Table Saw Vs Cabinet Saw: Your Ultimate Essential Guide

A cabinet saw is a high-end, stationary table saw featuring a powerful enclosed motor (3-5 HP), heavy-duty internal parts, and massive cast iron construction for ultimate accuracy and stability. Other table saws, like contractor or hybrid models, are less powerful, lighter, and have motors that are either external or less robust, making them better suited for hobbyists.

Hello, fellow makers! I’m Md Meraj, and I’m so glad you’re here. Stepping into the world of woodworking is exciting, but choosing your first major tool can feel overwhelming. You see terms like “table saw” and “cabinet saw,” and it’s easy to get confused. Are they the same thing? Which one is right for your garage workshop?

Don’t worry—this is a common hurdle for every new woodworker. The good news is that understanding the difference is much simpler than you think. In this guide, I’ll walk you through everything, step-by-step. We’ll break down the features, compare the pros and cons, and help you choose the perfect saw with confidence. Let’s build something great together!

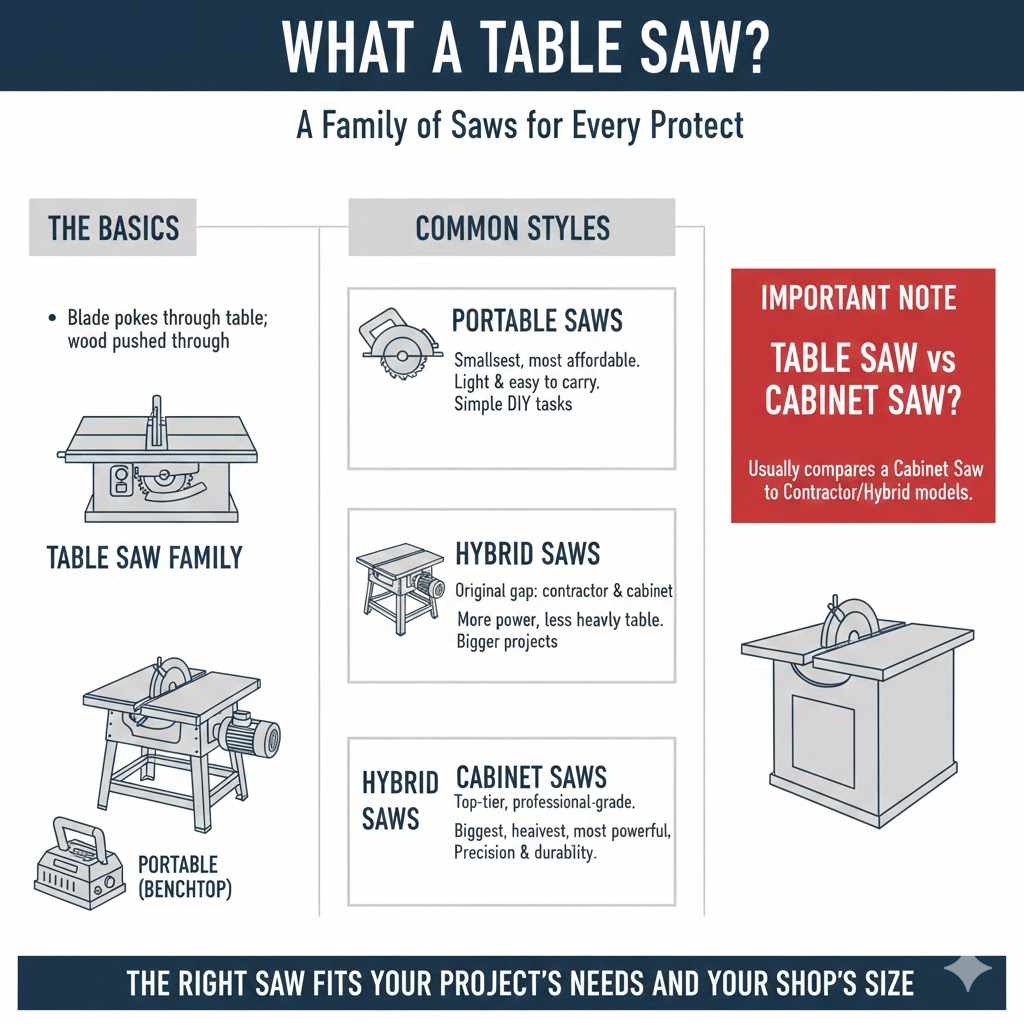

What is a Table Saw? The Big Picture

First, let’s clear up the biggest point of confusion. Think of “table saw” as a general family name, like “car.” Under that name, you have different types, like sedans, SUVs, and trucks. They all do the same basic job—drive—but they are built differently for specific needs.

