Urethane Varnish Vs. Polyurethane Varnish: Ultimate Guide

Urethane varnish and polyurethane varnish are the same thing, although different vendors may use one term exclusively or interchangeably with the other. Polyurethane varnish is a super-tough coating used as a finishing layer for protecting interior and exterior wooden floors, stairs, and other surfaces prone to wear and tear.

It is more durable and flexible than urethane due to its multiple layers. However, polyurethane varnish has some disadvantages, including poor thermal capability, weatherability, and flammability. We will explore the differences between urethane and polyurethane varnish, their uses, advantages, and disadvantages, as well as tips for choosing the right one for your project.

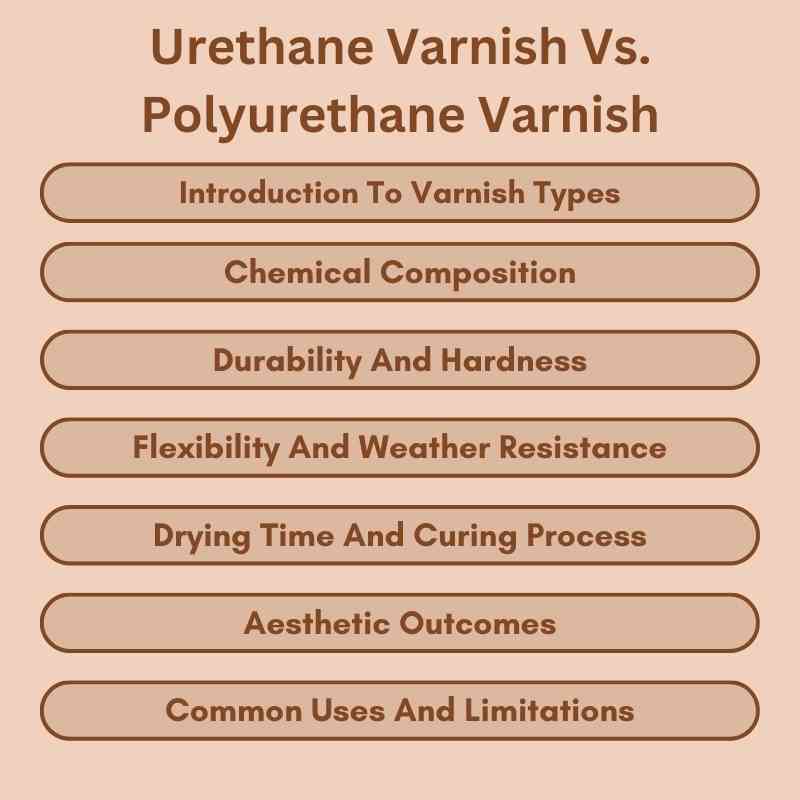

Introduction To Varnish Types

When it comes to protecting and enhancing the beauty of wood surfaces, varnish is a popular choice. However, not all varnishes are created equal. Two common types of varnish that you may come across are urethane varnish and polyurethane varnish. While these names may sound similar, there are some key differences between them that are worth exploring.

Basics Of Urethane Varnish

Urethane varnish, also known as alkyd varnish, is a type of varnish that is based on urethane resin. This type of varnish is commonly used for interior wood surfaces such as furniture, doors, and cabinets. Urethane varnish offers excellent durability and protection against scratches, stains, and moisture. It dries to a hard finish and provides a beautiful, glossy appearance to the wood.

One of the advantages of urethane varnish is its quick drying time, allowing for faster completion of projects. It also has good resistance to heat and chemicals, making it suitable for areas that may be exposed to such elements.

Basics Of Polyurethane Varnish

Polyurethane varnish, on the other hand, is a type of varnish that is based on polyurethane resin. This type of varnish is commonly used for both interior and exterior wood surfaces. Polyurethane varnish provides excellent protection against UV rays, moisture, and wear and tear. It forms a tough, durable coating that can withstand heavy use and exposure to various elements.

