Is Teak A Good Wood For Cutting Boards? Proven

Yes, teak is generally a good, durable, and water-resistant wood for cutting boards, thanks to its high natural oil content. However, beginners must source ethically harvested teak and ensure proper seasoning to prevent issues like excessive oil transfer onto food.

Picking the right wood for a cutting board can feel like a big first step in woodworking. You want something that looks great, lasts for years, and is safe for slicing veggies. Many folks hear about teak, that famous wood used for boat decks and fine outdoor furniture, and wonder if it’s tough enough for kitchen duty. Is teak really the perfect fit for your new chopping block? Don’t worry! As a fellow woodworker, I’ll walk you through exactly why teak might be just what you need, and any little catches to watch out for. We are going to break down the facts so you can craft a beautiful, functional board with total confidence. Ready to dive in and see if teak wins the chopping contest?

The Ultimate Guide: Is Teak A Good Wood For Cutting Boards? Proven Facts

When you’re looking at woods like maple, cherry, or walnut, teak often gets overlooked for kitchen use. This usually happens because we associate teak with outdoor projects. However, its natural strengths make it a strong contender for an everyday kitchen workhorse. Let’s look at why experienced woodworkers often recommend—or sometimes warn against—using teak for food preparation surfaces.

Understanding Teak’s Unique Properties

Teak (Tectona grandis) isn’t just any hardwood; it’s famous for its density and internal structure. These features directly impact how well it performs as a cutting board.

