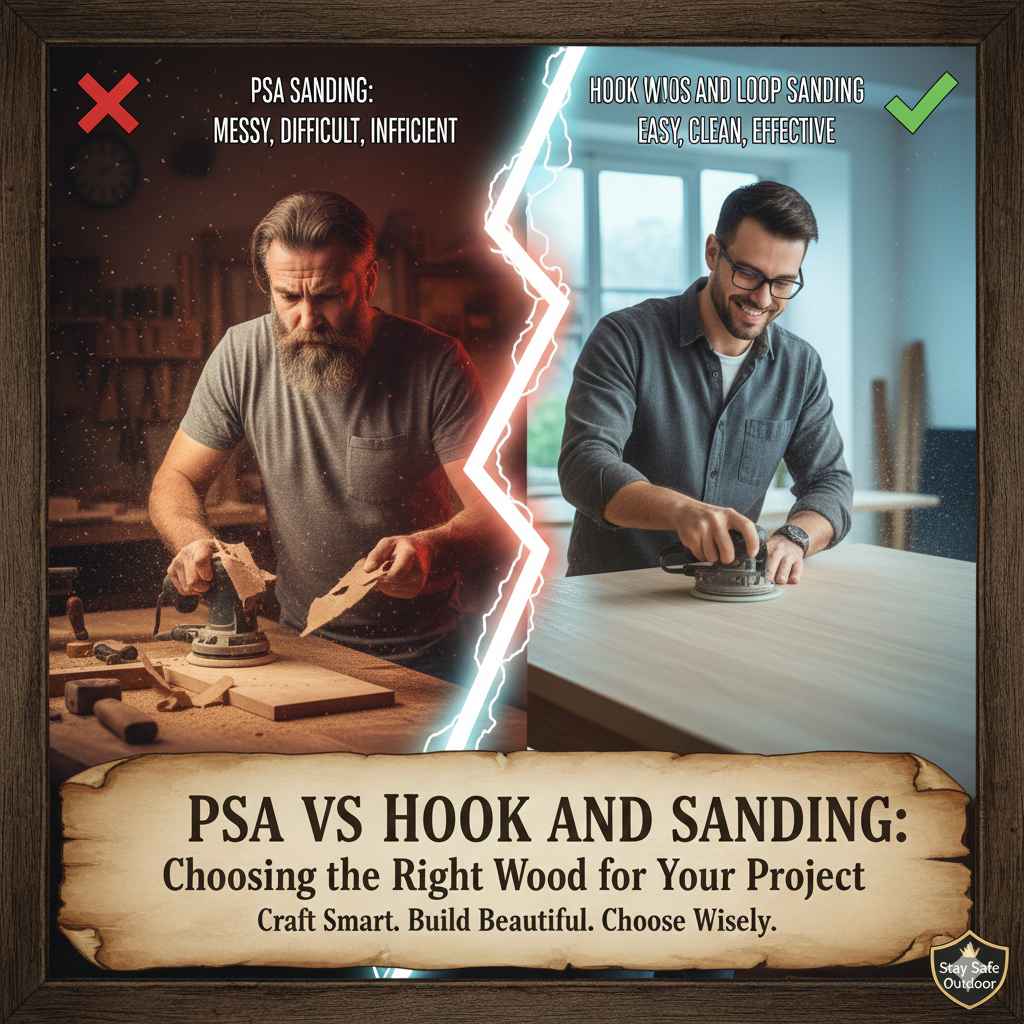

PSA vs Hook and Loop Sanding: Choosing the Right Option

Figuring out whether to use PSA vs Hook and Loop Sanding: Better Option? can be tricky when you’re starting a project. It’s a common question for many woodworkers and DIY enthusiasts because both systems have their pros and cons. Don’t worry, it’s simpler than you might think. This guide will break down the differences between PSA and Hook and Loop sanding systems. We’ll explore their benefits and drawbacks, helping you pick the perfect method for your needs. Get ready to discover which sanding system is the best fit for your next project!

