What is WPF Plywood: Unveiling Its Strength & Uses

WPF plywood, or Waterproof Film Faced Plywood, is a type of plywood designed for moisture resistance. It features a film overlay that enhances durability and surface quality.

WPF plywood stands out in the construction and furniture industries due to its unique properties. This plywood is engineered to withstand water exposure, making it ideal for both indoor and outdoor applications. The film overlay not only protects against moisture but also offers a smooth surface that resists scratches and stains.

Builders and designers appreciate its versatility, as it can be used for flooring, cabinetry, and even formwork in concrete construction. With its combination of strength and water resistance, WPF plywood serves as a reliable choice for various projects, ensuring longevity and aesthetic appeal.

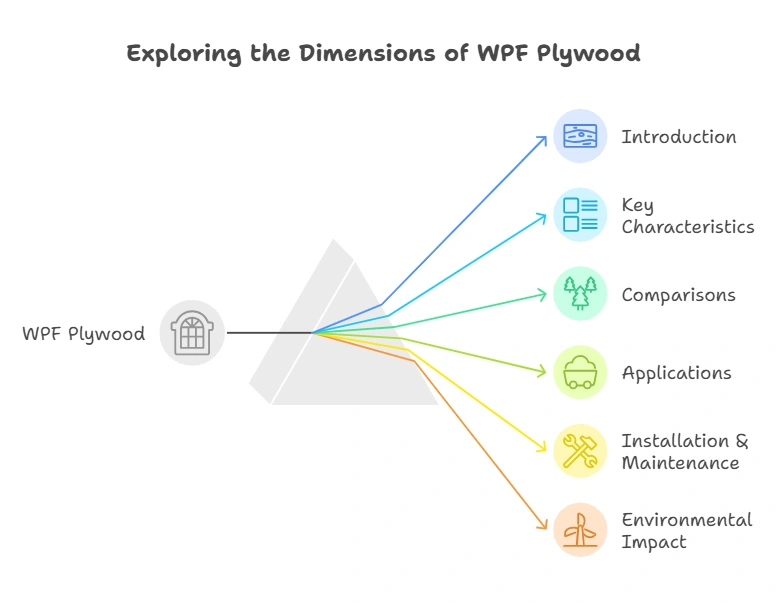

Introduction To WPF Plywood

WPF Plywood is a type of plywood made from wood fibers. It is popular for furniture and construction. This material is known for its strength and durability.

The history of WPF Plywood dates back to the early 20th century. It was developed to create a more eco-friendly alternative to solid wood. Over the years, manufacturing methods have improved. This has made WPF Plywood more accessible and affordable.

Today, WPF Plywood is widely used in various applications. Its versatility allows it to fit different design needs.

Key Characteristics

WPF plywood is made from layers of wood veneers. These layers are glued together. This process creates a strong and stable product. The material is often made from birch or maple. Other woods may also be used.

Durability is one of the key features of WPF plywood. It can withstand heavy loads. This plywood is resistant to warping and cracking. This makes it ideal for various uses. Common applications include furniture and cabinetry.

The strength of WPF plywood comes from its construction. The cross-laminated layers add support. This means it can handle stress better than solid wood. Its lightweight nature also makes it easy to work with.

Comparing WPF With Other Plywood Types

WPF plywood offers many benefits over traditional plywood. It is more durable and resistant to warping. This plywood type is also lighter, making it easier to handle.

WPF plywood is ideal for furniture making and home improvement projects. It works well in areas with high humidity, like kitchens and bathrooms. This plywood can also be used in craft projects and decorative items.

| Use Case | Benefits |

|---|---|

| Furniture Making | Lightweight and strong |

| Home Improvement | Resistant to moisture |

| Craft Projects | Easy to cut and shape |

| Decorative Items | Attractive finish |

Versatile Applications

WPF plywood is popular for its many uses. It is strong and durable. This makes it perfect for construction. Builders often choose WPF plywood for walls and roofs. It can handle heavy loads and resist moisture.