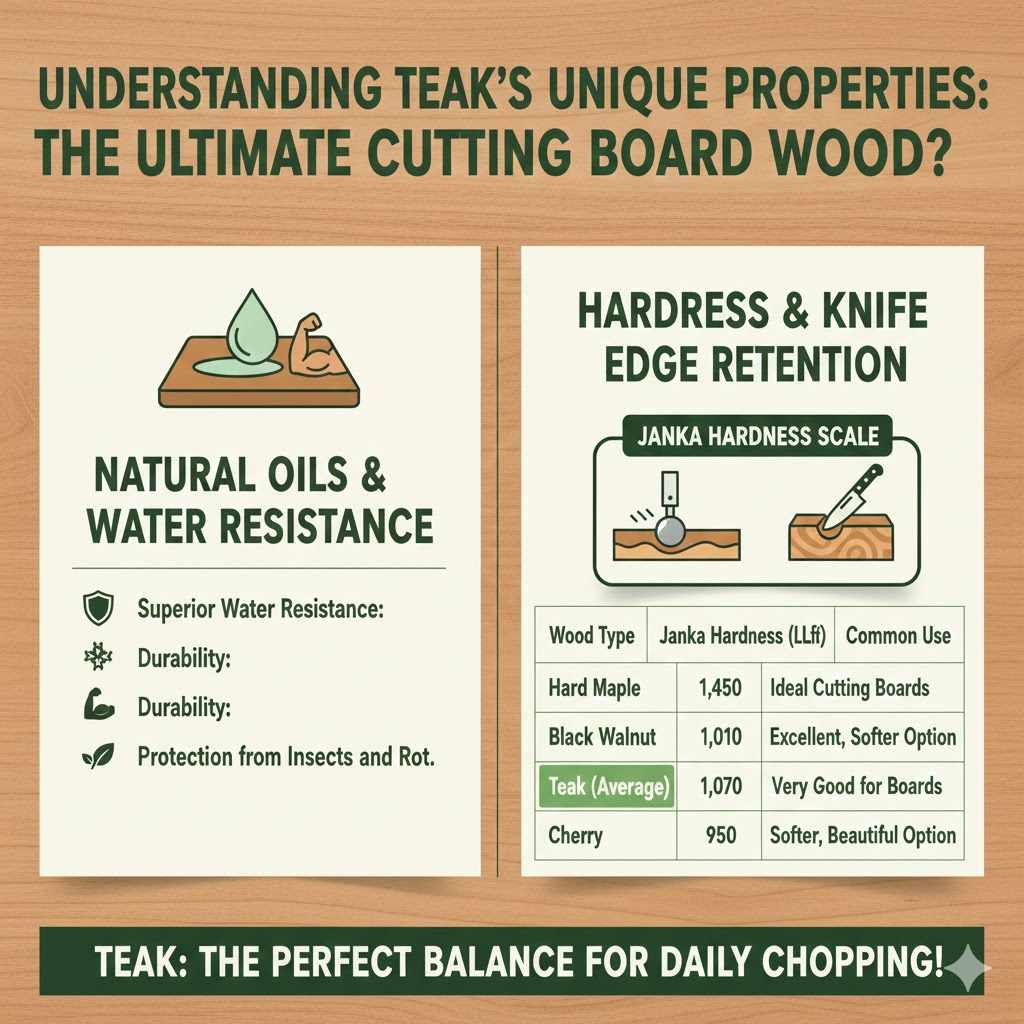

Natural Oils and Water Resistance

This is teak’s biggest selling point. Teak contains high levels of natural oils. In nature, these oils protect the tree from harsh weather, insects, and moisture—the very same qualities you want in a cutting board!

For a cutting board, this means:

- Superior Water Resistance: Teak naturally repels water better than most common domestic woods. This helps prevent warping, cracking, and mold growth—big wins for kitchen hygiene.

- Durability: The tight grain structure, reinforced by these oils, makes the wood naturally hard-wearing against knife cuts.

Hardness and Knife Edge Retention

Hardness is usually measured using the Janka scale. A Janka rating tells us how much force it takes to embed a steel ball halfway into the wood. This rating is crucial for a cutting board because wood that is too hard (like Oak or exotic woods like Purpleheart) can actually dull your expensive knives faster.

Here is how teak generally compares to other popular cutting board woods:

| Wood Type | Janka Hardness (Lbf) | Common Use |

|---|---|---|

| Hard Maple (Standard) | 1,450 | Ideal Cutting Boards |

| Black Walnut | 1,010 | Excellent, Softer Option |

| Teak (Average) | 1,070 | Very Good for Boards |

| Cherry | 950 | Softer, Beautiful Option |

As you can see, teak sits comfortably right near hard maple. It’s dense enough to resist deep scarring but soft enough not to excessively wear down your knife edges. That’s a great balance for daily chopping!

The Case For Teak: Pros for Cutting Board Use

When you use teak, you bring a lot of inherent benefits to your countertop. These advantages make the initial investment worthwhile for many home chefs.

1. Exceptional Longevity

Because of its density and oils, a well-maintained teak board can easily last decades. You won’t need to replace it often, which is great for the environment and your wallet over time.

2. Resistance to Staining and Odors

Those natural oils act as a barrier. This means liquids (like beet juice or strong spices) are less likely to soak deep into the wood fibers compared to a less oily wood. This barrier also helps inhibit bacterial growth slightly, making cleaning simpler—though proper cleaning is still required, of course!

3. Aesthetic Appeal

Teak boasts beautiful, rich golden-brown tones. When oiled, the grain really pops. It brings a high-end, custom look to any kitchen setup.

4. Workability (With a Caveat)

For the woodworker, teak machines fairly well, which is why boat builders love it. However, you will need sharp tooling because of its density and silica content (more on that in a moment).

The Cautionary Side: Cons and Concerns Beginners Must Know

Nothing in woodworking is perfect. When using teak, especially for food safety applications, there are a few important concerns you need to address before you start gluing up strips.

Silica Content: The Tool Killer

This is the main reason many woodworkers shy away from teak. Teak trees naturally absorb high amounts of silica (sand/quartz) from the soil, especially wood harvested near coastal areas. This silica acts like tiny pieces of glass embedded in the wood fibers.

- Effect on Tools: The silica rapidly dulls planer blades, jointer knives, and router bits. If you are planning on making multiple boards, be prepared to sharpen or replace your tooling frequently.

- Effect on Knives: While the Janka rating suggests it’s okay for knives, the microscopic silica dust loosened during hard chopping can subtly contribute to faster dulling than extremely pure woods like sugar maple.

Oil Leaching (The Main Food Safety Worry)

Because teak is so naturally oily, improperly sourced or heavily aged (old) teak can sometimes leach those oils, especially when first exposed to moisture or heat (like washing). This can leave a slightly greasy residue on your countertop or food.