Similarly, a table saw is any saw with a circular blade that pokes up through a flat table. You push the wood across the table and into the blade to make a cut. All the saws we’ll discuss are table saws, but they come in several common styles:

- Portable Saws (Benchtop & Jobsite): These are the smallest and most affordable. They’re designed to be light and easy to carry to a worksite. They are great for simple DIY tasks but lack the power and precision for fine furniture making.

- Contractor Saws: The original “home workshop” saw. These are larger than portable saws, with an open base and a motor that hangs off the back. They offer more power and a larger table for bigger projects.

- Hybrid Saws: A newer category that bridges the gap between contractor and cabinet saws. They often have an enclosed base like a cabinet saw but with internal parts that are a bit less heavy-duty.

- Cabinet Saws: This is the top-tier, professional-grade table saw. It’s the biggest, heaviest, and most powerful of them all.

When people say “table saw vs cabinet saw,” they are usually comparing a cabinet saw to the more common contractor or hybrid models. So, for the rest of this guide, that’s exactly what we’ll do.

A Closer Look: The Mighty Cabinet Saw

A cabinet saw gets its name from its most obvious feature: a fully enclosed base, or “cabinet.” This heavy-duty steel cabinet houses the motor and all the internal mechanics, which is a huge part of what makes it so special. It’s the kind of tool you find in professional cabinet shops and the workshops of serious hobbyists who demand the best.

Key Features of a Cabinet Saw

Let’s break down what sets a cabinet saw apart.

- Powerful Induction Motor: Cabinet saws are equipped with massive induction motors, typically ranging from 3 to 5 horsepower (HP) or even more. This motor is housed completely inside the cabinet. This immense power allows you to slice through thick, dense hardwoods like oak, maple, and walnut with ease, leaving a perfectly smooth finish.

- Heavy-Duty Construction: Weight is a good thing in a table saw! Cabinet saws are made with enormous amounts of cast iron for the tabletop, wings, and internal parts (called trunnions). This heavy build absorbs vibration, leading to cleaner cuts and a much safer operating experience. A typical cabinet saw can weigh between 500 and 800 pounds!

- Cabinet-Mounted Trunnions: The trunnions are the assembly that holds and tilts the saw blade. In a cabinet saw, this entire assembly is mounted directly to the massive cabinet frame. This design makes it incredibly stable and easy to keep the blade perfectly aligned with the miter slot and fence, which is the key to accurate cuts.

- Superior Dust Collection: The enclosed cabinet acts like a giant funnel. It directs nearly all the sawdust to a single, large 4-inch dust port at the bottom. When connected to a dust collector, it keeps your workshop air much cleaner and healthier.

- Premium Fence System: The fence is the guide you press your wood against for rip cuts. Cabinet saws come with high-end, precise, and heavy-duty fence systems that lock down rigidly and stay perfectly parallel to the blade.

Pros and Cons of a Cabinet Saw

Pros:

- ✅ Unmatched Power: Cuts through the toughest woods without slowing down.

- ✅ Incredible Accuracy: Heavy build and superior alignment mean perfect cuts every time.

- ✅ Extremely Stable: Minimal vibration makes it safer and more pleasant to use.

- ✅ Excellent Dust Collection: Keeps your shop clean and your lungs healthy.

- ✅ Built to Last a Lifetime: These are heirloom-quality tools made from the best materials.

Cons:

- ❌ Very Expensive: They represent a significant financial investment.

- ❌ Extremely Heavy: Once it’s in your shop, you won’t be moving it.

- ❌ Requires 240-Volt Power: Most models cannot run on a standard 120-volt home outlet, often requiring a dedicated circuit installed by an electrician.

- ❌ Large Footprint: It takes up a lot of floor space in a workshop.

