How to Build a Wood Lathe PDF: DIY Mastery Guide

To build a wood lathe, start by gathering materials like a motor, pulleys, and a sturdy frame. Follow a detailed plan or PDF guide to ensure accuracy and safety.

Creating your own wood lathe can be a rewarding project for woodworking enthusiasts. It allows for customization based on your specific needs and available space. A well-built lathe enhances your ability to create intricate designs, from bowls to spindles. This guide will walk you through the essential steps and materials required to construct a functional wood lathe.

Understanding the components and their assembly will help you achieve a high-quality tool tailored to your woodworking projects. Whether you’re a beginner or an experienced craftsman, building your lathe can elevate your craftsmanship significantly.

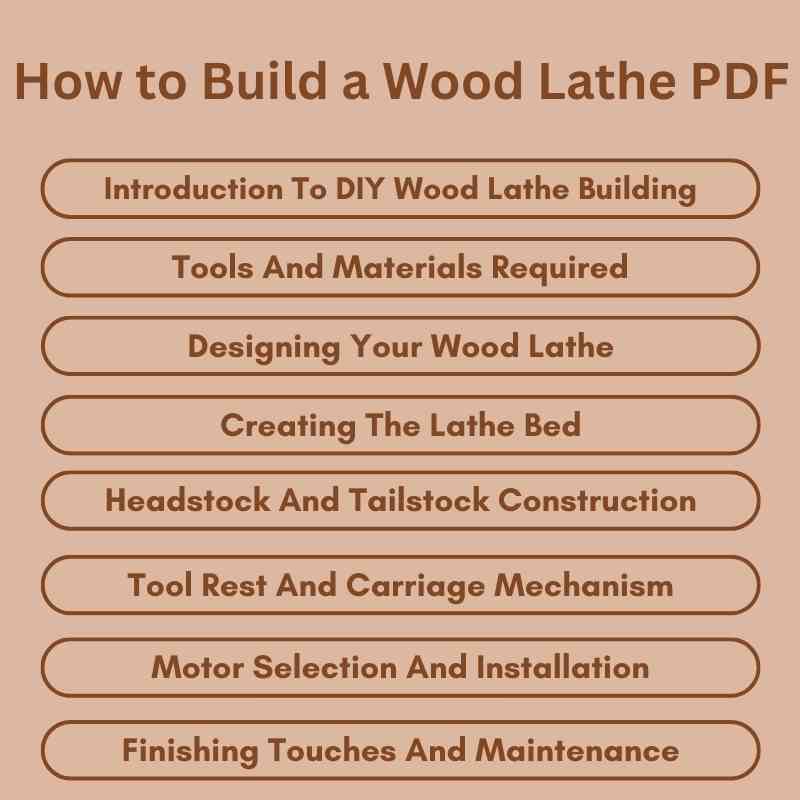

Introduction To DIY Wood Lathe Building

Building a wood lathe at home offers many benefits. Homemade tools can save money and provide a sense of achievement. Crafting your own lathe allows for customization to fit your specific needs. Many woodworkers enjoy the creative process involved in DIY projects.

Safety is very important before starting this project. Always wear protective gear such as goggles and gloves. Ensure the workspace is clean and free of clutter. Keep tools and materials organized to prevent accidents. Double-check all equipment for damage before use.

Tools And Materials Required

Building a wood lathe requires several essential power tools. First, you need a drill press. A band saw is also necessary for cutting wood. Don’t forget the sander for smoothing surfaces.

Next, gather the right wood types. Hardwoods like maple or oak work best. They provide strength and durability. Use plywood for base components. Ensure all pieces fit together well.

Gather fasteners such as screws and bolts. They hold everything securely. A good measuring tape helps in accurate cuts. Safety equipment like goggles and gloves is also important.

Designing Your Wood Lathe

Creating a blueprint for your wood lathe is crucial. Start with measurements of your workspace. Consider the size of the projects you will work on. Sketch the lathe design on paper first. Use grid paper for accurate measurements.

Focus on key components like the bed, tailstock, and headstock. Each part must fit well together. Ensure all parts are easy to access and operate. Think about adding special features for specific projects. This could include adjustable speeds or unique tool rests.

Customizing the lathe will make it more useful. Identify the types of wood you prefer to use. Design features that support your specific needs. This ensures the lathe works best for your projects.

Creating The Lathe Bed

To create a strong lathe bed, start with the right dimensions. Use a sturdy piece of wood, at least 4 inches wide and 2 inches thick. Cut the wood to your desired length, usually between 48 to 72 inches.

Make sure to assemble the bed with strong joints. Use wood glue and screws for extra strength. It is important that the bed is level. Use a leveling tool to check for any uneven spots.

For better stability, add support beams underneath. These beams should run parallel to the bed. This will help prevent any wobbling during use.

Finally, sand the surface of the bed. A smooth surface ensures precision when working on projects.

Headstock And Tailstock Construction

Building a secure headstock is crucial for your wood lathe. Use strong materials like hardwood or metal for strength. Ensure it fits tightly on the lathe bed to prevent movement. Proper alignment is key for smooth operation. Consider adding adjustable clamps for extra stability.