The Solution: You must properly finish the board to lock those surface oils in. This involves several coats of food-grade mineral oil and beeswax conditioner before the board ever touches food.

Ethical Sourcing Concerns

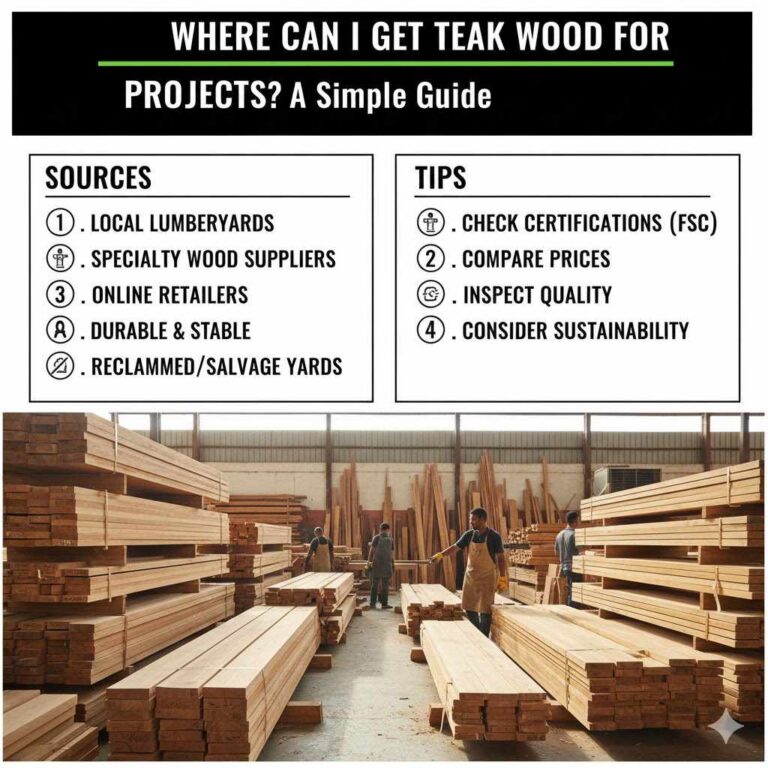

This is crucial for all of us who love natural materials. Most of the world’s high-quality teak is found in Southeast Asia (Indonesia, Myanmar). Unsustainable or illegal logging practices have ravaged natural teak forests. When purchasing teak, always look for:

- FSC Certification: Ensure your supplier provides Forest Stewardship Council (FSC) certification, meaning the wood was harvested responsibly.

- Plantation-Grown: Look for plantation teak, which is faster-growing and more readily available through certified vendors. If you cannot verify the source, choose a different, responsibly sourced domestic hardwood like maple or walnut. For reliable standards on sustainable forestry, you can consult organizations like the Forest Stewardship Council (FSC).

Step-by-Step: Preparing Teak for a Safe Cutting Board

If you decide that teak’s pros outweigh the cautions—and you have ethically sourced, high-quality stock—the next step is preparation. We must seal in those natural oils and remove surface contaminants.

Step 1: Inspect and Source Smartly

Only purchase kiln-dried or very well-seasoned lumber. If you can smell a very strong, pungent oil smell, you might have an unusually oily piece that needs extra curing time. If it’s rough-sawn, let it air dry in a controlled environment (like your workshop, not the garage) for a few months.

Step 2: Mill for Smoothness and Flatness

Because of the potential silica, take this process slowly. Sharpen your blades right before milling.

- Joint one face flat.

- Plane the opposite face parallel to the first.

- Square up one edge using the jointer.

- Rip the final edge parallel to the jointed face to achieve the final width.

Step 3: Decide on Grain Orientation (Edge Grain vs. End Grain)

For a beginner, the choice is straightforward for teak:

- Edge Grain: Strips glued up on their long side. Easier to construct and usually more affordable, but slightly tougher on knives and more prone to warping than end grain.

- End Grain: The chopping surface shows the “ends” of the wood fibers (like a checkerboard). This is gentler on knives because the fibers separate slightly when cut, then close back up. This is the professional recommendation.