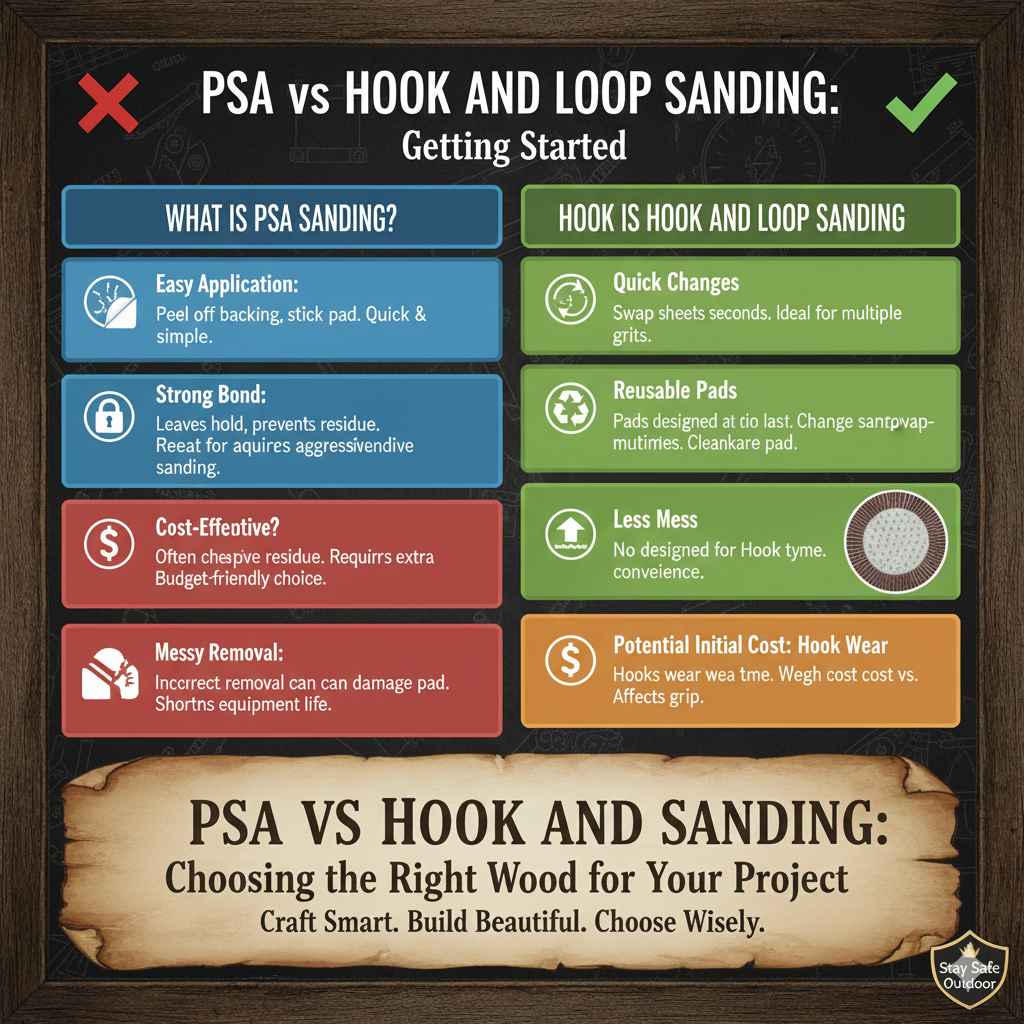

PSA vs Hook and Loop Sanding: Getting Started

Choosing between PSA (Pressure Sensitive Adhesive) and Hook and Loop sanding systems seems like a small decision, but it makes a big difference in how easily and quickly you can sand. The main difference lies in how the sandpaper sticks to the sanding pad. PSA uses an adhesive backing, similar to a sticker. Hook and Loop, on the other hand, utilizes a system with tiny hooks and loops, much like Velcro. This impacts how quickly you can change sandpaper, how well it stays in place, and how easily you can adapt to different sanding tasks. By weighing each system’s strengths, you’ll be well-equipped to select the ideal option for your woodworking projects.

