10%. It depends on the complexity of the design and the experience of the builder. When ordering materials, increase your estimate to account for this waste. This helps you avoid running out of materials. You can also prevent delays. It also helps avoid potential additional trips to the supply store, which would be an added expense.

Labor and Installation Expenses

Labor costs depend on experience and the complexity of the design. Factors like deck size, height, and the need for permits influence labor costs. If you are hiring a professional, they handle these tasks. They also ensure that the work meets code regulations. Knowing these aspects helps you budget accurately and communicate effectively with your contractor.

Hourly Rates: Contractors charge an hourly rate that varies based on experience and location.

Contractors’ hourly rates are a key factor in overall costs. These rates vary depending on the experience of the contractors. Those with more experience and specialized skills often charge higher rates. The location also plays a role. Metropolitan areas with higher costs of living usually have higher labor rates than rural regions. When getting quotes from contractors, ask for a detailed breakdown of labor costs. Ensure that the estimate includes all aspects of the project. This helps you compare quotes and avoid surprises. A clear understanding of hourly rates lets you manage the budget and make informed decisions.

Permitting and Inspections: These costs are often included in a contractor’s quote or are handled by the homeowner separately.

Permitting and inspections are crucial parts of any decking project. The cost of permits varies based on location. It is important to know about the local regulations. Contractors will often include these costs in their quotes. They ensure the deck meets local building codes and safety standards. If the homeowner handles the permitting process, they must factor in the permit fees. It’s necessary to budget for these expenses. This ensures that the deck meets all legal requirements. Thorough inspections are done at different stages of construction. These inspections help ensure that the deck is built to code. This protects the homeowner and ensures the safety and longevity of the deck.

Subcontractor Costs: If specialized work is needed (e.g., electrical), additional subcontractors may increase the overall labor cost.

The use of subcontractors is a factor in total labor costs. For some deck projects, specialized work might be needed. This includes electrical wiring for lighting or plumbing for an outdoor kitchen. In these cases, the primary contractor may bring in subcontractors who specialize in these areas. The costs for these services will be added to the labor expenses. When comparing quotes from contractors, ask if they plan to use subcontractors. Request a detailed breakdown of the subcontractor costs. This helps you understand the total costs involved. Coordinating with multiple subcontractors can also add to the project’s timeline. It also requires careful planning to ensure that all elements of the deck project are completed seamlessly.

Additional Expenses and Hidden Costs

Additional costs can include site preparation, waste disposal, and unexpected repairs. Weather delays can also affect the budget. It is always wise to add a buffer to your budget for these potential costs. This gives you financial flexibility and ensures that the project progresses smoothly, despite unforeseen challenges.

Site Preparation: Costs can include clearing the area, leveling the ground, and removing old structures.

Site preparation is a crucial step. It also impacts the overall project expenses. It involves preparing the area where the deck will be built. Costs include clearing the area of any obstructions, like trees, shrubs, or other structures. Leveling the ground ensures a stable and even foundation. Removing old decks or patios is another potential cost. The cost depends on the size and scope of the work needed. For example, if you have to remove a tree or stump, you’ll need to account for tree removal expenses. If the existing ground is uneven, the cost of leveling and grading may increase. Always include site preparation costs in your budget. You can avoid surprises that can throw off the project’s schedule and budget.

Waste Disposal Fees: Proper disposal of construction debris adds to the total cost.

Waste disposal fees are a significant and often overlooked aspect of deck-building expenses. After construction, there will be construction debris. This can include wood scraps, packaging materials, and other waste. The cost of disposing of this debris can be significant, especially if a large volume of waste is produced. The type of waste disposal method also impacts the costs. You may need to rent a dumpster. You might use a debris removal service. Costs vary based on the amount of waste generated. You must also comply with local regulations on waste disposal. Always include waste disposal fees in your budget. This can help prevent unexpected expenses. It also ensures proper environmental responsibility.

Contingency Funds: It’s advisable to have a contingency fund to cover unexpected expenses or unforeseen issues.

A contingency fund is a crucial element for any construction project. It provides financial protection against unexpected expenses or unforeseen problems. Things like hidden issues with the existing foundation or unforeseen material price increases are examples of potential problems. These can impact the total cost. Setting aside a contingency fund, typically 10% to 15% of the total budget, provides flexibility. It gives you some financial leeway. This allows you to handle unexpected costs without disrupting the project. It also gives you peace of mind. Without a contingency fund, you might have to make decisions that could compromise the project’s quality. This includes using cheaper materials or cutting corners. A contingency fund makes sure you are ready for any situation.

