Spline Jig Table Saw Secrets: Boost Your Woodwork!

A spline jig for a table saw is a tool that aids in creating precise grooves for spline joints. It enhances the accuracy and consistency of woodworking projects.

Creating strong and visually appealing joints is essential in woodworking. A spline jig table saw simplifies this process by allowing woodworkers to cut precise grooves, ensuring a perfect fit for spline joints. This tool is particularly useful for constructing picture frames, tabletops, and other projects that require robust connections.

Using a spline jig not only saves time but also improves the overall quality of your work. Understanding how to set up and use this jig effectively can elevate your woodworking skills. Whether you’re a hobbyist or a professional, incorporating a spline jig into your toolkit can lead to impressive results.

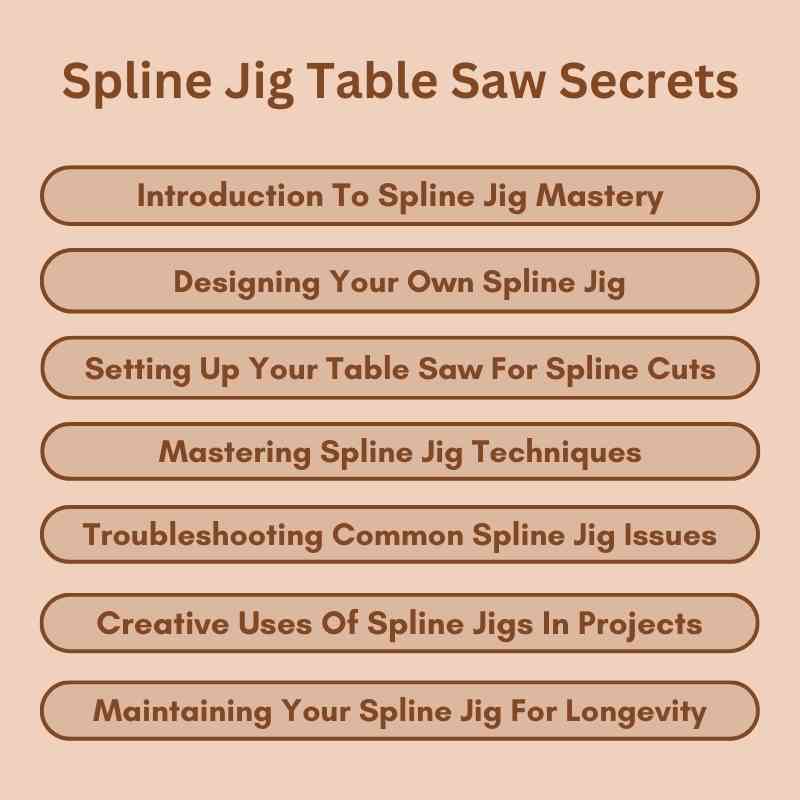

Introduction To Spline Jig Mastery

The spline jig is a game changer for woodworkers. It improves the quality of joints and enhances overall project precision. Mastering this tool can elevate your woodworking skills significantly.

The Role Of A Spline Jig

A spline jig is a tool used with a table saw. It helps create strong, tight joints. These joints are essential in various woodworking projects. Here are some key roles:

- Joint Alignment: Ensures pieces fit perfectly together.

- Strength: Provides added support for joints.

- Precision: Creates consistent, repeatable cuts.

Benefits For Woodworkers

Using a spline jig offers several advantages:

| Benefit | Description |

|---|---|

| Improved Accuracy | Achieve precise cuts every time. |

| Enhanced Joint Strength | Creates stronger connections between pieces. |

| Time Efficiency | Reduces time spent on corrections. |

| Versatility | Works with various wood types and projects. |

Mastering the spline jig leads to better craftsmanship. Woodworkers can tackle complex projects with ease. Enjoy the benefits of strong, beautiful joints.

Designing Your Own Spline Jig

Creating a spline jig for your table saw can enhance your woodworking projects. This simple tool improves joint strength and adds beauty to your designs. Building one is straightforward and requires minimal materials.

Materials You’ll Need

- Plywood: ¾ inch thick for durability.

- Wood screws: To hold pieces together.

- Wood glue: For added strength.

- Measuring tape: For accurate dimensions.

- Router: To create grooves.

- Table saw: For cutting pieces.

- Clamps: To secure the jig while assembling.

Step-by-step Construction Guide

- Measure and Cut: Cut the plywood into two rectangles, 12×24 inches.

- Mark Grooves: Measure and mark where the spline grooves will go.

- Router Setup: Use the router to create grooves along the marked lines.

- Assemble the Base: Attach the two plywood pieces at a right angle.

- Secure with Screws: Use screws to hold the base firmly in place.

- Apply Glue: Add wood glue to reinforce the joints.

- Clamp and Dry: Use clamps to hold everything together while it dries.

Building your own spline jig is fun and rewarding. It empowers you to create stronger joints in your woodworking projects. Enjoy the process and get creative!

