How to Seal End Grain of Wood: Expert Tips Revealed

To seal the end grain of wood, apply a thin layer of wood sealer or polyurethane. Allow it to dry completely before adding additional coats for optimal protection.

Sealing the end grain of wood is crucial for durability and longevity. End grain is more porous than other surfaces, making it susceptible to moisture and damage. Proper sealing prevents warping, splitting, and decay, especially in outdoor projects. Various sealants, such as oils, varnishes, or specialized end grain sealers, can provide effective protection.

Each option has unique benefits, catering to different wood types and project needs. Understanding the right sealing technique enhances the overall quality of your woodworking project. This guide will help you choose the best method to protect and preserve your wood, ensuring it remains beautiful and functional for years to come.

Introduction To End Grain Sealing

Sealing the end grain of wood is very important. The end grain absorbs moisture quickly. This can lead to damage and decay over time. Proper sealing helps protect the wood from water and stains.

Common challenges include inconsistent absorption. Different woods absorb sealers at different rates. Uneven sealing can lead to discoloration. Another challenge is the risk of cracking and splitting. This often happens when the wood dries out too fast.

Using the right techniques can help overcome these issues. A good sealer will provide a strong barrier. Make sure to apply it evenly for the best results.

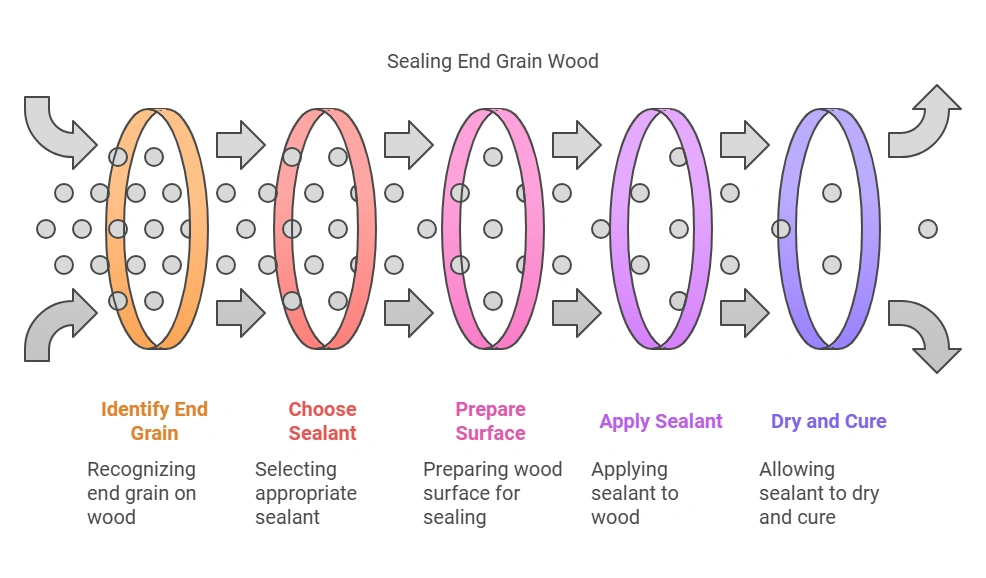

Identifying End Grain On Wood

End grain is found at the ends of wood pieces. It shows the tree’s growth rings. This part absorbs moisture differently than other wood sections.

Characteristics of end grain include a more porous texture. It often has a rough appearance. End grain can also appear darker than face and edge grain.

| Grain Type | Texture | Moisture Absorption |

|---|---|---|

| End Grain | Porous and rough | High absorption |

| Face Grain | Smooth | Low absorption |

| Edge Grain | Moderate texture | Moderate absorption |

Choosing The Right Sealant

Choosing the right sealant for wood is very important. Sealants protect wood from moisture and damage. Different types of sealants are available, each serving a specific purpose.

| Type of Sealant | Description |

|---|---|

| Polyurethane | Strong and durable. Works well for heavy use. |

| Varnish | Gives a glossy finish. Protects against UV rays. |

| Shellac | Quick-drying and easy to apply. Good for indoor use. |

| Oil-based Sealants | Penetrates deep into wood. Provides a natural look. |

Several factors influence the selection of a sealant. Wood type plays a crucial role. Hardwoods may need different treatment than softwoods. Environment matters too; outdoor projects require stronger sealants. Consider the finish you want, whether glossy or matte.

