Is Zinsser Shellac Dewaxed? What You Must Know to Succeed

Figuring out if Is Zinsser Shellac Dewaxed? What You Should Know is often a head-scratcher, especially if you’re new to woodworking or refinishing. It’s a common question that can feel a bit overwhelming at first. Don’t worry, though! This post breaks it down in easy-to-follow steps. We’ll explore the ins and outs of shellac, and by the end, you’ll feel confident about which Zinsser Shellac products are dewaxed and how that impacts your projects. Let’s get started!

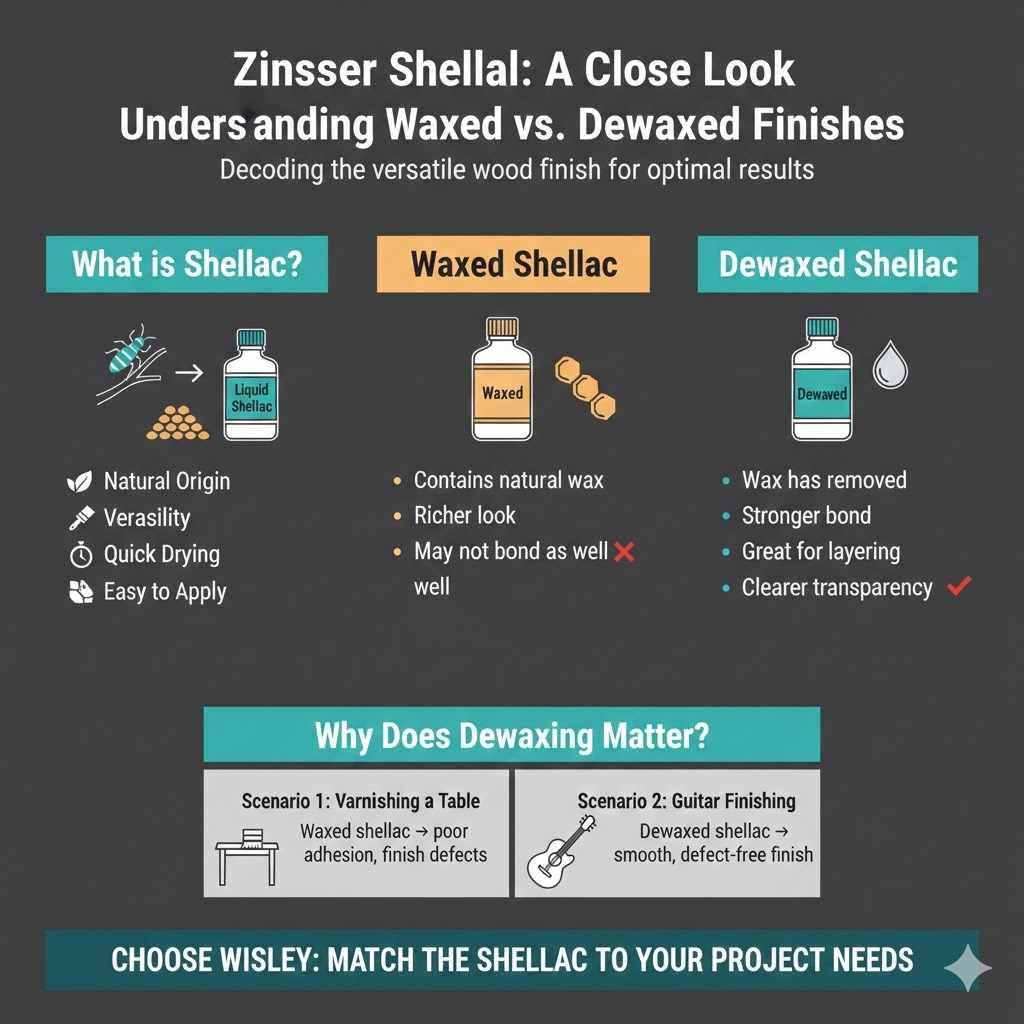

Zinsser Shellac: A Close Look

Shellac is a natural resin that’s used as a wood finish. It’s made from the secretions of the lac insect. It is a versatile product, prized for its ability to create a beautiful, protective coating on wood. But what sets Zinsser Shellac apart from other options? This section will show you.

What is Shellac?

