Pressure Treated Plywood vs Marine Plywood: Which is the Ultimate Choice?

Pressure treated plywood is chemically treated to resist rot and decay, while marine plywood is specifically designed for water exposure and has a higher grade. Pressure treated plywood is chemically treated to resist rot and decay, while marine plywood is specifically designed for water exposure and has a higher grade.

Pressure treated plywood is chemically treated to resist rot and decay, making it suitable for outdoor and above-ground applications, such as decks and fences. On the other hand, marine plywood is specifically designed for water exposure and is commonly used in applications such as boat building, docks, and other marine projects.

Both types of plywood have their advantages and uses, but it’s important to understand the specific requirements of your project before choosing between them. This article will compare pressure treated plywood and marine plywood in terms of their composition, durability, cost, and suitability for different applications.

When it comes to choosing the right plywood for your project, understanding the composition of different types is crucial. Two popular choices in the market are pressure treated plywood and marine plywood. Although they may appear similar, their composition sets them apart, making each suitable for specific applications.

Pressure Treated Plywood Composition

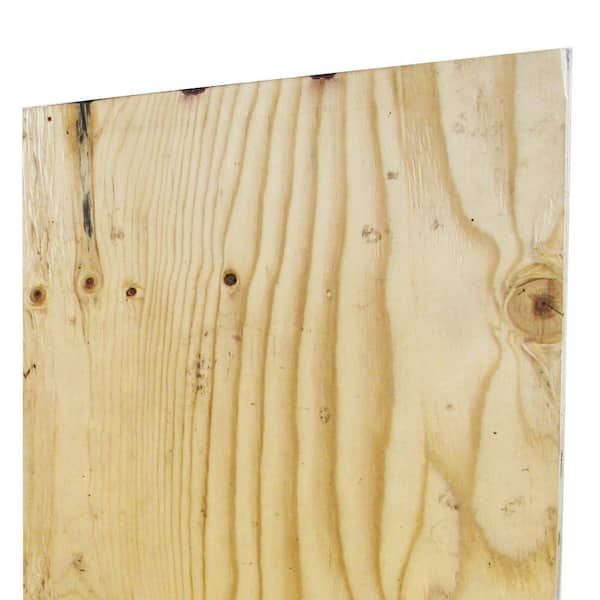

Pressure treated plywood is known for its durability and resistance to rot, decay, and insect infestation. The composition of pressure treated plywood involves a combination of plywood and chemical preservatives. The preservatives are forced into the wood fibers under high pressure, penetrating deep into the material to provide protection from environmental factors.

This type of plywood is made using softwood veneers, which are glued together with phenol-formaldehyde adhesive. The preservatives used in pressure treated plywood are typically copper-based, offering a reliable defense against moisture and fungal growth. This composition makes it an excellent choice for outdoor projects that are exposed to the elements, such as decks, fences, and exterior structures.

Marine Plywood Composition

Marine plywood, on the other hand, is specifically designed for water-based applications. It is made using high-quality hardwood veneers bonded together with waterproof adhesive. The composition of marine plywood also includes phenolic resin, which further enhances its water resistance and durability.

Unlike pressure treated plywood, marine plywood is void-free, which means it has no gaps or voids between the layers. This makes it highly stable and resistant to warping or splitting. The waterproof properties of marine plywood make it ideal for marine applications, including boat building, docks, and other projects exposed to constant moisture.

Additionally, marine plywood meets stringent quality standards, making it more reliable and long-lasting compared to other types of plywood. Its composition and construction allow it to withstand the harsh marine environment, including exposure to saltwater.

Properties

When it comes to choosing the right plywood for your project, understanding the properties of each type is crucial. Pressure treated plywood and marine plywood are two common options with distinct features that make them suitable for different applications. In this section, we will explore the properties of each type to help you make an informed decision.

Properties Of Pressure Treated Plywood

Pressure treated plywood has several key properties that make it a popular choice for outdoor projects:

- Durability: Pressure treated plywood is highly durable and resistant to rot, decay, and insect damage. This is due to the special treatment process it undergoes, where preservatives are infused into the wood fibers.

- Moisture Resistance: The treatment process also enhances the plywood’s moisture resistance, making it suitable for applications exposed to high humidity or moisture.

- Chemical Resistance: Pressure treated plywood is resistant to chemicals, making it ideal for use in projects that involve exposure to certain substances or environments.

- Strength: This type of plywood is generally known for its strength, providing structural support in various applications.

Properties Of Marine Plywood

Marine plywood possesses specific properties that make it a top choice for marine and water-related applications:

- Waterproof: Marine plywood is specially designed to be waterproof, making it unaffected by water exposure. It is constructed using a specific type of adhesive that can withstand both wet and humid conditions.

- Rot and Fungus Resistance: Due to its waterproof nature, marine plywood is inherently resistant to rot and fungal growth. This makes it ideal for boat and dock construction.

