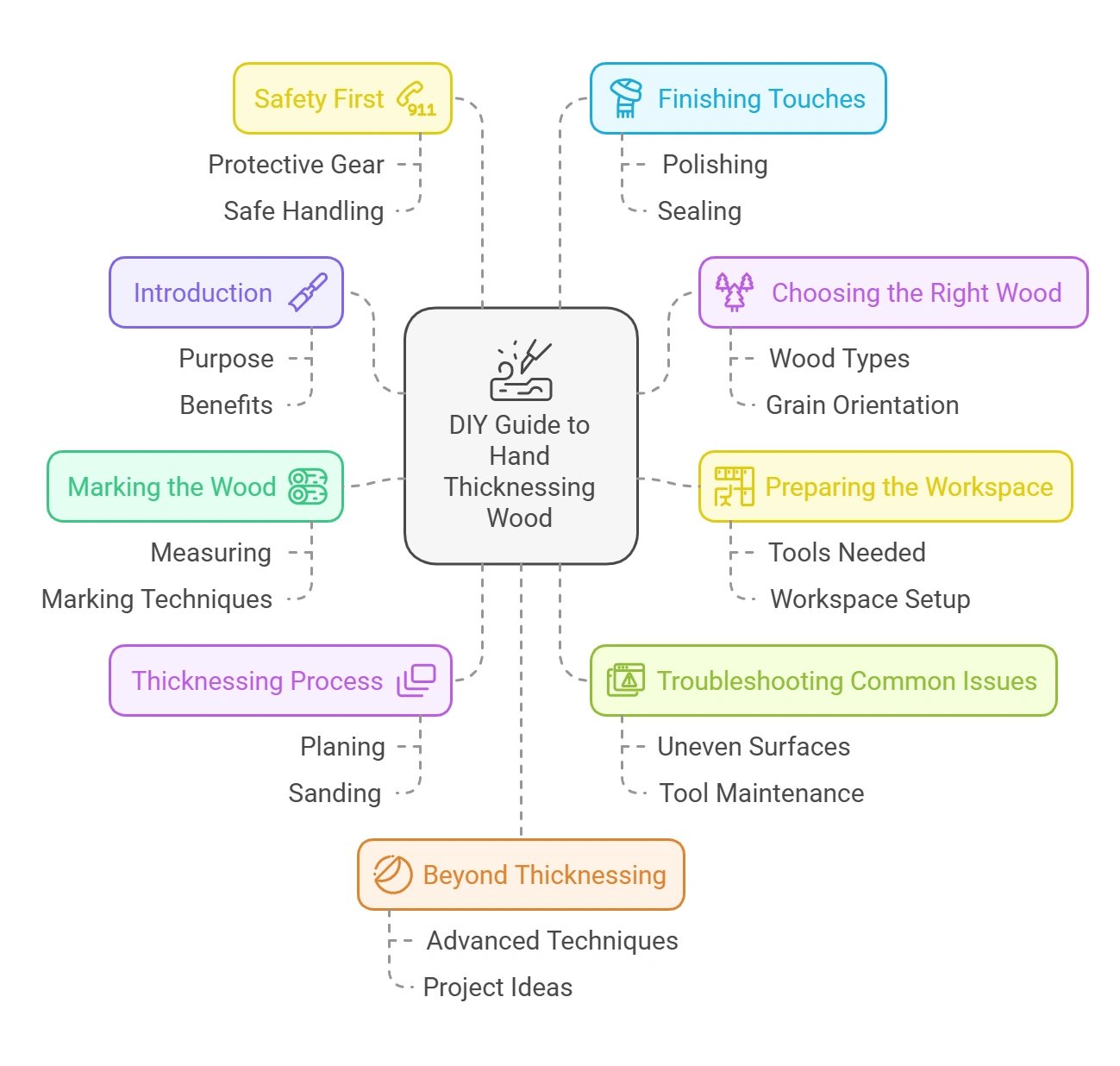

How to Thickness Wood by Hand: A DIY Guide

To thickness wood by hand, use a hand plane or a jointer. Measure the desired thickness and take even passes until you achieve it.

Thickening wood by hand is a rewarding skill for woodworkers and DIY enthusiasts. It allows for greater control over the final dimensions of your project. Hand tools provide a tactile experience, enhancing your connection to the material. This method also fosters precision, ensuring that each pass creates an even surface.

Whether you’re preparing wood for furniture, cabinetry, or crafts, knowing how to thickness wood properly is essential. With the right techniques and tools, you can achieve the perfect thickness for your woodworking needs. Mastering this skill opens up a world of possibilities in your woodworking journey.

Introduction To Hand Thicknessing Wood

Manual woodworking has a unique charm. Many people enjoy the craftsmanship involved. It allows for personal expression and creativity. Working with wood by hand connects you to nature. Each piece tells its own story.

To thickness wood by hand, you will need a few tools. Essential tools include a hand plane, a saw, and a measuring tape. A straight edge helps ensure accuracy. Remember to have some sandpaper for a smooth finish. Make sure your workspace is clean and organized.