One of the advantages of polyurethane varnish is its flexibility. It is able to expand and contract with the natural movement of the wood, preventing cracking or peeling. This makes it a great choice for surfaces that are subject to temperature and humidity changes.

Additionally, polyurethane varnish is available in different finishes, including gloss, semi-gloss, and satin, allowing you to choose the desired level of sheen for your project.

In conclusion, while both urethane varnish and polyurethane varnish offer excellent protection and durability for wood surfaces, there are some differences to consider. Urethane varnish is commonly used for interior applications and offers quick drying time, while polyurethane varnish is suitable for both interior and exterior surfaces and provides flexibility and resistance to various elements. Ultimately, the choice between the two types of varnish depends on the specific needs of your project.

Chemical Composition

Urethane varnish and polyurethane varnish are essentially the same thing, with different vendors using the terms interchangeably. Both coatings offer durability and flexibility, making them ideal for creating long-lasting products. However, polyurethane varnish is often preferred due to its multiple layers of urethane, which provide added strength.

Urethane varnish and polyurethane varnish are often used interchangeably, but they have subtle differences in their chemical composition that set them apart. Understanding the chemical composition of these varnishes is crucial in determining their performance and suitability for different applications.

Understanding Polymers

Polymers are large molecules composed of repeating subunits called monomers. In the case of urethane and polyurethane varnishes, these polymers play a vital role in determining the properties and performance of the final product. Urethane varnish typically contains a single type of polymer, while polyurethane varnish consists of multiple polymers, resulting in enhanced durability and flexibility.

Urethane And Polyurethane Bonding

Urethane varnish is formed through the polymerization of a specific type of monomer, resulting in a rigid and less flexible structure. On the other hand, polyurethane varnish is created by combining different types of monomers, leading to a more complex polymer structure with superior bonding capabilities and resilience. This bonding difference gives polyurethane varnish an edge in terms of durability and versatility compared to urethane varnish.

Durability And Hardness

Polyurethane varnish is harder and more durable than urethane varnish due to its multiple layers. While vendors may use the terms interchangeably, polyurethane is a better choice for creating long-lasting products. However, it has some disadvantages such as poor thermal capability, weatherability, and being attacked by most solvents.

When considering the durability and hardness of urethane varnish versus polyurethane varnish, it’s essential to understand how these two coatings compare in terms of toughness and impact on layers. Let’s delve into the key factors that determine the durability and hardness of these varnishes.

Comparing Toughness

Both urethane varnish and polyurethane varnish are known for their durability and hardness, but polyurethane varnish typically offers greater toughness due to its composition. The multiple layers of urethane in polyurethane varnish make it remarkably resilient and long-lasting, ideal for various applications requiring robust protection against wear and tear.

Impact Of Layers On Strength

The number of layers significantly influences the strength and durability of both urethane varnish and polyurethane varnish. Polyurethane varnish, with its multiple layers, provides enhanced resistance to impact, making it suitable for surfaces prone to heavy use and abrasion. On the other hand, urethane varnish, until its polymerization occurs, lacks the strength and usefulness offered by the layered composition of polyurethane varnish.

In conclusion, when it comes to durability and hardness, polyurethane varnish surpasses urethane varnish in terms of toughness and impact resistance, making it the preferred choice for applications requiring long-lasting and resilient protection.

Flexibility And Weather Resistance

When comparing urethane varnish and polyurethane varnish, one important aspect to consider is their flexibility and weather resistance. These properties determine how well the varnish can withstand temperature changes and external conditions.

Adaptability To Temperature Changes

Urethane varnish and polyurethane varnish both exhibit varying degrees of adaptability to temperature changes. However, polyurethane varnish tends to be more flexible, making it better suited for applications where temperature fluctuations are common. This flexibility allows the varnish to expand and contract with the wood, reducing the risk of cracking or peeling.

