How to Sand in Crevices: Expert Tips for Flawless Finishes

To sand in crevices, use a sanding sponge or a small sanding block. For tighter spaces, opt for sandpaper wrapped around a pencil or dowel.

Sanding in crevices can be challenging but essential for achieving a smooth finish. Properly addressing these hard-to-reach areas ensures a professional look in your projects. Whether you’re working on furniture, cabinetry, or intricate woodwork, the right techniques make a significant difference.

Selecting the appropriate tools is crucial for efficiency and effectiveness. Fine-grit sandpaper is ideal for delicate areas, while a sanding sponge can adapt to various shapes. Understanding the best methods for crevice sanding will enhance your craftsmanship and elevate the overall quality of your work. This guide will help you master the art of sanding in those tricky spots.

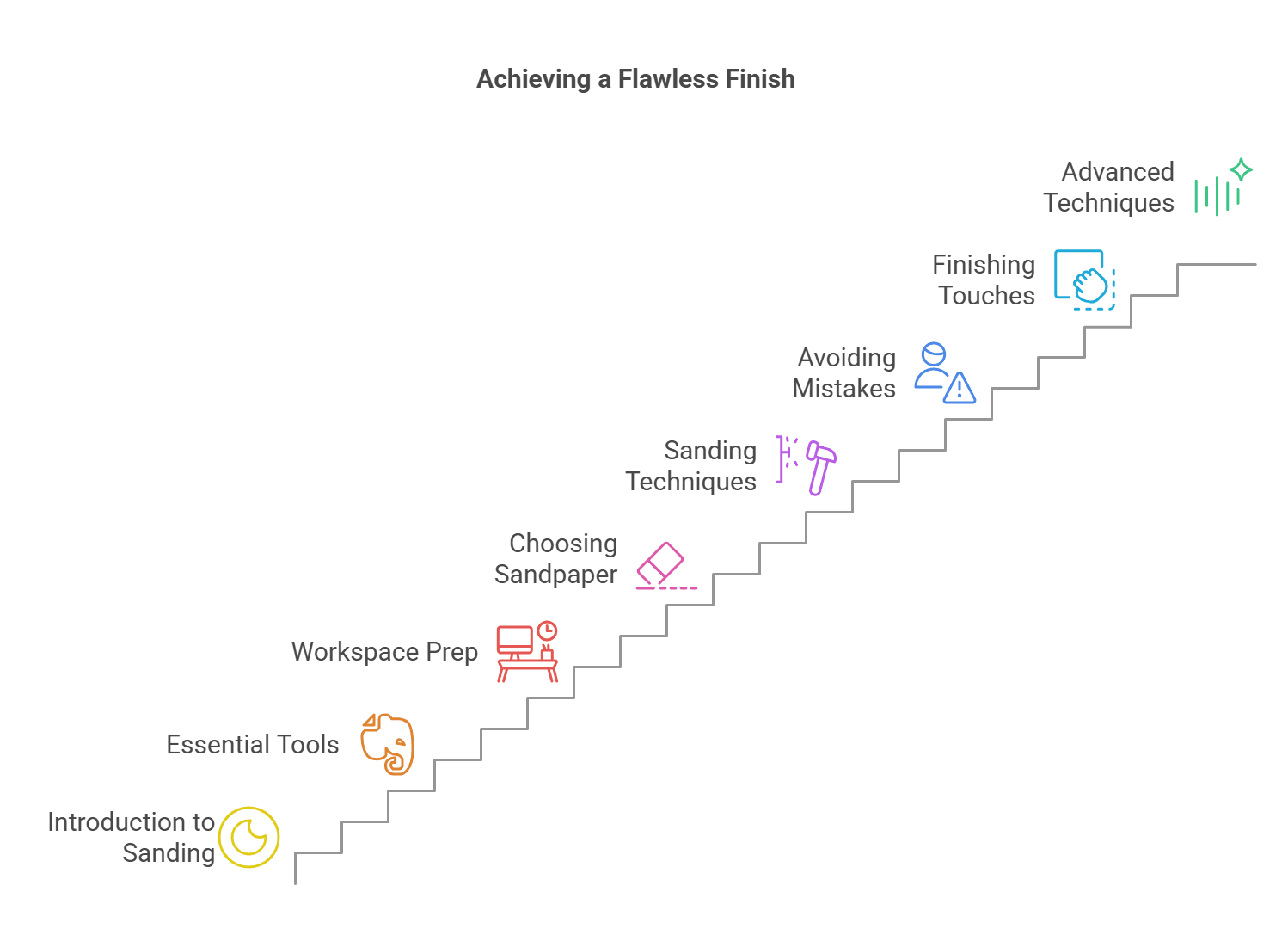

Introduction To Sanding Crevices

Sanding in crevices can be quite challenging. These small spaces require special tools and techniques. A smooth finish is very important for the overall look.

Using the right sanding tools can make a big difference. Consider using small sanding blocks or specialized sandpaper. These options fit perfectly into tight areas.

Taking your time is crucial. Rushing can lead to scratches or uneven surfaces. A careful approach ensures a professional look in every corner.

Remember to clean the area before sanding. Dust and debris can affect the finish quality. Proper preparation helps achieve the best results.

Tools You’ll Need

Choosing the right sanding tools is important for working in crevices. Manual tools are great for detailed work. They offer precision and control. Common manual tools include sandpaper and sanding blocks.

Power sanding tools save time and effort. They are useful for larger areas. Common power tools include random orbit sanders and detail sanders. These tools fit into tight spaces easily.

| Type | Advantages |

|---|---|

| Manual Tools | Precision and control |

| Power Tools | Speed and efficiency |

Specialized sanding tools help in tight spaces. Look for corner sanders or flexible sanding pads. These tools make it easier to reach narrow areas.