Shellac is nature’s own wood finish, created by the lac insect. These insects live on trees in Southeast Asia. They secrete a resin that’s collected, processed, and sold as shellac flakes or liquid shellac. This natural origin contributes to its popularity. Shellac is an excellent choice for a variety of projects, from furniture to musical instruments, because of its quick-drying properties and beautiful finish. It offers a clear, hard, and durable coat.

- Natural Origin: Shellac is derived from a natural source, making it a green choice for wood finishing.

- Versatility: Shellac can be used on various wood surfaces and is compatible with different stains and dyes.

- Quick Drying: One of the key benefits of shellac is its fast drying time.

- Easy to Apply: Shellac is easy to apply and can be brushed, sprayed, or wiped on.

The Difference Between Waxed and Dewaxed Shellac

Shellac can be found with or without wax. The presence or absence of wax is a critical detail that significantly affects how shellac behaves and how it is used. Waxed shellac, as the name suggests, contains a small amount of natural wax from the lac insect secretion. This wax can interfere with adhesion, making it less suitable for applications where subsequent coats or other finishes will be applied. Dewaxed shellac has had this wax removed during processing. This makes it ideal for projects where you need a strong bond or where you plan to layer finishes.

- Waxed Shellac: Contains natural wax. It can give a richer look but may not bond as well with other finishes.

- Dewaxed Shellac: The wax has been taken out. This gives a stronger bond and is great for layering.

- Adhesion: Dewaxed shellac provides superior adhesion, which is crucial when multiple coats are applied.

- Clarity: Dewaxed shellac is often clearer than waxed shellac, providing better transparency.

Why Does Dewaxing Matter?

Dewaxing shellac is a critical process because it determines how well the finish works with other products. Wax in shellac can prevent other finishes like varnish or paint from sticking properly. This can lead to problems like fish-eyeing (where the finish pulls away from the surface). Dewaxed shellac ensures a good bond. It’s very important to know what kind of shellac you’re using. Understanding the difference between waxed and dewaxed shellac will help you avoid problems.

- Consider a scenario where you’re restoring a table and plan to use a varnish over shellac. If you use waxed shellac, the varnish may not adhere correctly.

- Imagine you’re spraying shellac on a guitar. Dewaxed shellac is better to avoid finish defects.

Identifying Dewaxed Zinsser Shellac Products

Zinsser is a well-known brand for wood finishing products. Knowing which Zinsser shellac products are dewaxed helps you select the right product. Zinsser provides both waxed and dewaxed shellac options. It’s very important to know the difference for the best results.

Understanding Zinsser’s Product Labels

Zinsser’s product labels provide essential information. Look carefully at the label. It should clearly state whether the product is “dewaxed.” If the label doesn’t specifically mention “dewaxed,” it might contain wax. Always read the label. It often includes details about intended use and compatibility with other finishes. This simple step saves you from making mistakes. It also helps you get the finish you want.

- Product Name: The product name will often indicate whether it’s dewaxed. Look for terms like “SealCoat” or “Clear Shellac.”

- Label Clarity: Zinsser’s labels usually highlight key features. The labels clearly state whether the product is dewaxed.

- Product Descriptions: Read the descriptions on the can or online to verify whether the product is dewaxed.

- Online Resources: Zinsser’s website provides detailed product information. This helps you confirm the shellac type.

Popular Zinsser Shellac Products and Their Wax Content

Zinsser has a few popular shellac products. “SealCoat” is a well-known, dewaxed shellac sanding sealer. It’s often used as a base coat. It’s very compatible with other finishes. Other Zinsser shellac products may be waxed. Knowing the specific type is key. If you are uncertain, check the label or the Zinsser website. This information will help you pick the best shellac for your project. A product that’s often used is Zinsser’s “Amber Shellac”. This product comes in different forms.

| Product | Wax Content | Best Used For |

|---|---|---|

| SealCoat | Dewaxed | Sealing wood, base coat for finishes |

| Zinsser Amber Shellac | Varies, check label | General purpose finishing, color enhancement |

How to Confirm if a Shellac Product Is Dewaxed

If you’re unsure if a Zinsser shellac product is dewaxed, there are steps you can take. First, look at the label. Read the product description carefully. If the label doesn’t specify “dewaxed,” you can contact Zinsser’s customer support. They can confirm the exact product’s properties. You can also research the product online. Check the manufacturer’s website or reviews from other users. This helps confirm the wax content of the product.

- Check the Label: This is the first place to look. The label should mention if the product is dewaxed.

- Search Online: Look up the product name online and read the product description.

