Sanding in between Coats of Stain: Pro Tips for Flawless Finishing

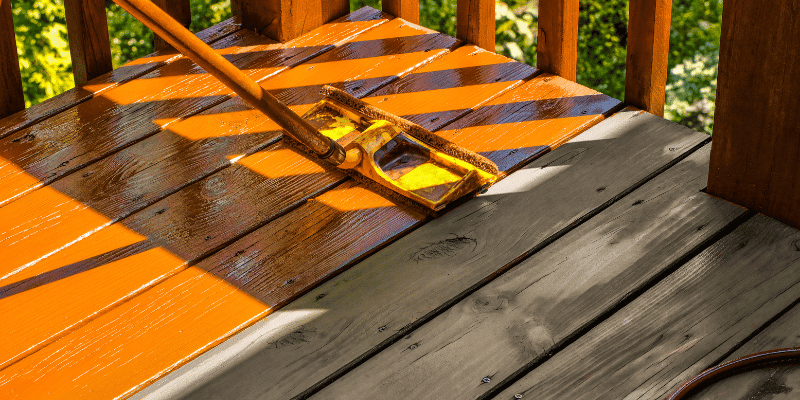

Sanding between coats of stain helps to create a smooth and even surface for the next coat to adhere to, ensuring a professional and flawless finish. This process is crucial to remove any imperfections, raised grain, or dust particles that may have settled on the previous coat of stain.

By sanding between coats, you can achieve a more uniform and attractive appearance for your stained wood surface. Properly sanding between coats of stain requires attention to detail and patience to achieve the best results. In this guide, we’ll explore the importance of sanding between coats of stain, the suitable materials and techniques to use, and the essential steps to follow for a successful staining project.

Whether you’re a DIY enthusiast or a professional woodworker, mastering the art of sanding between coats of stain will elevate the quality and durability of your stained wood projects.

Importance Of Sanding Between Stain Coats

When applying stain to wood surfaces, it is crucial to recognize the significance of sanding between coats. This simple yet essential step can make all the difference in achieving a flawless finish. In this blog post, we will delve into the importance of sanding between stain coats, focusing on two key aspects: ensuring a smooth and even finish, and preparing for optimal adhesion of subsequent coats.

Ensuring Smooth And Even Finish

Sanding between stain coats is an integral part of the staining process. It helps to smooth out any imperfections, such as raised grain or uneven application, resulting in a uniform appearance. By eliminating rough patches and leveling the surface, sanding allows the subsequent coat of stain to penetrate and adhere evenly, enhancing the overall aesthetic appeal of the wood.

Preparing For Optimal Adhesion Of Subsequent Coats

Sanding between stain coats facilitates improved adhesion of subsequent layers of stain or topcoat. The gentle abrasion created by sanding creates a microscopically rough surface, which enhances the bonding ability of the next coat. This ensures that each subsequent layer adheres securely, minimizing the risk of peeling or flaking, and ultimately contributing to a durable and long-lasting finish.

Choosing The Right Sandpaper Grits

Critical to achieving a smooth and polished finish on your woodworking project is choosing the right sandpaper grits. Sanding between coats of stain is a crucial step that can greatly influence the final appearance of your woodwork. Here, we will delve into the importance of understanding the role of grit size and the proper grit progression for different wood types and stains.

Understanding The Role Of Grit Size

The grit size of sandpaper determines its coarseness or fineness. Lower grit numbers indicate coarser sandpaper, while higher numbers represent finer grits. When sanding between coats of stain, it’s essential to start with a coarser grit to remove any imperfections or raised grain from the previous coat and then progress to finer grits for a smooth and even surface.

Proper Grit Progression For Different Wood Types And Stains

For hardwoods, such as oak or maple, begin with a 120-150 grit sandpaper to remove any visible imperfections. Then, progressively move to 220-240 grit for a finer finish. Softwoods, like pine or cedar, may require starting with a slightly finer grit, such as 100-120, due to their more delicate nature, and then moving to 180-220 for a smooth surface.

When working with dark stains, it’s crucial to sand carefully between coats to avoid raising the wood grain and creating a rough, uneven finish. Using a higher grit sandpaper, usually 320-400, for the final sanding between coats of dark stain helps to produce a lustrous and flawless surface.

Techniques For Effective Sanding Between Stain Coats

When applying stain to wood, sanding in between coats is a crucial step to achieving a smooth and professional finish. Proper sanding technique is essential to ensure the next coat of stain adheres effectively and that the wood’s surface is fully prepared to receive it. In this article, we’ll explore some effective techniques for sanding between stain coats, focusing on proper sanding motion and pressure, as well as tips for avoiding over-sanding and achieving an even surface.