Resistance To External Conditions

When it comes to resistance to external conditions, polyurethane varnish has the upper hand. It offers superior protection against moisture, UV rays, and general wear and tear compared to urethane varnish. This makes it an ideal choice for outdoor furniture, decks, and other wood surfaces exposed to harsh weather conditions.

Application Techniques

Urethane varnish and polyurethane varnish are often used interchangeably, as they are essentially the same thing. However, polyurethane varnish is typically more durable and flexible due to its multiple layers, making it a better choice for long-lasting products. On the other hand, polyurethane varnish has some disadvantages, including poor thermal capability, weatherability, and flammability.

Tools And Methods

When it comes to applying urethane varnish and polyurethane varnish, the tools and methods used are generally the same. Both types of varnish can be applied using a brush, roller, or spray gun, depending on the project and the desired finish.

Brushes are the most common tool used for applying varnish, as they allow for precise control and can be easily cleaned. When using a brush, it is important to use a high-quality brush with natural bristles, as synthetic bristles may not hold up well with oil-based varnishes.

Rollers and spray guns can also be used for applying varnish, but they require a bit more skill and experience to achieve a smooth, even finish. Rollers are best for larger, flat surfaces, while spray guns are ideal for intricate or hard-to-reach areas.

Preparing Surfaces For Varnishing

Before applying any varnish, it is important to properly prepare the surface to ensure a smooth, even finish. This involves cleaning the surface of any dirt or debris, sanding it down to remove any rough spots, and filling in any gaps or imperfections with wood filler.

Once the surface is clean and smooth, it should be wiped down with a tack cloth to remove any dust or debris. This will ensure that the varnish adheres properly and provides a durable, long-lasting finish.

In conclusion, when it comes to applying urethane varnish and polyurethane varnish, the tools and methods used are generally the same. Both types of varnish require proper surface preparation and can be applied using a brush, roller, or spray gun. By following these simple guidelines, you can achieve a beautiful, durable finish that will protect your wood surfaces for years to come.

Drying Time And Curing Process

When it comes to the drying time and curing process, there is no significant difference between urethane varnish and polyurethane varnish. Both types of varnish require a similar amount of time to dry and fully cure. It is important to follow the manufacturer’s instructions for optimal results.

Time Management For Projects

When it comes to choosing a varnish for your project, drying time and curing process can be important factors to consider. Urethane varnish and polyurethane varnish have different drying times and curing processes, which can impact your project’s timeline.

Environmental Factors Affecting Drying

It is important to note that environmental factors can affect the drying time of both urethane and polyurethane varnishes. Factors such as temperature, humidity, and airflow can all impact how quickly the varnish dries. In general, a warmer and less humid environment with good airflow will result in faster drying times. However, it is important to follow the manufacturer’s guidelines for recommended environmental conditions for optimal drying time and curing process.

Time Comparison Table

To help you make an informed decision about which varnish to use for your project, here is a comparison table for drying time and curing process for urethane and polyurethane varnishes:

| Varnish Type | Drying Time | Curing Process |

|---|---|---|

| Urethane Varnish | 24-48 hours | Full cure in 7-10 days |

| Polyurethane Varnish | 6-12 hours | Full cure in 30 days |

As you can see, polyurethane varnish has a faster drying time compared to urethane varnish. However, it takes longer to fully cure. This may be a factor to consider if you need your project to be completed quickly but also require a fully cured finish.

In addition to drying time and curing process, it is important to consider other factors such as durability, toxicity, and environmental impact when choosing a varnish for your project. By taking all of these factors into consideration, you can make an informed decision and achieve the best possible outcome for your project.

Aesthetic Outcomes

Aesthetic outcomes are a crucial aspect to consider when choosing between urethane varnish and polyurethane varnish for your woodworking projects. The finish type and sheen you select can significantly impact the final appearance of your wooden surfaces, so it’s important to understand the differences and effects of each.

Finish Types And Their Effect

Urethane varnish and polyurethane varnish offer different finish types, each with its own unique effects on the appearance of the wood. Urethane varnish typically provides a slightly warmer, amber tone to the wood, enhancing its natural color and depth. On the other hand, polyurethane varnish tends to create a clearer, more transparent finish, preserving the wood’s original color with minimal alteration.