What is PSA Sanding?

PSA sanding uses sandpaper with an adhesive backing. It’s like a giant sticker that sticks directly onto the sanding pad. This setup is straightforward and often considered cost-effective, but also has some downsides. The adhesive is typically strong, ensuring the sandpaper stays put during sanding. However, changing sandpaper can sometimes be a messy and time-consuming task. Additionally, PSA sandpaper can leave adhesive residue on the sanding pad if removed improperly, which can affect the sandpaper’s hold. These factors are important when considering PSA vs Hook and Loop Sanding: Better Option?

- Easy Application: PSA sandpaper is very easy to apply; you peel off the backing and stick it on. This simplicity makes it a quick choice, especially when you’re in a hurry. You don’t need any special tools or complicated procedures.

- Strong Bond: PSA sandpaper provides a very secure hold. The adhesive is designed to withstand the stress of sanding, so the sandpaper stays put during vigorous use, reducing the chances of it shifting or coming loose.

- Cost-Effective: PSA sandpaper can often be cheaper to purchase than Hook and Loop options. This makes it an attractive choice for projects where you’ll be going through a lot of sandpaper, offering budget-friendly sanding solutions.

- Messy Removal: Removing PSA sandpaper can be messy. Residue from the adhesive can stick to your sanding pad, requiring extra cleaning, which sometimes gets in the way of sanding.

- Potential for Pad Damage: Incorrect removal of the sandpaper can damage the sanding pad. This damage may make it challenging for the sandpaper to stick to the pad the next time, shortening the life of your sanding equipment.

What is Hook and Loop Sanding?

Hook and Loop sanding uses sandpaper with a fabric backing that has tiny loops. These loops attach to a sanding pad covered in small hooks. This system is known for its convenience, especially when switching between different grits of sandpaper. Unlike PSA sandpaper, it allows for fast and easy changes without leaving residue. However, Hook and Loop sandpaper can sometimes cost more than PSA sandpaper. This method is a great solution when debating PSA vs Hook and Loop Sanding: Better Option?

- Quick Changes: The main perk of Hook and Loop is the speed at which you can change sandpaper. You can swap out sheets in seconds, which is great if you’re working with various grits or types of materials.

- Reusable Pads: Hook and Loop pads are often reusable. The hooks on the pad are designed to last, letting you easily change the sandpaper multiple times before needing a new pad.

- Less Mess: Changing sandpaper leaves less mess than PSA. Because there’s no sticky adhesive, you don’t have to worry about cleaning up residue, keeping your workspace cleaner and more efficient.

- Higher Initial Cost: Hook and Loop sandpaper can be more expensive than PSA sandpaper, which might be a concern if you’re on a tight budget. You’ll have to decide whether the ease of use makes up for the higher cost.

- Potential for Hook Wear: The hooks on the pad can wear out over time, especially with frequent use. As the hooks wear down, the sandpaper may not attach as securely, impacting performance.

Materials and Durability: PSA vs Hook and Loop

When you’re comparing PSA vs Hook and Loop Sanding: Better Option? it’s important to explore the materials involved and how durable each system is. The quality of the materials used in both the sandpaper and the backing impacts how well the sandpaper performs and how long it lasts. The backing material, the adhesive in PSA, and the hooks and loops in Hook and Loop contribute to overall durability. Considering these elements helps you pick the right system for the job.

Backing Material in Sandpaper

The backing material of sandpaper greatly affects its performance. Common materials include paper, cloth, and a combination of the two. Paper backings are often the most affordable but can tear easily. Cloth backings are more durable and flexible, making them ideal for sanding uneven surfaces. A paper-cloth mix offers a balance of durability and cost. Choosing the correct backing material can impact the outcome of the project. This is a very important aspect of the PSA vs Hook and Loop Sanding: Better Option? decision.