Setting Up Your Table Saw For Spline Cuts

Creating perfect spline joints requires precise setup. Follow these steps to prepare your table saw. A well-prepared saw ensures accuracy and safety.

Safety First: Preparing Your Work Area

Safety is the top priority. A clutter-free workspace helps prevent accidents. Here are essential safety tips:

- Clear the area of tools and debris.

- Wear safety goggles and hearing protection.

- Use a push stick for small pieces.

- Ensure proper lighting in your workspace.

- Check that the saw blade is sharp and clean.

Set up the table saw on a stable surface. Make sure it is level and secure. This helps in getting straight cuts.

Adjusting The Table Saw For Precision

Precision is key for spline cuts. Follow these steps to adjust your table saw:

- Set the Blade Angle: Adjust the blade to the desired angle.

- Height Adjustment: Set the blade height for the material thickness.

- Align the Fence: Ensure the fence is parallel to the blade.

- Check the Miter Gauge: Adjust it for correct spline width.

Use a measuring tape for accuracy. Measure your material before cutting. This prevents mistakes.

| Adjustment | Action | Tools Needed |

|---|---|---|

| Blade Angle | Adjust to desired angle | Wrench |

| Blade Height | Set to material thickness | Ruler |

| Fence Alignment | Align with the blade | Square tool |

| Miter Gauge | Adjust for spline width | Measuring tape |

Double-check all adjustments. Confirm they match your project requirements. This ensures smooth and accurate cuts.

Mastering Spline Jig Techniques

Mastering spline jig techniques enhances your woodworking skills. This method creates strong joints. It is perfect for picture frames and furniture. Follow these tips to improve your projects.

Basic Cuts: A Starter Guide

Getting started with spline jigs is easy. Here are some basic steps:

- Set your table saw to the right angle.

- Choose your wood pieces. Use a straight edge for cuts.

- Measure the width of your joint. Mark the cut line clearly.

- Adjust the jig to match your mark.

- Make the cut. Keep your hands safe and steady.

These basic cuts help form the spline groove. Use a test piece first to practice.

Advanced Tips For Perfect Splines

Once you master the basics, try these advanced tips:

- Use a zero-clearance insert: It reduces tear-out.

- Adjust the blade height: Match it to your wood thickness.

- Mark your splines: Always mark where to cut.

- Run multiple passes: It ensures cleaner cuts.

- Sand the edges: Smooth edges improve glue adhesion.

Practice these advanced techniques. They lead to stronger and cleaner joints. A well-fitted spline enhances your woodworking projects.

Troubleshooting Common Spline Jig Issues

Using a spline jig on your table saw can enhance your woodworking projects. However, problems may arise. Identifying these issues quickly helps improve your workflow. This section covers common spline jig issues and their solutions.

Aligning The Jig Accurately

Accurate alignment is crucial for successful spline cutting. Misalignment can lead to poor fits and uneven cuts. Follow these steps for proper alignment:

- Ensure the table saw is level.

- Check the jig against the blade. Use a square for accuracy.

- Adjust the jig as needed to ensure it is parallel to the blade.

Use a caliper to measure the distance from the blade to the jig. This ensures the distance is the same on both ends. Make small adjustments until perfect alignment is achieved.

Dealing With Wood Tear-out

Wood tear-out can ruin your project. It often happens during spline cutting. Here are tips to minimize tear-out:

- Use a sharp blade for clean cuts.

- Cut with the wood grain, not against it.

- Apply painter’s tape along the cut line.

- Make a scoring cut before the final cut.

Consider the following table for blade types:

| Blade Type | Purpose |

|---|---|

| Fine-Toothed Blade | Best for smooth cuts |

| Combination Blade | Versatile for various cuts |

| Ripping Blade | Great for making quick cuts |

Using these methods can help you achieve cleaner cuts. This reduces the risk of tear-out and enhances the quality of your work.

Creative Uses Of Spline Jigs In Projects

Spline jigs are fantastic tools. They add precision and style to woodworking projects. Let’s explore two creative uses of spline jigs.

Adding Aesthetic Appeal

Using spline jigs can transform the look of your projects. They allow for intricate designs that catch the eye. Here are some ways to enhance aesthetics:

- Decorative Panels: Use splines to create stunning wall panels.

- Picture Frames: Make unique frames with splines for added charm.

- Furniture Accents: Add splines to tabletops for an elegant touch.

These applications not only look great but also showcase your skills. Spline joints can be stained or painted, allowing for personalization.

Enhancing Joint Strength

Spline joints improve the strength of your wood connections. They provide more surface area for glue, ensuring a solid bond. This is crucial for high-stress areas. Here are key benefits:

| Benefit | Description |

|---|---|

| Durability | Spline joints resist separating over time. |

| Alignment | They help keep pieces aligned during assembly. |

| Versatility | Useful for various projects, from cabinets to frames. |

Using spline jigs leads to strong, reliable joints. This strength is vital for the longevity of your projects.