Choosing The Right Wood

Choosing the right wood is key for thicknessing. Different types of wood have unique qualities. Some are hard, while others are soft. Here are a few common types:

| Type of Wood | Characteristics |

|---|---|

| Oak | Strong and durable, great for furniture. |

| Pine | Soft and easy to work with, ideal for beginners. |

| Maple | Hard and smooth, perfect for cabinets. |

Assess the wood’s condition before starting. Look for cracks, warps, or deep knots. Good condition wood makes thicknessing easier. Always choose a piece that feels sturdy. This ensures better results in your project.

Preparing The Workspace

To begin, set up your workbench in a clean area. Ensure good lighting for safety. Use a sturdy surface for better control while working.

Gather necessary tools like a hand plane, chisels, and a measuring tape. Keep these tools within reach for convenience. Make sure they are clean and sharp for effective use.

Check your tools regularly. Sharp tools work better and are safer. Keep your hand plane well-maintained. A properly maintained tool lasts longer and performs well.

Store tools in a designated area. This keeps your workspace organized. An organized area helps prevent accidents and saves time.

Marking The Wood For Thicknessing

To achieve accurate thicknessing, proper measuring and marking techniques are essential. Start by using a straight edge to create a reference line. This line helps ensure you cut evenly.

Use a caliper or ruler to measure the wood’s initial thickness. Mark your desired thickness clearly with a pencil. Always double-check your measurements before cutting.

For precision, consider using a square to ensure your marks are straight. This helps maintain the wood’s integrity during the thicknessing process. Precision in your measurements leads to better results.

The Thicknessing Process

Using hand planes can make your wood smooth and even. Start with a sharp blade to ensure efficiency. Hold the plane with both hands for better control. Push the plane in a straight line for an even finish.

Make light passes to avoid taking off too much wood. Check the thickness often to ensure you achieve the right size. Adjust the plane depth for different areas of the wood. Practicing this technique improves skills and confidence.

Remember to keep the wood secure while planing. Use clamps to hold it in place. This prevents any slipping and ensures safety during the process. Enjoy the satisfying feeling of a well-planed surface!

Troubleshooting Common Issues

Warped wood can be tricky to work with. Start by placing the wood on a flat surface. Use weights to press down the high spots. This can help flatten the wood.

For uneven thickness, measure each part of the wood. Use a hand plane to remove the excess material. Take small shavings for better control. Check the thickness often as you work.

Consider using a straight edge to guide your planing. This helps maintain an even surface. Remember to sand the edges to avoid sharp corners.

Safety First

Safety is very important when working with wood. Always wear the right Personal Protective Equipment (PPE). This includes safety glasses, gloves, and ear protection. These items help keep you safe from dust and noise.

Handle tools with care. Always keep your fingers away from blades. Use clamps to hold wood pieces steady. This prevents slipping and accidents.

Check tools before use. Make sure they are in good condition. Replace any worn or damaged parts. Safe tools make work easier and protect you better.

Finishing Touches

Sanding helps achieve a smooth finish on wood. Use a fine-grit sandpaper for best results. Start with coarse sandpaper to remove any rough spots. Work your way up to finer grits. Always sand in the direction of the grain. This prevents scratches and improves appearance.

After sanding, clean the surface to remove dust. A damp cloth works well for this. Wait for the wood to dry completely before sealing. Sealing protects the wood and enhances its beauty.

Choose a good quality wood finish. Options include oils, stains, or sealants. Apply the finish evenly using a brush or cloth. Allow it to dry before applying a second coat.

Beyond Thicknessing

Thicknessing wood by hand opens up many creative possibilities. It allows for joining and shaping wood pieces in unique ways. Using simple tools can help achieve the desired thickness.

Consider these projects to showcase your skills:

- Wooden Table: Create a sturdy table by joining thick pieces.

- Picture Frame: Shape thinner wood for beautiful frames.

- Wooden Toys: Craft engaging toys using well-thicknessed wood.

Each project enhances your ability to work with wood. Enjoy the process and the beauty of handmade items!

Frequently Asked Questions

How Can I Thickness Wood By Hand?

You can thickness wood by hand using simple tools like a hand plane or a scraper. Start by marking your desired thickness on the wood. Use the hand plane to shave off material gradually. Check your progress frequently to ensure you achieve an even thickness throughout.

What Tools Are Needed For Thicknessing Wood?

The essential tools for thicknessing wood by hand include a hand plane, a straightedge, and a measuring tape. A chisel may also be helpful for fine adjustments. These tools allow you to effectively remove material and achieve the desired thickness without complicated machinery.

Is It Difficult To Thickness Wood By Hand?

Thicknessing wood by hand can be challenging but rewarding. It requires patience, skill, and practice. Beginners may find it tough initially but will improve over time. With the right techniques and tools, you can achieve excellent results while gaining valuable woodworking skills.

How Do I Ensure An Even Thickness?

To ensure even thickness, start with a flat surface. Use a straightedge to check your progress frequently. Plane in the same direction to avoid tear-out. Take light passes and regularly measure your thickness to maintain consistency. This will help you achieve a uniform finish.

Conclusion

Mastering the art of thicknessing wood by hand can greatly enhance your woodworking skills. It allows for greater precision and control over your projects. With practice, you’ll gain confidence and improve your craftsmanship. Embrace these techniques, and enjoy the rewarding process of transforming raw wood into beautiful, usable pieces.

Happy woodworking!