- Paper Backing: Paper backings are budget-friendly and suitable for light sanding tasks. They work well for sanding flat surfaces but can tear easily, especially with high pressure.

- Cloth Backing: Cloth backings are more durable than paper and can withstand more wear. They’re flexible, making them great for sanding curved or uneven surfaces without tearing.

- Paper-Cloth Mix: These backings offer a balance between affordability and durability. They are sturdier than paper but might not be as flexible as cloth.

- Hook and Loop Sandpaper Backing: Hook and Loop sandpaper typically uses a cloth or a strong paper backing. This backing needs to be tough enough to hold the loops and withstand the force of sanding.

- PSA Sandpaper Backing: PSA sandpaper can use paper, cloth, or a mix of both. The backing needs to be smooth for the adhesive to work correctly, allowing for a strong bond to the sanding pad.

Adhesive Quality

The quality of the adhesive in PSA sandpaper plays a major role in its effectiveness. A strong, heat-resistant adhesive holds the sandpaper securely and keeps it from coming loose during sanding. A poor-quality adhesive may let the sandpaper come off, causing frustration and possibly damaging the project. The adhesive must withstand the friction and heat generated during sanding, especially when working on hardwoods or using power tools. The adhesive can also have an impact on the decision of PSA vs Hook and Loop Sanding: Better Option?

- Bond Strength: Good adhesive ensures the sandpaper stays in place, letting you sand efficiently. This is very important for power sanding, where a strong bond prevents the sandpaper from slipping or tearing.

- Heat Resistance: The adhesive needs to resist heat, which is generated by friction during sanding. Heat-resistant adhesives prevent the sandpaper from loosening or melting, ensuring consistent performance.

- Residue: Some adhesives may leave residue. While some adhesive residue can be cleaned up, it can still interfere with the sanding process and could affect the finished outcome.

- Application: The application of adhesive is also crucial. It should be evenly applied across the back of the sandpaper to provide a consistent bond. Poor application can lead to uneven adhesion, and that can influence PSA vs Hook and Loop Sanding: Better Option?.

- Durability: The adhesive’s durability determines how long the sandpaper will last. A durable adhesive keeps the sandpaper securely in place throughout its lifespan, offering good value for your money.

Practical Applications and Performance: PSA vs Hook and Loop

Knowing how PSA and Hook and Loop sanding systems perform in real-world situations helps you make the best choice. This includes considering different types of wood, project sizes, and the tools you’re using. Some projects benefit more from one system over the other, depending on factors such as sanding speed, precision, and the need for frequent sandpaper changes. Exploring these aspects will let you decide PSA vs Hook and Loop Sanding: Better Option?

Wood Types and Sanding Needs

The type of wood and your specific sanding requirements have a huge impact on whether PSA or Hook and Loop is better. Hardwoods, like oak or maple, require durable sandpaper that can endure the increased friction, and require more powerful sanding tools. Softwoods, like pine, are easier to sand, and therefore make the choice more flexible. Different finishes also affect your sanding process. The decision of PSA vs Hook and Loop Sanding: Better Option? can be significantly impacted by these variables.

- Hardwoods: When working with hardwoods, Hook and Loop systems often come into play because they allow for quick changes. This means you can switch between grits easily.

- Softwoods: Softwoods are simpler to sand, so both systems can work. PSA might be a good choice. Since you won’t need to change grits as often, PSA can save you time.

- Project Size: For smaller projects, where you don’t need to change grits frequently, PSA’s ease of application is helpful. Hook and Loop shines when you are working on a bigger project that may require more sandpaper changes.

- Finishing: If you are planning to paint or stain the wood, the final sanding step becomes very important. Hook and Loop is useful because you can use higher grit sandpaper for a smooth finish.

- Power vs. Hand Sanding: Power sanding tools benefit from Hook and Loop’s quick sandpaper changes, especially for extensive projects. Hand sanding can be done with either system, but the method you choose affects the PSA vs Hook and Loop Sanding: Better Option? outcome.