In furniture making, WPF plywood shines. Many furniture pieces are made from it. Chairs, tables, and cabinets are common items. The smooth surface allows for easy finishing.

For decorative projects, WPF plywood is a great choice. Artists and crafters use it for signs and wall art. Its versatility makes it easy to cut and shape. This plywood adds beauty to any project.

Installation And Maintenance Tips

For best practices in installing WPF plywood, ensure a clean surface first. Use quality adhesives for strong bonding. Cut the plywood accurately for a perfect fit. Always allow for expansion gaps to avoid warping. Secure with screws instead of nails for better hold.

To maintain WPF plywood, keep it dry and clean. Regularly inspect for any damage or wear. Apply a protective sealant to extend its lifespan. Avoid exposure to extreme humidity or temperature changes. Store unused plywood in a dry place to prevent mold.

Environmental Impact

WPF plywood is made from renewable wood sources. This makes it a great choice for the environment. It helps reduce waste and saves trees.

Sustainability factors are important. WPF plywood is durable and long-lasting. This means fewer replacements are needed over time. Using it supports sustainable forestry practices.

Recycling and disposal of WPF plywood are easy. It can be recycled into new products. This reduces landfill waste significantly. Always check local recycling options for proper disposal.

Cost Analysis

WPF plywood is often a popular choice for many projects. Its quality and durability make it valuable. Prices can vary based on several factors. Here is a simple comparison:

| Type | Price per Sheet | Value for Money |

|---|---|---|

| Standard WPF Plywood | $30 | Good |

| Marine Grade WPF Plywood | $50 | Excellent |

| High-Quality WPF Plywood | $70 | Very Good |

Choosing the right plywood type is essential for your project. Standard types are budget-friendly. Marine grade offers better resistance against water. High-quality plywood provides the best durability.

Future Trends And Innovations

WPF plywood is gaining attention for its unique properties. Technological advancements are shaping its future. New manufacturing techniques enhance strength and durability.

Smart technology integration is also on the rise. This includes sensors for moisture and temperature control. Such features make WPF plywood more versatile.

Emerging uses are seen in various markets. Architects and builders prefer it for green buildings. Its lightweight nature reduces transportation costs.

New applications in furniture design are also popular. Designers appreciate its aesthetic appeal and flexibility.

| Emerging Markets | Uses |

|---|---|

| Construction | Eco-friendly structures |

| Furniture | Custom designs |

| Automotive | Interior components |

Frequently Asked Questions

What Is WPF Plywood Used For?

WPF plywood is commonly used for construction and furniture. It offers durability and a smooth surface. This type of plywood is ideal for applications requiring water resistance. It’s often used in cabinetry, flooring, and decorative projects.

How Is WPF Plywood Different From Regular Plywood?

WPF plywood is treated for water resistance, unlike regular plywood. This treatment makes it suitable for humid environments. Regular plywood may warp or swell when exposed to moisture. WPF plywood maintains structural integrity, providing better longevity.

Can WPF Plywood Be Painted Or Stained?

Yes, WPF plywood can be painted or stained effectively. Its smooth surface allows for even application. Ensure proper preparation to enhance adhesion and finish. Using quality products will yield the best results, enhancing aesthetics.

Is WPF Plywood Eco-friendly?

WPF plywood can be eco-friendly, depending on the manufacturing process. Many manufacturers use sustainable wood sources and low-VOC adhesives. Always check for certifications like FSC to ensure environmental responsibility. Choosing eco-friendly options supports sustainable practices in the industry.

Conclusion

WPF plywood stands out for its versatility and durability. It’s an ideal choice for various projects, from furniture to cabinetry. Understanding its properties can help you make informed decisions. Embracing WPF plywood means investing in quality and longevity. Choose wisely and enjoy the benefits it brings to your creations.