The Contenders: Contractor and Hybrid Saws

Now let’s look at the saws that are most often compared to cabinet saws. These are fantastic tools in their own right and are the perfect choice for a huge number of woodworkers.

What is a Contractor Saw?

The contractor saw was designed to be powerful enough for serious work but portable enough to be taken to a job site (though at 200-300 pounds, “portable” is a relative term!). Its key feature is an open base on four legs, with the motor hanging off the back. This motor drives the blade with a belt.

- Power: They typically have 1.5 to 2 HP motors, which is plenty for most hobbyist projects, including cutting hardwoods up to about 2 inches thick.

- Construction: They still use a good amount of cast iron for the tabletop but are much lighter overall than a cabinet saw.

- Trunnions: The trunnions on a contractor saw are mounted to the underside of the table, not the base. This can make them slightly more difficult to keep in perfect alignment over time.

- Dust Collection: Because the base is open, dust collection is a major challenge. Sawdust tends to fall onto the floor underneath the saw.

What is a Hybrid Saw?

A hybrid saw is the modern middle ground. It takes some of the best features from both cabinet and contractor saws. It looks like a cabinet saw because it has an enclosed base, which greatly improves dust collection. However, its internal parts and motor are generally lighter-duty than a true cabinet saw.

- Power: Most hybrid saws fall in the 1.75 to 2 HP range and typically run on standard 120-volt power, making them perfect for home workshops.

- Construction: They offer more weight and stability than a contractor saw but less than a massive cabinet saw.

- Trunnions: This is a key difference. Some hybrid saws have cabinet-mounted trunnions (better), while others have table-mounted trunnions like a contractor saw.

- Dust Collection: The enclosed base gives them far better dust collection than a contractor saw, though usually with a smaller dust port.

Head-to-Head: Cabinet Saw vs. Contractor/Hybrid Saw

Seeing the features side-by-side makes the choice much clearer. Let’s compare them directly on the points that matter most to a woodworker.

| Feature | Cabinet Saw | Contractor / Hybrid Saw |

|---|---|---|

| Motor Power | 3 HP – 5+ HP (240V required) | 1.5 HP – 2 HP (120V standard) |

| Construction & Weight | Extremely heavy (500-800+ lbs), mostly cast iron and thick steel. | Lighter (200-400 lbs), combination of cast iron and steel. |

| Accuracy & Stability | Exceptional. Cabinet-mounted trunnions and massive weight virtually eliminate vibration. | Very good. Table-mounted trunnions may require more frequent alignment. More vibration. |

| Dust Collection | Excellent. Enclosed base funnels dust to a 4″ port. | Poor (Contractor) to Good (Hybrid). Open base on contractor saws is messy. |

| Footprint | Very large and permanently stationary. | Smaller footprint, often available with mobile bases. |

| Price | $3,000 – $10,000+ | $800 – $2,500 |

| Ideal User | Professional woodworkers, dedicated hobbyists with a large shop. | Serious hobbyists, DIYers, and woodworkers with limited space or budget. |

Power and Performance: Why Horsepower Matters

The difference between a 1.75 HP motor and a 3 HP motor is night and day when you’re cutting tough material. A lower-powered saw might bog down or burn the wood when cutting a thick piece of hard maple. A cabinet saw, with its 3+ HP motor, won’t even notice. This power means you can use a full-kerf blade for maximum stability, make faster cuts, and get a cleaner finish on the wood with fewer saw marks.

Accuracy and Stability: The Foundation of Good Woodworking

Accuracy is everything. The massive weight of a cabinet saw is its superpower. When a tool doesn’t vibrate or shift, your cuts are more precise. According to the U.S. Occupational Safety and Health Administration (OSHA), stable and well-maintained machinery is crucial for safe operation. The cabinet-mounted trunnions are a huge part of this. Because they are bolted to the heavy frame, the blade’s alignment to the fence is incredibly stable and rarely needs adjustment. On contractor and some hybrid saws, the lighter table-mounted trunnions can shift slightly over time, requiring you to check and adjust them more often to ensure perfect 90-degree cuts.

Safety: Modern Features for Peace of Mind

While all table saws demand respect and safe practices, modern cabinet and high-end hybrid saws often come with advanced safety features. This can include flesh-sensing technology that stops the blade in milliseconds upon contact with skin, as well as high-quality riving knives and blade guards that are easy to use. While these features are becoming more common on all types of saws, they are standard on premium models.