Ways to Save on Decking Expenses

You can use different strategies to control your costs. Choosing affordable materials, designing a simple deck, and taking on some of the work yourself are great ideas. Getting several quotes from contractors lets you compare prices. The right choices let you achieve your desired outdoor space while staying within your budget. Being thoughtful throughout the planning process and being open to adjustments also helps.

Material Selection Strategies

Choosing the right materials is essential to control costs. Selecting pressure-treated wood over premium hardwoods is one way to cut expenses. It also involves exploring composite decking. You can also balance cost and aesthetics. Purchasing materials during sales or off-season can lead to savings. You can also source materials from multiple suppliers to get better deals. Being smart about material selection can significantly reduce your costs.

Choosing Affordable Materials: Opting for pressure-treated lumber instead of premium hardwoods can reduce material costs.

One of the most effective ways to save money is to select affordable materials. Pressure-treated lumber is often the most economical choice. It provides good value. It offers durability and resistance to rot and insects. This makes it suitable for many decking projects. While hardwoods like Ipe and Mahogany offer unmatched beauty and longevity, their higher costs can strain a budget. By comparing options, you can often find suitable, lower-cost materials that still meet your needs. Be aware of the long-term impact on maintenance. If you choose a less expensive option, like pressure-treated wood, make sure to budget for staining or sealing. This will help maintain the deck’s appearance and protect the wood.

Considering Composite Decking: While more expensive upfront, composite decking can save money on maintenance and replacement in the long run.

Composite decking, although it has a higher initial cost, presents a smart cost-saving strategy. Composite decks require little or no maintenance. There is no need for staining or sealing. This is a significant difference from traditional wood decks, which need regular maintenance. Over the years, the cumulative costs of stain, sealants, and labor can add up. Composite decking resists fading, rotting, and insect damage. It also extends the deck’s lifespan. By thinking about both the short-term and long-term costs, composite decking often proves to be a smart investment. You can reduce ongoing expenses and potential repair costs. The initial expense is offset by savings over the deck’s lifetime.

Shopping for Sales and Discounts: Buying materials during off-season sales or from multiple suppliers can help reduce expenses.

Another cost-saving tactic is to be strategic about when and where you purchase your materials. Many suppliers offer seasonal sales and discounts. This is often during the off-season. Purchasing materials during these periods can lead to substantial savings. It’s also smart to source materials from different suppliers. This allows you to compare prices. Some suppliers might offer better deals on certain items. You can save money by being flexible. You can adjust your plans to take advantage of these savings. Before making any purchases, get quotes from multiple suppliers. Ask about ongoing sales and discounts. This can help you maximize your savings. Careful planning and being prepared to act when prices are favorable can make a big difference.

Design and Labor Cost-Saving Tips

Simplifying the deck’s design helps cut expenses. You can also consider doing some of the work yourself. However, you should only attempt this if you have the skills. Always hire licensed contractors to ensure quality and compliance with local regulations. These strategies help you balance functionality, aesthetics, and affordability when designing your deck.

Simple Design: Opting for a simple, rectangular design reduces material and labor costs.

A simple design is a good way to save money. Rectangular decks are easier and faster to construct. They require less planning and fewer complex cuts. This leads to reduced labor costs. Simple designs also use fewer materials. The straightforward approach cuts material expenses. Complex designs, such as those with curves or multiple levels, increase costs. They also require specialized skills. Keep the design simple to reduce expenses and streamline the construction process. This doesn’t mean you can’t have a beautiful deck. It simply means choosing a design that prioritizes ease of construction and material efficiency. You can still create an outdoor space that suits your needs and budget.

DIY Tasks: Taking on some of the work yourself, if you have the skills, can save on labor costs.

Taking on some of the work yourself can lower overall project expenses. Tasks like demolition, site preparation, and painting can often be done by the homeowner. This decreases the amount of labor you need to hire. Before you do any work, know your skills. Decide which tasks you are comfortable with. Ensure you comply with local building codes. If you choose to handle parts of the project yourself, do your research. Watch tutorials and learn the correct methods. You can also save money. It helps you control costs. It also gives you more control over the project. Consider hiring professionals for critical construction tasks. This ensures quality and compliance with regulations.