If using teak, end grain construction is often better because it naturally flexes and closes wounds better than edge grain, which can lead to small splits around high-oil areas.

Step 4: Glue Up

Use a high-quality, water-resistant glue, such as Titebond III Ultimate Wood Glue, which offers superior moisture resistance compared to standard yellow glue. Apply an even coating and clamp firmly.

Step 5: Mandatory Sealing—The Critical Step for Teak

Before using the board, you must use food-safe sealants to lock in any potentially leaching surface oils and provide an inert, safe chopping surface. You should apply more conditioning than you might for a standard maple board.

- Allow the glue to cure fully (usually 24 hours).

- Sand the board thoroughly, starting at 80 grit and moving up to 220 grit. Ensure every trace of glue squeeze-out is removed.

- Apply liberal coats of food-grade mineral oil. Let it soak in for 30 minutes, wipe off the excess. Repeat this process 3 to 4 times over two days until the oil stops being quickly absorbed.

- Apply a “board butter” made of mineral oil and beeswax (or carnauba wax). This sits on top, providing a harder, protective seal. Rub it in well and let it haze up.

- Buff off the haze with a clean, soft cloth.

This aggressive oiling schedule creates a deep barrier, effectively stabilizing the surface for kitchen use.

Teak vs. The Cutting Board Champion: Maple

Since maple is often cited as the gold standard, it’s useful to see how teak stacks up side-by-side, focusing on the practical aspects for a beginner builder.

| Feature | Teak | Hard Maple |

|---|---|---|

| Water Resistance | Excellent (Natural Oils) | Good (Requires Heavy Oiling) |

| Knife Friendliness (Janka) | Good (Approx. 1,070 lbf) | Excellent (Approx. 1,450 lbf, but soft enough) |

| Tool Wear | High (Silica Content) | Low to Moderate |

| Source Concern | High (Sustainability Risks) | Low (Abundant Domestic Supply) |

| Maintenance After Sealing | Standard | Standard |

For the absolute beginner making their very first board, I often point them toward hard maple because it’s inexpensive, easily sourced sustainably, and won’t prematurely ruin their shop blades. However, if you already have a supply of quality teak and prioritize natural water resistance, it can certainly be done successfully with careful preparation.

Caring For Your Teak Cutting Board: Maintenance Matters

Once your beautiful teak board is complete and sealed, maintenance ensures it stays food-safe and lasts forever. Since teak is inherently oily, it holds onto its conditioning well, but kitchen use requires diligence.

Cleaning Do’s and Don’ts

Remember, even though teak is water-resistant, it is still wood. Never treat it like plastic.

- Do NOT soak the board in water.

- Do NOT put it in the dishwasher (the high heat and harsh detergents will destroy it).

- DO clean immediately after use with hot water and a mild dish soap. Wipe it dry instantly with a towel.

- DO occasionally clean deep cuts with a weak solution of white vinegar and water for extra sanitizing power, then rinse quickly.

Re-Oiling Schedule

The mineral oil finish you applied initially will wear away over time, especially near high-use zones. This is where bacteria can begin to seep in if you stop oiling.

If you use your board daily:

- Apply a fresh coat of mineral oil once every 4 to 6 weeks.

- When the wood starts looking visibly dull, dry, or when water stops beading on the surface, it’s time for conditioning.

- Always finish the re-oiling process with a hard wax blend (beeswax or carnauba) to lock the oil in place. For tips on creating great board conditioners, reputable resources like woodworking magazines or University Extension sites often share tested formulas for longevity. For instance, the University of Minnesota Extension often publishes guidelines on food safety for wood surfaces.

Exploring Food-Safe Adhesives and Finishes

Your success in using teak hinges on using materials that meet safety standards. When bonding teak strips together, you are relying on the glue line to be the strongest part of the board, resisting separation even under the stress of moisture changes.

Why Titebond III is the Go-To

As a mentor, I rely on specific product reliability. Titebond III is popular for cutting boards because it passes the American National Standards Institute (ANSI) Type I water-resistance specification. This means it can withstand being submerged in water for a specified time without failing.

