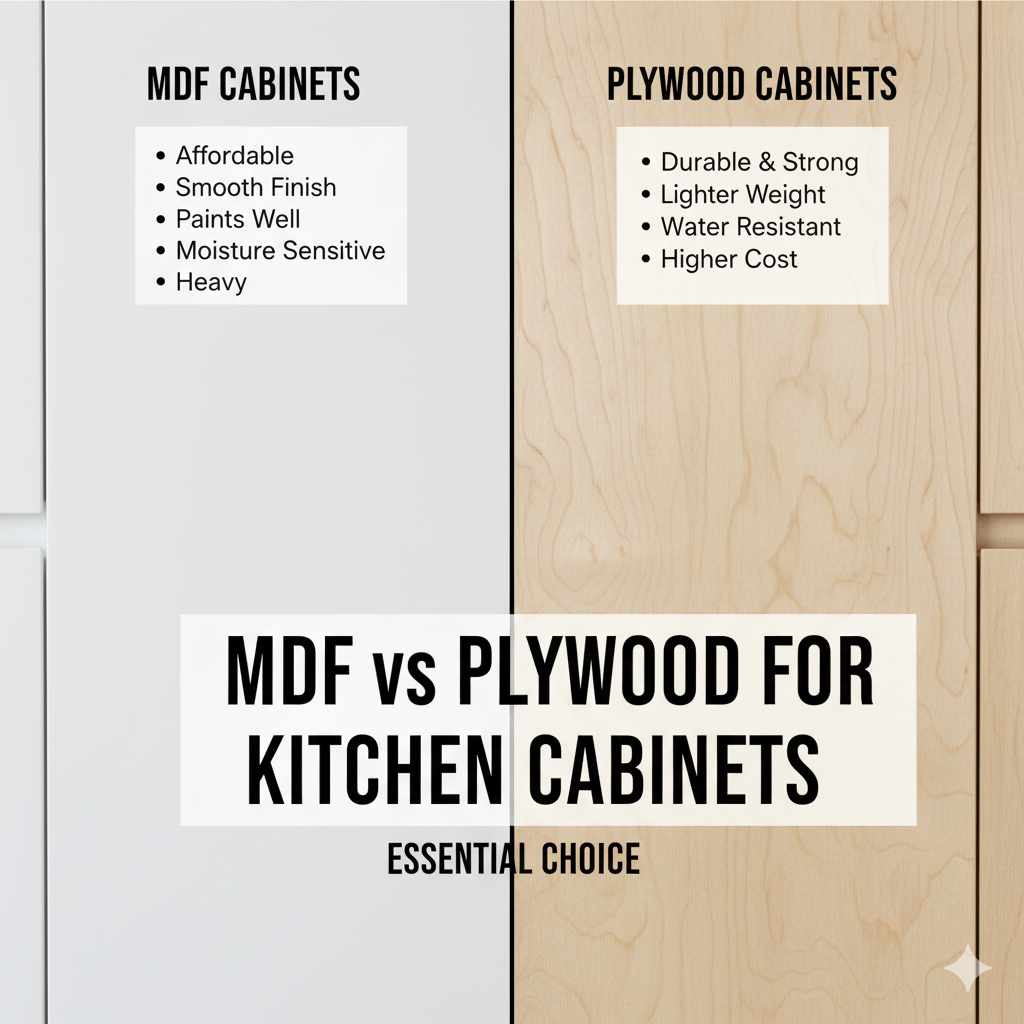

MDF vs Plywood for Kitchen Cabinets: Essential Choice

For kitchen cabinets, plywood is generally the better choice for durability and moisture resistance, especially for the cabinet boxes. MDF can be an option for cabinet doors due to its smooth surface, but it’s less ideal for areas prone to moisture.

Building your dream kitchen is an exciting project! One of the biggest decisions you’ll make is what material to use for your cabinets. It might seem a little overwhelming with all the options, but I’m here to help simplify things. The choice between MDF and plywood is a common one, and it’s important to get it right for cabinets that look great and last for years. We’ll break down exactly what each material is, its pros and cons for kitchen use, and help you make the best choice for your home.

Understanding MDF and Plywood

Before we dive into which is best, let’s get to know our contenders: Medium Density Fiberboard (MDF) and Plywood. They are both engineered wood products, meaning they aren’t solid planks of wood. Instead, they are made by combining wood fibers or thin sheets of wood with adhesives and pressing them into panels.

What is MDF?