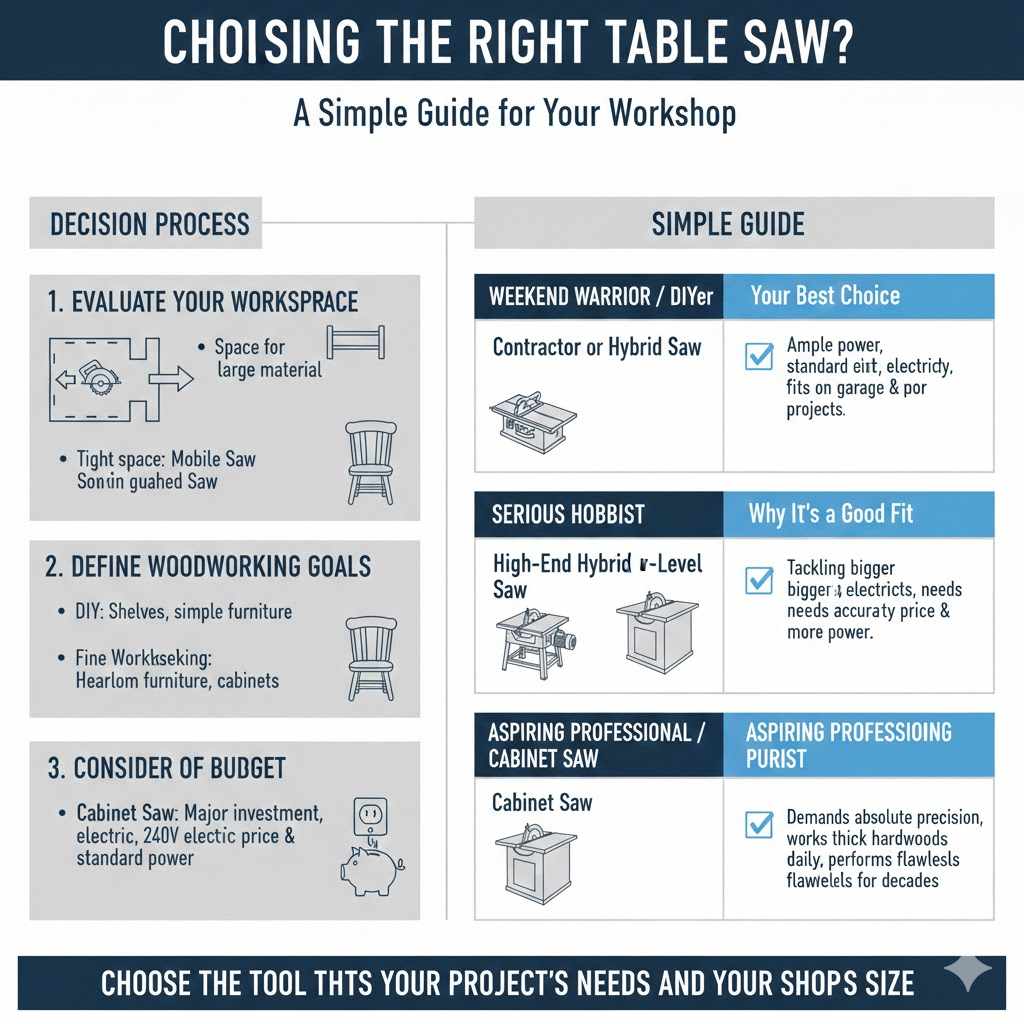

How to Choose the Right Saw for Your Workshop

So, which saw is right for you? There’s no single right answer—only what’s right for your situation. Let’s walk through the decision process.

1. Evaluate Your Workspace

This is the most important first step. Do you have a large, dedicated workshop, or are you working out of a one-car garage? A cabinet saw requires a permanent, spacious home. You need room not only for the saw itself but also clearance in front and behind it to handle large sheets of plywood. If space is tight or you need to be able to move your tools around, a hybrid saw on a mobile base is a far more practical choice.

2. Define Your Woodworking Goals

Be honest about the kind of projects you want to build.