Project Scale and Sanding Efficiency

The size and scope of your project have a big impact on which sanding system is more efficient. For small projects, the time saved by a Hook and Loop’s quick changes may not be as important as the simplicity of PSA. Large projects, however, benefit from the convenience of fast sandpaper changes. Knowing the scale of your project helps you select the sanding method that ensures maximum efficiency and the best results. Efficiency matters a lot when considering PSA vs Hook and Loop Sanding: Better Option?.

- Small Projects: For a small project, such as a single wooden box, PSA may be the right option. The initial setup is fast, and you might not need to change grits very often.

- Large Projects: For a large project, such as a deck, Hook and Loop provides a real advantage. The ability to switch between grits quickly saves time.

- Repetitive Tasks: If your project involves sanding multiple pieces of the same item, PSA’s initial setup is efficient, and the sandpaper will stay in place throughout.

- Custom Projects: Custom projects benefit from Hook and Loop. Because you can change grits quickly, it’s easy to adapt to the wood and your needs.

- Restoration: For restoration work, where various sanding grits are needed, Hook and Loop is usually best. This way, you can easily switch between grits.

Case Studies: Real-World Results

Looking at real-life examples can show you how PSA and Hook and Loop sanding systems perform in practice. These case studies highlight the benefits and drawbacks of each approach in different situations. You’ll see how each system affects project efficiency, the quality of the finish, and the overall time needed to complete the job. Practical examples provide great insight for deciding PSA vs Hook and Loop Sanding: Better Option?.

Case Study 1: Refinishing a Wooden Table

Scenario: A homeowner is refinishing an old wooden table. The table has several layers of old paint and varnish. They need to strip off the old finish, sand the wood, and apply a new finish.

PSA Sanding Results: The homeowner used PSA sandpaper on a handheld sander. They started with coarse grit to remove the old finish and progressively used finer grits. The adhesive was strong, and the sandpaper stayed in place. However, switching grits required peeling off the old sandpaper and applying new sheets. After removing the sandpaper, some glue residue was left behind. While the process was effective, changing sandpaper was time-consuming, especially when switching between grits.

Hook and Loop Sanding Results: In contrast, a different homeowner used a Hook and Loop sander. They removed the old finish using a coarse grit. Changing grits was very fast and easy, making the process more efficient. The homeowner finished the table with no residue. Hook and Loop made the project faster and easier, especially when switching between the many different grits.

Case Study 2: Building a Bookshelf

Scenario: A woodworker is building a bookshelf from solid oak. The bookshelf requires precise sanding for the joints and a smooth finish on the shelves.

PSA Sanding Results: The woodworker used PSA sandpaper, and they found it very effective for the initial sanding. However, since the bookshelf required a lot of sanding and changes in grits, PSA was slightly slower. The initial adhesion was excellent. The woodworker noted some difficulty when removing the adhesive. The initial results were good, but changing grits took more time.

Hook and Loop Sanding Results: The woodworker used Hook and Loop for the joints and the finish sanding. Changing between different grits was extremely fast. This was especially helpful for the intricate details of the bookshelf. They found the Hook and Loop system significantly sped up the sanding process, which was crucial for a project that required multiple rounds of sanding. The speed of changing the paper was the main advantage.

| Feature | PSA | Hook and Loop |

|---|---|---|

| Sandpaper Change | Slower, peel and apply | Faster, easy swap |

| Adhesion | Strong, reliable | Secure with hooks |

| Residue | Possible adhesive residue | No adhesive residue |

| Cost | Often less expensive | Often more expensive |

| Best For | Small projects, infrequent changes | Large projects, frequent changes |