- Contact the Manufacturer: Contact Zinsser directly. They will give you the most accurate answer.

- Read Reviews: Check reviews from other users who have used the product. They might mention their experiences.

The Impact of Dewaxed Shellac on Your Projects

Using dewaxed shellac can impact the quality of your project. Dewaxed shellac creates a better bond for other finishes. It’s suitable for projects where you need a strong surface. Understanding these differences helps you decide the correct shellac to use.

Advantages of Using Dewaxed Shellac

Dewaxed shellac provides many benefits. It offers excellent adhesion. It means that any topcoats or subsequent finishes will bond well to the surface. Dewaxed shellac provides a clearer, more transparent finish. It allows the natural beauty of the wood to shine through. Dewaxed shellac ensures a smooth finish, reducing the risk of imperfections. Choosing dewaxed shellac is a good decision for professional results.

- Superior Adhesion: Dewaxed shellac bonds very well with other finishes.

- Enhanced Clarity: The absence of wax leads to a clearer finish, enhancing the wood’s appearance.

- Reduced Imperfections: Using dewaxed shellac reduces the chance of imperfections, leading to better results.

- Versatility: It can be used as a base coat or a topcoat. It works with many different finishes.

When to Choose Dewaxed Shellac

Dewaxed shellac is best for certain projects. Use it when you are planning to apply multiple coats. This will ensure that each layer bonds properly. It’s excellent for projects where clarity is very important, such as on furniture where you want to highlight the wood grain. If you want a perfectly smooth surface, dewaxed shellac is a good choice. It gives a professional-looking finish. For applications that require a strong, lasting bond, dewaxed shellac gives the best results.

Comparing Waxed vs. Dewaxed Shellac in Common Scenarios

Understanding the differences between waxed and dewaxed shellac helps you to choose the correct shellac for your project. Waxed shellac, with its wax content, can sometimes give a richer look. It may not provide the same strong bond as dewaxed shellac. Dewaxed shellac bonds better. It creates a good base. This comparison helps you pick the right finish for your needs.

| Feature | Waxed Shellac | Dewaxed Shellac |

|---|---|---|

| Adhesion | Can be less reliable | Excellent adhesion |

| Clarity | Can have a slightly cloudy appearance | High clarity |

| Compatibility | May not work well with all topcoats | Works well with most topcoats |

| Best Use | Decorative projects, single-coat applications | Projects requiring multiple coats, furniture finishing |