Maintaining Your Spline Jig For Longevity

Keeping your spline jig in top shape is essential. Regular care ensures it works effectively. Maintenance helps prevent wear and tear. Follow these tips for a longer lifespan.

Routine Cleaning Tips

Regular cleaning keeps your spline jig in excellent condition. Dust and debris can affect performance. Follow these cleaning tips:

- Daily Wipe: Use a soft cloth to remove dust.

- Deep Clean: Every month, use a brush to clear small parts.

- Check for Rust: Inspect metal parts and clean with oil.

- Use Compressed Air: Blow out hard-to-reach areas.

Routine cleaning enhances the jig’s accuracy and longevity. Keep it tidy for best results.

Storage Solutions To Prevent Damage

Proper storage is key to protecting your spline jig. Avoid damage from moisture or dust. Here are effective storage solutions:

| Storage Method | Benefits |

|---|---|

| Tool Box | Protects from dust and accidental damage. |

| Wall Mount | Keeps it visible and accessible. |

| Climate-Controlled Area | Prevents rust and warping. |

Choose a storage method that suits your space. Proper storage maintains functionality.

Learning From The Experts: Spline Jig Case Studies

Understanding the use of a spline jig can elevate your woodworking skills. Expert woodworkers share their insights through real-life case studies. These examples show effective techniques and innovative ideas. Let’s explore their secrets and creative methods.

Professional Woodworkers’ Secrets

Expert woodworkers use spline jigs to achieve precision and strength. Here are some techniques they recommend:

- Proper Setup: Ensure the jig aligns perfectly with the table saw.

- Blade Selection: Use a high-quality blade for clean cuts.

- Material Choice: Select durable woods for better spline joints.

Experts emphasize practice. Mastering these techniques takes time. They suggest starting with simple projects.

Innovative Techniques To Try

Many woodworkers experiment with new methods. Here are some innovative techniques to consider:

- Adjustable Spline Jigs: Create custom jigs for different projects.

- Using Templates: Make templates for consistent cuts across multiple pieces.

- Combining Materials: Use splines with different wood types for unique designs.

These techniques can enhance your woodworking projects. They add creativity and efficiency. Experimenting with these ideas leads to better results.

| Technique | Benefit |

|---|---|

| Adjustable Spline Jigs | Custom fit for various projects |

| Using Templates | Consistent and accurate cuts |

| Combining Materials | Unique and artistic designs |

Learning from professionals can improve your skills. Use these insights to take your woodworking to the next level.

Conclusion: Elevating Your Craft

Using a spline jig table saw transforms woodworking projects. It allows for precise cuts and enhances your creativity. This tool opens up new possibilities for your craft.

Embracing New Jig Techniques

Experimenting with new jig techniques can elevate your skills. Here are some popular techniques to explore:

- Crosscut Jigs: Perfect for making accurate crosscuts.

- Box Joint Jigs: Create strong joints easily.

- Router Jigs: Ideal for decorative edges.

Using these jigs can improve your project outcomes. Each technique brings unique advantages to your work.

Continued Learning And Practice

Growth in woodworking requires continuous learning. Here are ways to enhance your skills:

- Attend workshops to learn from experts.

- Watch online tutorials for hands-on guidance.

- Join local woodworking clubs for community support.

Practice consistently to develop your techniques. Every project offers a chance to learn. Keep challenging yourself to master new skills.

With dedication, your craft will reach new heights.

Frequently Asked Questions

What Is A Spline Jig For A Table Saw?

A spline jig is a tool used with a table saw to create precise spline joints. These joints enhance the strength and appearance of woodworking projects. By accurately cutting grooves for splines, you can achieve seamless connections in your workpieces.

It’s essential for fine woodworking and cabinetry.

How Do You Use A Spline Jig?

To use a spline jig, first set it up on your table saw. Align your workpiece with the jig, ensuring it’s secure. Adjust the blade height for the desired spline thickness. Finally, make the cuts slowly and steadily for accuracy.

This process results in clean, professional joints.

What Materials Can I Use With A Spline Jig?

You can use various materials with a spline jig, including hardwoods, softwoods, and plywood. Popular choices include oak, maple, and birch. The material you choose depends on your project’s requirements and aesthetics. Always ensure the material is suitable for the intended joint strength.

Why Is A Spline Joint Useful?

A spline joint is beneficial because it provides additional strength and stability to the connection. It also enhances the aesthetic appeal of your woodworking projects. By using splines, you can create wider joints and improve alignment. This technique is popular in furniture making and cabinetry.

Conclusion

A spline jig table saw is an essential tool for any woodworker. It enhances precision and efficiency in creating strong joints. Investing in this equipment can elevate your projects. Embrace the benefits of a spline jig to achieve clean, professional results.

Your woodworking endeavors will greatly improve with this valuable addition.