- For weekend DIY projects, like building shelves, simple furniture from pine, or cutting plywood for home repairs, a contractor or hybrid saw is more than enough power and precision.

- For serious fine woodworking, like crafting heirloom furniture from thick hardwoods, building large cabinets, or wanting a glass-smooth finish right off the saw, the power and accuracy of a cabinet saw will save you time and frustration.

3. Consider Your Budget

A cabinet saw is a major investment. It’s not just the cost of the saw itself; you may also need to budget for a 240V electrical installation and a powerful dust collection system to take full advantage of it. A hybrid saw offers a huge amount of capability for a fraction of the cost and runs on standard power. Remember, a great hybrid saw is better than a cheap cabinet saw.

Which Saw is Best for You? A Simple Guide

| If You Are a… | Your Best Choice Is Likely a… | Why It’s a Good Fit |

|---|---|---|

| Weekend Warrior / DIYer | Contractor or Hybrid Saw | Provides ample power for most projects, runs on standard electricity, and fits well in a home garage. It’s the perfect balance of price and performance. |

| Serious Hobbyist | High-End Hybrid or Entry-Level Cabinet Saw | You’re building furniture and tackling bigger projects. You need excellent accuracy and more power. A top-tier hybrid saw offers many cabinet saw features without the huge cost or power needs. |

| Aspiring Professional / Woodworking Purist | Cabinet Saw | Woodworking is your passion or your business. You demand absolute precision, work with thick hardwoods daily, and need a tool that will perform flawlessly for decades. The investment is justified by the performance. |

Frequently Asked Questions (FAQ)

What is the main difference between a cabinet saw and a contractor saw?

The three biggest differences are the base, the motor, and the trunnions. A cabinet saw has a fully enclosed base for great dust collection, a powerful (3+ HP) motor inside, and heavy trunnions mounted to the cabinet for stability. A contractor saw has an open base, a less powerful (1-2 HP) motor hanging off the back, and lighter trunnions mounted to the table.

Can a beginner use a cabinet saw?

Absolutely! A cabinet saw is not more difficult to operate than any other table saw. In fact, its stability and smooth operation can make it feel safer and easier to use. The main barriers for a beginner are the high cost and the large space and power requirements, not the learning curve.

Is a hybrid saw a good compromise?

Yes, for most serious hobbyists, a hybrid saw is the perfect compromise. It gives you the enclosed cabinet and improved dust collection of a cabinet saw, plus enough power for most projects, all while running on a standard 120V outlet and costing significantly less.

How much power do I really need in a table saw?

For cutting plywood, pine, and hardwoods up to 2 inches thick, a 1.5 to 2 HP motor is sufficient. If you plan to regularly cut thick, dense hardwoods (like 3-inch maple or oak) or use heavy dado blades, you will appreciate the extra power of a 3 HP or larger motor.

Are cabinet saws safer?

In some ways, yes. Their massive weight makes them far more stable, which reduces the chance of the machine moving during a cut. They are also more likely to come with premium safety systems. However, any table saw is a dangerous tool. Safe operation, including using a riving knife, blade guard, and push sticks, is what truly creates a safe environment, regardless of the saw type.

Why is dust collection so important with a table saw?

Fine wood dust is harmful to your respiratory system. A table saw produces a huge amount of it. Good dust collection keeps the dust out of the air you breathe, improving your long-term health. It also keeps your shop cleaner, reduces fire risk, and can even help the saw perform better by clearing debris from the blade.

Conclusion: Making the Cut With Confidence

Choosing between a cabinet saw and another type of table saw ultimately comes down to a simple question: What kind of woodworker are you, and what kind do you want to become? There is no “best” saw, only the best saw for you, your workshop, and your projects.

Don’t feel pressured to buy the biggest and most expensive tool. A modern hybrid saw provides more than enough power and accuracy to build beautiful, high-quality furniture that will last a lifetime. But if you have the space, the budget, and the ambition to make woodworking a central part of your life, a cabinet saw is an investment that will pay you back with flawless performance for decades to come.

No matter which path you choose, the most important step is the first one. Get the tool that fits your needs now, learn to use it safely, and start building. Your skills and confidence will grow with every project, and that’s what this wonderful craft is all about. Happy cutting!