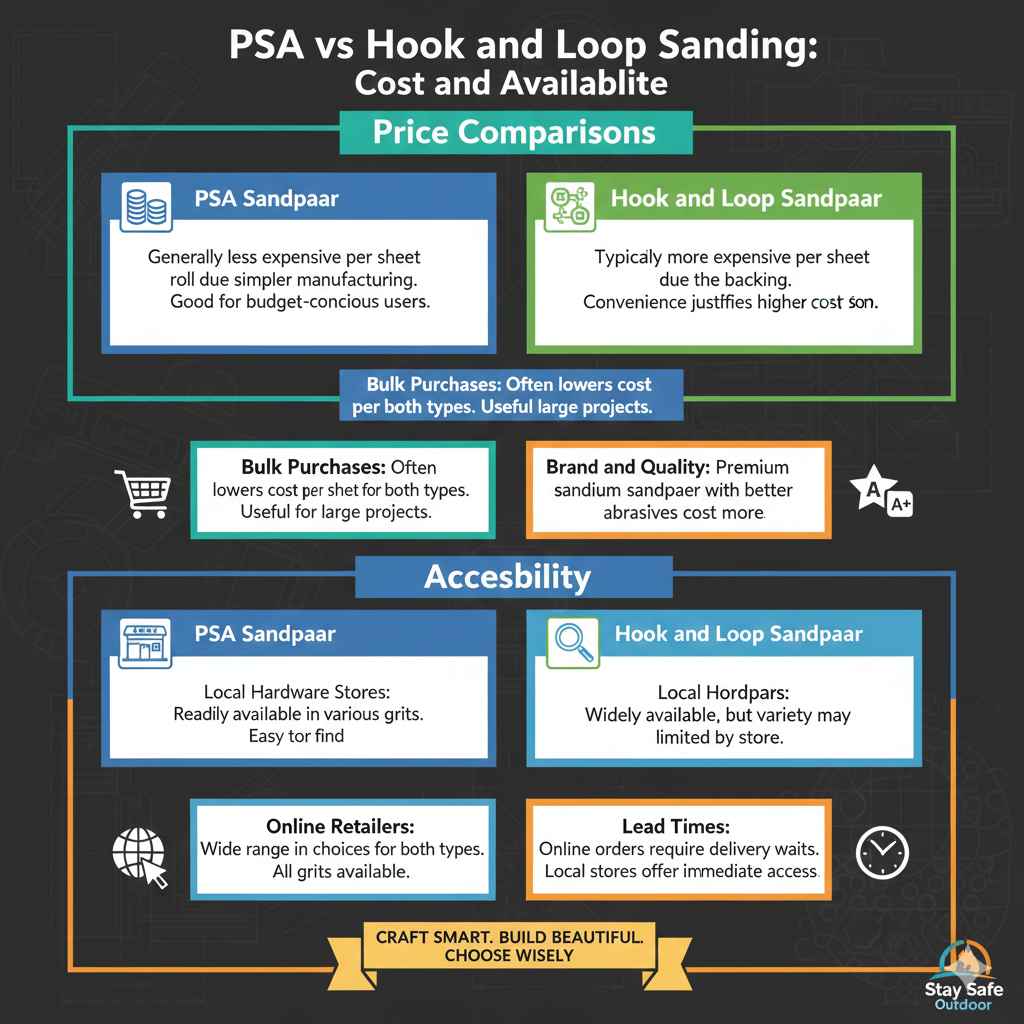

Cost and Availability: PSA vs Hook and Loop

The cost and accessibility of PSA and Hook and Loop sandpaper have a significant effect on your purchasing choices. The price of sandpaper is a key factor, particularly if you are doing several projects or working on a big job where you’ll use a lot of sandpaper. Availability ensures you can easily get the sandpaper when you need it, whether at your local hardware store or online. A thorough evaluation of cost and accessibility helps you choose the best PSA vs Hook and Loop Sanding: Better Option?.