Compare Contractor Quotes: Obtaining multiple quotes helps to compare prices and find the best value.

Comparing quotes from several contractors helps you get the best deal. Contractors have different pricing strategies. Each contractor has different overhead costs. Getting multiple quotes provides a good understanding of what the project should cost. It also allows you to compare the services included in each quote. Always request a detailed breakdown of the costs. Make sure the estimates are the same for materials, labor, and other services. Before making a choice, check references and look at past work examples. By doing so, you can choose a contractor that offers the best balance of price, quality, and experience.

Long-Term Cost Considerations

Prioritizing durable materials and regular maintenance can prevent costly repairs. Investing in quality materials, such as composite decking or hardwoods, can be more cost-effective in the long run. Regular maintenance, including cleaning and resealing, can extend the life of your deck. These efforts can help you avoid expensive repairs and replacements. These smart strategies help you to maintain a beautiful and functional deck for years.

Durability of Materials: Choosing durable materials can reduce the need for frequent repairs and replacements.

The durability of your chosen materials has a direct effect on long-term costs. While more expensive, materials like composite decking and hardwoods (like Ipe) last longer. They also withstand the elements and regular use better. Less durable materials, such as low-quality wood, can require more frequent repairs or, eventually, replacement. By investing in durable materials, you can minimize long-term expenses. This approach saves money on repairs and replacements. It also reduces the need for regular maintenance. The initial investment might be higher, but you get a deck that lasts a long time. It provides better value over the years. Consider the upfront and long-term costs. Make a decision that maximizes your investment.

Regular Maintenance: Regular cleaning and maintenance extend the deck’s lifespan and prevent costly repairs.

Regular maintenance is essential to prevent costly repairs and extend your deck’s lifespan. Cleaning your deck regularly removes dirt and debris. This helps to prevent mold and mildew growth. It also helps to prevent moisture buildup. This can damage the wood. Applying a sealant or stain protects the wood from the elements. This also helps to reduce cracking, warping, and fading. You can also inspect the deck periodically. You can look for signs of damage or wear. Addressing problems early saves you from needing expensive repairs later on. Consistent maintenance, even though it requires time and effort, is a cost-effective strategy. This helps you maintain the beauty and functionality of your deck for years.

Professional Inspections: Periodic professional inspections can help identify potential issues early on.

Periodic professional inspections can identify problems early. Experienced professionals can look for signs of wear and tear, structural weaknesses, or damage. They can spot issues that you might miss. An inspection might find hidden problems. These issues could lead to extensive repairs. Addressing these problems early can prevent small problems from becoming large, expensive ones. Professionals know about local building codes. They can ensure your deck meets all safety standards. Scheduling inspections every few years can save money in the long run. You can also extend the life of your deck. You can also prevent costly repairs and preserve the value of your outdoor space.

Frequently Asked Questions

Question: How much does a deck cost per square foot?

Answer: Deck costs vary greatly. You should expect to pay from $15 to $75+ per square foot, depending on the materials and complexity.

Question: What’s the cheapest type of wood for a deck?

Answer: Pressure-treated lumber is generally the most affordable wood for decks, making it a budget-friendly option.

Question: How long does a deck typically last?

Answer: Deck lifespan depends on materials and maintenance. Pressure-treated wood decks might last 10-15 years. Composite decks can last 20-30 years.

Question: Do I need a permit to build a deck?

Answer: Yes, in most areas, you need a permit. Check with your local building department for the rules.

Question: Is it cheaper to build a deck yourself or hire a professional?

Answer: Building yourself can save money on labor, but hiring a professional ensures quality and code compliance. Consider your skills and available time.

Final Thoughts

Understanding How Much Is a Wood Deck? Real Price Guide is essential before starting your project. This exploration shows how factors like material selection, design, and labor impact expenses. We also covered ways to save. Planning your project carefully is essential. Compare material choices. Get multiple quotes. Consider the long-term benefits of your decisions. You can build a deck that meets your budget, while ensuring quality. Remember, a well-planned deck project blends aesthetics, function, and affordability. Get started today and create an outdoor space you can enjoy for years. This is your chance to expand your home and transform your property. Your dream deck is within reach with careful planning.