Preparation For Sealing

Start by removing dirt and dust from the wood surface. Use a damp cloth for this task. Make sure the wood is completely dry before sealing.

Next, sanding helps create a smooth finish. Use fine-grit sandpaper for best results. Sand along the wood grain to avoid scratches. After sanding, clean the surface again to remove any dust.

These steps ensure the wood is ready for sealing. Proper preparation leads to a better seal and a smoother finish.

Application Techniques

Choosing between brush and spray application affects the finish of your wood. Brush application gives more control. It works well for detailed areas. Spray application covers large areas quickly. It can create a smoother finish.

Ensure even coverage for the best results. Start from one corner and move across. Keep the brush or spray moving. Overlap each stroke slightly for uniformity. Check for drips or puddles often. Smooth out any mistakes right away.

Drying And Curing Time

For best results, drying wood in a warm and dry area is key. The temperature should be between 60°F and 80°F. Humidity levels should stay below 50%. This helps prevent mold and decay.

Wait at least 24 hours before applying a second coat. This ensures the first coat is fully cured. Checking the hardness of the wood can help determine if it’s ready. A test can be done by gently pressing your fingernail into the surface.

Troubleshooting Common Issues

Bubbles and drips can ruin a smooth finish on wood. If bubbles appear, use a fine brush to pop them. Apply gentle pressure to avoid damaging the wood. For drips, smooth them out quickly with a clean rag. Wipe in the direction of the wood grain.

Sometimes, sealant may not dry as expected. This can happen due to high humidity or low temperatures. Ensure the area is well-ventilated for faster drying. If the sealant remains sticky, try increasing the room temperature. Avoid applying a thick layer, as it takes longer to dry.

Regularly check the sealant’s instructions for proper drying times. Follow all guidelines for the best results.

Maintenance And Care

Regular maintenance is key to keeping wood in great shape. Inspect your wood regularly for signs of wear. Look for cracks or damage that may need attention.

Apply sealant every one to three years. This timing depends on the wood type and exposure to moisture. Check the sealant’s effectiveness each year.

Use a simple test to see if reapplication is needed. Drop a small amount of water on the surface. If it beads up, the sealant is still good. If it soaks in, it’s time to reapply.

Expert Tips And Tricks

Sealing end grain is crucial for wood projects. Different wood types need special care. Softwoods like pine absorb moisture quickly. Use a penetrating sealant for best results. Hardwoods like oak require a thicker finish to seal properly.

Always test the sealant on a small area first. This helps ensure compatibility. Use brush-on sealants for easy application. Spray sealants provide a smooth finish but require careful control.

For professional results, consider these advanced techniques:

- Sand the end grain before sealing.

- Apply multiple coats for better protection.

- Use a heat gun to encourage deeper penetration.

Frequently Asked Questions

How Do You Seal End Grain Of Wood?

Sealing end grain of wood involves applying a protective finish to prevent moisture absorption. Common methods include using sealants, oils, or wax. Ensure the wood surface is clean and dry before application. Multiple coats may be necessary for optimal protection.

Allow adequate drying time between each coat for best results.

What Materials Are Best For Sealing End Grain?

The best materials for sealing end grain include polyurethane, epoxy, and wood oils. Each option offers different protection levels and finishes. Polyurethane is durable, while epoxy provides excellent moisture resistance. Oils enhance wood’s natural beauty but may require more frequent reapplication.

Choose based on your project’s needs and desired finish.

How Long Does It Take To Seal End Grain?

The time it takes to seal end grain varies by method. Typically, applying sealants or oils can take a few hours to a day, including drying time. Multiple coats may extend the process. Always check the manufacturer’s instructions for specific drying times.

Rushing may compromise the seal’s effectiveness.

Can I Use Paint To Seal End Grain?

While paint can seal end grain, it may not be the best option. Paint creates a barrier but may not adhere well to wood surfaces. Over time, it can chip or peel, exposing the wood to moisture. For better protection, consider dedicated wood sealants or finishes designed for this purpose.

Conclusion

Sealing the end grain of wood is essential for durability and aesthetics. Proper sealing prevents moisture damage and enhances the wood’s natural beauty. By following the right techniques and using quality products, your wood projects will last longer and look stunning.

Invest time in sealing, and enjoy the benefits for years to come.