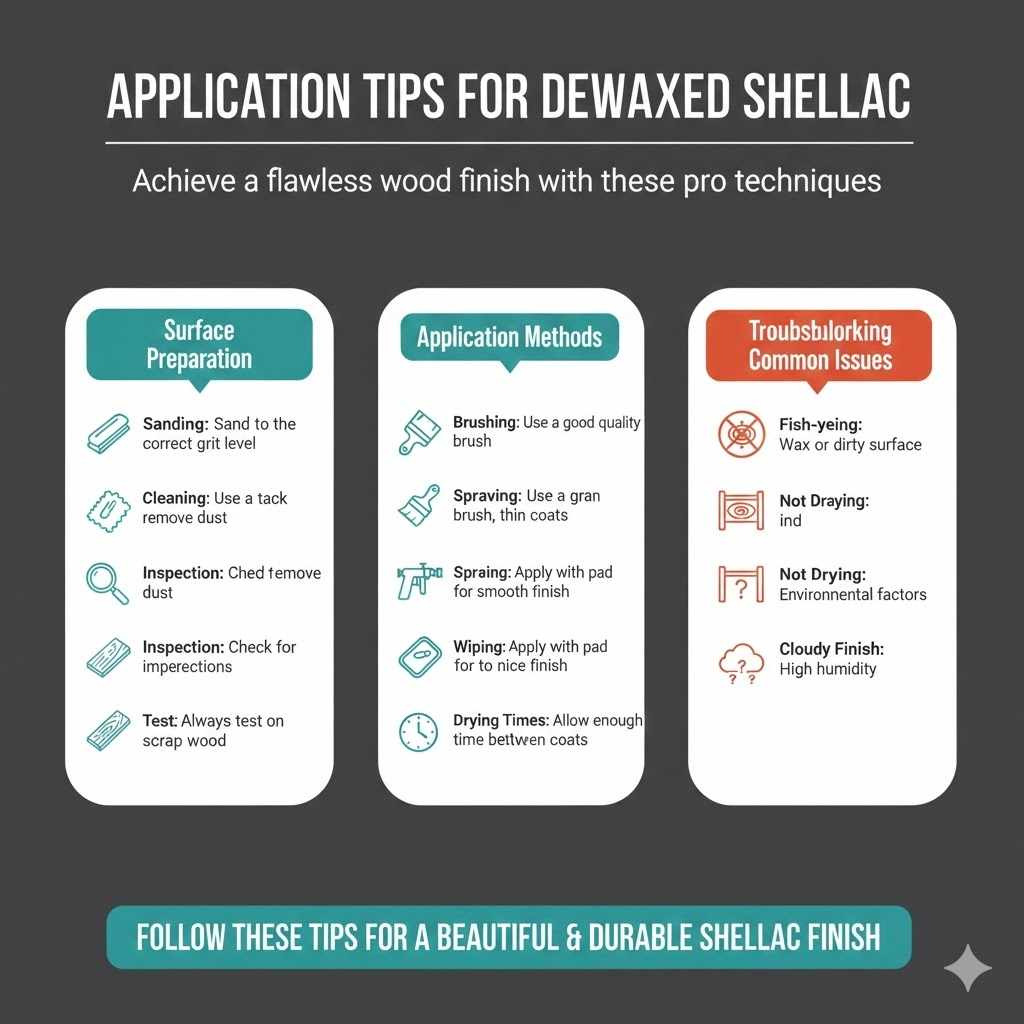

Application Tips for Dewaxed Shellac

Applying dewaxed shellac is a straightforward process when you know the correct methods. Proper preparation and the right techniques will ensure your project gets a beautiful, durable finish. This section explores how to correctly apply dewaxed shellac.

Surface Preparation

Correct surface preparation is essential for a good finish. Start by sanding the wood to create a smooth surface. Remove any dust. Use a tack cloth. Clean the wood. Make sure there is no old finish, dirt, or wax. Surface preparation gives you a good base. It helps with adhesion. Proper prep makes for the best finish.

- Sanding: Sand the wood to the correct grit level.

- Cleaning: Use a tack cloth to remove any dust after sanding.

- Inspection: Check for imperfections. Correct any issues before applying the shellac.

- Test: Always test on a scrap piece. This will make sure you are getting the results you want.

Application Methods

Dewaxed shellac can be applied using different methods. Brushing is easy and good for smaller projects. Spraying gives a smooth finish for bigger projects. Wiping the shellac on with a pad can create a professional look. The method you use depends on your project size, your skill level, and the desired results. Try different methods.

- Brushing: Use a good quality brush. Apply thin, even coats.

- Spraying: Spraying gives a very smooth finish. Use a spray gun for best results.

- Wiping: Apply the shellac with a pad. This gives a nice finish.

- Drying Times: Allow enough time between coats. Read the label for guidance.

Troubleshooting Common Issues

Even with care, problems can arise. Fish-eyeing can happen if wax is present or if the surface isn’t clean. The finish might not dry properly. If the finish gets cloudy, it can be from applying it in humid conditions. Fixing these issues is simple if you know what is going on. Take your time, pay attention, and make corrections as needed. Be patient with your project. You will get the best results.

Frequently Asked Questions

Question: Is all Zinsser shellac dewaxed?

Answer: No, not all Zinsser shellac products are dewaxed. It’s essential to check the product label to confirm.

Question: How can I tell if a Zinsser shellac product is dewaxed?

Answer: Check the product label. It will clearly state “dewaxed” if it is.

Question: What is the best use for dewaxed shellac?

Answer: Dewaxed shellac is best used when multiple coats of finish or other coatings will be applied, ensuring good adhesion.

Question: Can I use waxed shellac as a base coat?

Answer: While you can, it’s not ideal if you plan to apply additional finishes. The wax can interfere with adhesion.

Question: Where can I find more information about Zinsser shellac products?

Answer: You can find detailed product information on the Zinsser website or by contacting their customer support.

Final Thoughts

Now you understand the ins and outs of shellac, and what to look for when choosing Zinsser Shellac. You have learned that Is Zinsser Shellac Dewaxed? What You Should Know is vital, so that you pick the right product for your project. Knowing the difference between waxed and dewaxed is key to a good finish. Always check the label. Prepare your surface correctly. This information is your guide to excellent results. Go out there and create! With these tips, you can confidently choose the correct shellac for your projects. You will get the best look and durability every time. Enjoy your work!