- High Strength: Marine plywood is known for its high strength and durability, making it a reliable choice for marine and structural applications that require resistance to heavy loads and impact.

- Quality Construction: Marine plywood is manufactured with high-quality veneers, ensuring a consistent and uniform thickness throughout the sheet. This leads to better stability and ease of use in various woodworking projects.

By understanding the distinctive properties of pressure treated plywood and marine plywood, you can confidently select the right type for your project. Consider the specific requirements of your application, such as exposure to moisture or the need for water resistance, and choose the plywood type that best meets those needs.

Common Applications

Pressure treated plywood and marine plywood are two popular options for various construction and outdoor projects. They each have their own unique qualities that make them suitable for specific applications. Understanding these applications can help you determine which type of plywood is the right choice for your project.

Common Applications Of Pressure Treated Plywood

Pressure treated plywood is highly resistant to moisture, rot, and insect damage. This makes it ideal for outdoor projects that are exposed to the elements and require long-term durability. Some common applications of pressure treated plywood include:

- Decking: Pressure treated plywood is often used as a decking material due to its ability to withstand moisture and withstand heavy foot traffic.

- Fencing: It is commonly used as fence panels and posts, providing a sturdy and long-lasting barrier.

- Sheds and outdoor storage: Pressure treated plywood is an excellent choice for constructing sheds, playhouses, and other outdoor storage structures that need to withstand harsh weather conditions.

- Exterior furniture: Outdoor furniture, such as tables, chairs, and benches, can be made using pressure treated plywood for added strength and durability.

- Boat docks: Pressure treated plywood is often used in the construction of boat docks and marinas due to its resistance to water damage.

Common Applications Of Marine Plywood

Marine plywood is specifically designed for applications that require a high level of moisture resistance and greater structural integrity. Some common applications of marine plywood include:

- Boat building: Marine plywood is the preferred choice for constructing boat hulls, decks, and other parts that are constantly in contact with water.

- Outdoor cabinets: It is commonly used for constructing outdoor kitchen cabinets due to its resistance to moisture and durability.

- Wet rooms and bathrooms: Marine plywood is often used in wet rooms, bathrooms, and other areas where there is frequent exposure to moisture.

- Furniture: It is suitable for making furniture that may be used outdoors or in areas where moisture resistance is required.

- High-humidity environments: Marine plywood is used in areas with high humidity, such as saunas and steam rooms.

Comparison And Considerations

Pressure treated plywood is a cost-effective option, providing protection against rot and insect damage. Marine plywood, on the other hand, is highly durable and ideal for projects exposed to moisture and harsh conditions. Consider your specific needs when choosing between the two.

When it comes to choosing the right plywood for your project, two popular options often come to mind: Pressure Treated Plywood and Marine Plywood. Understanding the differences between these two types of plywood is essential to make an informed decision. In this section, we will compare the strength and durability, moisture resistance, cost, and environmental considerations of Pressure Treated Plywood and Marine Plywood.

Strength And Durability

Both Pressure Treated Plywood and Marine Plywood are known for their strength and durability. Pressure Treated Plywood is made by injecting chemicals into the wood to enhance its ability to withstand rot, decay, and insect damage. This treatment improves the plywood’s overall durability, making it suitable for outdoor projects exposed to harsh weather conditions.

On the other hand, Marine Plywood is specifically engineered to withstand moisture and is highly durable. It is constructed using waterproof glue and is made from high-quality wood veneers. This makes it ideal for applications that are directly exposed to water, such as boat building and marine environments.

Frequently Asked Questions For Pressure Treated Plywood Vs Marine Plywood

Why Is Marine Plywood Not Treated?

Marine plywood is not treated because it is made using high-quality adhesives and superior quality wood. The wood used in marine plywood is naturally resistant to moisture and decay, eliminating the need for additional treatment. This makes it ideal for use in water-related applications where durability is crucial.

Can You Use Pressure Treated Plywood On A Boat?

Yes, it is safe to use pressure treated plywood on a boat. The pressure treatment helps protect the wood from rot and insects, making it suitable for marine applications. However, proper sealing and maintenance are still necessary to ensure the longevity and performance of the plywood on a boat.

What Are The Disadvantages Of Marine Plywood?

The disadvantages of marine plywood include the high cost, limited availability, and susceptibility to water damage. It is also heavier compared to other types of plywood and can have a shorter lifespan if not properly maintained.

Do I Really Need Marine Grade Plywood?

Yes, you need marine grade plywood for marine or outdoor projects. It’s durable, water-resistant, and able to withstand harsh conditions. Regular plywood may weaken or rot when exposed to moisture, but marine grade plywood is specifically designed to resist damage caused by water.

Conclusion

Choosing between pressure treated plywood and marine plywood depends on the specific project requirements. While pressure treated plywood is a cost-effective option for projects that require weather resistance, marine plywood offers unrivaled durability and strength for water-related applications. Consider the intended use, budget, and longevity when making your decision.