Preparing Your Workspace

Before starting, gather all the necessary protective gear. Wear safety goggles to shield your eyes. A dust mask is important to protect your lungs. Use ear protection if using loud tools.

Set up your workspace in a well-ventilated area. Cover nearby surfaces with a drop cloth. This helps minimize cleanup later. Keep your tools and materials organized. This saves time and reduces mess.

Ensure proper lighting in your workspace. Good lighting helps you see all the details. Clear away any clutter that might cause accidents.

Selecting The Right Sandpaper

Choosing the right sandpaper is crucial for your project. Different grit sizes serve various purposes. Use coarse grit (40-60) for heavy material removal. Medium grit (80-120) works well for smoothing surfaces. For fine finishing, select fine grit (150-220) sandpaper.

Using the right grit helps achieve the best results. Coarse sandpaper removes material quickly but can leave scratches. Medium grit smooths out rough areas effectively. Fine grit provides a smooth finish for paint or varnish.

| Grit Size | Use |

|---|---|

| Coarse (40-60) | Heavy material removal |

| Medium (80-120) | Smoothing surfaces |

| Fine (150-220) | Final finishing |

Techniques For Sanding Crevices

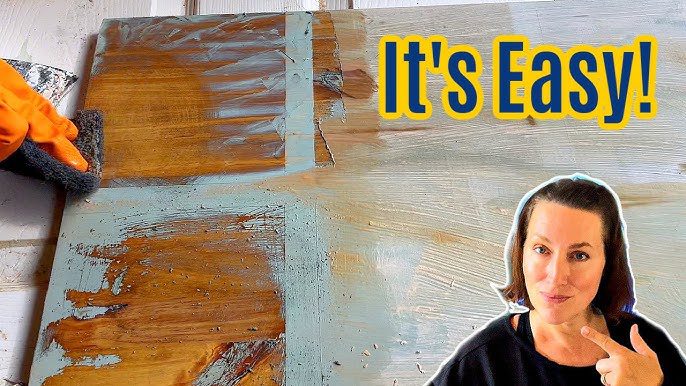

Manual sanding methods are great for reaching tight spaces. Use sandpaper or sanding blocks. Cut sandpaper into small strips for better control. Wrap it around a stick for deeper crevices. This method gives a smooth finish.

Using power tools can speed up the process. Select a detail sander for small areas. Attach fine-grit sandpaper to avoid damage. Always keep the tool steady to prevent uneven surfaces. Wear protective gear like goggles and masks for safety.

Tips For Avoiding Common Mistakes

Applying the right pressure is key. Too much pressure can damage the surface. Use light, even pressure to avoid this problem. Always test on a small area first.

Navigating complex shapes requires patience. Start with a finer grit sandpaper. This helps fit into tight spots. Move slowly to ensure even sanding throughout. Use a sanding sponge for better control.

Always keep the sandpaper clean. Clogged paper can scratch surfaces. Changing it regularly helps maintain effectiveness. Remember to wear a mask to avoid inhaling dust.

Finishing Touches For A Flawless Surface

Cleaning after sanding is very important. Start by using a soft brush. This helps remove dust from the surface. A vacuum with a soft brush attachment works well too. Always ensure the area is completely clean before applying any finish.

Applying finishes in difficult areas can be tricky. Use a small brush for tight spots. A foam applicator can also help reach crevices. Spray finishes are great for even coverage. Always test on a scrap piece first.

For the best results, work slowly and carefully. Pay attention to details for a smooth finish. Patience during this step will pay off in the end.

Advanced Techniques

Wet sanding is a technique that provides superior finishes. It uses water to minimize dust and improve results. This method works well for crevices and detailed areas. Use fine-grit sandpaper for the best effect.

Start by applying a wetting agent to the surface. This helps the sandpaper glide smoothly. Keep the area damp while sanding. Rinse the surface often to remove debris.

For rework and touch-ups, inspect the area closely. Look for imperfections or rough spots. Focus on these areas with a finer grit. This ensures a smooth, even finish.

Remember to allow the surface to dry completely before applying any finishing coats. Drying prevents trapping moisture and ensures a durable result.

Frequently Asked Questions

How Do You Sand Tight Crevices Effectively?

To sand tight crevices effectively, use specialized sanding tools like detail sanders or sanding sponges. These tools help you reach narrow spaces easily. Additionally, consider using sandpaper with a finer grit for a smoother finish. Always work gently to avoid damaging the surrounding surface.

What Tools Are Best For Sanding In Corners?

The best tools for sanding in corners include corner sanders, sanding sponges, and flexible sanding pads. These tools fit snugly into corners and tight spaces. For intricate designs, a rotary tool with a sanding attachment can be helpful. Always choose the right grit for your project.

Can You Use An Electric Sander In Crevices?

Yes, you can use an electric sander in crevices with caution. A detail sander or palm sander is ideal for this purpose. Ensure the sander has a narrow profile to navigate tight areas. Always test on a small area first to avoid damage.

What Grit Sandpaper Is Best For Crevices?

For crevices, start with 120-grit sandpaper for initial sanding. This grit removes rough spots effectively. For finishing, switch to 220-grit sandpaper to achieve a smoother surface. Always assess the material you are working on to choose the best grit.

Conclusion

Sanding in crevices can be a challenging task, but with the right techniques, it becomes manageable. Use the appropriate tools and take your time for the best results. This attention to detail not only enhances your project but also ensures a professional finish.

Happy sanding! Your efforts will pay off beautifully.