Price Comparisons

When you look at sandpaper costs, you’ll see a range of prices. PSA sandpaper is frequently more affordable than Hook and Loop sandpaper, which makes it a good option if you are on a budget. However, the costs will depend on the sandpaper quality, the size of the sheets, and the quantity you buy. Some retailers may provide discounts when buying sandpaper in bulk, which could impact the cost-effectiveness of the choice. Comparing prices is an important part of assessing PSA vs Hook and Loop Sanding: Better Option?.

- PSA Sandpaper: Generally less expensive per sheet or roll. This is due to the simpler manufacturing process. The total cost is often lower, making it a good choice for those who are budget-conscious.

- Hook and Loop Sandpaper: Typically more expensive per sheet. The increased cost is due to the addition of the Hook and Loop backing. However, the added convenience might make up for the cost.

- Bulk Purchases: Purchasing sandpaper in bulk often lowers the cost per sheet for both types of sandpaper. It’s useful if you do several projects or if you frequently use the same grit.

- Brand and Quality: The brand and the quality of the sandpaper have an effect on the price. Premium sandpaper with better abrasive materials will cost more.

- Overall Project Budget: The total cost of the project should also be considered. If you’re doing a small job with a small budget, the lower initial cost of PSA might be the deciding factor.

Accessibility

The accessibility of sandpaper is just as crucial as its cost. The ease with which you can find and buy sandpaper influences your choice. PSA sandpaper is generally accessible in most hardware stores. Hook and Loop sandpaper is widely available as well, but the options may vary depending on the store and the specific grit sizes you need. Online retailers often offer a wider selection of both types. Assessing the accessibility is important when deciding PSA vs Hook and Loop Sanding: Better Option?.

- Local Hardware Stores: Most hardware stores sell both PSA and Hook and Loop sandpaper. PSA sandpaper is often readily available in various grits. Hook and Loop options may be slightly more limited in variety.

- Online Retailers: Online stores provide a wide range of choices for both PSA and Hook and Loop sandpaper. You can find all grits. This is especially helpful if you need specific types of sandpaper or large quantities.

- Specialty Stores: Some specialty woodworking stores carry specialized PSA and Hook and Loop sandpaper, with high-quality abrasives. This may be beneficial for those who are doing professional woodworking.

- Availability by Region: Accessibility can differ from region to region. In areas with lots of woodworking, the range of sandpaper choices will typically be greater.

- Lead Times: Buying online may mean you have to wait for delivery. If you need sandpaper right away, going to a local hardware store is the faster option. Lead times and access are important to consider when deciding PSA vs Hook and Loop Sanding: Better Option?.

Frequently Asked Questions

Question: Is PSA better than Hook and Loop?

Answer: It depends on your needs! PSA is cost-effective but can take longer to change. Hook and Loop offers quick changes and is useful for larger projects.

Question: Can I use PSA sandpaper on a Hook and Loop sander?

Answer: No, the PSA sandpaper won’t attach properly. You need the specific Hook and Loop sandpaper for these sanders.

Question: Does the adhesive leave residue?

Answer: Yes, PSA sandpaper can leave some adhesive residue. Hook and Loop systems do not have this problem.

Question: Is Hook and Loop more expensive?

Answer: Usually, yes. Hook and Loop sandpaper often costs more. But, it is very quick and easy to change, especially with large projects.

Question: What’s the main benefit of Hook and Loop?

Answer: The major advantage of Hook and Loop is the speed with which you can change sandpaper grits.

Final Thoughts

Choosing between PSA vs Hook and Loop Sanding: Better Option? comes down to understanding your specific needs. PSA sandpaper is a good choice for projects where you don’t need to change grits frequently and you’re on a budget. It’s easy to apply, providing a strong bond to your sanding pad. Hook and Loop sanding offers speed and convenience, especially when working on projects that require multiple grit changes or larger surface areas.

While it may cost more upfront, the ability to switch sandpaper quickly can save you valuable time and make your projects more efficient. Think about the scope and type of the job you’re doing, the kind of wood you’re working with, and the amount of sanding that’s needed. Then, you can pick the best system for your project! Consider your usual workflow and decide which method will make the most sense for you.