Proper Sanding Motion And Pressure

When sanding between coats of stain, it’s important to use the correct motion and pressure to achieve the best results. The proper sanding motion involves making smooth, overlapping strokes in the direction of the wood grain. This helps to evenly remove any raised grain or imperfections while maintaining the wood’s natural pattern. Additionally, using moderate pressure during sanding helps to avoid removing too much stain or damaging the wood surface.

Tips For Avoiding Over-sanding And Uneven Surfaces

Over-sanding can result in uneven surfaces and may compromise the adhesion of the next coat of stain. To avoid over-sanding, it’s important to use a fine-grit sandpaper (such as 220-grit) and to sand lightly, checking the surface frequently to ensure an even result. Using a sanding block or a sanding sponge can also help distribute pressure evenly, preventing over-sanding in concentrated areas. Additionally, wiping the surface with a tack cloth after sanding can help remove any residual dust, ensuring a smooth and clean surface for the next coat of stain.

Optimizing Stain Application After Sanding

After sanding between coats of stain, it’s crucial to ensure that subsequent applications are executed meticulously to achieve a flawless finish. Optimizing the stain application process by properly removing sanding residues and applying subsequent coats is essential for achieving the desired results.

Ensuring Proper Removal Of Sanding Residues

Proper removal of sanding residues is essential to prevent imperfections in the final finish. After sanding, ensure that all sanding dust and debris are effectively removed from the surface. Use a tack cloth to wipe down the surface, removing any remaining dust particles. This step is crucial for achieving a smooth and uniform base for the subsequent coat of stain.

Applying Subsequent Coats For A Flawless Finish

When applying subsequent coats of stain, it’s important to do so with precision and attention to detail. Ensure that each coat is applied evenly and consistently across the entire surface. Use a quality brush or applicator to achieve a smooth and uniform application. Allow each coat to dry completely before applying the next one, following the manufacturer’s recommended drying times.

Common Mistakes To Avoid

When staining wood, sanding in between coats is a crucial step that should not be overlooked. Proper sanding helps to achieve a smooth and flawless finish, ensuring that each coat of stain adheres and penetrates the wood surface effectively. However, there are some common mistakes that people often make when sanding in between coats of stain. Let’s take a look at these mistakes to avoid for a successful staining project.

Overlooking Sanding In Between Coats

One common mistake to avoid is overlooking the importance of sanding in between coats of stain. Some DIY enthusiasts may be tempted to skip this step, thinking it’s not necessary. However, each coat of stain can raise the wood grain, creating a rough surface. By sanding between coats, you can smooth out the raised grain and ensure that subsequent coats adhere properly, resulting in a professional-quality finish.

Applying Excessive Pressure While Sanding

Another mistake to avoid is applying excessive pressure while sanding in between coats. Sanding should be done with a light touch to avoid removing too much of the previous coat of stain or damaging the wood surface. Using gentle, even strokes and a fine-grit sandpaper will help to achieve the desired smoothness without causing any damage.

Frequently Asked Questions On Sanding In Between Coats Of Stain

What Is The Purpose Of Sanding Between Coats Of Stain?

Sanding between coats of stain smoothens the surface, removes imperfections, and allows the subsequent coat to adhere better. It also enhances the finish’s overall appearance, ensuring a professional and polished look.

How Long Should I Wait Before Sanding Between Coats Of Stain?

Wait for the previous coat of stain to dry completely before sanding, typically around 24 hours. This ensures the surface is fully cured, allowing for effective sanding and preventing any damage to the existing coat.

What Grit Sandpaper Should I Use For Sanding Between Coats Of Stain?

For sanding between coats of stain, start with a fine-grit sandpaper, such as 220-grit, to smooth the surface and remove any imperfections. Then, finish with an even finer grit, like 320-grit, for a silky-smooth finish.

Can I Apply More Than Two Coats Of Stain Without Sanding In Between?

While it’s possible to apply multiple coats of stain without sanding, it’s recommended to sand between coats to achieve a smoother finish and better adhesion for subsequent coats. Sanding between coats ensures a professional-looking and durable outcome.

Conclusion

In wrapping up, sanding between coats of stain ensures a smoother and more professional finish. By taking the time to sand down rough patches, you can achieve a beautifully even application of the stain. This process not only enhances the aesthetics but also prolongs the longevity of the wood surface.

Incorporating this technique into your staining projects will elevate the overall quality of your work.