MDF is made from wood fibers that are broken down into tiny pieces, then combined with a resin and wax, and finally pressed together under high heat and pressure. Think of it like a really dense, smooth particleboard. This process creates a very uniform panel without knots or grain patterns.

How it’s made: Wood waste (like sawdust and wood chips) is processed into fine fibers. These fibers are mixed with wax and resin binders and then hot-pressed into flat, dense panels.

Key Characteristics:

Very smooth and stable surface.

No grain pattern to interrupt paint or veneer.

Consistent density throughout the panel.

Heavier than plywood of the same thickness.

Prone to swelling if exposed to moisture.

What is Plywood?

Plywood is made by taking thin sheets of wood veneer, layering them on top of each other with the grain running in alternating directions, and then gluing and pressing them together. This cross-graining technique gives plywood more strength and stability than solid wood.

How it’s made: Thin “peeled” layers of wood veneer are glued together with their grain patterns oriented at right angles to each other. This process is repeated for the desired thickness.

Key Characteristics:

Strong and stable due to the cross-grained layers.

Resistant to shrinking, swelling, and warping.

Has a visible wood grain pattern.

Can be susceptible to delamination if exposed to excessive moisture over time.

Available in various grades and wood species.

MDF vs. Plywood for Kitchen Cabinets: The Big Comparison

Now, let’s put them head-to-head for kitchen cabinet applications. The kitchen is a busy place, often with steam, spills, and constant use, so durability and moisture resistance are super important!

Strength and Durability

Plywood: Plywood is generally stronger and more durable than MDF. The layered construction with alternating grain directions makes it resistant to bending and breaking. This is crucial for cabinet boxes that hold heavy dishes, appliances, and pantry staples. Plywood can handle screws and nails very well, providing a strong hold for hinges and drawer slides.

MDF: While MDF is dense and stable, it’s not as strong as plywood in terms of load-bearing capacity and resistance to impact. It can be more prone to chipping or damaging around screw holes if not reinforced.

Moisture Resistance

This is a big one for kitchens!

Plywood: Plywood has better moisture resistance than MDF, especially when sealed properly. While prolonged exposure to standing water can cause delamination, it holds up much better to everyday kitchen humidity and minor splashes. Marine-grade plywood is specifically designed for superior moisture resistance.

MDF: MDF is highly susceptible to moisture. If water gets into the material, it will swell, warp, and lose its structural integrity. Even with a good seal, moisture can eventually seep in, especially around edges or if the finish is compromised. This makes it a risky choice for cabinet boxes in a kitchen.

Surface Finish and Aesthetics

Plywood: Plywood has a natural wood grain, which appeals to many people. It can be stained and clear-coated to showcase its beauty or painted for a different look. However, the grain pattern might show through thinner paint layers or affect a perfectly smooth painted finish.

MDF: MDF offers an incredibly smooth and uniform surface. This makes it an excellent substrate for painting. It accepts paint beautifully, creates a flawless, pore-free finish, and doesn’t have any distracting grain patterns or knots. This is why it’s often used for cabinet doors, especially in modern or minimalist styles.

Cost

Plywood: Plywood prices can vary widely depending on the grade, wood species, and thickness. High-grade plywood can be more expensive, but mid-grade options are often competitive with MDF.

MDF: MDF is typically more affordable than plywood, especially when comparing similar thicknesses. This can make it an attractive option for budget-conscious projects.

Weight

Plywood: Plywood is lighter than MDF of the same thickness. This can make it easier to handle and install, especially for larger cabinet sections.

MDF: MDF is denser and therefore heavier. This can be a consideration during installation.

Ease of Working

Plywood: Plywood is relatively easy to cut and work with. You need to be mindful of tear-out when cutting, but good blades and techniques make it manageable. It holds fasteners well.

MDF: MDF cuts very cleanly, producing a smooth edge. However, it can create a lot of fine dust, so good dust collection and respiratory protection are essential. Its density means it can dull cutting tools faster than plywood. Screws don’t hold as well in MDF as in plywood without pre-drilling and sometimes using special anchors or inserts.

When to Use MDF for Kitchen Cabinets

Given its properties, MDF is best suited for specific cabinet components and certain kitchen styles:

Cabinet Doors: This is where MDF shines! Its smooth surface is perfect for a painted finish, offering a flawless look without visible grain. It’s also stable, meaning it won’t warp or twist, which is important for doors.

Cabinet Drawer Fronts: Similar to doors, drawer fronts benefit from MDF’s smooth surface if a painted finish is desired.