Choosing The Right Sheen

When it comes to selecting the right sheen for your wooden surfaces, both urethane and polyurethane varnishes offer options that can impact the overall aesthetic. Matte sheens can provide a subtle, understated look, while satin finishes offer a gentle glow without being too glossy. Semi-gloss sheens provide a balanced shine, while gloss finishes offer a high level of shine and reflectivity, adding depth and richness to the wood’s appearance.

Common Uses And Limitations

When it comes to choosing between urethane varnish and polyurethane varnish, it’s essential to understand their common uses and limitations. Each type of varnish has its ideal use cases as well as recognized limitations.

Ideal Use Cases For Each Type

Urethane varnish is ideal for surfaces that are prone to heavy wear and tear, such as wooden floors, stairs, and outdoor furniture. Its high durability and resistance to abrasion make it suitable for protecting these surfaces from pedestrian traffic and harsh environmental conditions. On the other hand, polyurethane varnish is commonly used for interior wooden surfaces, providing a tough and protective finish that enhances the natural beauty of the wood.

Recognizing Varnish Limitations

It’s important to recognize the limitations of urethane varnish, including its poor thermal capability and weatherability. Additionally, urethane varnish is susceptible to damage from solvents and may contain toxic isocyanates, making proper ventilation and safety precautions crucial during application. Polyurethane varnish, while offering excellent protection, is flammable and may pose risks during application and storage. Moreover, both varnishes can be affected by the natural expansion and contraction of wood due to changes in humidity and temperature.

Cost And Market Availability

When it comes to choosing the right varnish for your project, considering the cost and market availability is crucial. In this section, we will compare the prices and availability of urethane varnish and polyurethane varnish, helping you find the best option for your budget.

Price Comparison

Let’s take a look at the cost comparison between urethane varnish and polyurethane varnish:

| Varnish Type | Price Range |

|---|---|

| Urethane Varnish | $$ – $$$ |

| Polyurethane Varnish | $$ – $$$$ |

Finding The Right Varnish For Your Budget

When selecting a varnish, it’s essential to consider your budget. Urethane varnish tends to be more affordable, making it a suitable option for budget-conscious projects. On the other hand, polyurethane varnish may have a wider price range, offering both mid-range and high-end options.

Maintenance And Longevity

Preserving the finish of your woodwork is essential to maintain its beauty and protect it from wear and tear. When it comes to urethane varnish vs. polyurethane varnish, understanding how to properly maintain and ensure longevity is crucial.

Preserving The Finish

Both urethane varnish and polyurethane varnish offer excellent protection for your woodwork. They create a hard and durable finish that can withstand daily use and exposure to elements. However, proper maintenance is essential to preserve the finish over time.

Here are some tips to preserve the finish of your varnished woodwork:

- Regularly clean the surface with a mild soap and water solution, avoiding harsh chemicals that can damage the varnish.

- Wipe away spills and stains immediately to prevent them from penetrating the varnish.

- Use coasters and placemats to protect the surface from hot or wet objects.

- Avoid dragging heavy objects across the varnished surface to prevent scratches.

- Apply a fresh coat of varnish every few years to rejuvenate the finish and maintain its protective properties.

When To Reapply Varnish

Over time, the varnish on your woodwork may begin to show signs of wear. Knowing when to reapply varnish is important to ensure the continued protection and longevity of your woodwork.

Here are some signs that indicate it’s time to reapply varnish:

- The varnish appears dull or has lost its shine.

- There are visible scratches or marks on the surface.

- The woodwork feels rough or uneven to the touch.

- The varnish is peeling or flaking off.

- Water or spills are no longer beading on the surface.

By monitoring the condition of your varnished woodwork and addressing any signs of wear or damage promptly, you can extend its lifespan and maintain its beauty for years to come.