The tailstock should offer flexibility for various projects. Look for features like easy height adjustment and a solid locking mechanism. A removable tailstock can enhance versatility. It allows for different workpiece sizes. Always ensure the tailstock aligns perfectly with the headstock.

Tool Rest And Carriage Mechanism

Design an adjustable tool rest for your wood lathe. This tool rest helps with different projects. Use a sturdy material for durability. Make sure it can move easily up and down.

The carriage system should allow smooth movement. It must support the weight of the wood pieces. Use bearings for easy sliding. A good design prevents any wobbling during operation.

Consider using locking mechanisms to hold the tool rest in place. This feature ensures safety while working. Test the setup before starting your project. Fine-tune any parts that need adjustment.

Motor Selection And Installation

Choosing the right motor is crucial for a wood lathe. Consider the power needed for your projects. A motor between 1 to 2 horsepower usually works well. Speed control is also important. Look for a motor that allows for variable speed settings.

Electrical safety is vital during installation. Always ensure the motor is properly grounded. Use circuit breakers to prevent overload. Check all connections to avoid short circuits. Keep the work area dry and free from debris.

| Motor Type | Power (HP) | Speed Control |

|---|---|---|

| Induction Motor | 1-2 HP | Variable |

| DC Motor | 1-3 HP | Variable |

Finishing Touches And Maintenance

To ensure your wood lathe lasts, proper sanding and finishing are essential. Use fine-grit sandpaper to smooth the surface. This helps prevent splinters and improves appearance. After sanding, apply a quality wood finish. This protects the wood and enhances its beauty.

Routine maintenance keeps your lathe performing well. Regularly check for loose parts and tighten them. Clean the lathe after every use to remove dust and debris. Lubricate moving parts with appropriate oil. This reduces wear and keeps everything running smoothly.

Creating Your First Project

Creating a simple bowl on your wood lathe is exciting. Follow this step-by-step guide to start.

Materials needed:

- Wood blank

- Lathe

- Chisels

- Safety goggles

Steps:

- Secure the wood blank on the lathe.

- Turn on the lathe at a low speed.

- Use a roughing gouge to shape the bowl.

- Switch to a bowl gouge for finer details.

- Sand the bowl for a smooth finish.

- Apply wood finish for protection.

For advanced projects, consider crafting a spindle, a table lamp, or intricate wooden toys. Each project offers unique challenges and fun.

Troubleshooting Common Issues

To reduce vibration and noise from your wood lathe, check for loose parts. Tightening screws and bolts can help. Ensure the lathe is on a stable surface. Use rubber feet or pads to absorb vibrations.

For mechanical failures, inspect the drive belt. A worn or loose belt can cause issues. Replace it if necessary. Check the motor for any signs of overheating. Clean the motor to keep it in good condition.

Regular maintenance is key. Lubricate moving parts to prevent wear. Follow the manufacturer’s instructions for care. This will keep your lathe running smoothly.

Expanding Your Woodturning Skills

Joining a woodturning community can boost your skills. Sharing tips and experiences helps everyone grow. Many online forums exist for woodturners. Engaging with these groups is fun and educational.

Many resources are available. Books, videos, and tutorials can teach complex techniques. Look for local classes to learn hands-on. Experienced woodturners often offer valuable advice.

Taking on complex designs can be exciting. Start with simple projects and gradually increase difficulty. This method builds confidence and skill. Always practice safety while using tools.

Conclusion: Mastering The Craft

Building a wood lathe is a rewarding experience. It allows you to create beautiful projects. Each step teaches valuable skills and techniques. You gain confidence as you progress.

Sharing your work is important. Show your finished projects to friends and family. Use social media to connect with other DIY enthusiasts. Their feedback can inspire you to improve.

Document your journey. Take photos of each stage. Write down what worked and what didn’t. This record will help you and others in the future.

Encouragement from the community makes a big difference. Join forums or groups that focus on woodworking. Share tips, tricks, and experiences with others.

Frequently Asked Questions

How Do I Start Building A Wood Lathe?

To start building a wood lathe, gather essential materials like wood, screws, and a motor. Choose a design that fits your skills and space. Follow a detailed plan or PDF guide. Ensure you have the right tools for assembly and safety equipment for protection during use.

What Tools Do I Need For A Wood Lathe?

Essential tools for building a wood lathe include a drill, saw, and wrenches. A measuring tape and square will help ensure accuracy. You may also need clamps for stability during assembly. Having safety gear like goggles and gloves is crucial for protection while working.

Can I Use Recycled Materials For A Wood Lathe?

Yes, you can use recycled materials to build a wood lathe. Reclaimed wood and old machinery parts can be effective. Ensure the materials are sturdy and in good condition. This approach is eco-friendly and can save costs while still providing a functional lathe.

How Much Does It Cost To Build A Wood Lathe?

The cost to build a wood lathe varies widely. On average, expect to spend between $100 and $300. This depends on material quality and design complexity. Using recycled items can significantly reduce expenses, making it an affordable DIY project.

Conclusion

Building a wood lathe can be a rewarding project. With careful planning and the right materials, you can create a tool that enhances your woodworking skills. Follow the steps outlined in this guide for a successful build. Enjoy the process and unleash your creativity as you craft beautiful wooden pieces.