Decorative Panels or Accents: MDF can be a good choice for non-structural decorative elements that will be painted.

Important Consideration for MDF: If you use MDF in the kitchen, especially for doors, ensure it is properly primed and painted with high-quality finishes. For areas where there’s a higher risk of steam or splashes directly hitting the material (like near the sink or stove), consider using a waterproof sealant on exposed edges in addition to the paint.

When to Use Plywood for Kitchen Cabinets

Plywood is the workhorse of cabinetry, offering a great balance of strength, durability, and moisture resistance.

Cabinet Boxes (Carcasses): This is where plywood is often the superior choice. The strength and stability of plywood ensure that your cabinet boxes can hold significant weight and withstand the daily rigors of kitchen use. Its resistance to moisture is also a significant advantage in this environment. Look for cabinet-grade birch or maple plywood for the best combination of strength and fine appearance.

Shelving: Plywood is excellent for cabinet shelves as it’s strong enough to support heavy items without sagging.

Drawer Sides and Bottoms: While some prefer solid wood for drawer sides, good quality plywood is a strong and stable option that resists changes in humidity, which can cause solid wood to swell or shrink.

Types of Plywood to Consider:

Cabinet Grade Plywood: Look for plywood designated as “cabinet grade.” This means it has smooth, flawless veneers on at least one face, making it suitable for visible surfaces. Common options include birch, maple, oak, and poplar.

Hardwood Plywood: This is generally stronger and more durable than softwood plywood.

Formaldehyde-free Plywood: For those concerned about indoor air quality, many manufacturers now offer plywood with low or no added formaldehyde. This is always a good option to consider for home building materials. To learn more about formaldehyde in building materials, you can check out resources from the U.S. Environmental Protection Agency (EPA).

Comparing Material Performance in a Table

Let’s summarize the key differences in a handy table.

| Feature | MDF | Plywood |

|---|---|---|

| Strength & Durability | Good stability, prone to chipping/damage around fasteners. Lower load capacity. | Excellent. High strength-to-weight ratio, holds fasteners well. Ideal for heavy loads. |

| Moisture Resistance | Poor. Swells and disintegrates when wet. | Good (better than MDF). Resists humidity; prolonged water exposure can cause issues. |

| Surface Finish | Extremely smooth, perfect for painting. No grain. Accepts veneer well. | Wood grain visible. Can be stained, painted, or veneered over. |

| Cost | Generally more affordable. | Can range from moderate to expensive depending on grade and species. |

| Weight | Heavy andDense. | Lighter than MDF of comparable thickness. |

| Ease of Working | Cuts cleanly, but produces fine dust. Fasteners need careful handling. | Easy to cut, but can chip. Holds fasteners exceptionally well. |

| Best Use in Kitchens | Cabinet doors, drawer fronts (especially for painted finishes). | Cabinet boxes, shelving, drawer boxes, visible cabinet frames. |

Building Cabinet Boxes: Plywood is Usually the Winner

When it comes to the actual boxes that make up your cabinets – what we call the carcasses – plywood is almost always the preferred material for good reason.

Structural Integrity: Cabinet boxes need to be strong. Think about the weight of dishes, pots, pans, and appliances. Plywood’s layered construction, with alternating grain patterns, provides superior strength and rigidity. It’s less likely to sag or warp under load compared to MDF. The structural integrity of cabinet boxes is paramount for longevity.

Fastener Holding Power: Hinges, drawer slides, handles, and the screws that hold the cabinet box together all rely on the material’s ability to grip fasteners. Plywood offers much better screw-holding power than MDF. This means your hardware will be more secure and less likely to loosen over time.

Moisture Management: Kitchens are inherently humid environments. There are sinks, dishwashers, and cooking that generate steam. While you should always seal and finish your cabinet boxes well, plywood offers better inherent resistance to moisture absorption than MDF. If a small splash of water happens, plywood is more forgiving.

Choosing the Right Plywood for Your Boxes

For cabinet boxes, you’ll want to select a good quality cabinet-grade plywood. Aim for:

Hardwood Plywood: Woods like birch, maple, or oak are common and offer durability. Birch plywood, in particular, is a very popular choice for its smooth, uniform surface and good strength.

Thickness: 3/4-inch (19mm) is the standard thickness for cabinet carcasses. It offers excellent strength. For very long spans or extremely heavy loads, thicker plywood might be considered, but 3/4-inch is generally sufficient.