Health And Safety Considerations

When considering health and safety, it is important to understand the difference between urethane varnish and polyurethane varnish. While different vendors may use the terms interchangeably, they are essentially the same thing. Both varnishes provide a durable and long-lasting finish for wooden surfaces, but it’s essential to consider any potential disadvantages and limitations, such as poor thermal capability and flammability, when choosing the right varnish for your project.

Voc Content And Toxicity

When it comes to health and safety considerations, one important factor to consider is the VOC (volatile organic compounds) content and toxicity of urethane and polyurethane varnishes. VOCs are chemicals that can vaporize and be released into the air, potentially causing harm to human health and the environment.

Polyurethane varnishes typically have higher VOC content compared to urethane varnishes. This is because polyurethane varnishes often contain solvents such as mineral spirits or turpentine, which contribute to the release of VOCs during application and drying. These VOCs can cause respiratory irritation and contribute to indoor air pollution.

On the other hand, urethane varnishes usually have lower VOC content and are considered to be less toxic. They are often water-based or contain low levels of solvents, reducing the emission of harmful chemicals into the air. This makes urethane varnishes a safer option, especially for individuals with respiratory sensitivities or those concerned about indoor air quality.

Safe Application Practices

When using urethane or polyurethane varnishes, it is important to follow safe application practices to minimize health risks and ensure optimal results. Here are some key practices to keep in mind:

1. Adequate ventilation: Ensure proper ventilation in the application area to reduce the concentration of VOCs in the air. Open windows or use exhaust fans to improve air circulation during and after application.

2. Personal protective equipment (PPE): Wear appropriate PPE, such as gloves, goggles, and a respirator, to protect yourself from direct contact with the varnish and inhalation of potentially harmful fumes.

3. Avoid direct skin contact: Avoid prolonged contact with the varnish on your skin. If contact occurs, wash the affected area with soap and water immediately.

4. Follow manufacturer’s instructions: Read and follow the manufacturer’s instructions on the varnish container carefully. This includes information on application methods, drying times, and recommended safety precautions.

5. Dispose of waste properly: Dispose of any leftover varnish or empty containers according to local regulations. Avoid pouring varnish down the drain or throwing it in the regular trash.

By following these safe application practices, you can minimize health risks associated with urethane and polyurethane varnishes while achieving a professional and durable finish on your projects. Remember to always prioritize your health and safety when working with any chemical products.

Frequently Asked Questions

What Is The Difference Between Urethane And Polyurethane Varnish?

Urethane and polyurethane varnish are actually the same thing. Different vendors may use either term exclusively or interchangeably. Polyurethane is more durable and flexible due to its multiple layers, making it ideal for solid and long-lasting products. However, polyurethane varnish has some disadvantages, such as poor thermal capability, poor weatherability, and being attacked by most solvents.

It is commonly used as a protective finishing layer for interior and exterior wooden surfaces.

Which Is Harder Polyurethane Or Urethane?

Polyurethane is harder than urethane due to its multiple layers, making it more durable and flexible. It’s ideal for creating long-lasting products and providing superior protection for wooden surfaces.

What Are The Disadvantages Of Polyurethane Varnish?

Polyurethane varnish disadvantages include poor thermal capability, weatherability, susceptibility to solvents, use of toxic isocyanates, and flammability.

What Is Polyurethane Varnish Used For?

Polyurethane varnish is used to protect interior and exterior wooden surfaces from wear and tear. It provides a super-tough coating for floors, stairs, and other wooden surfaces.

Conclusion

To sum up, the terms “urethane” and “polyurethane” are often used interchangeably in the industry. While some vendors may exclusively use one term over the other, they essentially refer to the same product. Polyurethane varnish offers durability and flexibility due to its multiple layers, making it a great choice for long-lasting products.

However, it is important to note that polyurethane varnish has some disadvantages, such as poor thermal capability and flammability. Overall, understanding the similarities and differences between urethane and polyurethane varnish can help you make an informed decision for your specific needs.