When building the board:

- Ensure you apply enough glue—it should squeeze out thinly between every joint.

- Wipe off the excess glue squeeze-out while it is still wet (like soft cheese) using a damp rag. If you wait until it cures hard, sanding those oily glue lines will be frustrating and ineffective.

Food-Safe Top Coats

While mineral oil is standard, you might want extra protection, especially given teak’s oily nature. Hard finishes can create a more robust seal, though they require re-application less frequently.

Alternatives that you can layer over your initial heavy oiling include:

- Pure Tung Oil (Polymerized): Note: You must use 100% pure, food-grade Tung Oil, not Tung Oil Finish (which contains solvents). This takes a long time to cure but offers excellent protection.

- Shellac (if homemade): Edible-grade shellac flakes dissolved in denatured alcohol can provide a very hard, non-reactive barrier coat, though it is generally not as favored as natural oils for wood that sees heavy knife use.

Teak Alternatives Worth Considering (If Sourcing is Hard)

If you struggle to find certified teak, or if the thought of constantly sharpening tools worries you, these domestically available hardwoods are fantastic alternatives that offer similar or better performance in certain areas:

- Hard Maple: The workhorse. It’s durable, has a tight, low-oil grain, and is usually FSC certified readily available. Great for end-grain construction.

- Hickory: Extremely hard (Janka around 1,820 lbf), offering supreme durability, but it is harder on knives than maple. Use end-grain construction if you choose hickory.

- Beech: Often overlooked, Beech is tough, has a relatively straight grain, and absorbs finishes very well, making it a beautiful, safe option that performs similarly to maple.

Conclusion: The Verdict on Teak Cutting Boards

So, is teak a good wood for cutting boards? Yes, it absolutely can be, provided you follow specific woodworking guidelines. Its superior natural water and rot resistance is a massive benefit that few other domestic woods can match. It offers the density needed to handle heavy chopping without sacrificing knife longevity.

However, the success of your teak cutting board hinges on two critical areas that you, as the beginner builder, must manage diligently: responsible sourcing to avoid harming forests, and careful, extensive preparation (especially that multi-step sealing process) to manage its high natural oil and silica content. If you conquer the tooling dulling and seal the board correctly, you will end up with a stunning, highly functional, and incredibly durable piece of kitchen gear that honors the beauty of exotic hardwood craftsmanship.

Frequently Asked Questions (FAQ) About Teak Cutting Boards

Q1: Is teak wood safe for cutting raw meat?

Yes, any dense hardwood, including teak, is safe for raw meat if it is properly sealed (oiled/waxed) and cleaned immediately afterward. The wood grain naturally traps bacteria temporarily, but proper oiling ensures a non-porous barrier. Always clean and sanitize your board after preparing raw meat.

Q2: Does teak leach oils into food, making it taste weird?

This is a real possibility with inadequately sealed or very oily pieces of teak. If you apply at least 4 coats of food-grade mineral oil followed by a heavy beeswax finish, you seal the surface oils in. This greatly minimizes leaching and odor transfer onto your food.

Q3: How do I know if my teak is sustainably harvested?

Look for Forest Stewardship Council (FSC) certification from your supplier. This verification confirms that the wood was grown and harvested under strict environmental and social standards. If the seller cannot provide this, consider an alternative wood like maple or walnut.

Q4: Will using teak ruin my router bits and planer blades quickly?

It is very likely to dull tools faster than domestic woods because of the embedded silica. Work slowly through your milling stages, use sharp carbide tooling if possible, and plan on sharpening frequently. This is the main maintenance trade-off when working with teak.

Q5: Should I make my first cutting board out of end grain or edge grain teak?

If you are building with teak, end grain construction is highly recommended. The self-healing properties of end grain help manage the subtle expansions and contractions caused by the high oil content, resulting in a board that resists cracking better.

Q6: How often must I oil a teak cutting board versus a maple one?

Teak boards might need oiling slightly less often initially because they hold onto oil better naturally. However, after the initial sealing period, the frequency depends only on usage. When water stops beading on the surface, it’s time to oil, regardless of whether it’s teak or maple.