Veneer Quality: Look for plywood with smooth, consistent veneers on both sides. Avoid panels with voids or large knots if they will be visible, though for internal cabinet boxes, this is less critical as long as the structural integrity is there.

Making Cabinet Doors: MDF Shines for Painted Finishes

When it comes to cabinet doors, the decision often hinges on your desired finish.

The Magic of a Painted Surface: If you’re dreaming of a smooth, sleek, painted finish, MDF is often the top choice for cabinet doors. Its density and lack of grain mean there are no imperfections for paint to settle into. You get a perfectly flat, consistent surface that accepts paint like a dream. This is why many modern and contemporary kitchens feature painted MDF doors.

Stability: MDF is very stable and doesn’t expand or contract much with changes in humidity, which helps painted finishes last longer and prevents cracking along joints.

Detailing: MDF can be easily routed to create elaborate door profiles and raised panel designs. The smooth surface allows for crisp, clean lines in these detailed areas.

Consider Veneering: For a smooth, non-wood grain look that can be stained, MDF can also be veneered. High-quality wood veneers can be applied to MDF panels for a consistent appearance.

When Plywood Works for Doors

Plywood can certainly be used for cabinet doors, especially if you love the look of natural wood grain.

Stained Finishes: If you want to stain your cabinet doors to show off the wood grain, plywood is a great option. You can choose from various wood species like oak, maple, or cherry plywood.

Wood Doors: For traditional or shaker-style doors, solid wood or high-quality hardwood plywood are excellent choices.

Durability: High-quality hardwood plywood doors are durable and can withstand the wear and tear of kitchen life.

A Note on Moisture: Even with painted MDF doors, if they are in a very high-moisture area – for example, directly above a dishwasher without good ventilation – they can still be susceptible to water damage over time, especially if the paint is compromised.

FAQ: Your Burning Questions Answered

As a woodworking mentor, I know you might have a few questions swirling around. Let’s tackle some common ones:

1. Can I use MDF for all my kitchen cabinets?

While MDF can be used for cabinet doors and drawer fronts, it’s generally not recommended for the cabinet boxes (carcasses) in a kitchen. This is because MDF absorbs moisture easily and can swell, warp, and lose its structural integrity in a humid kitchen environment. Plywood is a much better choice for cabinet boxes due to its strength and better moisture resistance.

2. Is plywood stronger than MDF for cabinets?

Yes, generally plywood is stronger and more durable than MDF, especially when it comes to supporting weight and resisting bending or warping. The layered structure of plywood with alternating grain directions gives it excellent structural integrity, which is important for cabinet boxes that hold heavy items. Plywood also holds screws and fasteners better than MDF.

3. Which material is better for painted kitchen cabinets?

For painted kitchen cabinets, MDF is often the preferred material, especially for the doors and drawer fronts. MDF provides an incredibly smooth, uniform surface without any wood grain, making it ideal for a flawless paint finish. Plywood can be painted, but the wood grain might show through, and it won’t achieve the same ultra-smooth, pore-free look as MDF.

4. How does moisture affect MDF and Plywood in the kitchen?

Moisture is the enemy of MDF. It will readily absorb water, swell up significantly, and lose its strength, often becoming unusable. Plywood is more resistant to moisture than MDF, but prolonged exposure to standing water can still cause it to delaminate over time. In a typical kitchen, sealed plywood performs much better against humidity and minor splashes.

5. What’s the price difference between MDF and Plywood for cabinets?

MDF is typically more affordable than plywood. However, the price difference can vary depending on the grade, thickness, and specific type of plywood you choose (e.g., birch plywood versus a lower-grade pine plywood). For cabinet boxes, the added cost of plywood is often justified by its superior durability and moisture resistance.

6. Should I use a specific type of plywood for my kitchen cabinets?

Yes! For kitchen cabinets, it’s best to use cabinet-grade hardwood plywood. Options like birch, maple, or oak plywood are excellent choices. They offer smooth surfaces for finishing, good strength, and durability. Avoid construction-grade plywood, as it may have more voids and a rougher surface that isn’t suitable for visible cabinet parts.

7. Can I mix MDF and Plywood in my kitchen cabinet project?

Absolutely! This is a very common and smart approach. You can use strong, moisture-resistant plywood for the cabinet boxes and shelves, and then use smooth MDF for the cabinet doors and drawer fronts to achieve a beautiful painted finish. This strategy leverages the best properties of each material for different parts of the cabinet.